Patents

Literature

60results about How to "Convenient for temperature detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

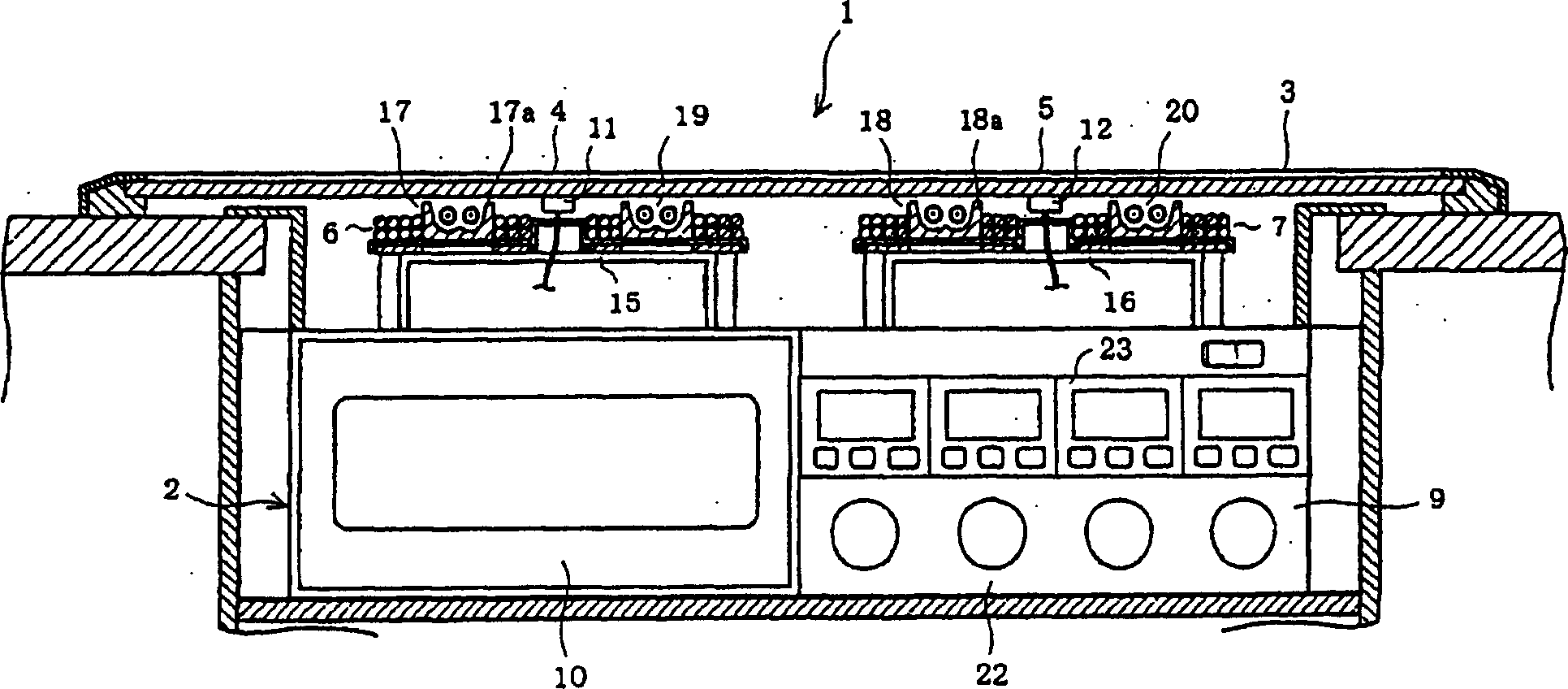

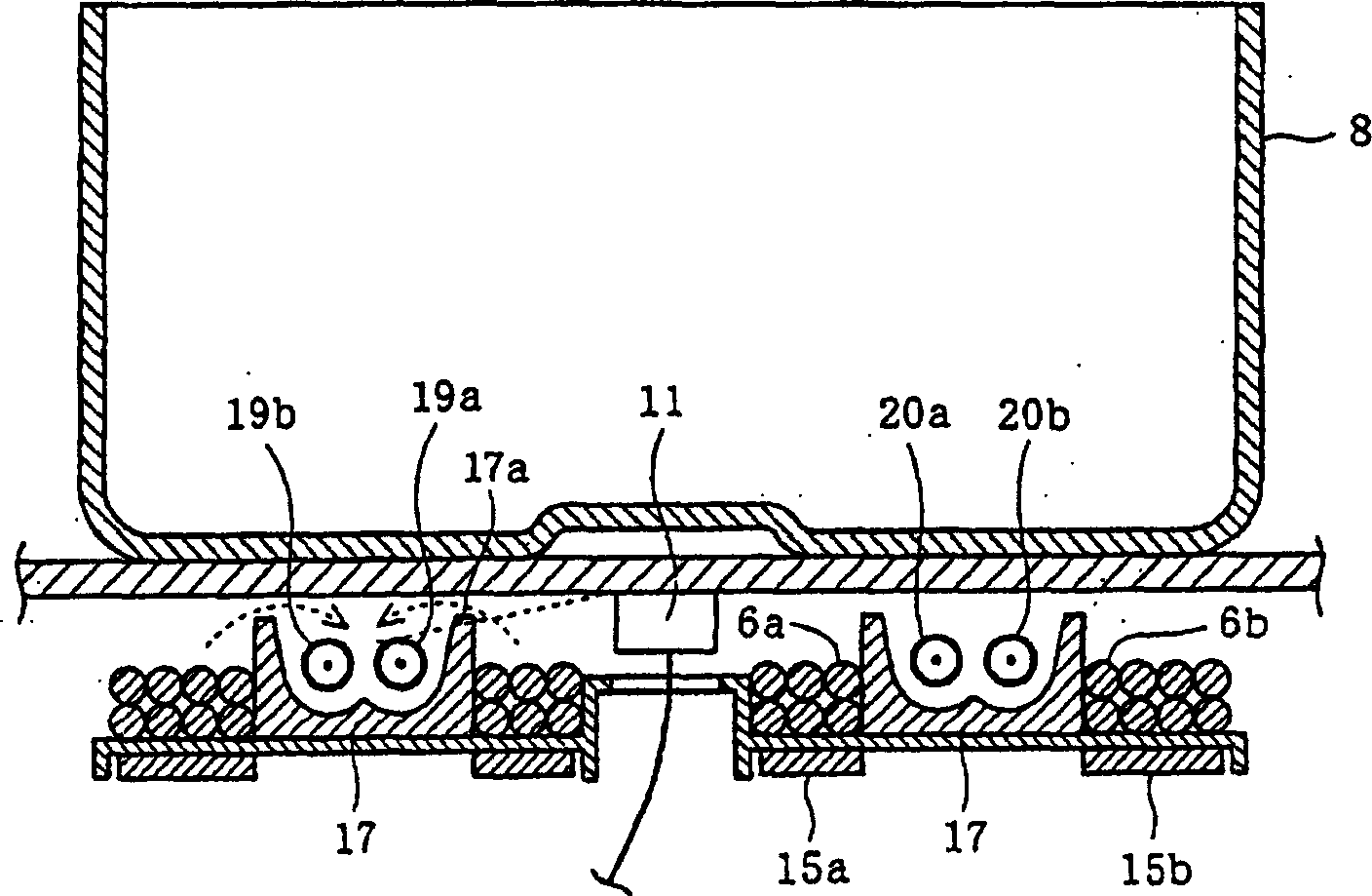

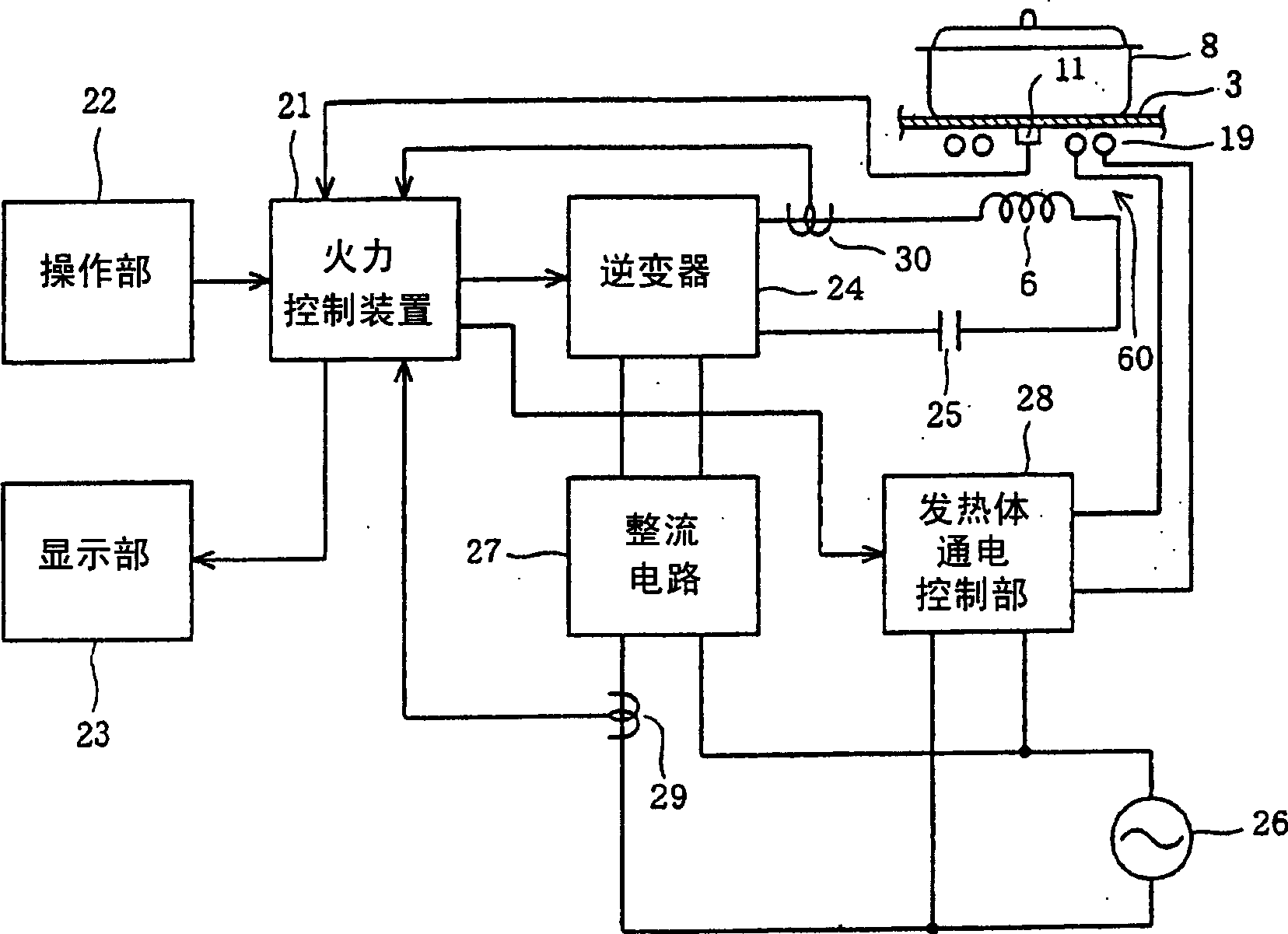

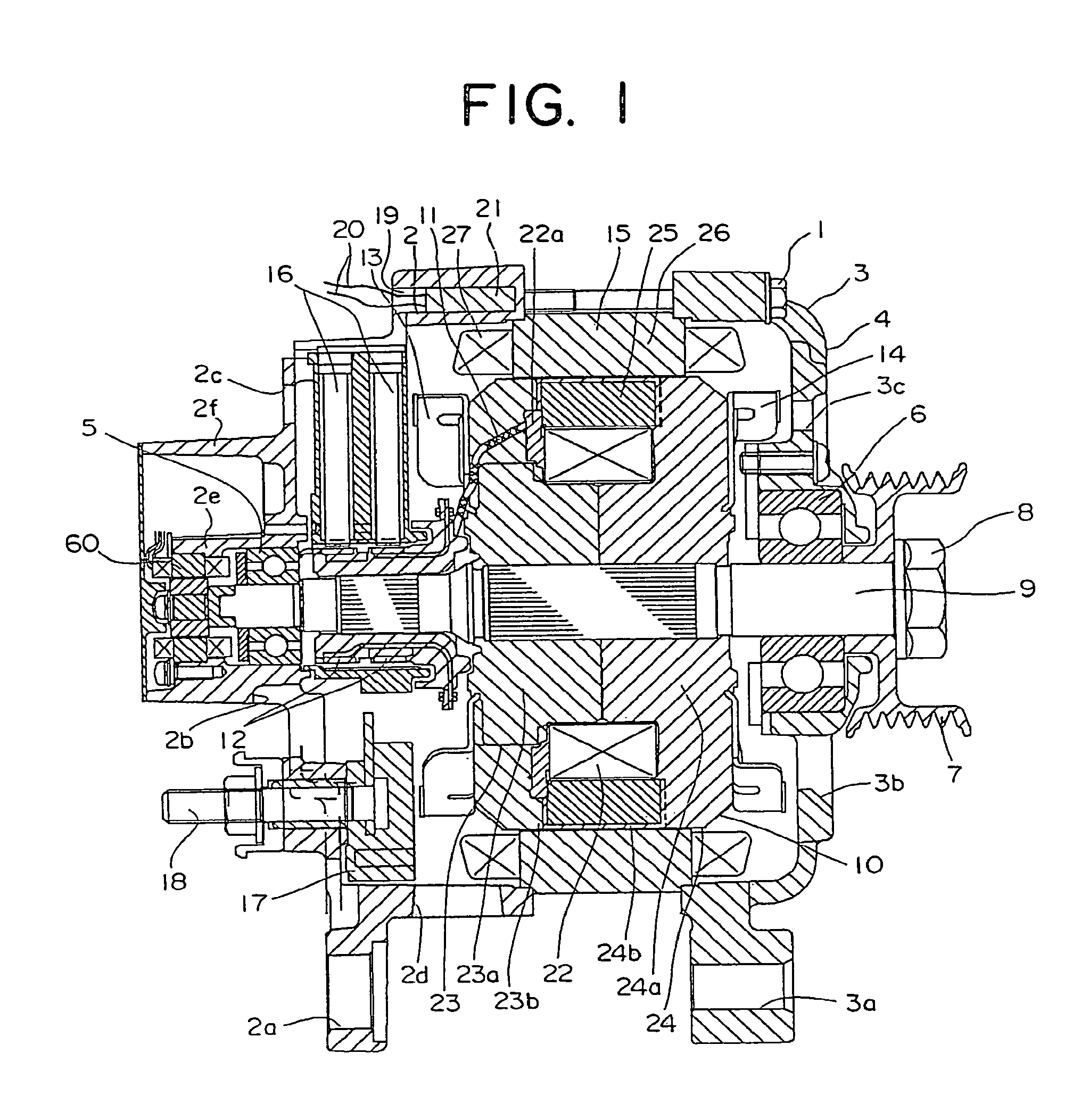

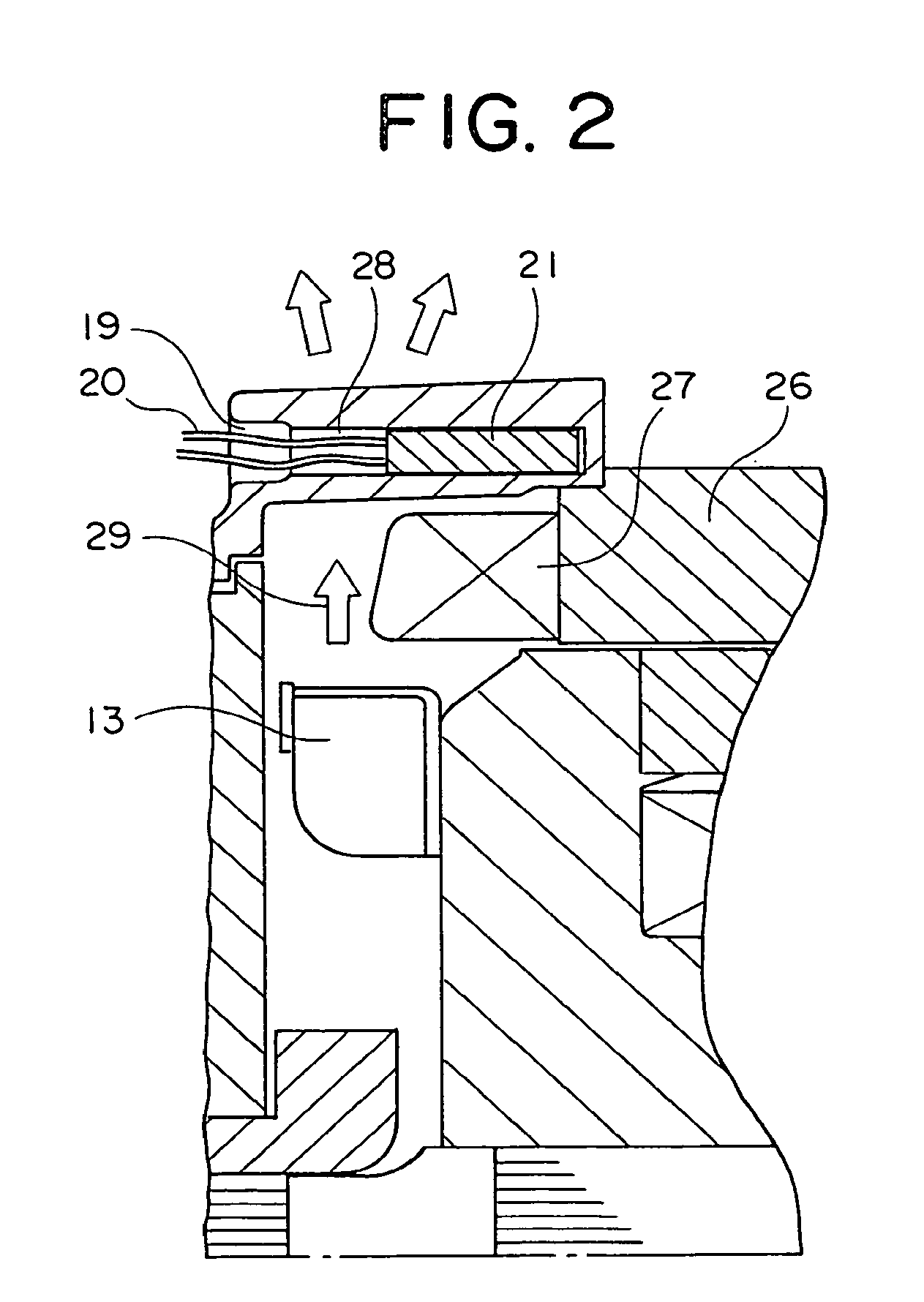

Heating cooker

InactiveCN1809229AReduce the number of turnsReduce the number of twisted wiresBuilding material handlingInduction heating apparatusEngineeringHeating power

The present invention provides a heating cooker capable of further efficiently heating cookware to be heated that is made of a low-permeability material. This heating cooker comprises an induction heating coil 6 and an infrared heater 19 for heater heating. A heating power controller determines the material of the cookware 8 to be heated and controls an inverter and a heating element conducting section according to the material determined, thereby controlling the heating ratio between the induction heating coil 6 and the infrared heater 19. A temperature detection part 11 is disposed inside the infrared heater 19 forming a ring-like shape; and a heater installation member 17 is so structured that its side wall 17a prevents an infrared ray radiated from the infrared heater 19 from reaching the temperature detection part 11.

