Heating cooker

A cooker and cooking container technology, which is applied in the direction of induction heating, induction heating devices, and building material processing, can solve the problems of inability to heat cooking, high coil voltage, and high-frequency current flow, so as to avoid configuration interference, good precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

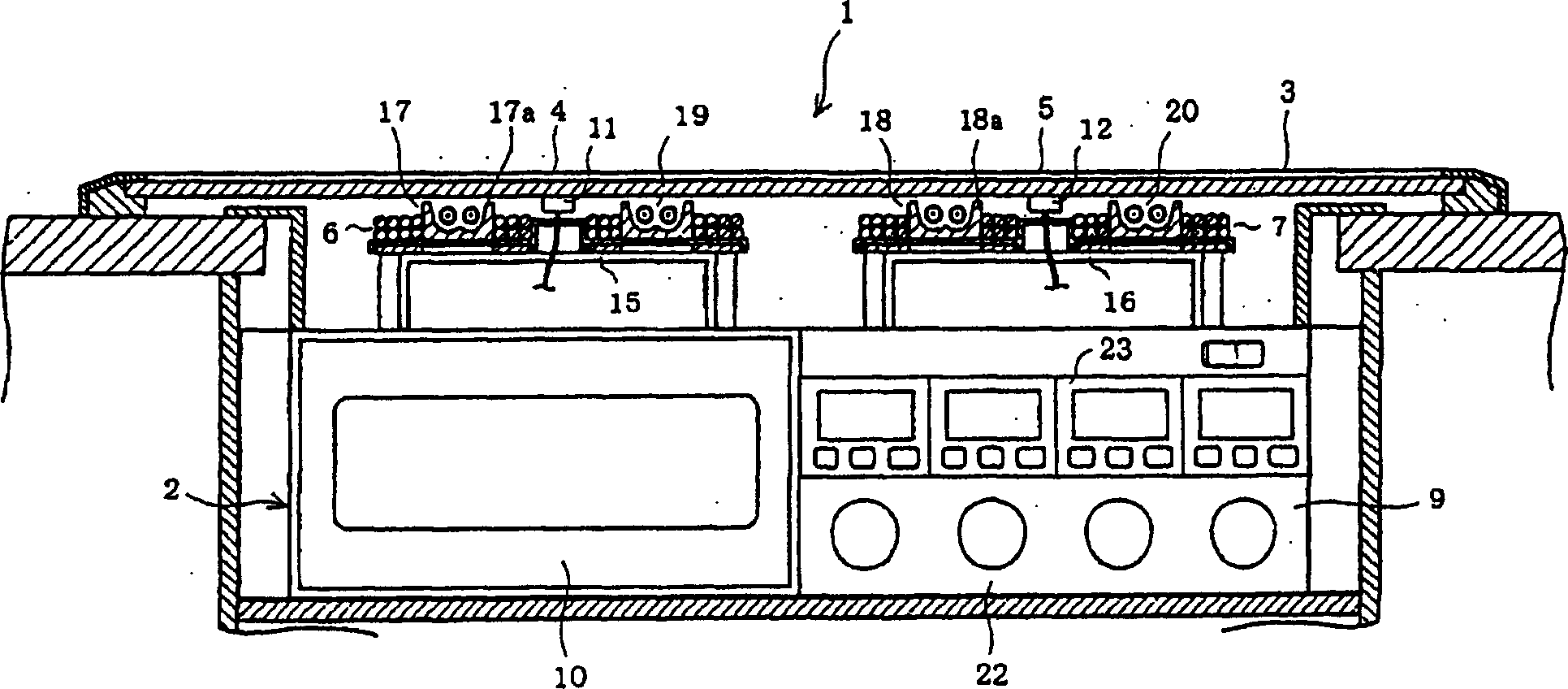

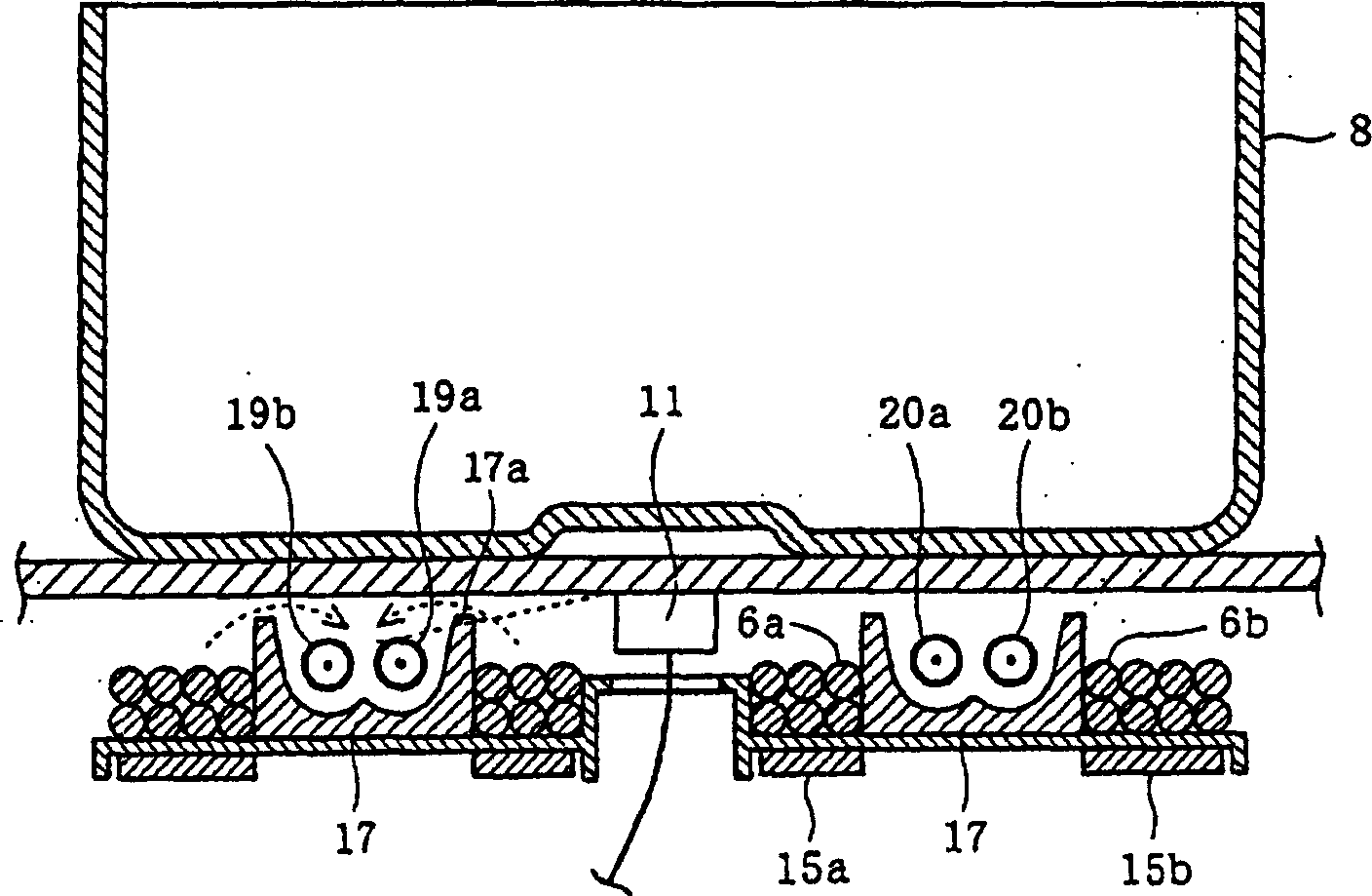

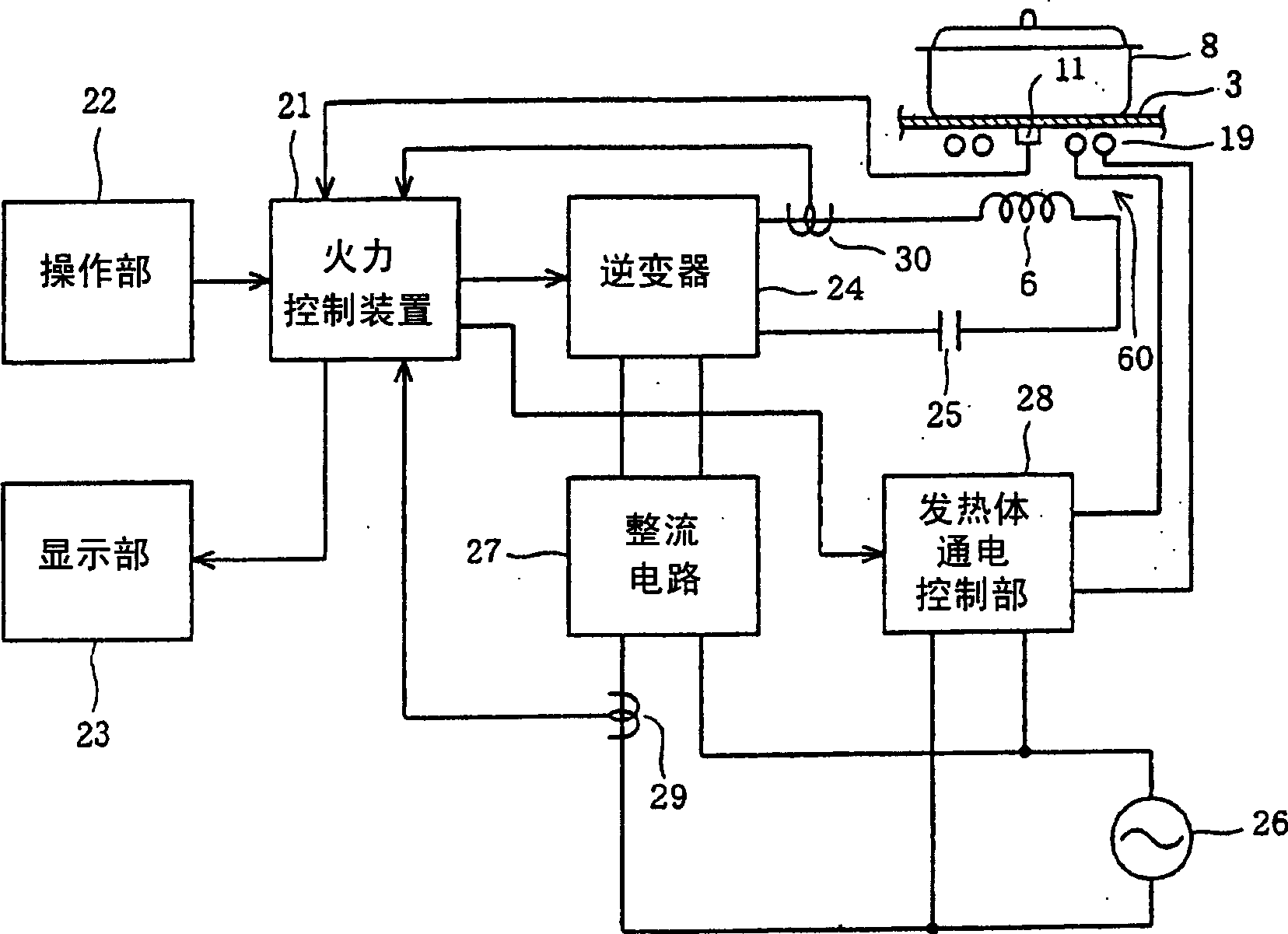

[0035] Refer to the following Figure 1 to Figure 6 The first embodiment of the present invention will be described. figure 1 A partial front view of the heating cooker 1 is shown as a longitudinal section. In the heating cooker 1, the outer casing is a casing 2, and the top plate 3 is positioned above it, and constitutes the upper surface of the casing. Inside the casing 2, induction heating coils 6, 7 are disposed directly under the mounting portions 4, 5 of the top plate 3, so that the cooking containers 8 mounted on the mounting portions 4, 5 are respectively induction heated. (refer to figure 2 ). in addition, figure 2 zoom in figure 1 part of the placement part 4.

