A method for winding unequal-turn windings of a compact manipulator joint motor

A winding method and technology of mechanical arms, which are applied in electromechanical devices, electric components, manufacturing of motor generators, etc., can solve problems such as motor torque fluctuation, and achieve the effect of saving limited axial space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

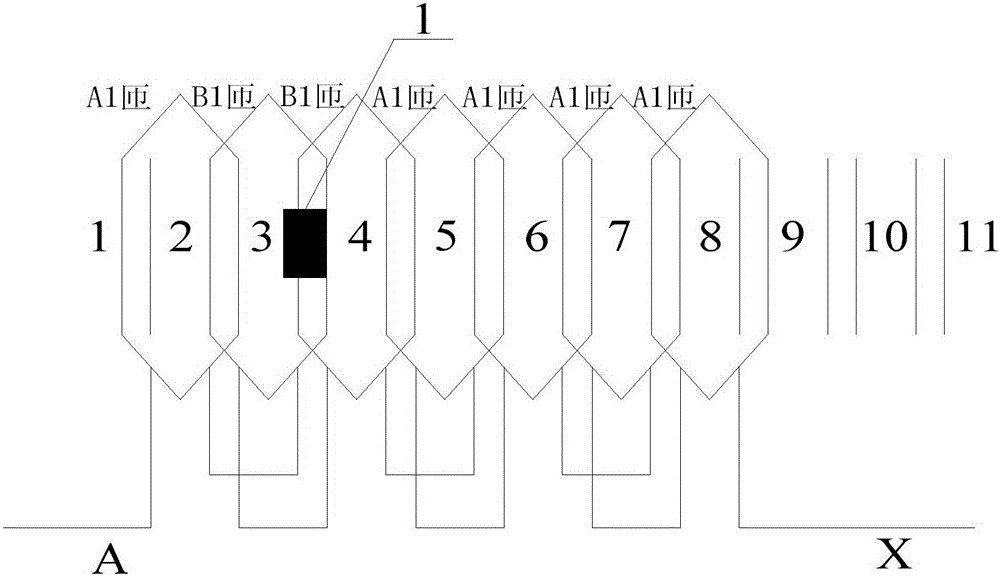

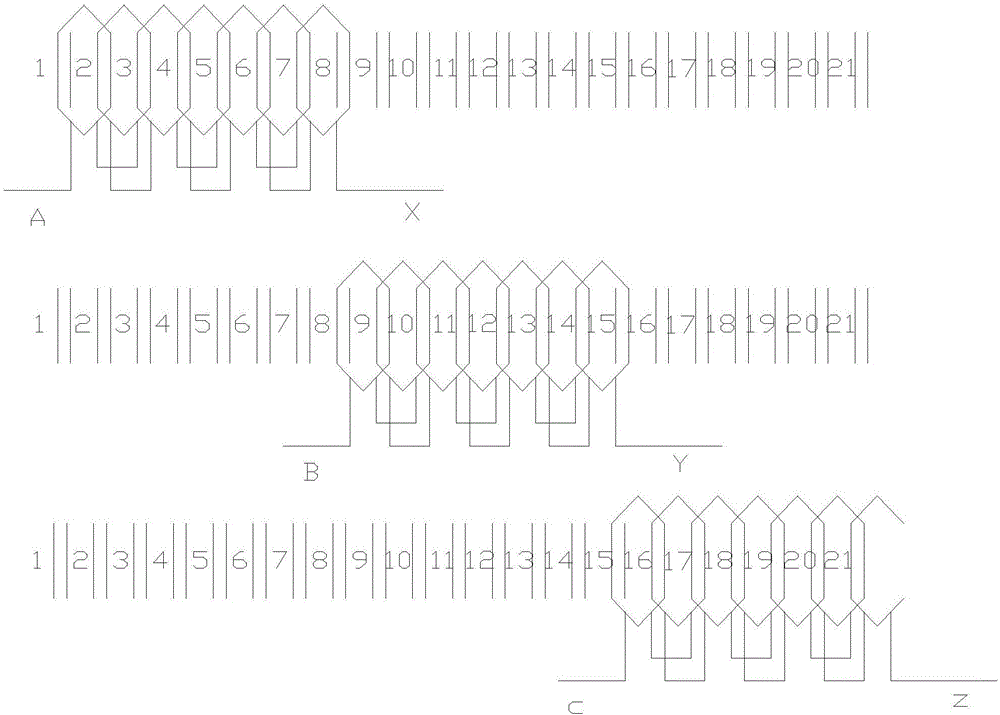

[0014] Specific implementation mode one: the following combination figure 1 and figure 2 This embodiment is described. In this embodiment, a winding method for unequal turns of a compact mechanical arm joint motor is described. The compact permanent magnet brushless motor includes a hollow multi-pole permanent magnet rotor and a stator embedded with a Hall element. , the stator includes a stator core, and a plurality of stator slots are arranged on the stator core, and three Hall elements 1 are embedded in the stator slots in a three-phase symmetrical manner;

[0015] The method of winding the three-phase symmetrical winding in the stator slot is: the number of turns of the winding wound in the stator slot where the Hall element 1 is located is less than the number of turns of other stator slots, and the number of turns reduced is determined by the size of the Hall element 1. And the windings of the stator slots where the three Hall elements 1 are located are arranged symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com