Owner:KK TOSHIBA +2

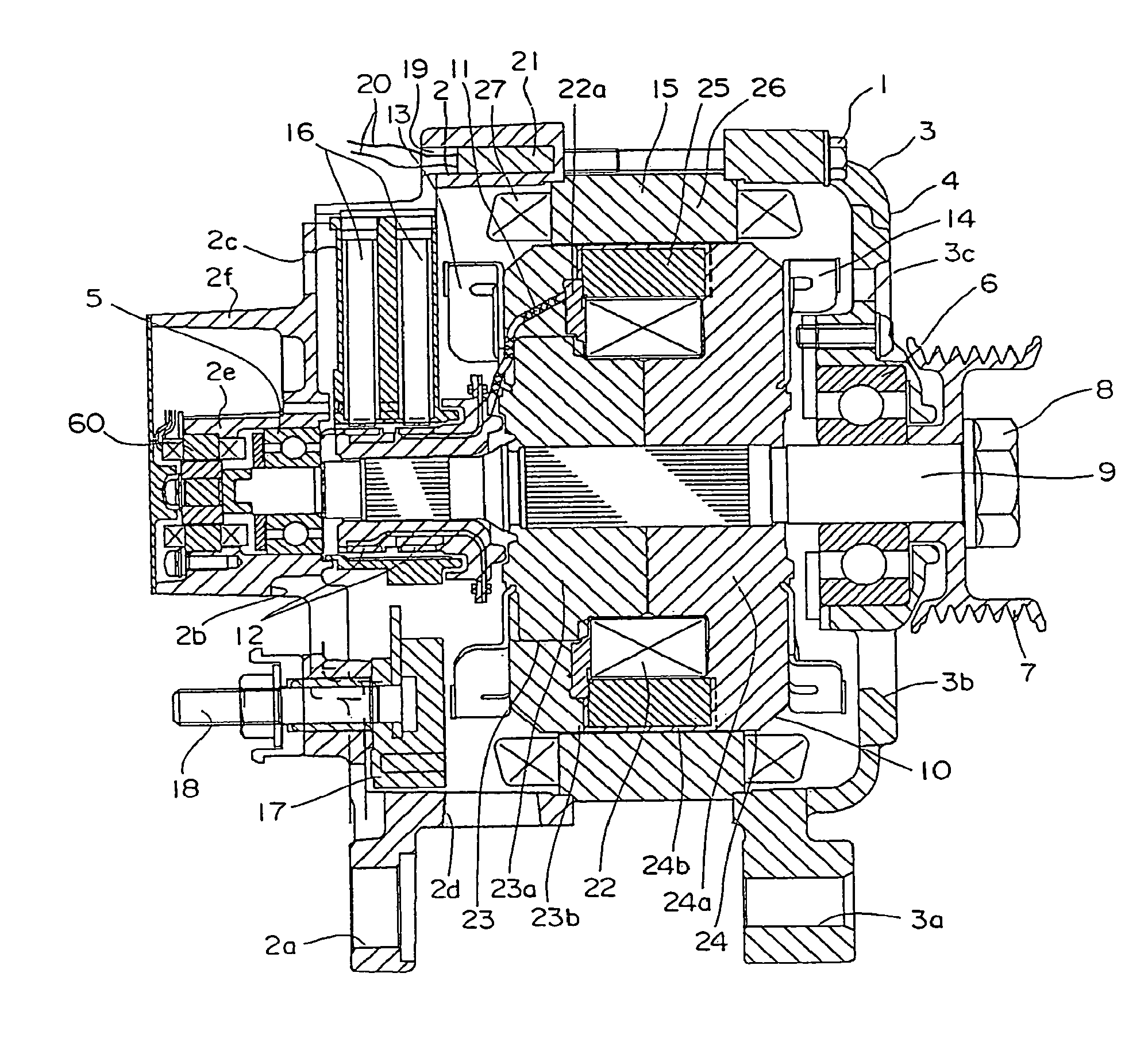

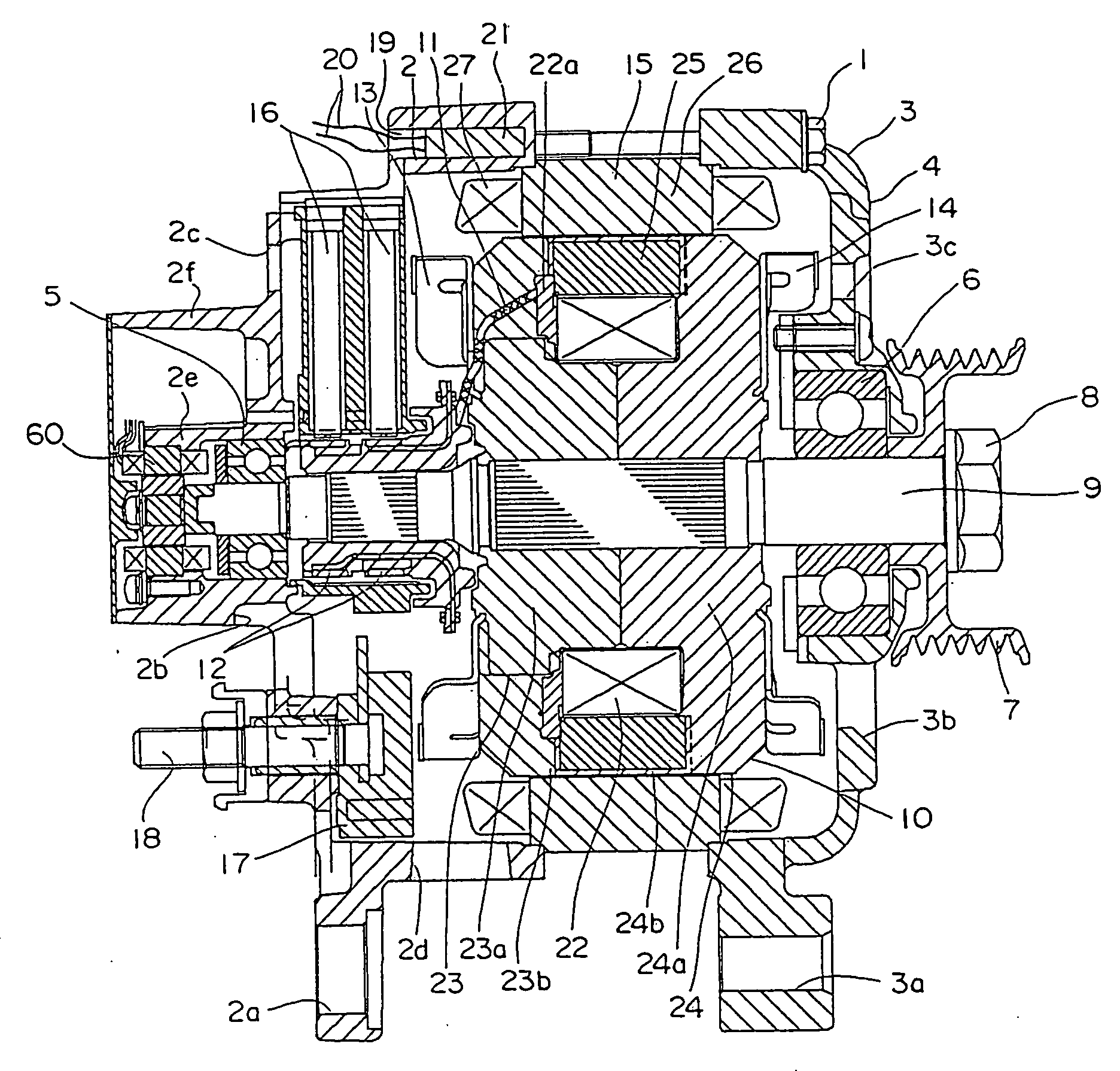

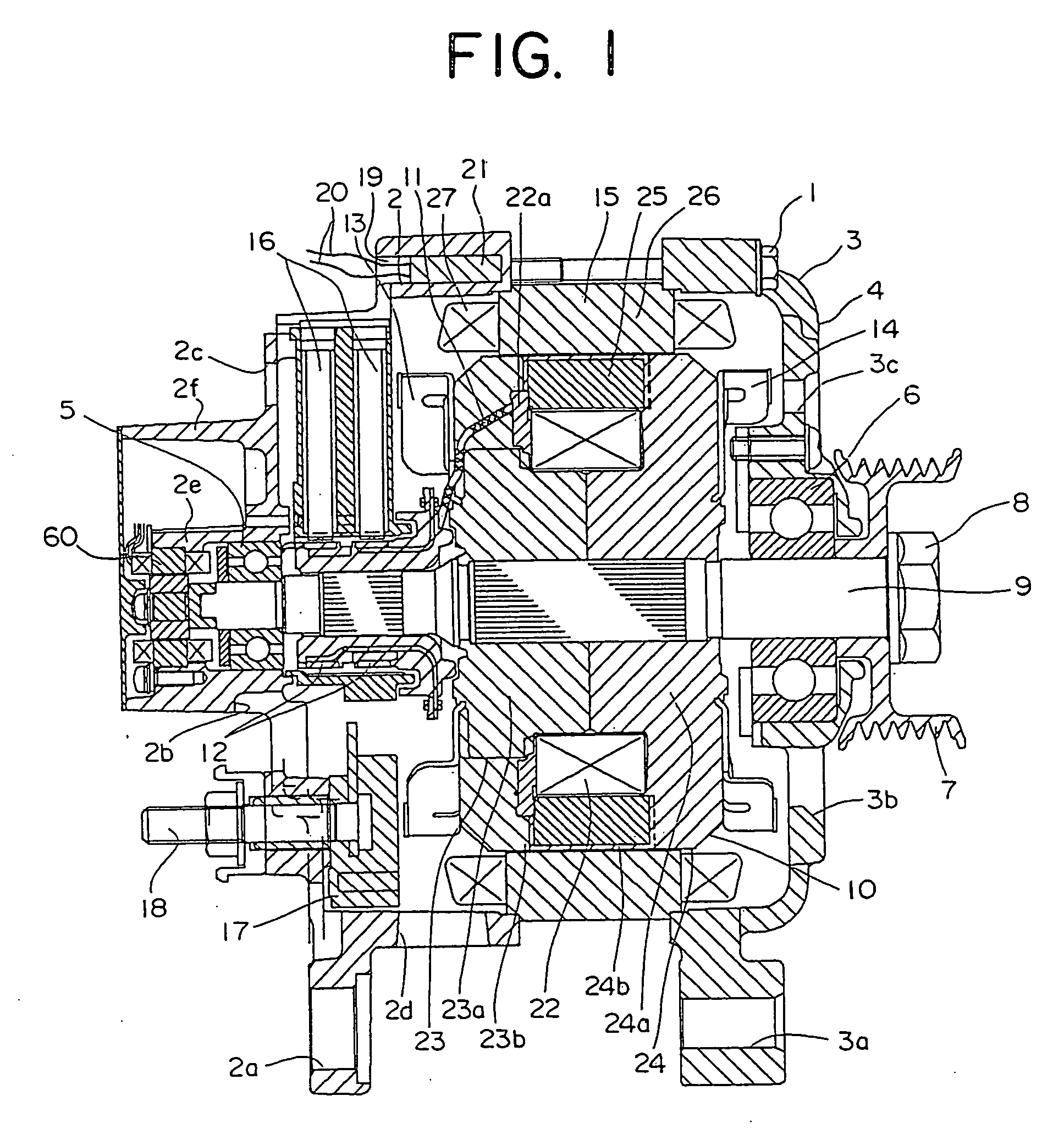

Dynamoelectric machine

ActiveUS7633197B2Easy to assembleImprove precisionSynchronous generatorsElectric motor controlEngineeringConductor Coil

A dynamoelectric machine enabling stator winding temperature detecting precision of a temperature measuring means to be improved while also improving assembly of the dynamoelectric machine is provided.The dynamoelectric machine according to the present invention includes: a stator winding disposed in a stator; a temperature sensor for estimating a stator winding temperature of the stator winding; and a thermally-conductive bracket disposed between the stator winding and the temperature sensor. An estimated value of the stator winding temperature is calculated using a sum of a measured temperature measured by the temperature measuring means and a correcting value for correcting the measured temperature.

Owner:MITSUBISHI ELECTRIC CORP

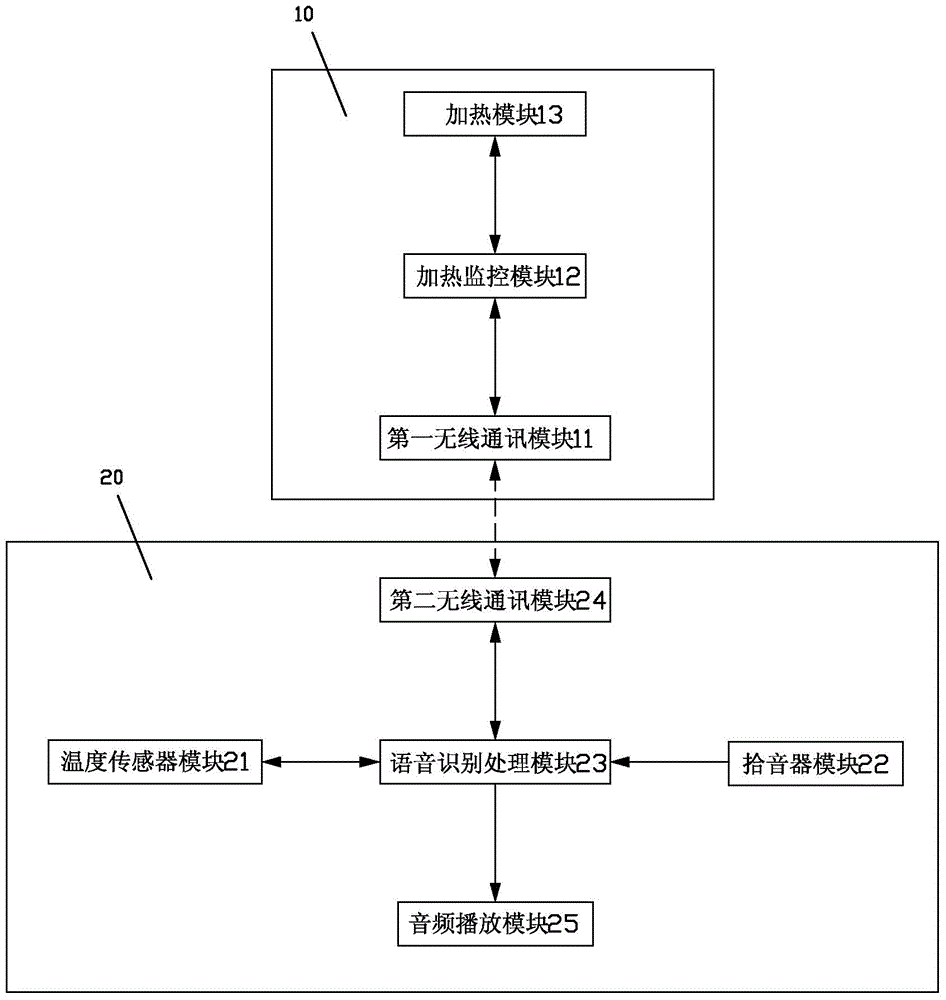

Water heater control system and control method thereof

The invention discloses a water heater control system and a control method thereof. The water heater control system comprises a water heater body and a wireless control terminal which are arranged separately. The water heater body is provided with a first wireless communication module, a heating monitoring module and a heating module which are electrically connected in sequence. The wireless control terminal is provided with a temperature sensor module used for detecting the environment temperature, a pickup module used for picking up voice signals of users, a voice recognition processing module used for carrying out new / old user voiceprint recognition and control instruction recognition on the voice signals picked up by the pickup module, and a second wireless communication module used for being in communication with the water heater body, wherein the pickup module, the voice recognition processing module and the second wireless communication module are electrically connected in sequence. The temperature sensor module is electrically connected with the voice recognition processing module. The wireless control terminal is further provided with an audio playing module electrically connected with the voice recognition processing module. The water heater control system is simple in structure, convenient to control and capable of achieving voice input control and audio playing feedback and user experience is good.