[0036] The front of the casing 2 is provided with an operation panel 9 and a door 10 of the oven, through the operation panel 9, the user can operate the above-mentioned induction heating coils 6, 7. The inside of 2 is connected to a stove (not shown). In addition, on the lower surface of the top pl...

no. 2 Embodiment

[0065] Figure 7 The second embodiment of the present invention is shown, and the same parts as those of the first embodiment are denoted by the same reference numerals, and description thereof will be omitted, and only the different parts will be described below. The second embodiment differs in the arrangement of the induction heating coils and the infrared heaters on the lower side of the top plate 3 . That is, its composition as equivalent to figure 2 of Figure 7 As shown, the induction heating coil 31 wound in two stages is arranged on the central side of the mounting part 4, and the infrared heater support 32 and two infrared ring heaters 33a, 33b are arranged on the outer peripheral side. The induction heating coil 31 and the infrared ring heaters 33A, 33b constitute a heating unit 61 .

[0066] The same effect as that of the first embodiment can be obtained also in the second embodiment having the above-mentioned structure.

no. 3 Embodiment

[0068] Figure 8 A third embodiment of the present invention is shown. The third embodiment also shows an example in which the configurations of the induction heating coils and the infrared heaters on the lower side of the top plate 3 are different, as in the second embodiment. That is, if Figure 8 shown. The infrared heater support 34 is arranged on the central side of the mounting portion 4 , and the infrared band-shaped heater 35 is arranged in a state of being wound in multiple turns inside the infrared heater support 34 . An induction heating coil 36 wound in two stages is disposed on the outer peripheral side of the infrared band heater 35 .

[0069] In addition, the side wall forming the infrared heater support body 34 is the same as the infrared heater support bodies 17, 32 in the first and second embodiments, so that the infrared rays having the function of preventing the radiation of the infrared band-shaped heater 35 are irradiated to the temperature detection. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com