Rotary material taking device

A technology of reclaiming device and rotating cylinder, which is applied in the direction of transportation and packaging, conveyor objects, furnaces, etc., can solve the problem of many rotation steps, achieve the effect of improving efficiency, increasing fast circulation speed, and realizing fast and efficient production on the assembly line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

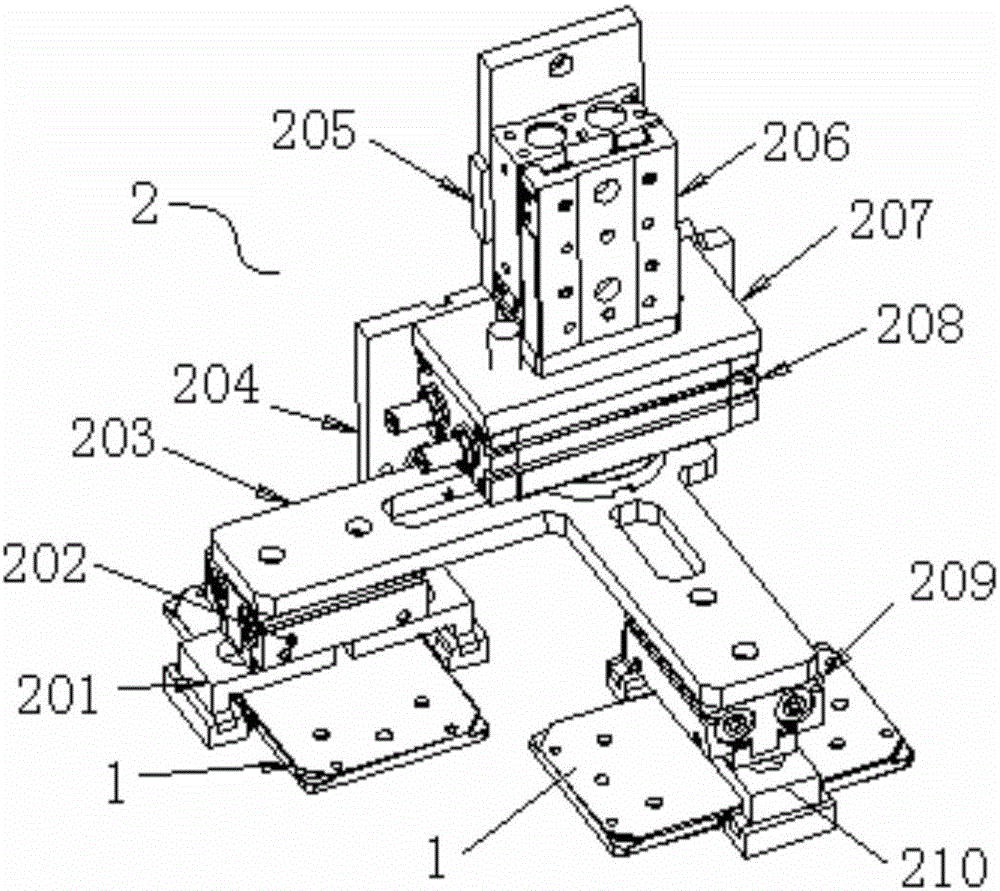

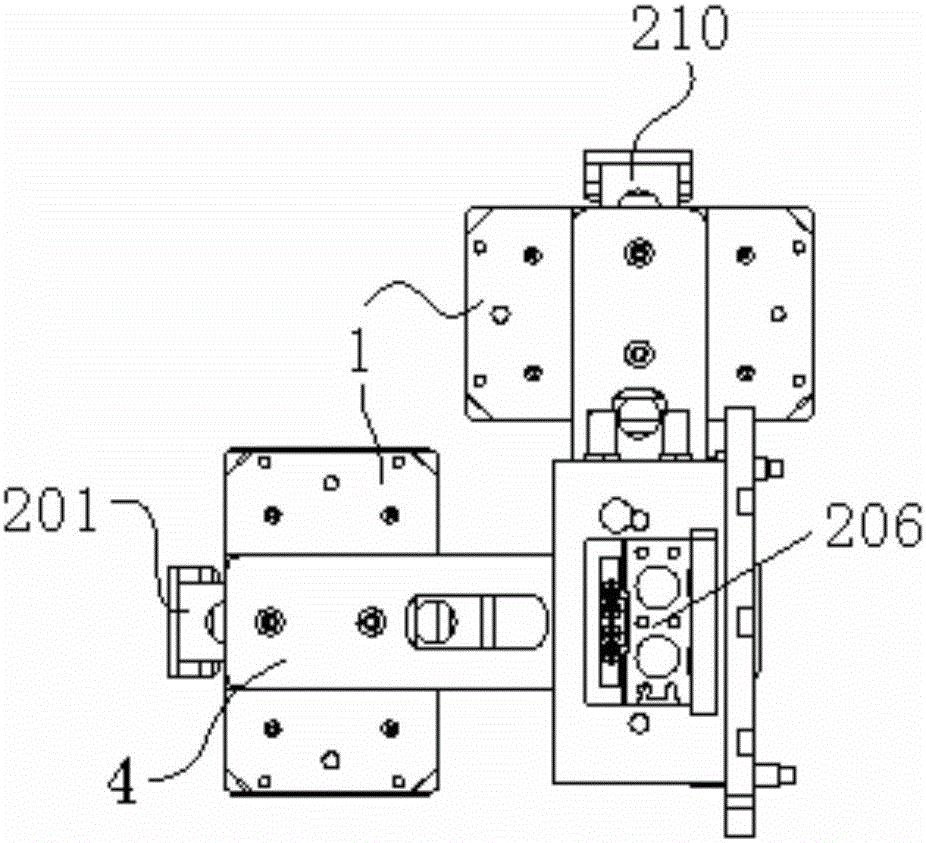

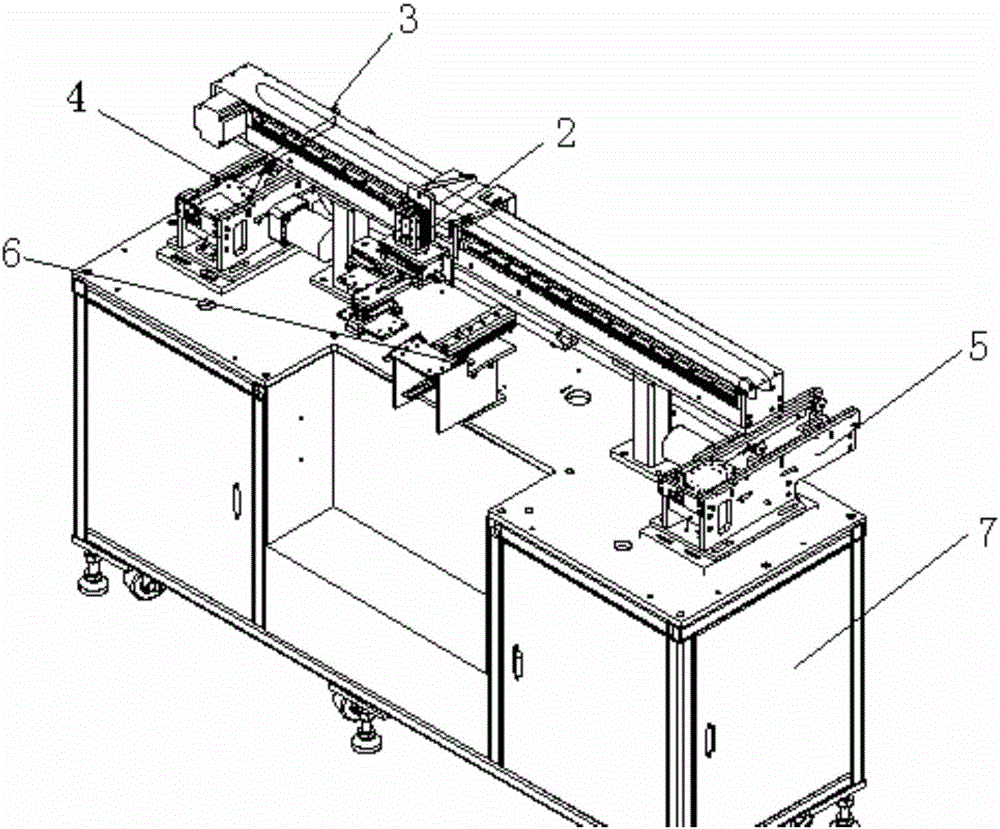

[0030] see figure 1 with figure 2 , the rotary reclaiming device in the illustration is a preferred embodiment of the present invention, specifically including a first jaw 201, a first jaw cylinder 202, a reclaiming mounting plate 203, a rotation angle adjusting plate 204, a lifting cylinder mounting plate 205, Parts such as lifting cylinder 206, rotating cylinder mounting plate 207, rotating cylinder 208, the second jaw cylinder 209, the second jaw 210.

[0031] The rotary retrieving device in this embodiment uses pneumatic grippers as the retrieving component, and the corresponding gripping material is the jig 1 for clamping glass lenses. In practical applications, negative pressure vacuum adsorption parts can also be used as smooth and flat materials. The retrieving components.

[0032] In this embodiment, the first jaws 201 and the second jaws 210 are respectively arranged at two different ends of the pick-up mounting plate 203, the jaws are driven by air cylinders, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com