Owner:VATTI CORP LTD

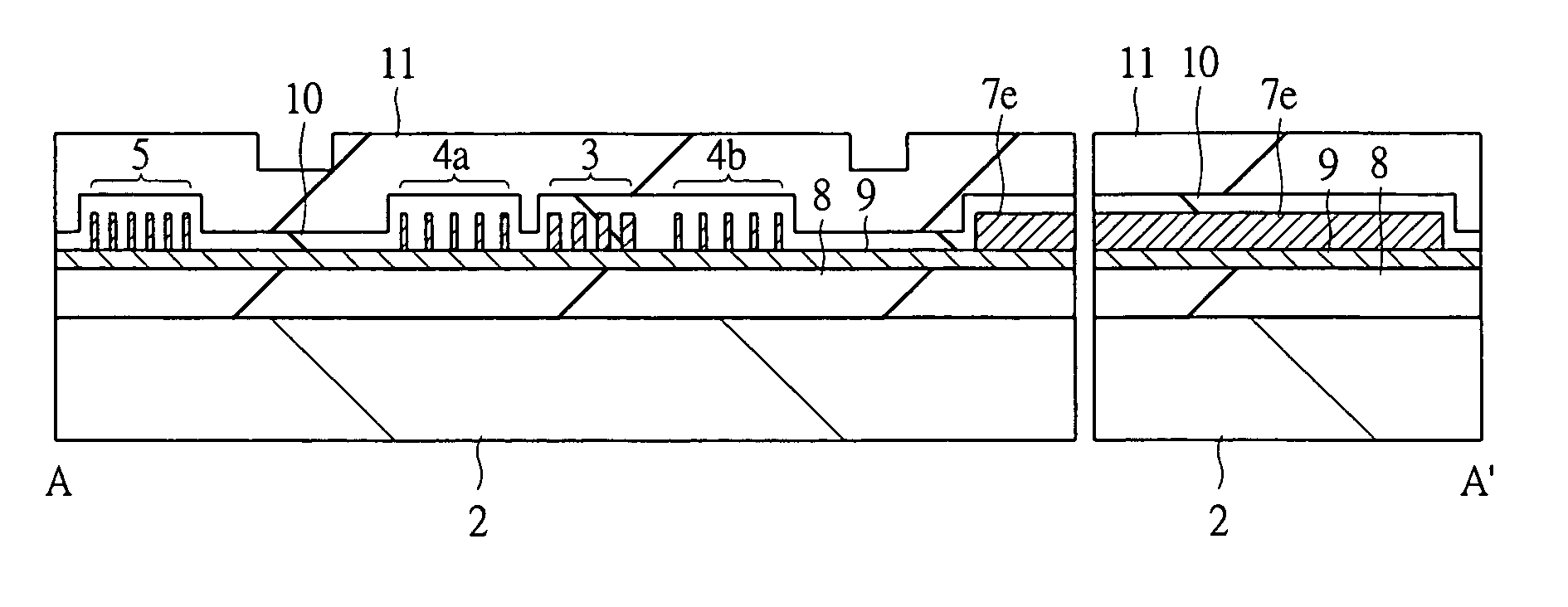

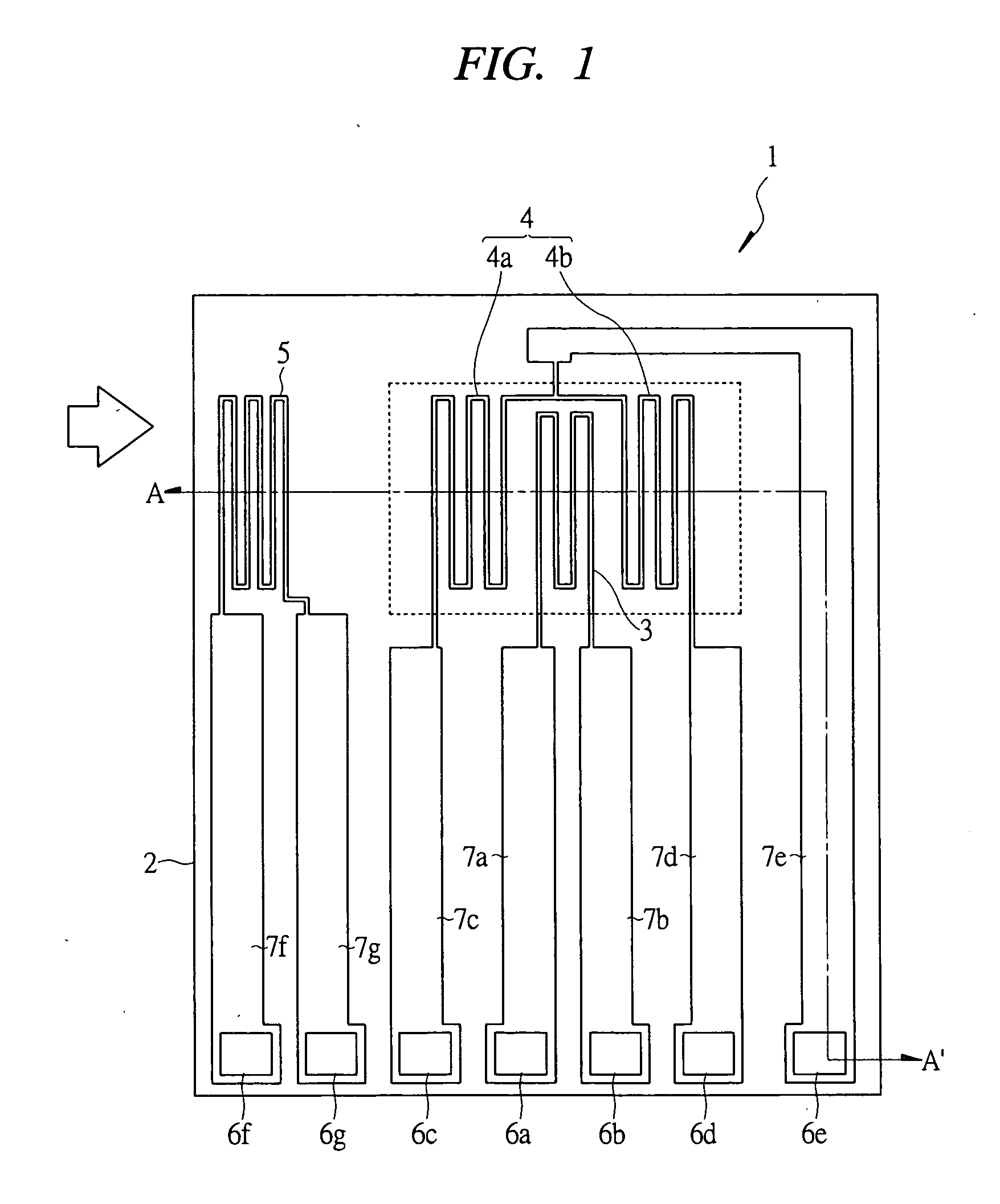

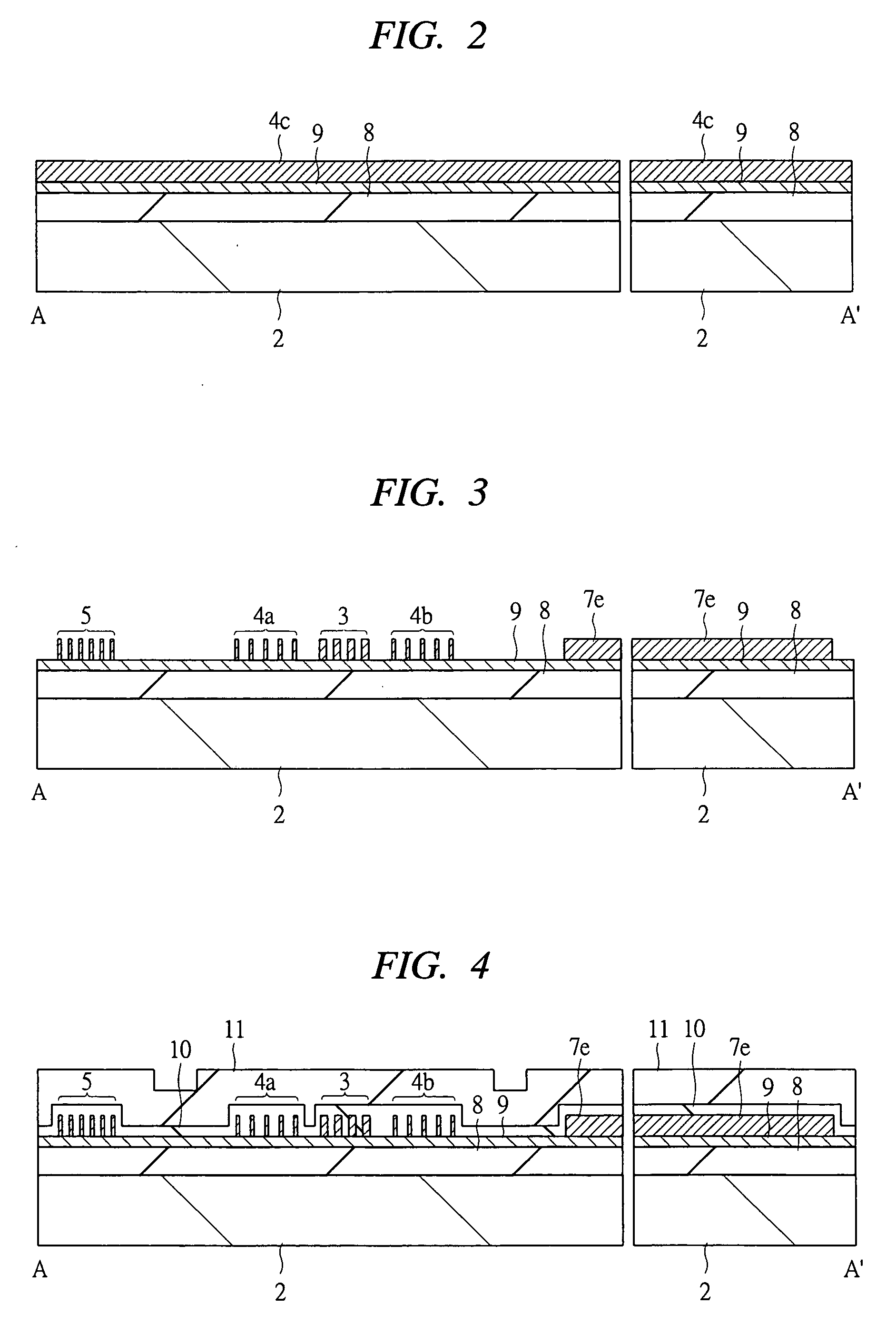

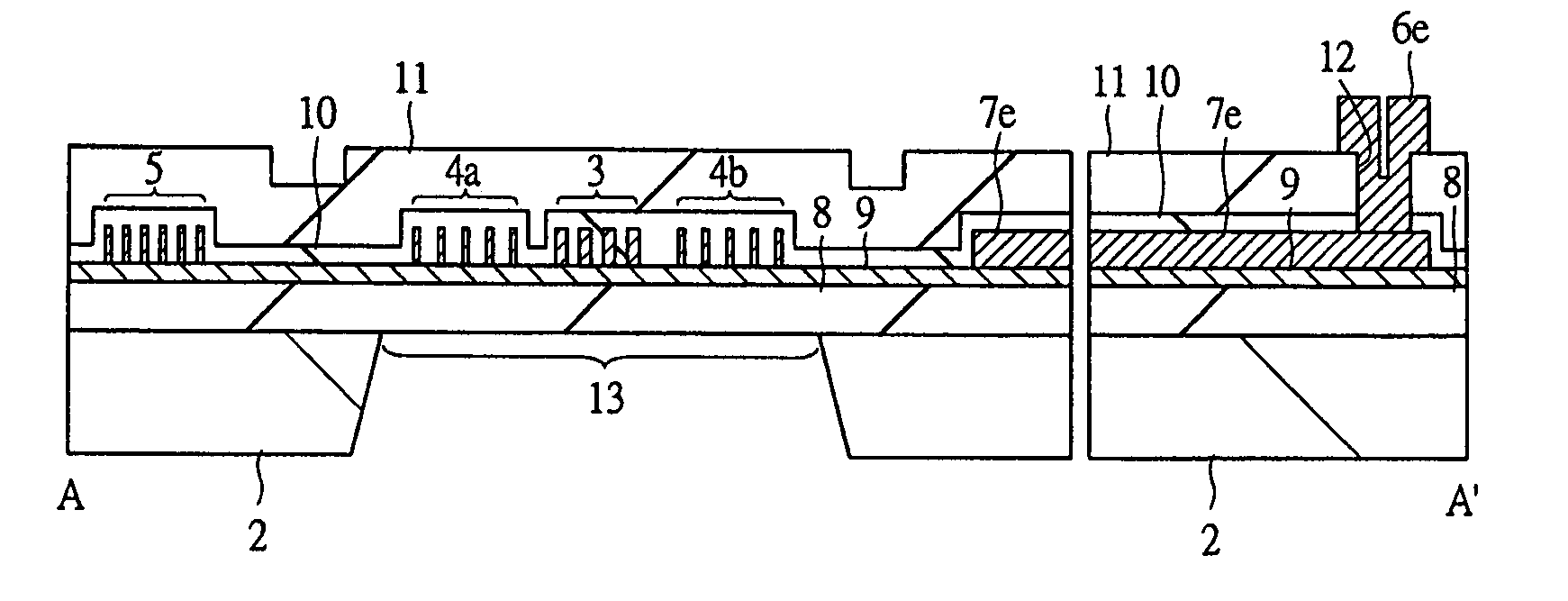

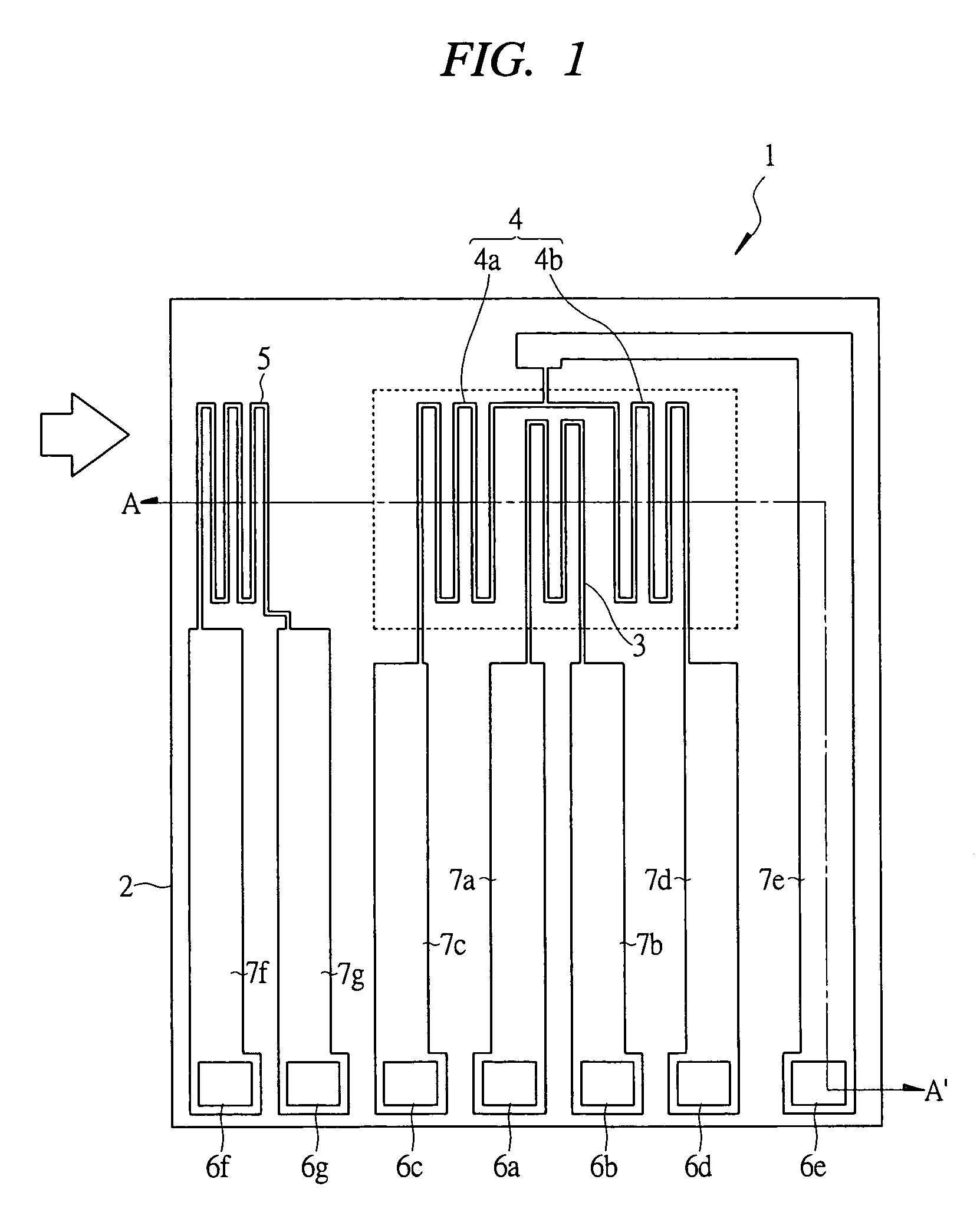

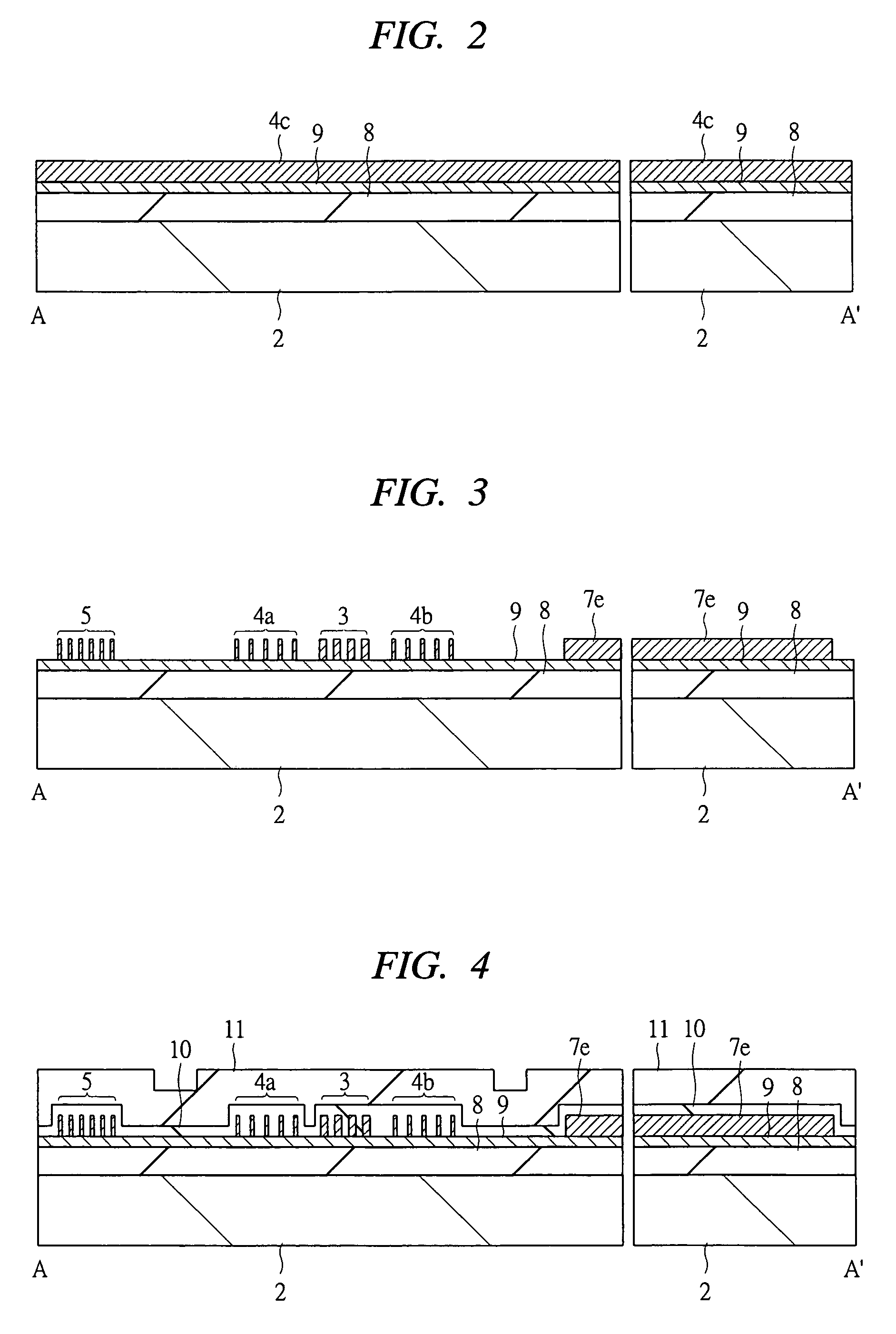

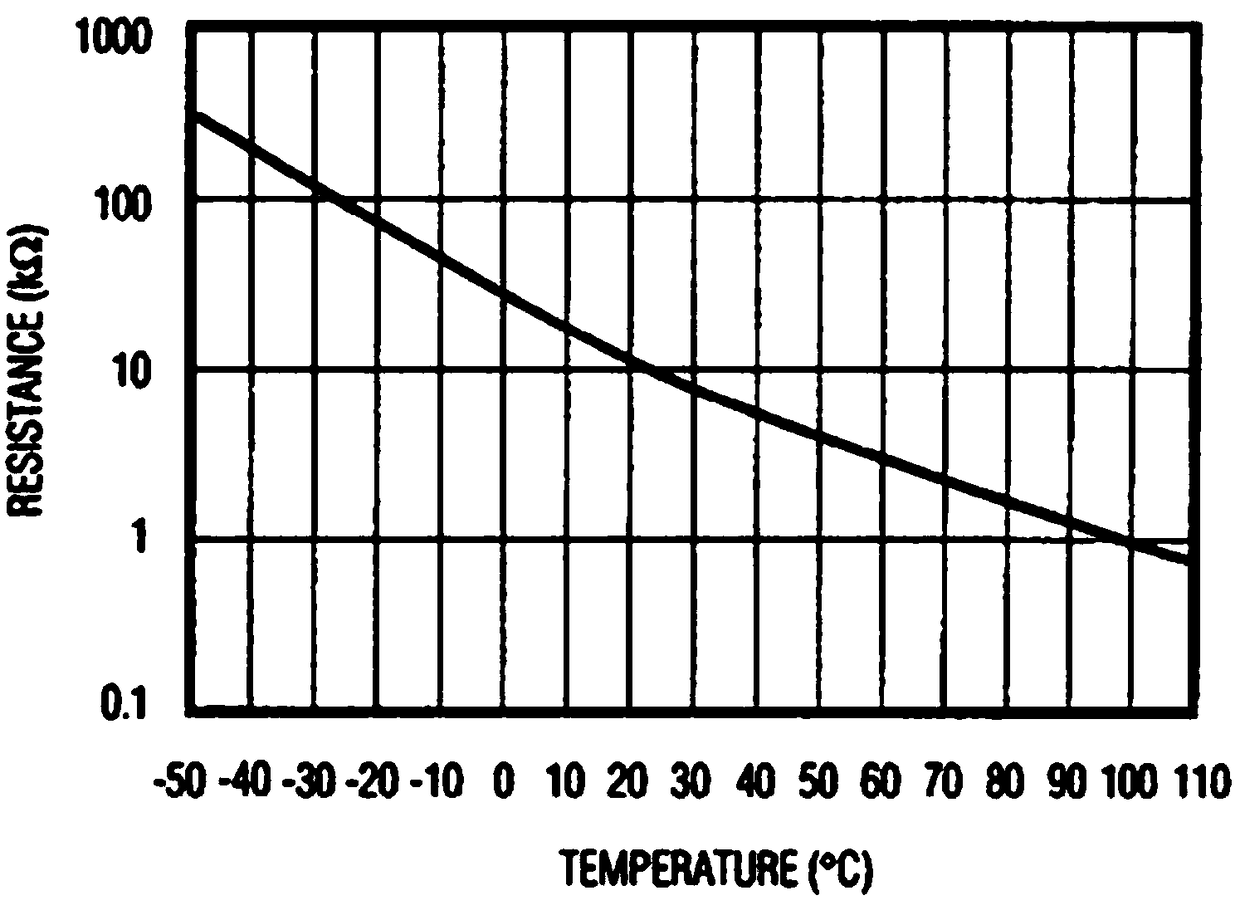

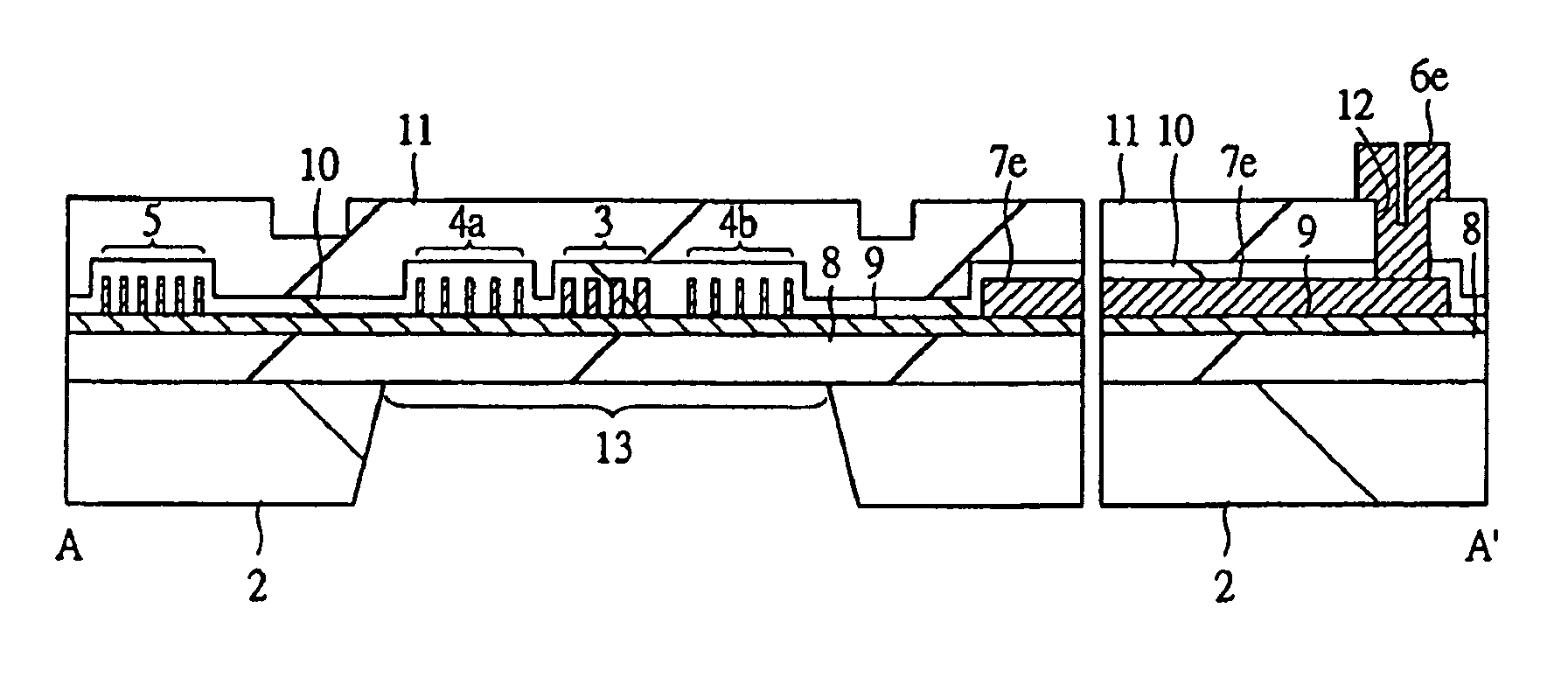

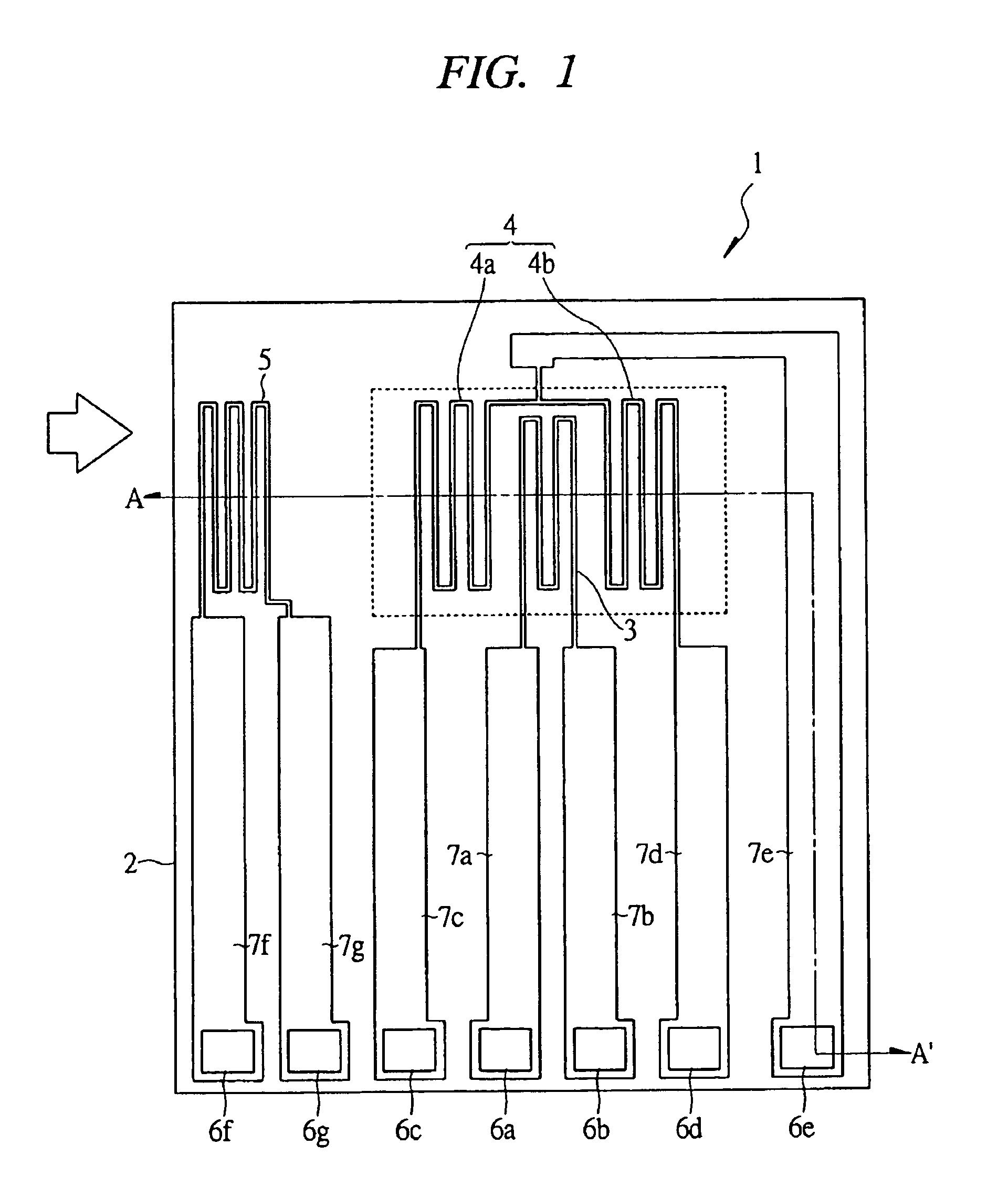

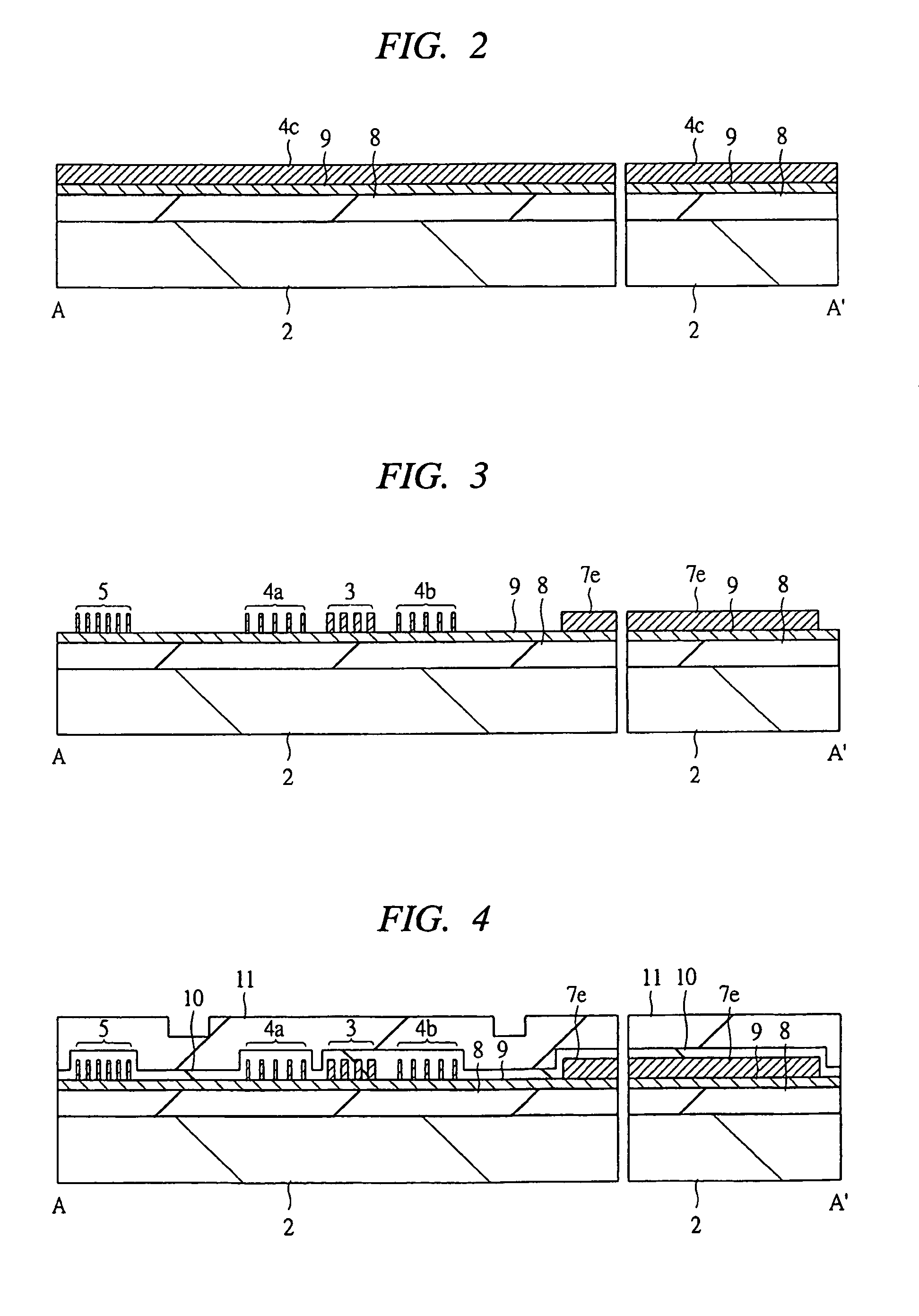

Flow sensor

ActiveUS20070056366A1Convenient for temperature detectionHigh TCR inherentVolume/mass flow by thermal effectsFluid speed measurement using thermal variablesFlow transducerElectrical resistance and conductance

The present invention provides a technology capable of achieving a highly-sensitive flow sensor, by forming a metal film having a relatively high TCR on a semiconductor substrate via an insulating film. A measurement device which is a thermal fluid flow sensor includes a heat element, resistance temperature detectors (upstream-side resistance temperature detector and downstream-side resistance temperature detector), and a resistance temperature detector for air which are all formed of a first metal film. The first metal film is formed of an α-Ta film having a resistivity lower than three times the resistivity of a Ta ingot and obtained by deposition through sputtering on an amorphous film containing metal.

Owner:HITACHI LTD

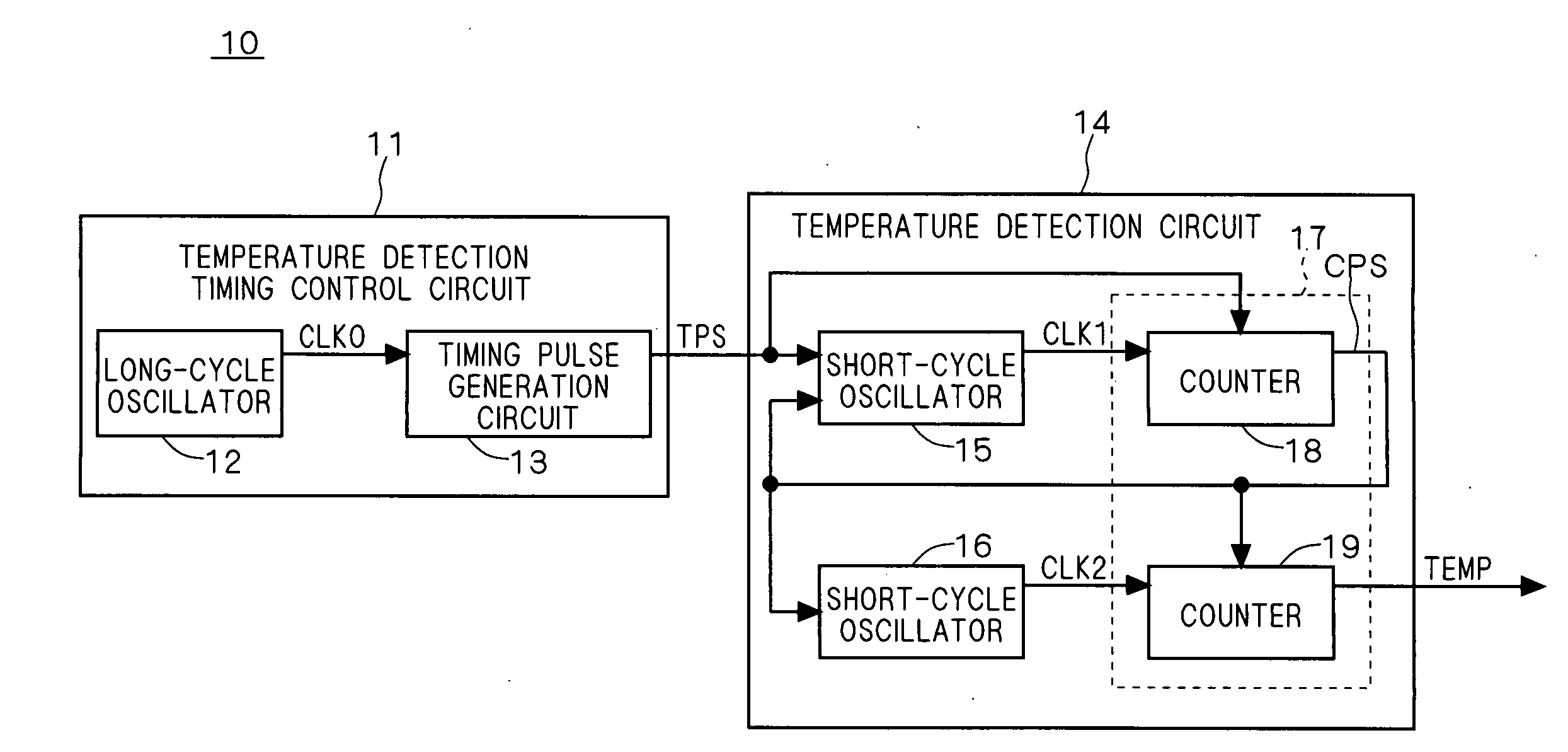

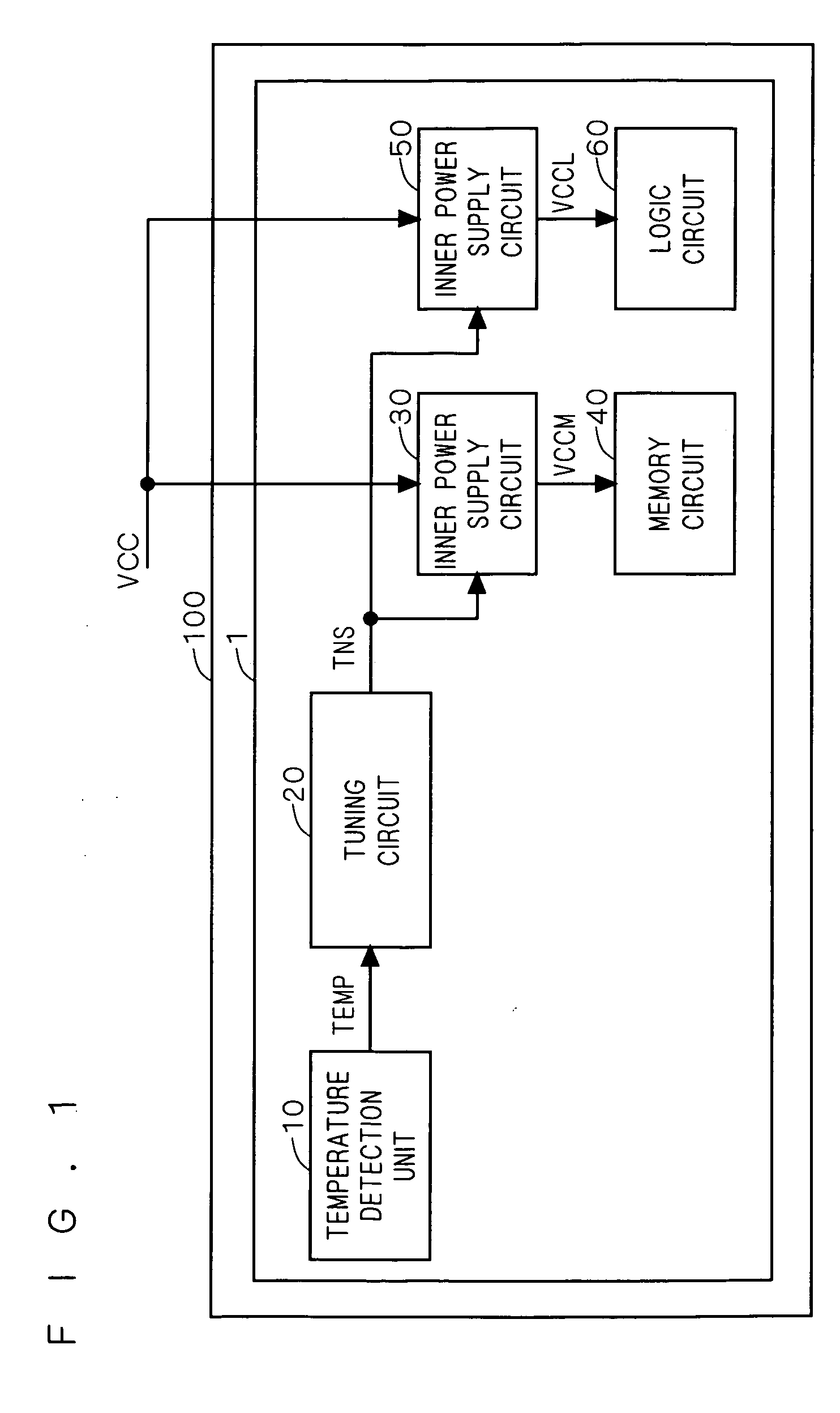

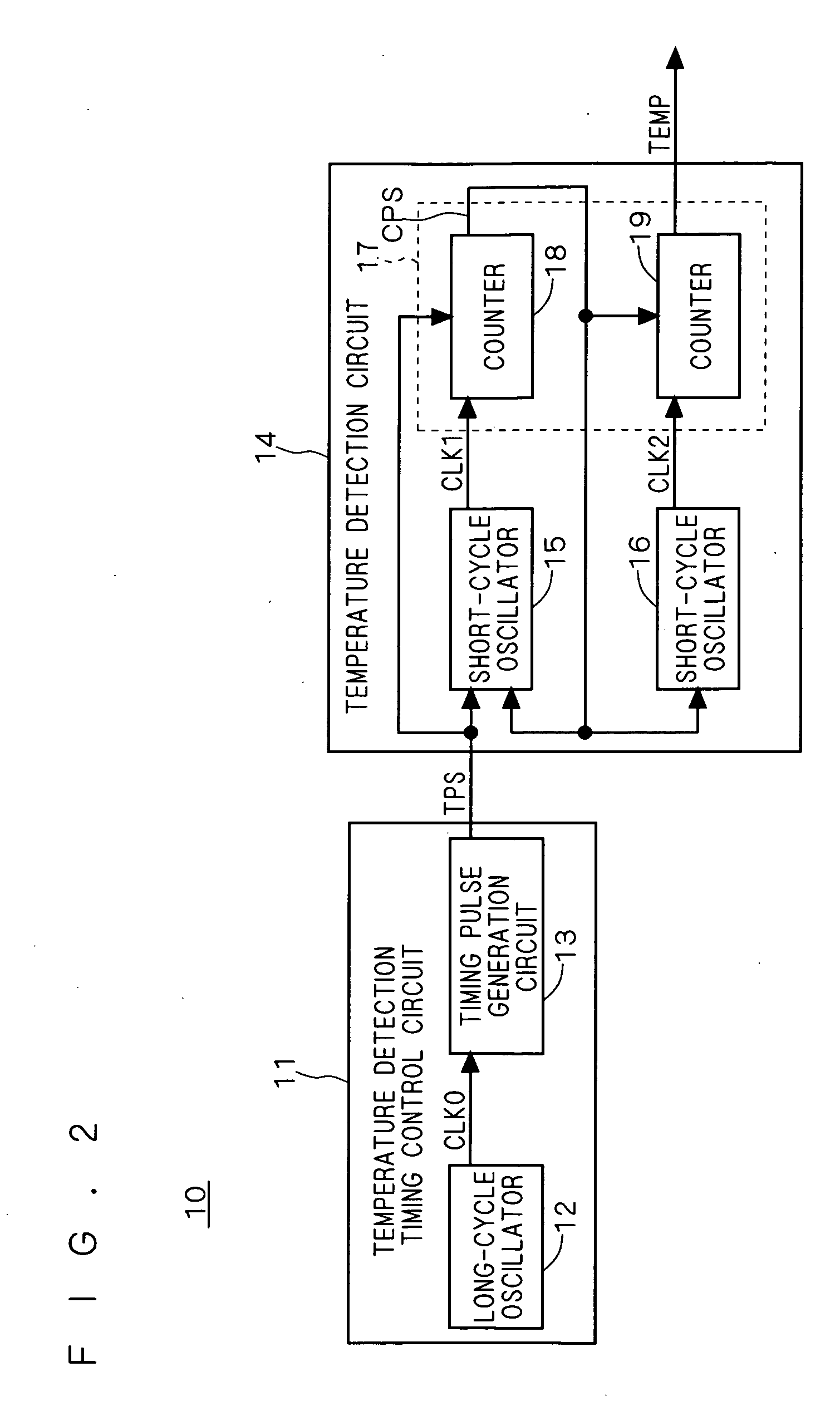

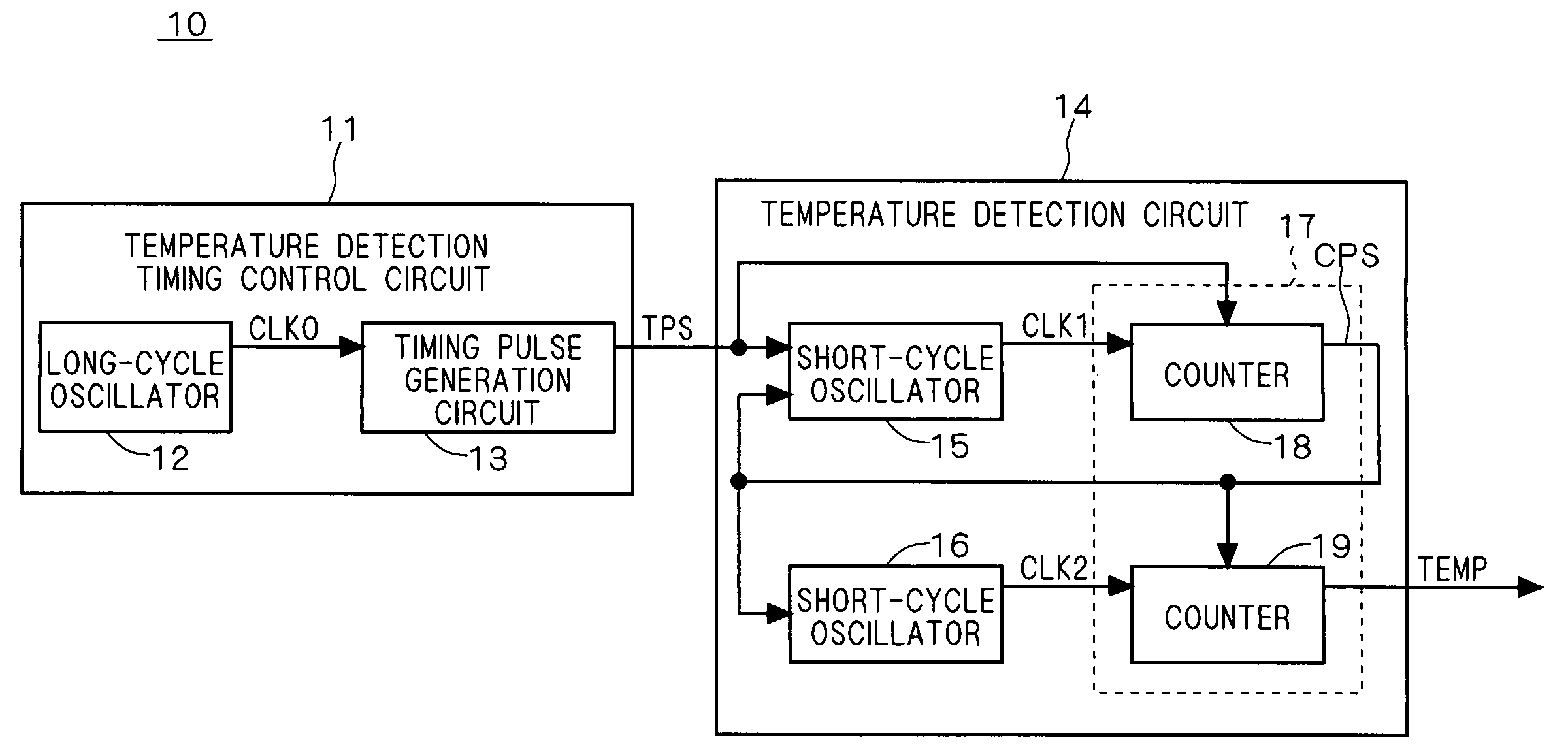

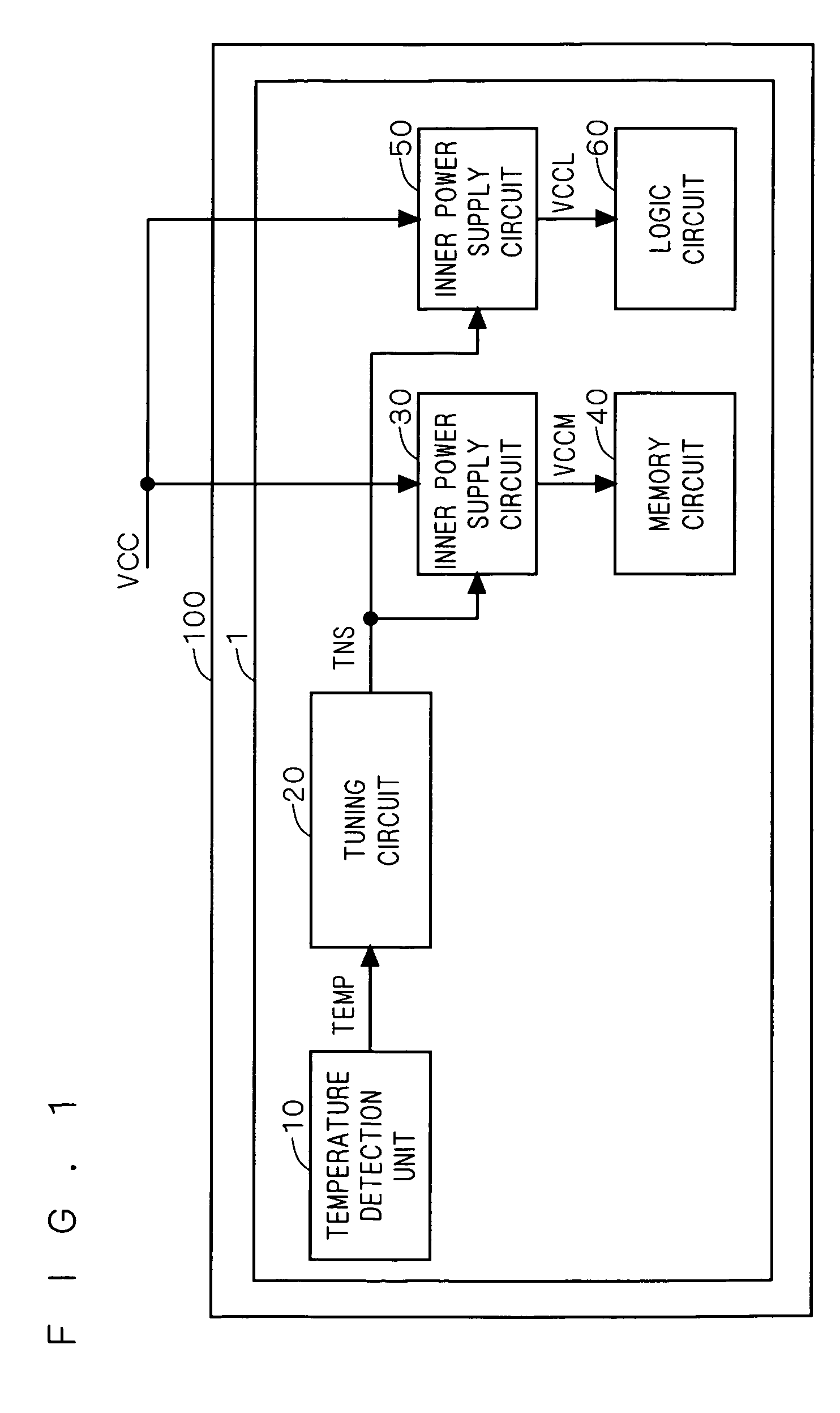

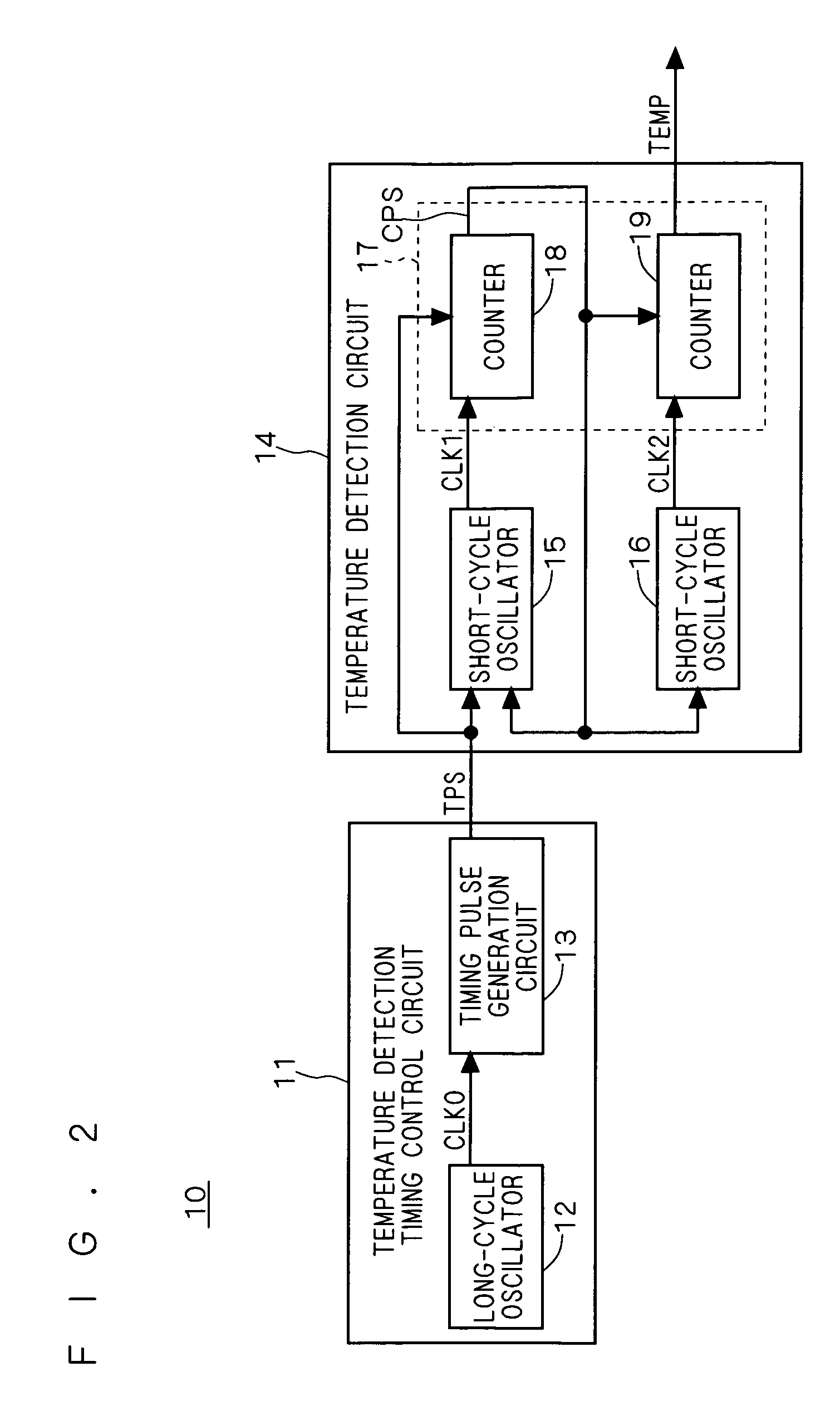

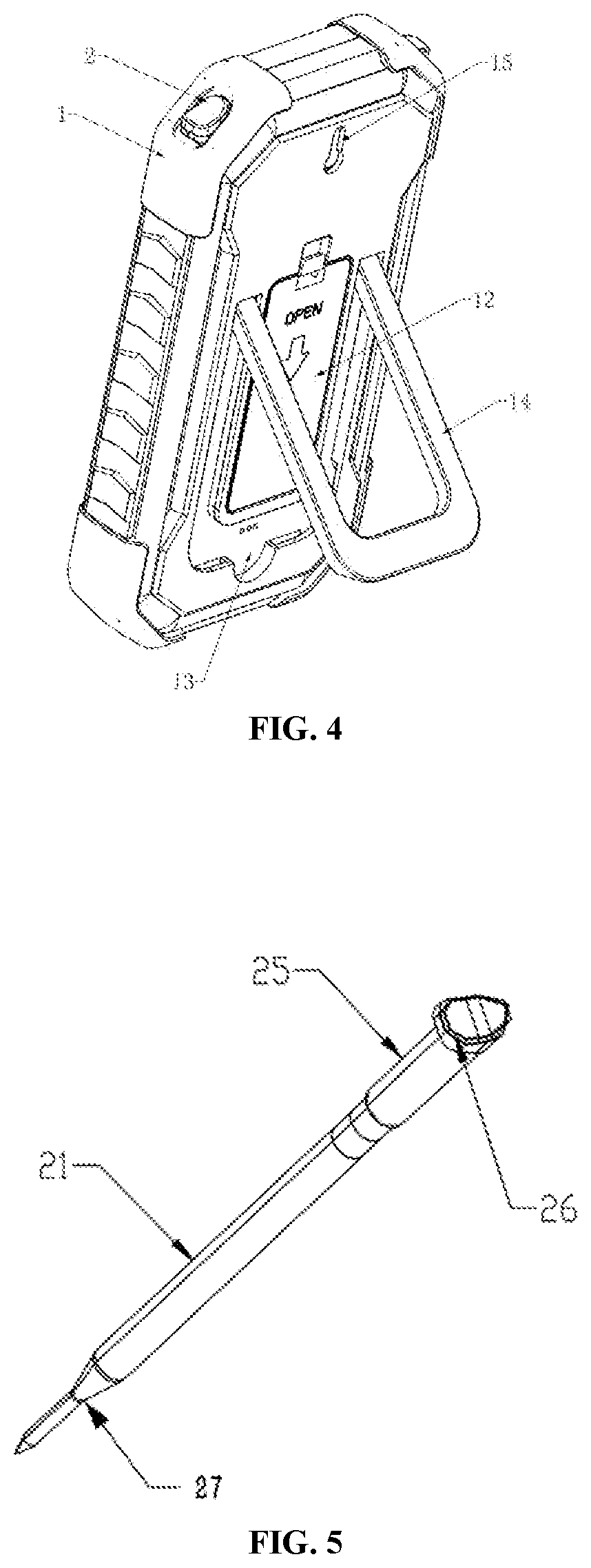

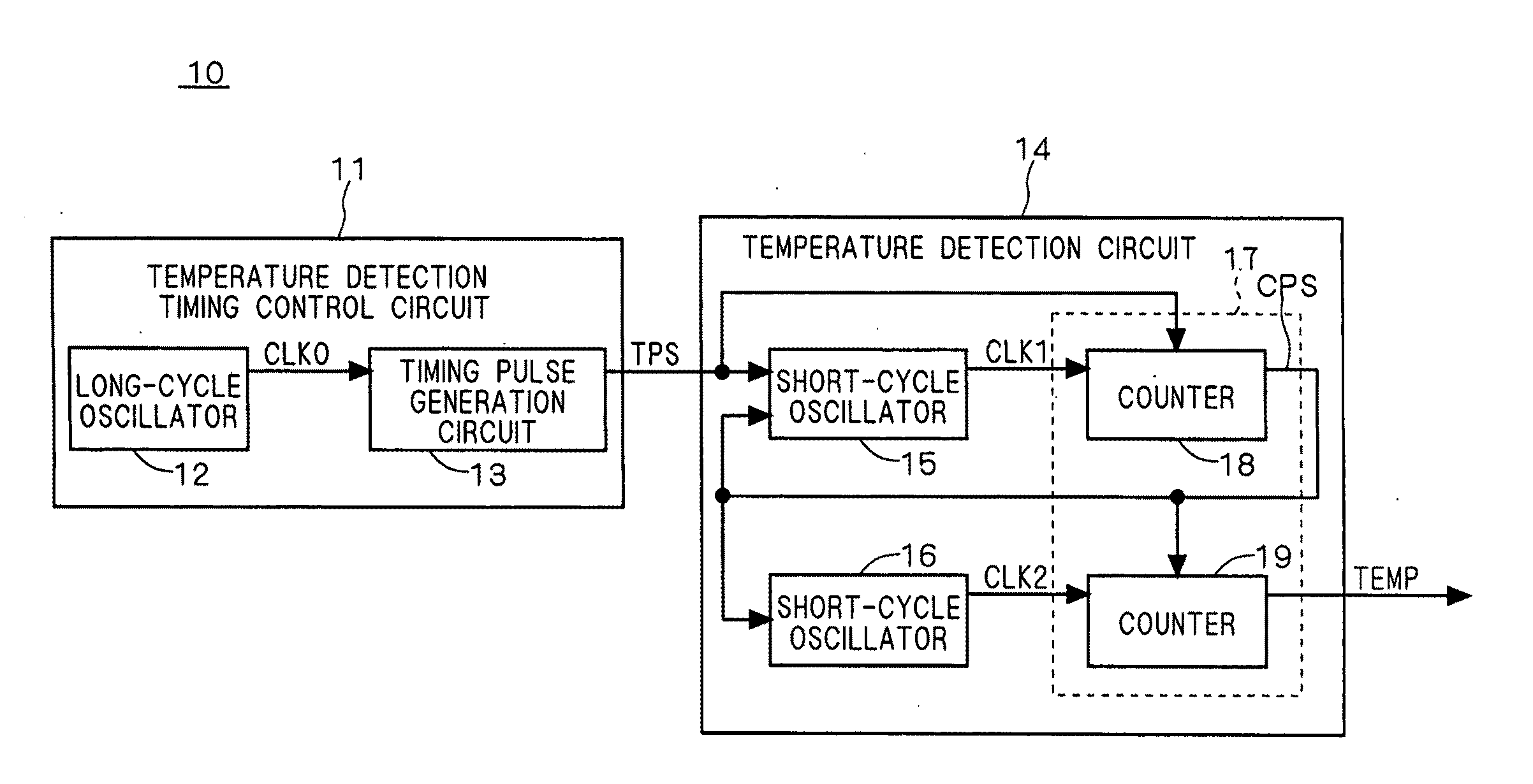

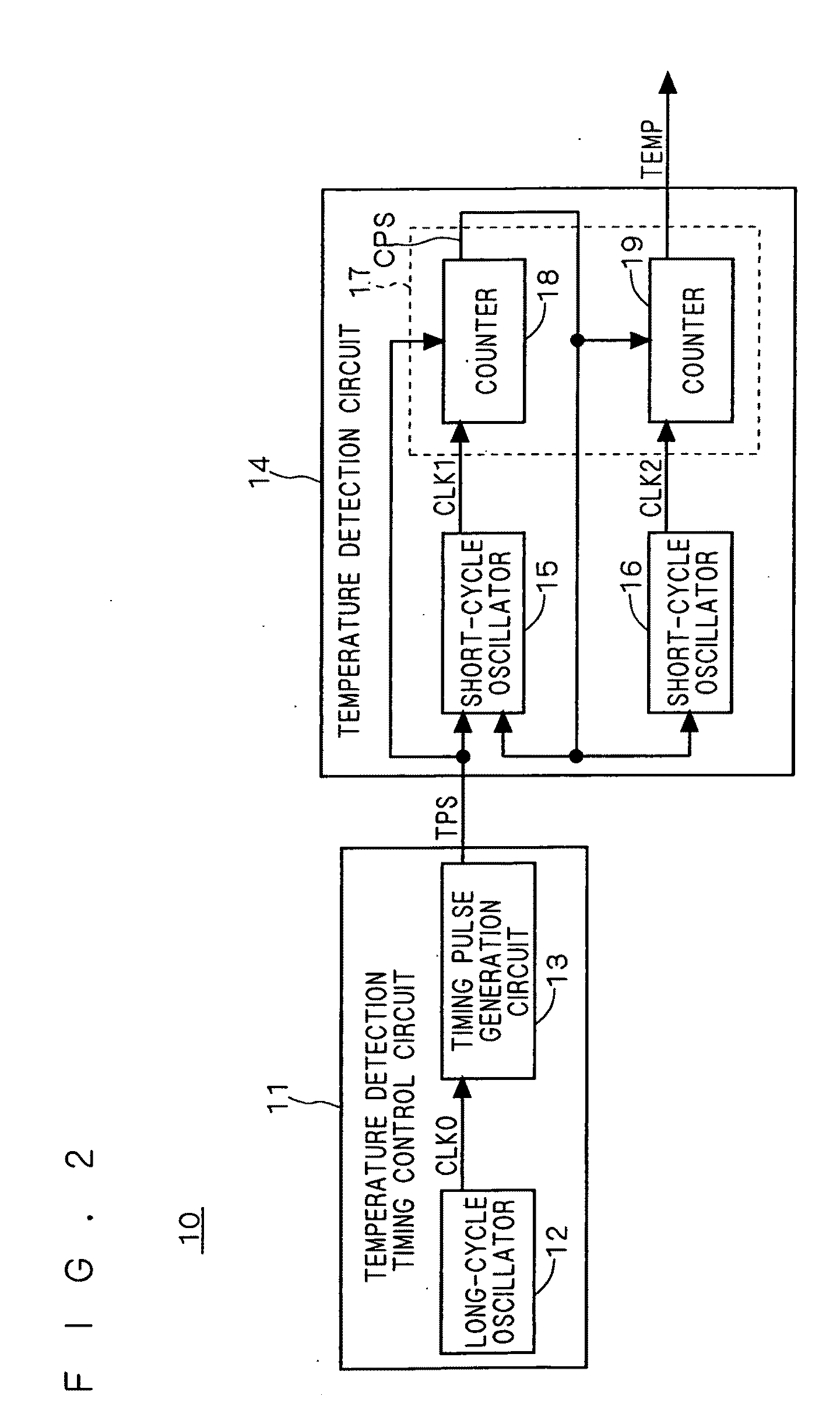

Semiconductor device

ActiveUS20060285576A1Improve accuracyEasy to adjustRadiation pyrometryElectric heatingNegative temperatureDevice material

There is provided a technique which is capable of detecting a temperature of a semiconductor device with high precision. A temperature detection circuit detecting a temperature of a semiconductor device includes a first short-cycle oscillator generating a first clock signal having positive temperature characteristics with respect to a frequency, a second short-cycle oscillator generating a second clock signal having negative temperature characteristics with respect to the frequency, and a temperature signal generation unit generating a temperature signal which is varied according to the temperature of the semiconductor device based on the first and second clock signals.

Owner:RENESAS ELECTRONICS CORP

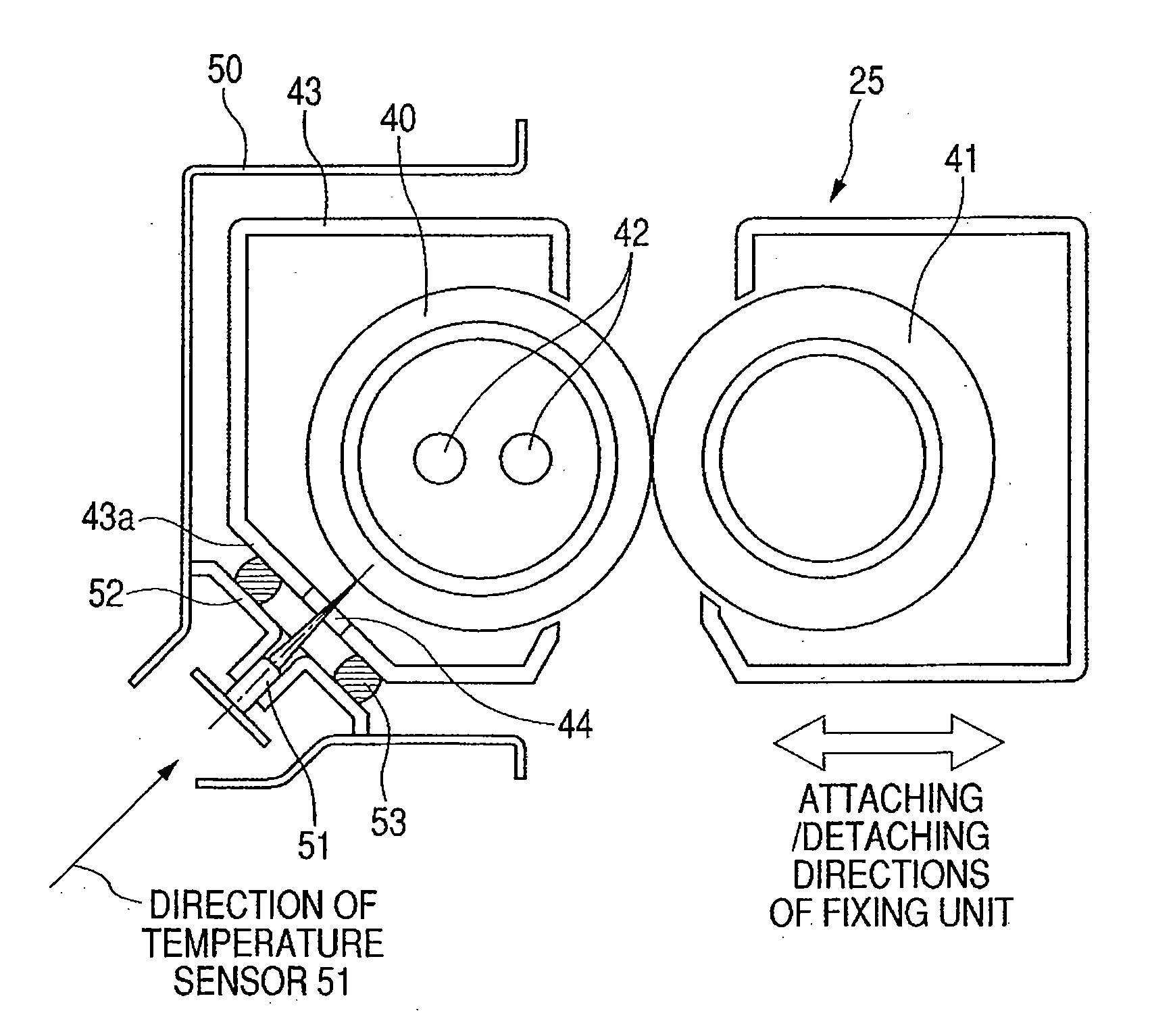

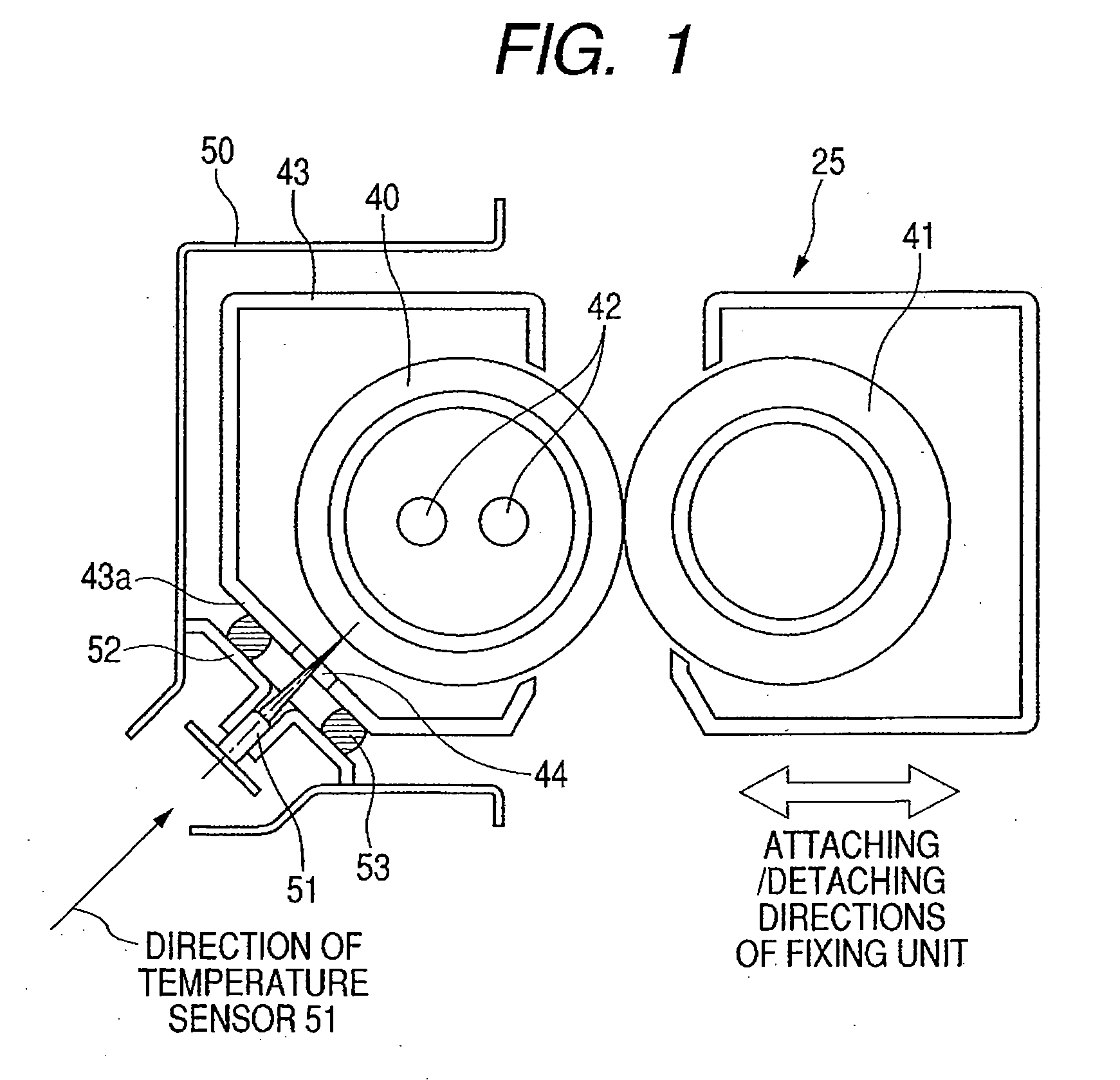

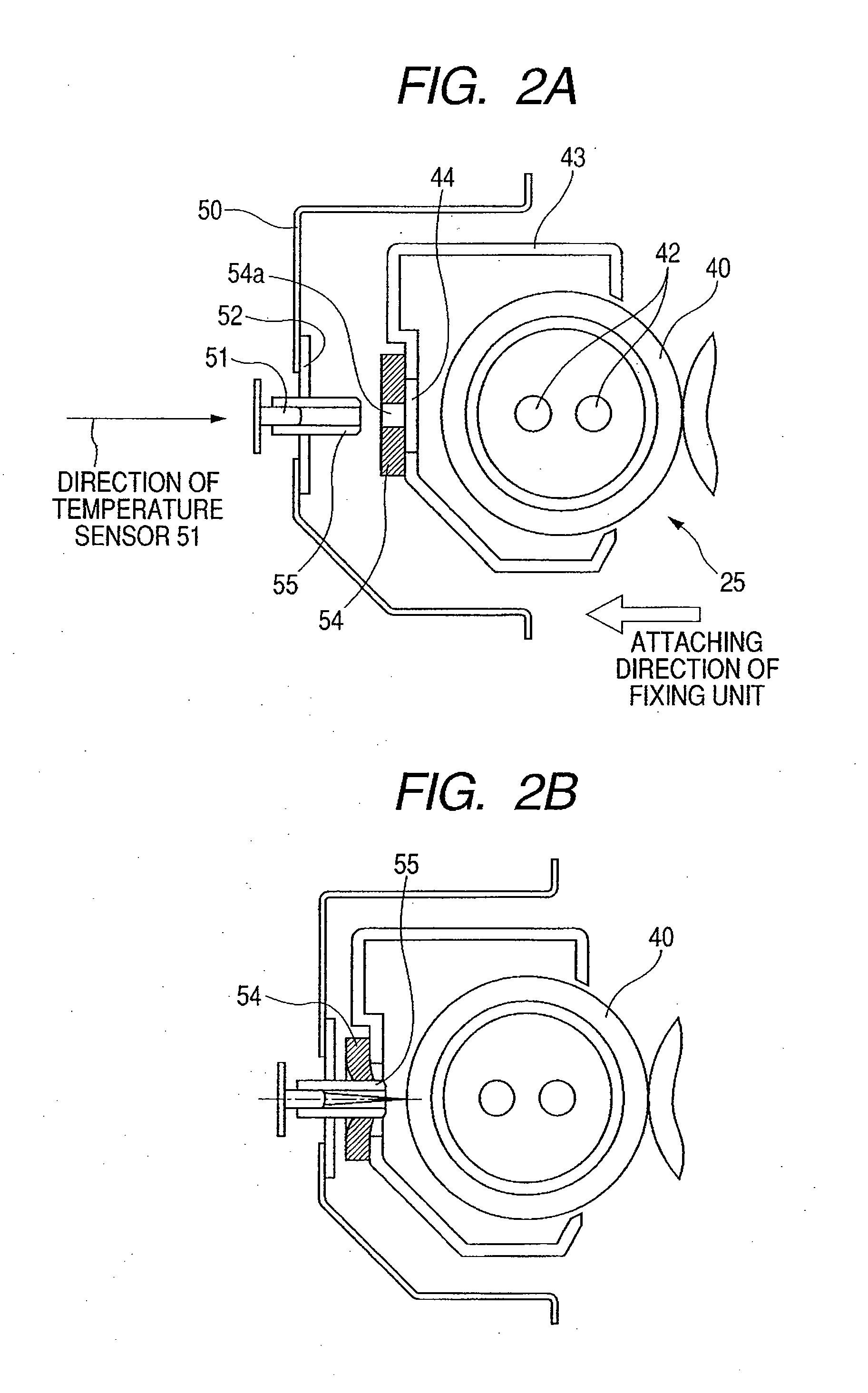

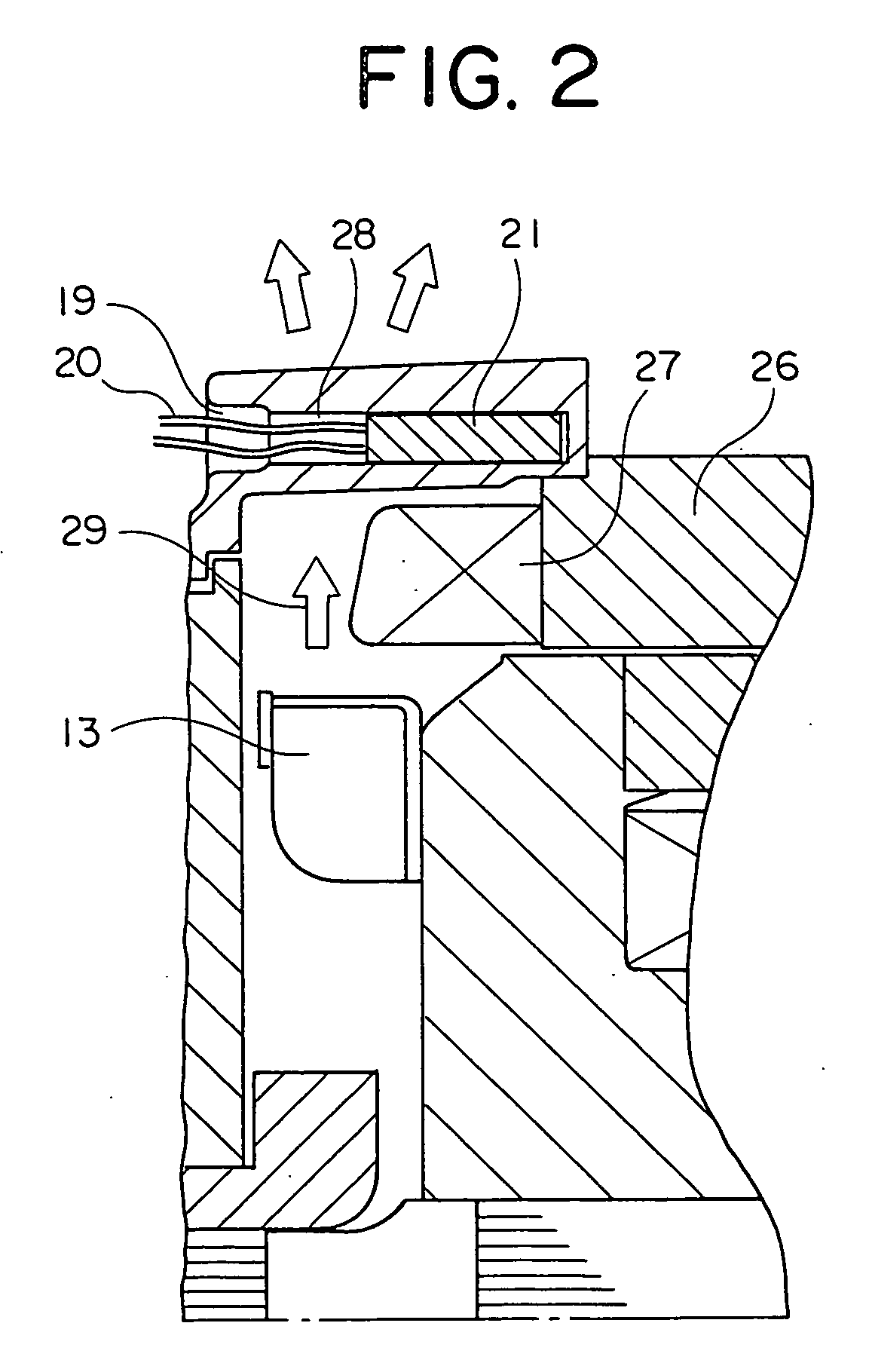

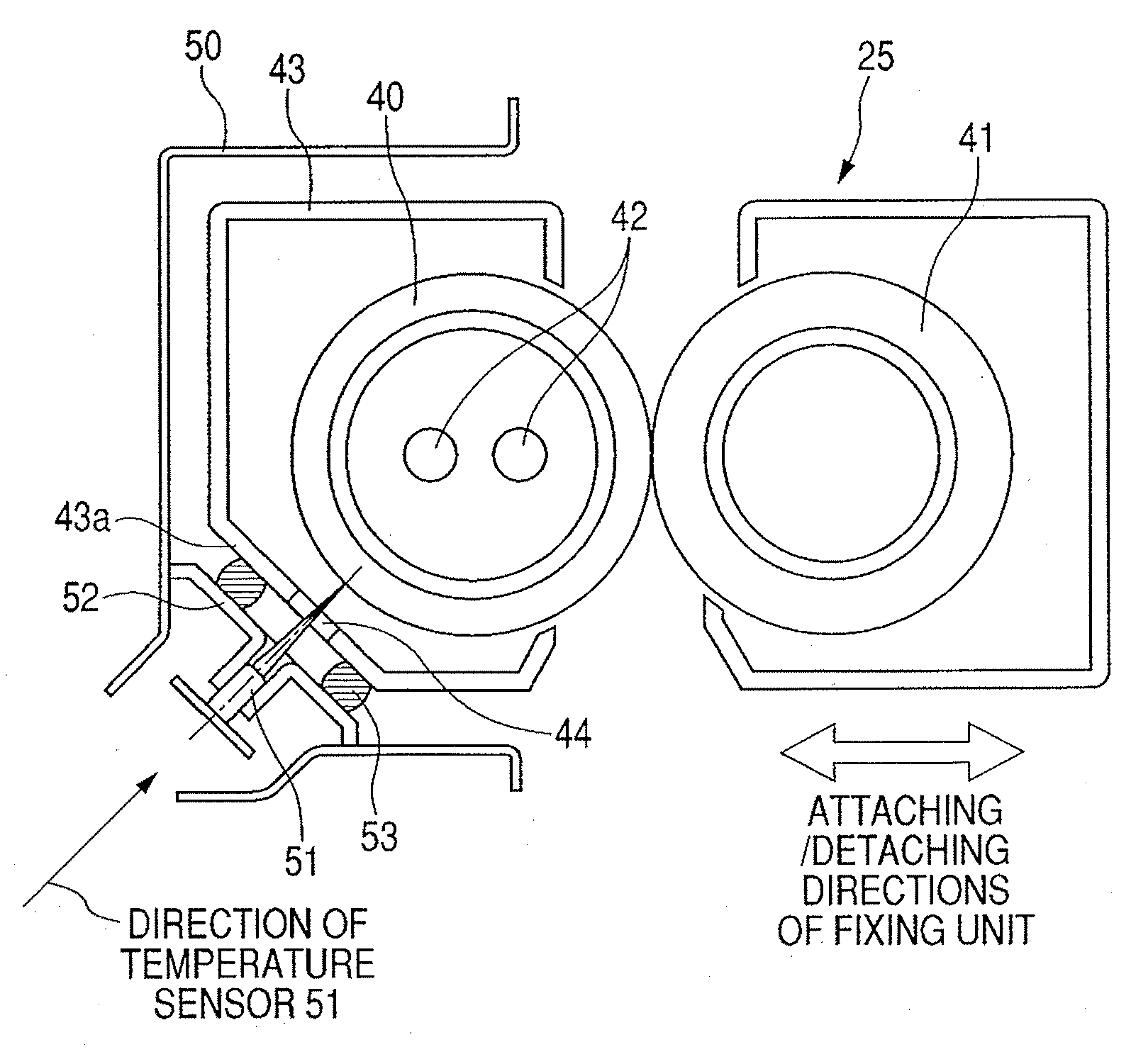

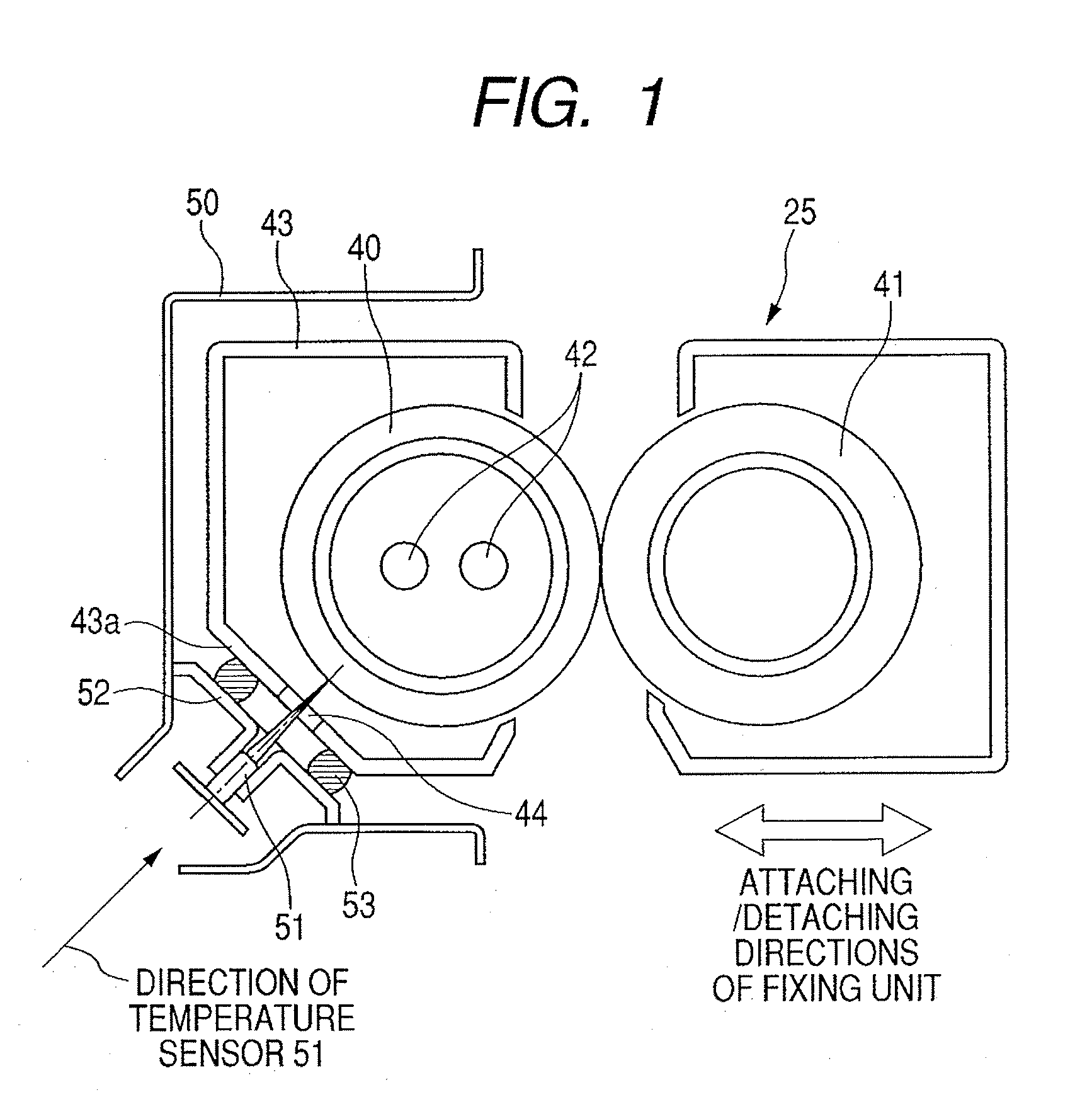

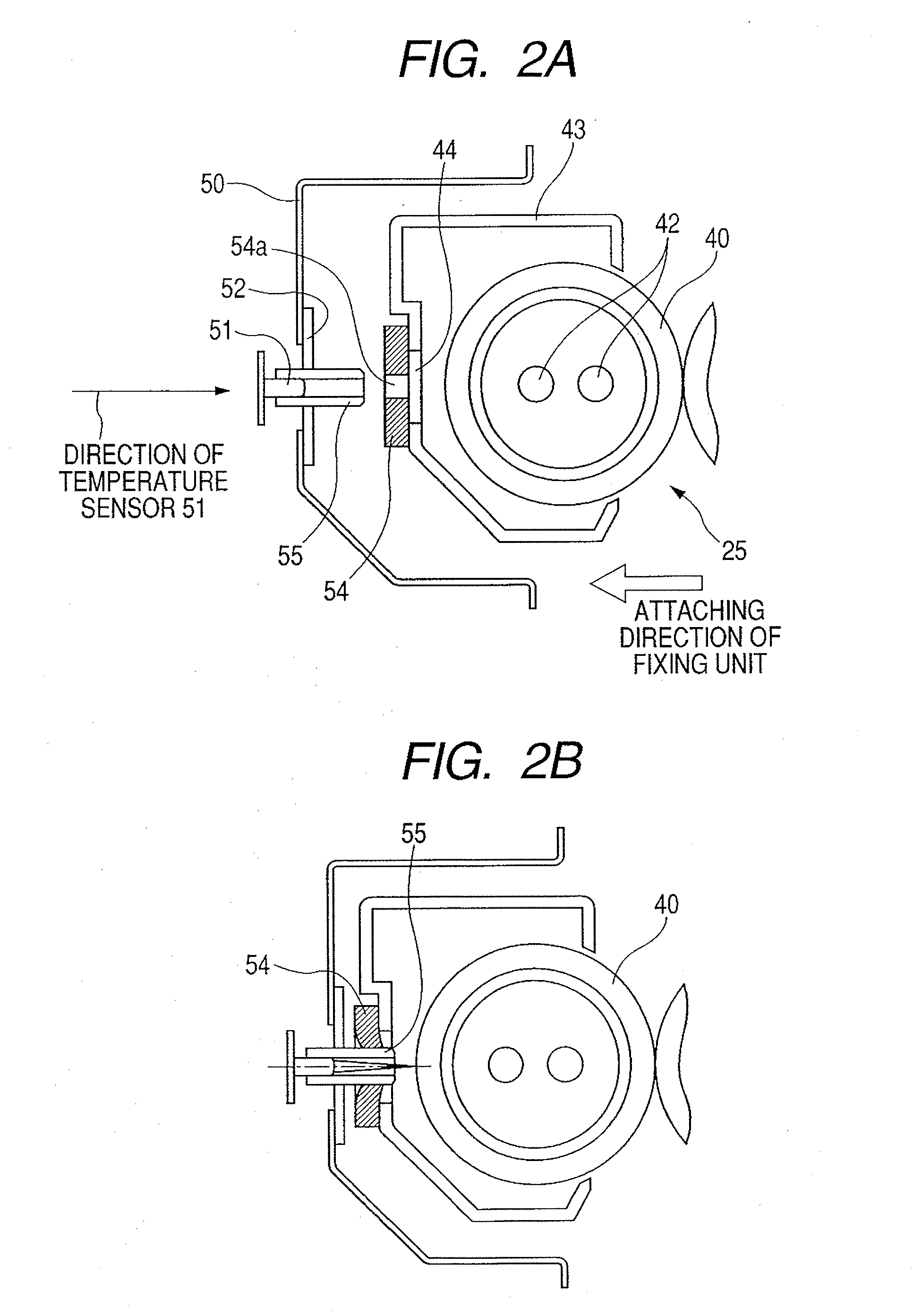

Image forming apparatus having contactless type temperature sensor

InactiveUS20090028595A1Convenient for temperature detectionNot easy to flowElectrographic process apparatusImage formationEngineering

Owner:CANON KK

Dynamoelectric Machine

ActiveUS20080150376A1Easy to assembleEasy to detectSynchronous generatorsElectric motor controlConductor CoilElectric motor

A dynamoelectric machine enabling stator winding temperature detecting precision of a temperature measuring means to be improved while also improving assembly of the dynamoelectric machine is provided.The dynamoelectric machine according to the present invention includes: a stator winding disposed in a stator; a temperature sensor for estimating a stator winding temperature of the stator winding; and a thermally-conductive bracket disposed between the stator winding and the temperature sensor. An estimated value of the stator winding temperature is calculated using a sum of a measured temperature measured by the temperature measuring means and a correcting value for correcting the measured temperature.

Owner:MITSUBISHI ELECTRIC CORP

Image forming apparatus having contactless type temperature sensor

ActiveUS20070177895A1Convenient for temperature detectionNot easy to flowElectrographic process apparatusImage formationElectrical and Electronics engineering

Owner:CANON KK

Temperature detecting semiconductor device

ActiveUS7459983B2Improve accuracyEasy to adjustRadiation pyrometryTemperatue controlNegative temperatureEngineering

There is provided a technique which is capable of detecting a temperature of a semiconductor device with high precision. A temperature detection circuit detecting a temperature of a semiconductor device includes a first short-cycle oscillator generating a first clock signal having positive temperature characteristics with respect to a frequency, a second short-cycle oscillator generating a second clock signal having negative temperature characteristics with respect to the frequency, and a temperature signal generation unit generating a temperature signal which is varied according to the temperature of the semiconductor device based on the first and second clock signals.

Owner:RENESAS ELECTRONICS CORP

Flow sensor using a heat element and a resistance temperature detector formed of a metal film

ActiveUS7404320B2Convenient for temperature detectionHigh TCR inherentVolume/mass flow by thermal effectsFluid speed measurement using thermal variablesElectrical resistance and conductanceMeasurement device

Owner:HITACHI LTD

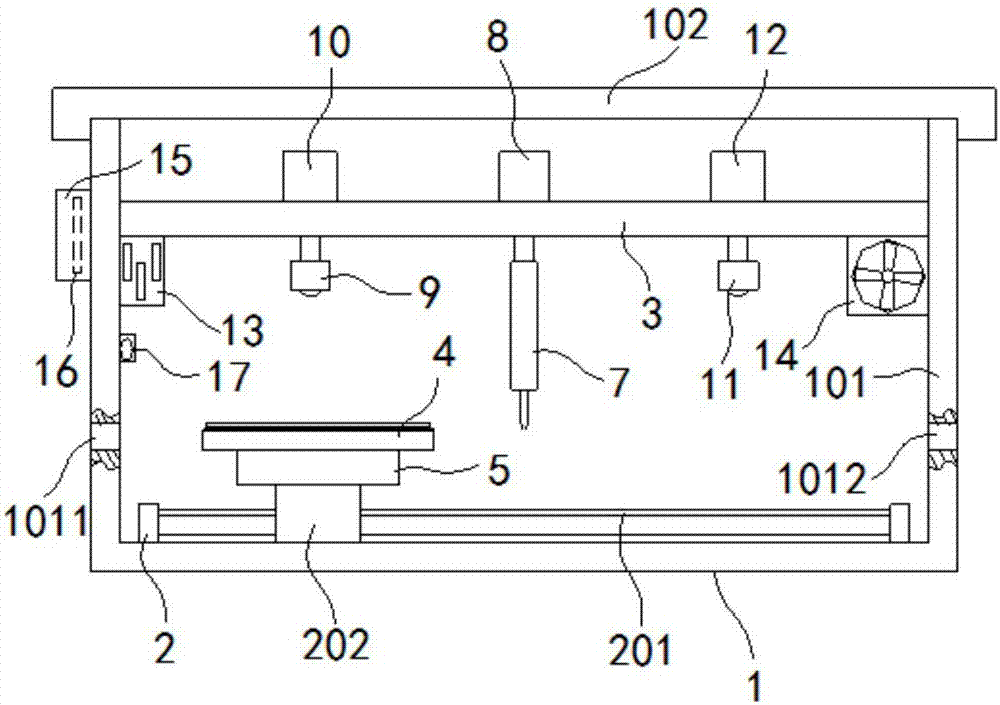

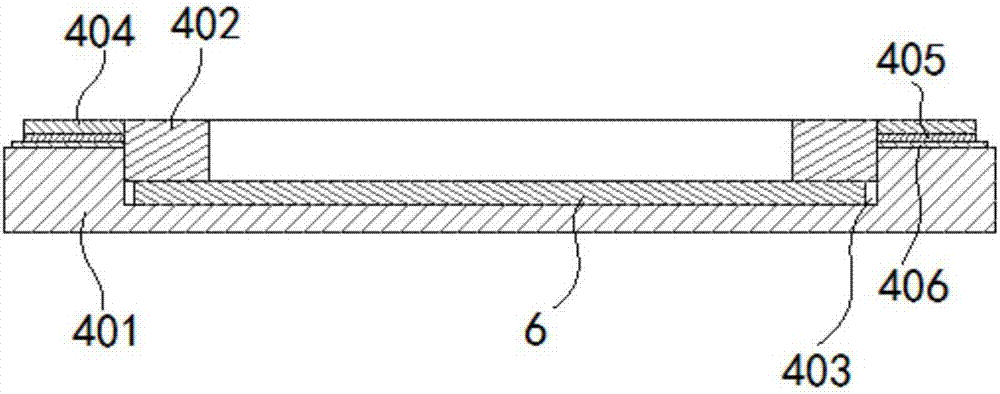

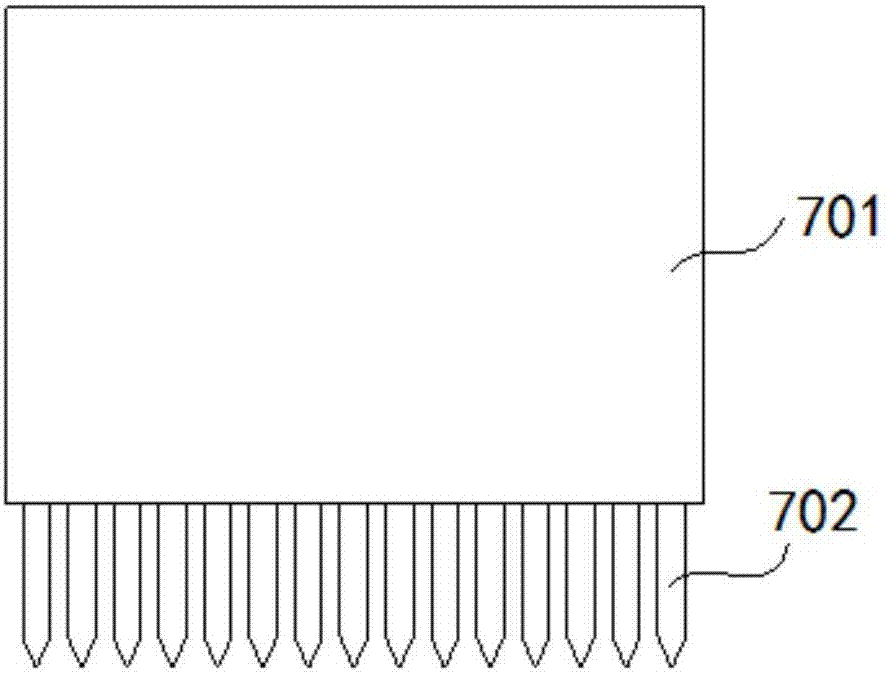

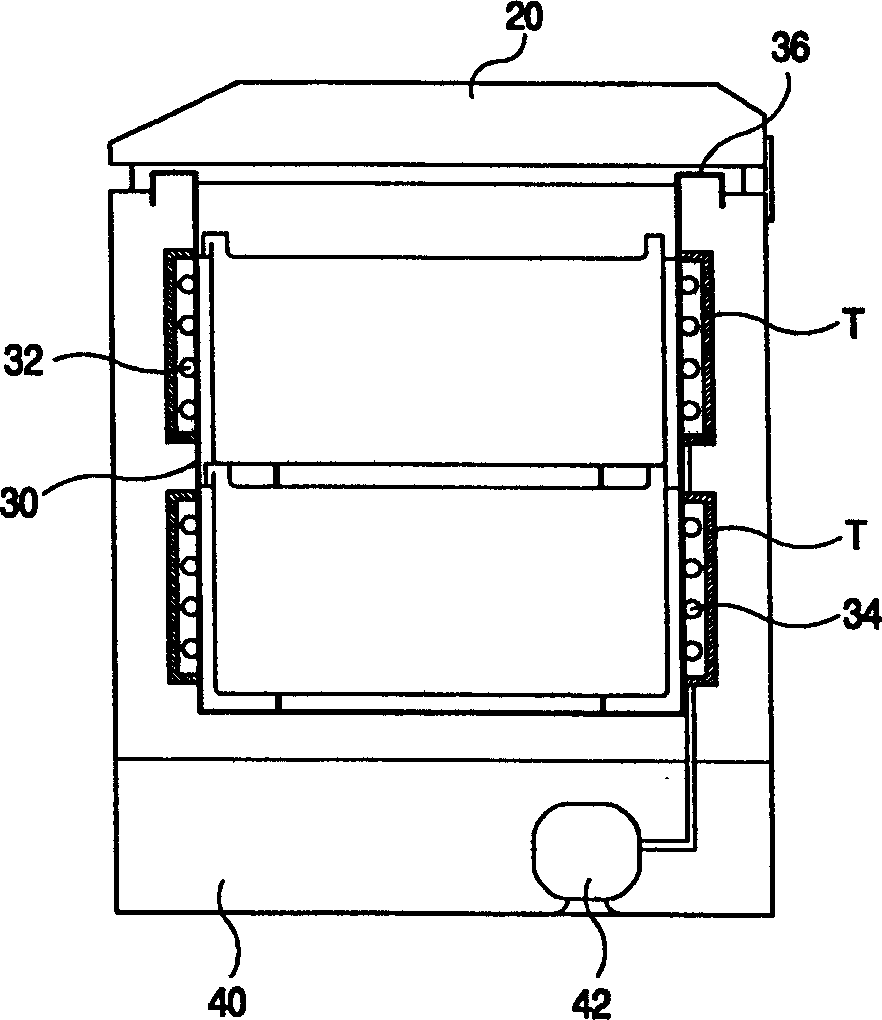

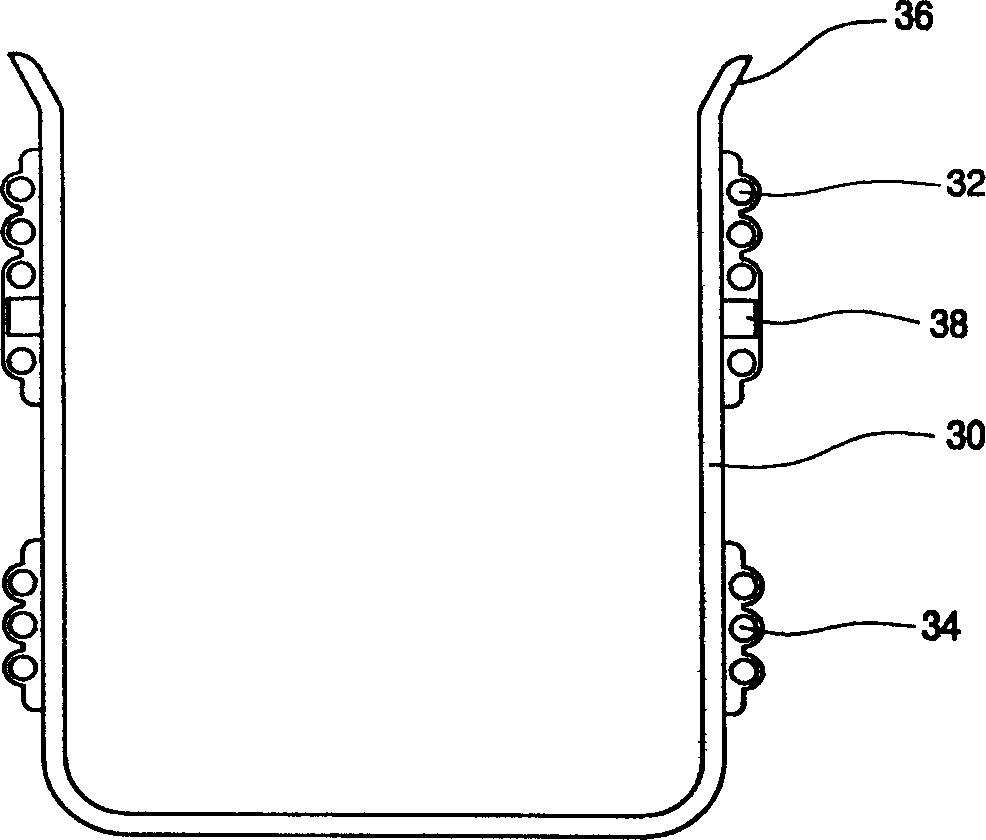

Full-automatic display screen detection device

InactiveCN107449584ARealize lighting detectionAchieving wear resistance testingElectrical testingOptical apparatus testingControl circuitComputer engineering

The invention discloses a full-automatic display screen detection device, which comprises a detection box, a sliding device, a support plate, a clamp, an adsorption disc, a scratch pin device, a first lift cylinder, a first camera device, a second lift cylinder, a second camera device, a third lift cylinder, a heating device, a radiator fan and a control box and the like. The detection box is internally provided with the first camera device, a control circuit board controls a display screen in the clamp to be on, and a display screen image of the lightened display screen is obtained through the first camera device, thereby realizing lightening detection of the display screen; through the heating device, the temperature in the detection box can be controlled, and display screen images under a plurality of temperatures are obtained by utilizing the first camera device, thereby realizing high and low temperature detection of the display screen; and through the scratch pin device and the second camera device, the display screen in the clamp is driven to move by the sliding device, and when the display screen passes under the scratch pin device, the display screen is scratched by scratch pins, and a display screen image of the display screen obtained after being scratched by scratch pins is obtained by utilizing the second camera device, thereby realizing abrasion resistance detection of the display screen.

Owner:ACCU JIANGSU CO LTD

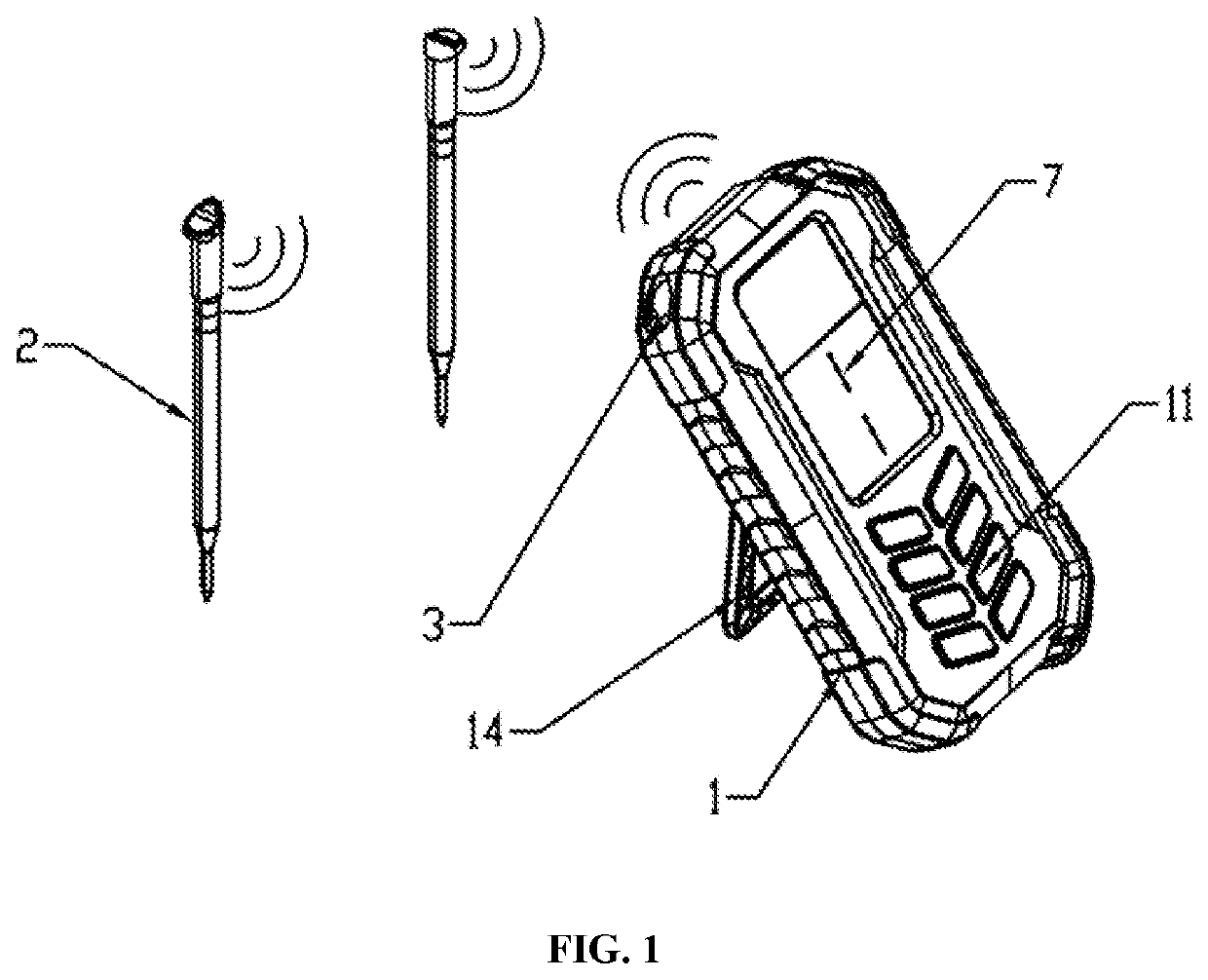

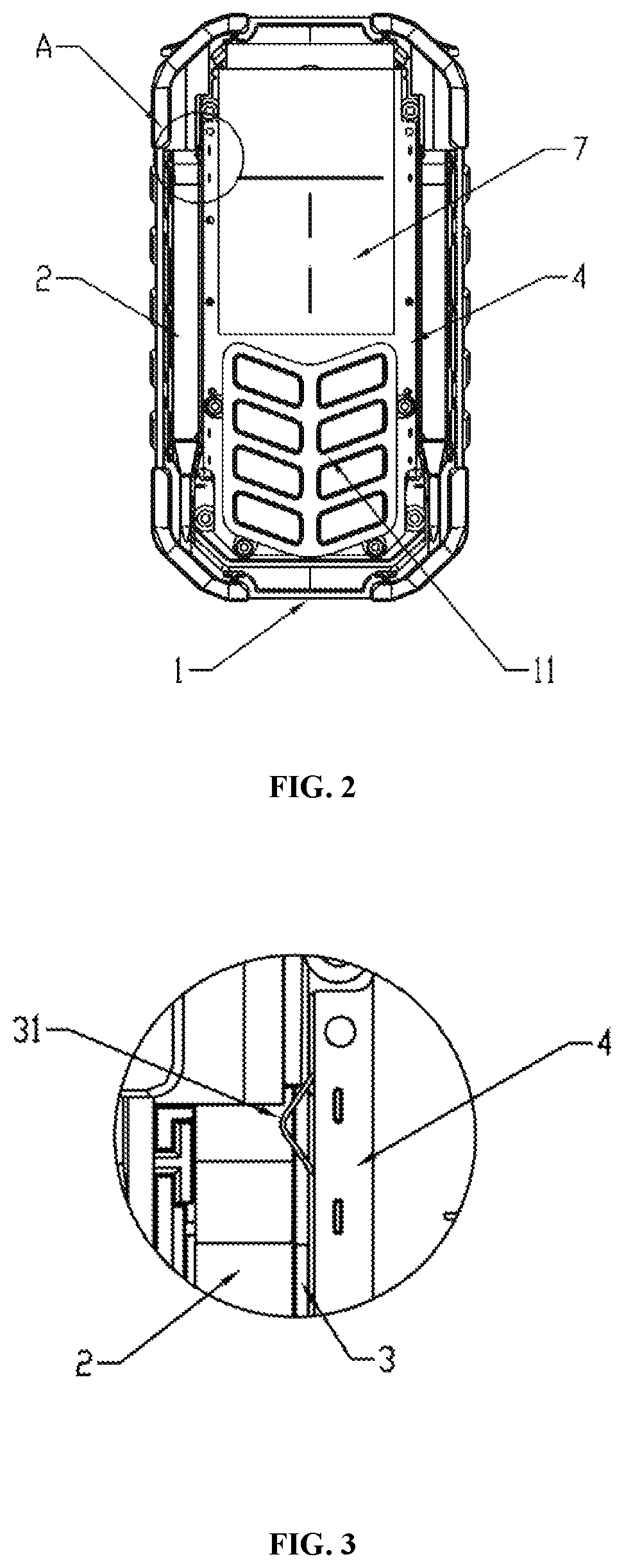

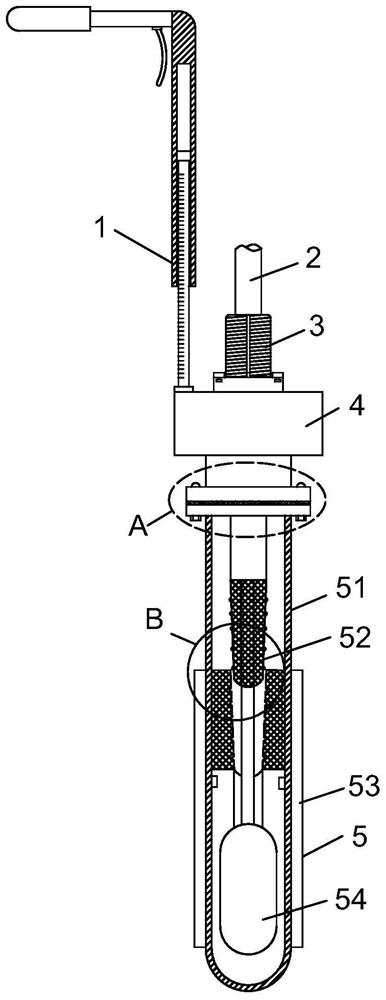

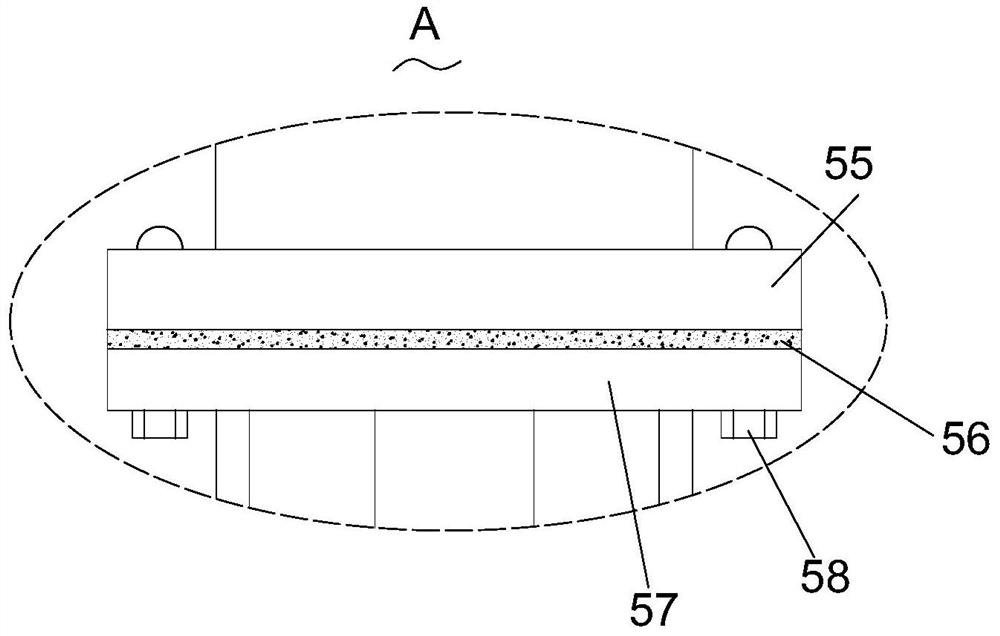

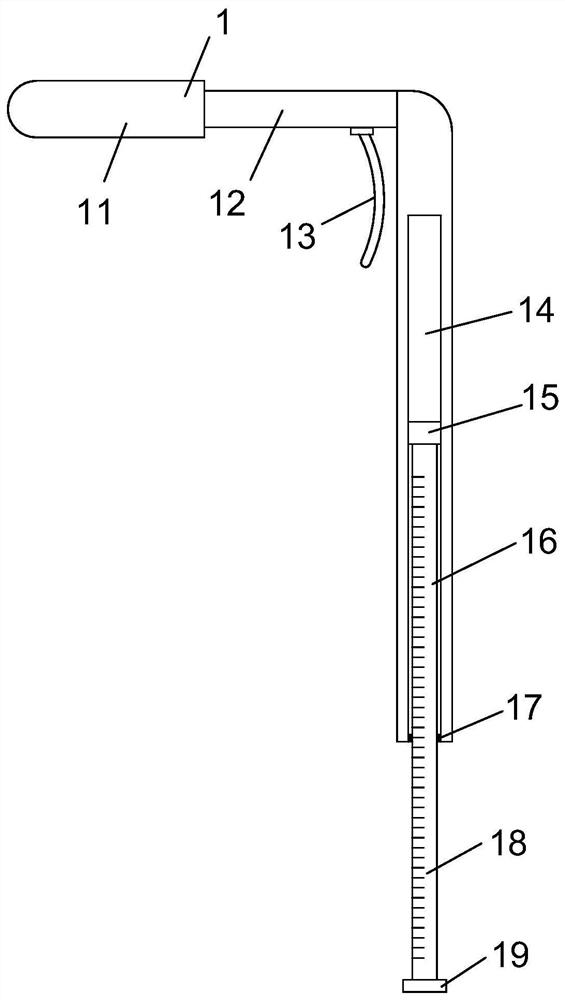

Wireless detecting thermometer for barbecue

ActiveUS11366018B1Improve convenienceEasy to observeThermometer detailsTransmission systemsTransceiverDisplay device

The present disclosure relates to temperature detection equipment and in particular to a wireless detecting thermometer for barbecue, which comprises a host and a temperature probe, wherein the host is provided with a storage slot and a control circuit board integrated with a Bluetooth adapter, a central processing unit and a digital display; the temperature probe comprises a metal casing, a temperature-sensing resistor and a temperature measuring chip; the temperature measuring chip is connected to a Bluetooth transceiver signally communicated with the Bluetooth adapter in the host. A Bluetooth protocol is applied for data transmission to get rid of a data cable, so that the temperature probe can be put into an oven, thus to improve the convenience of the product. Besides, the temperature data and the power data are shown on the digital display, which is convenient to observe, and the temperature detection is convenient.

Owner:SHENZHEN HONGKANG INT ELECTRONICS TECH CO LTD

Temperature detecting semiconductor device

InactiveUS20090058543A1Improve accuracyEasy to adjustRadiation pyrometryTemperatue controlNegative temperatureEngineering

There is provided a technique which is capable of detecting a temperature of a semiconductor device with high precision. A temperature detection circuit detecting a temperature of a semiconductor device includes a first short-cycle oscillator generating a first clock signal having positive temperature characteristics with respect to a frequency, a second short-cycle oscillator generating a second clock signal having negative temperature characteristics with respect to the frequency, and a temperature signal generation unit generating a temperature signal which is varied according to the temperature of the semiconductor device based on the first and second clock signals.

Owner:RENESAS TECH CORP

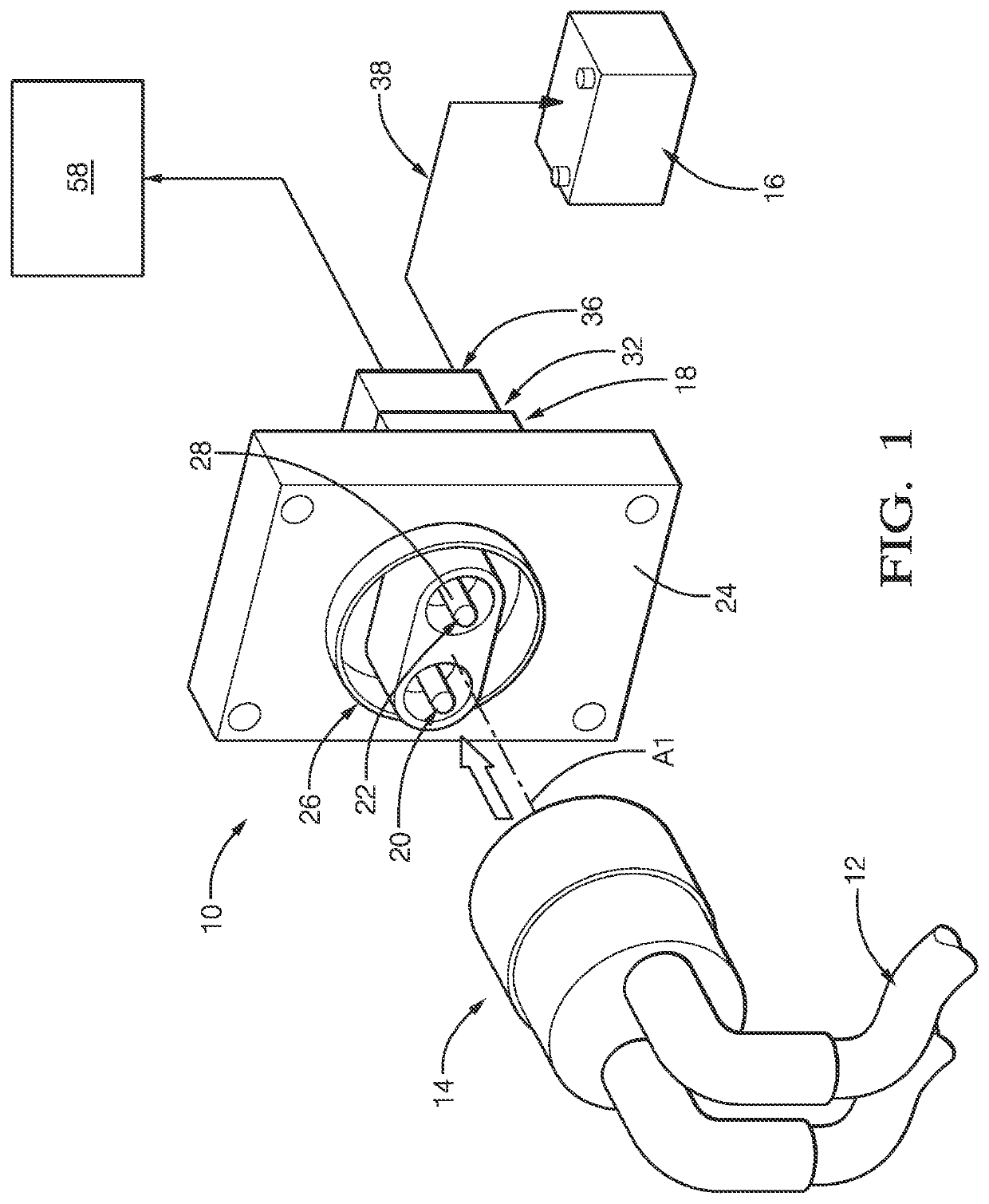

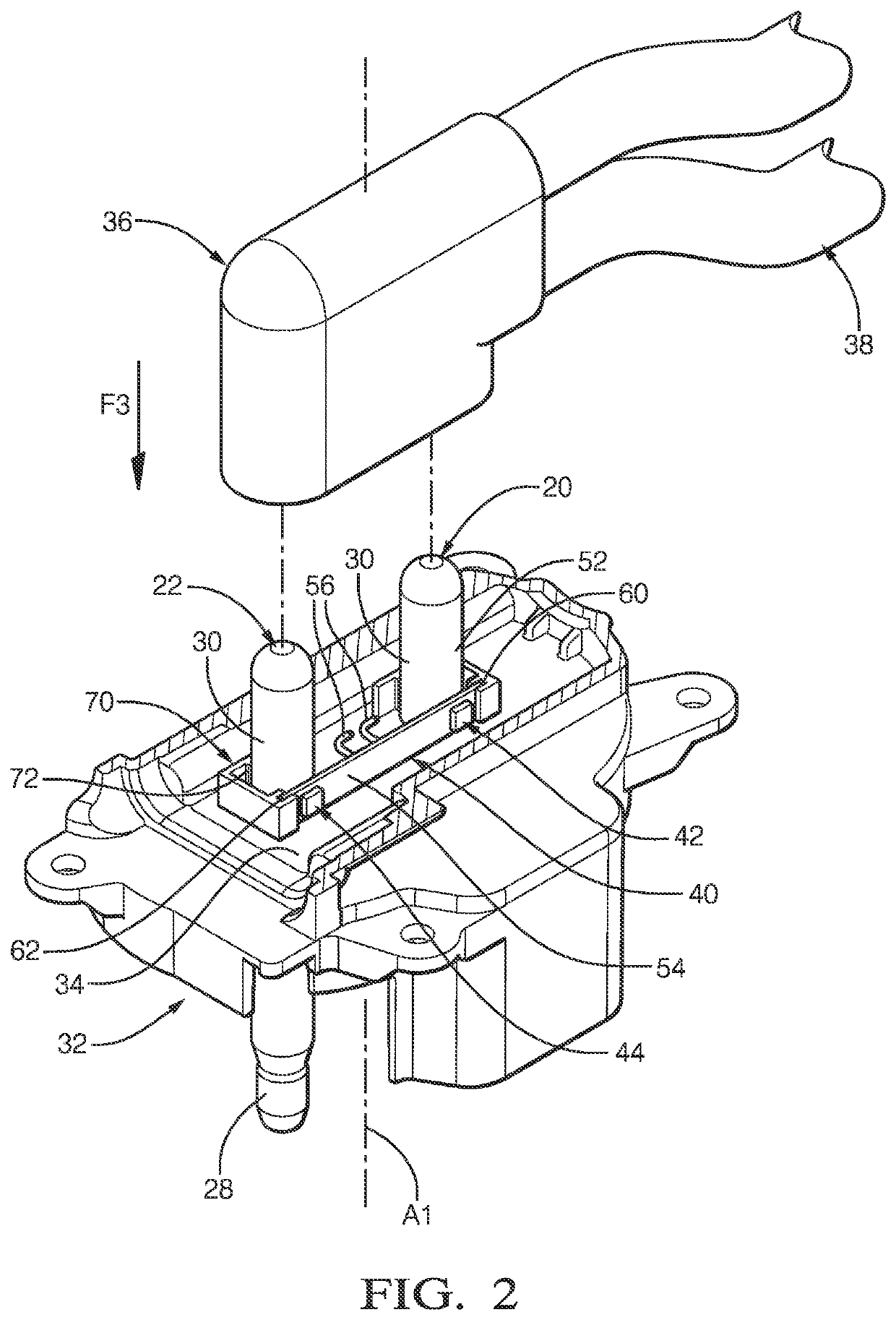

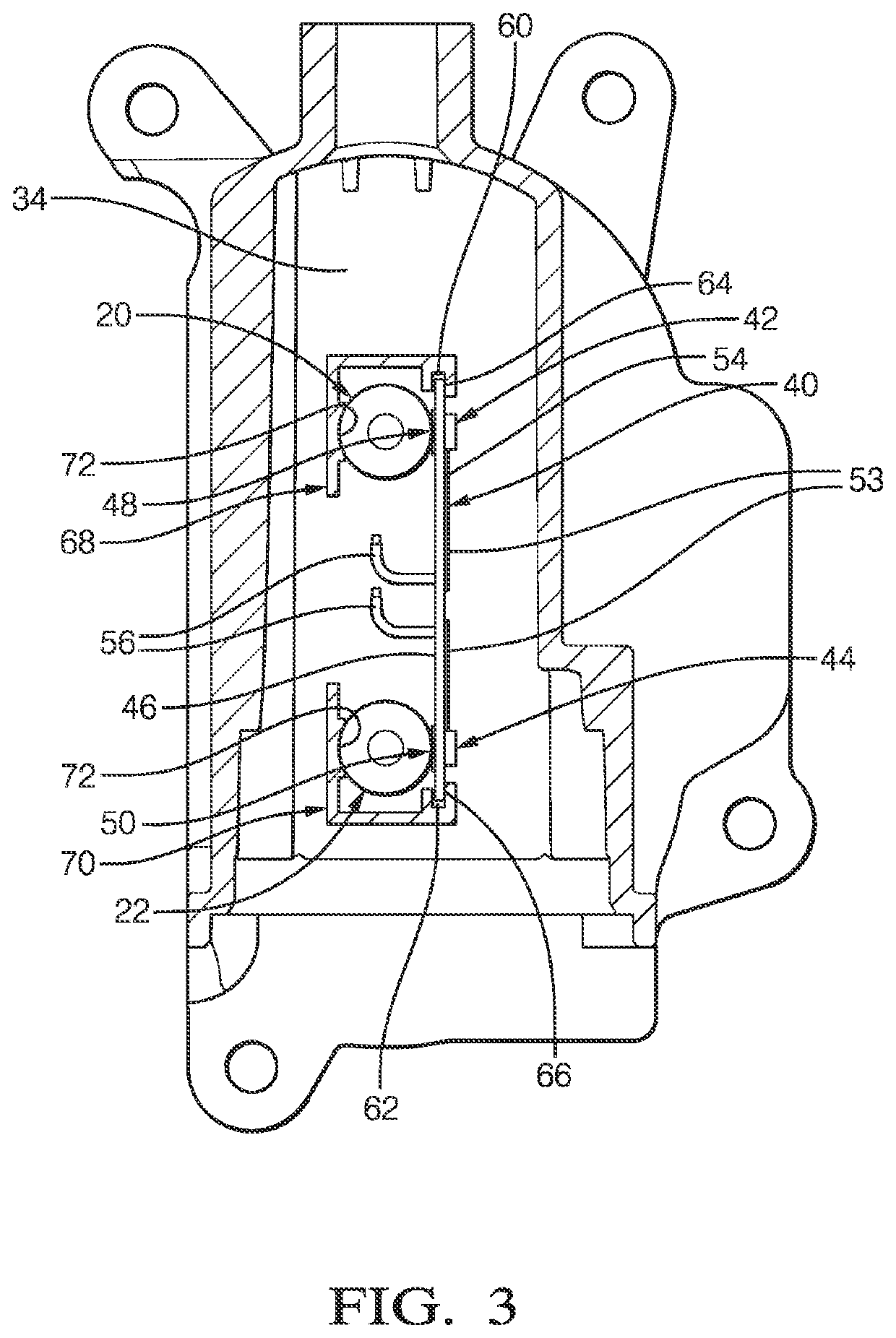

Connection device for vehicle equipped with a temperature sensor

PendingUS20210370785A1Improve temperature detectionRapid detectionThermometer detailsVehicle connectorsPrinted circuit boardEngineering

A connection device for electrical connection of a vehicle to a charging cord provided with a charging socket is presented herein. The connection device includes a housing, at least a first and a second power contact disposed within the housing. Each power contact has a front section disposed in a front part of the housing which extends in a connection base and a rear section disposed in a rear part of the housing which extends in a direction substantially parallel to a direction of connection of the charging socket. The connector device also includes a printed circuit board mounted in the rear part of the housing. The printed circuit board extends in a plane substantially parallel to the direction of connection. The printed circuit board has a first face provided with a first metal pad which is compressed between the printed circuit board, an axial surface of the rear section of the first power contact, and a second face provided with a first temperature sensor which is arranged opposite the first metal pad.

Owner:APTIV TECH LTD

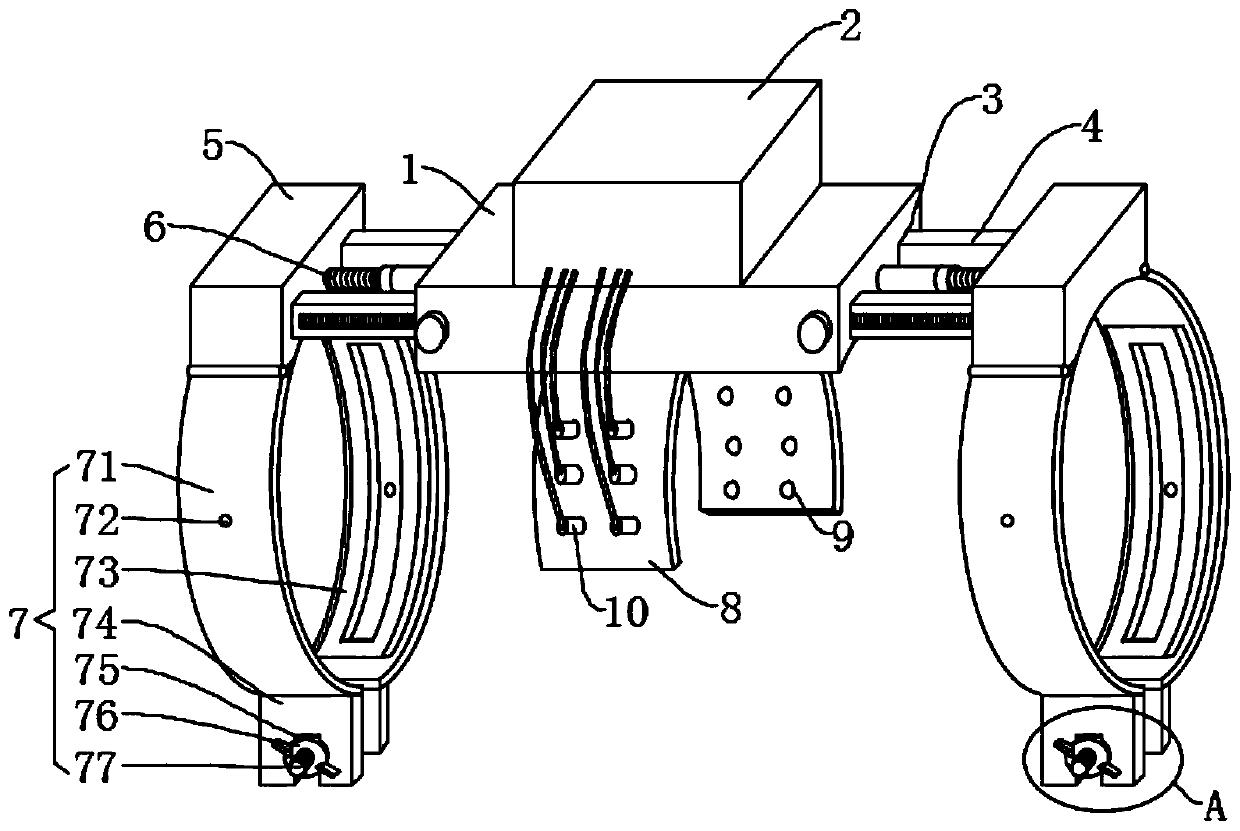

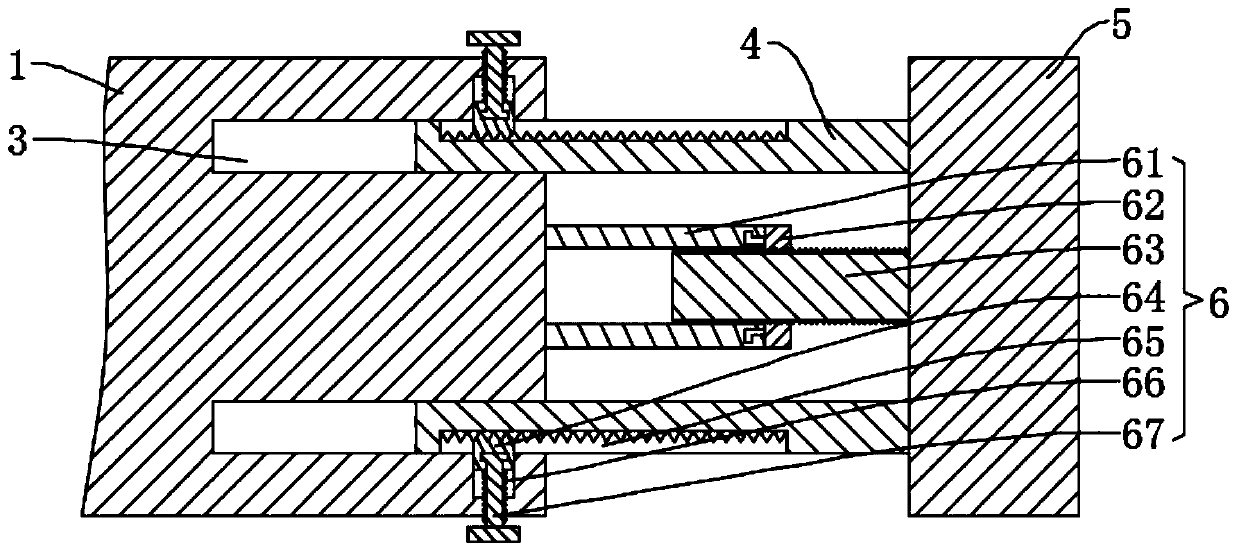

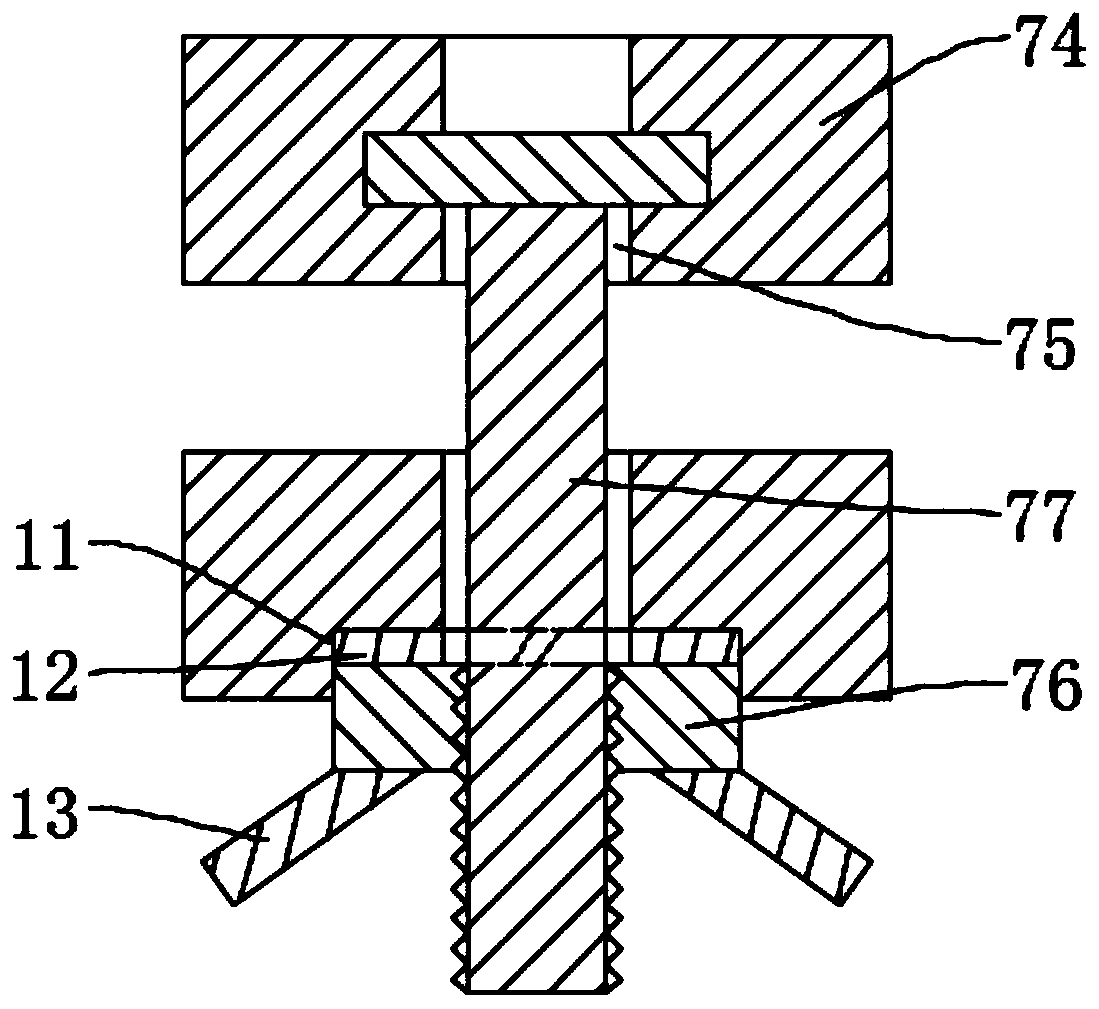

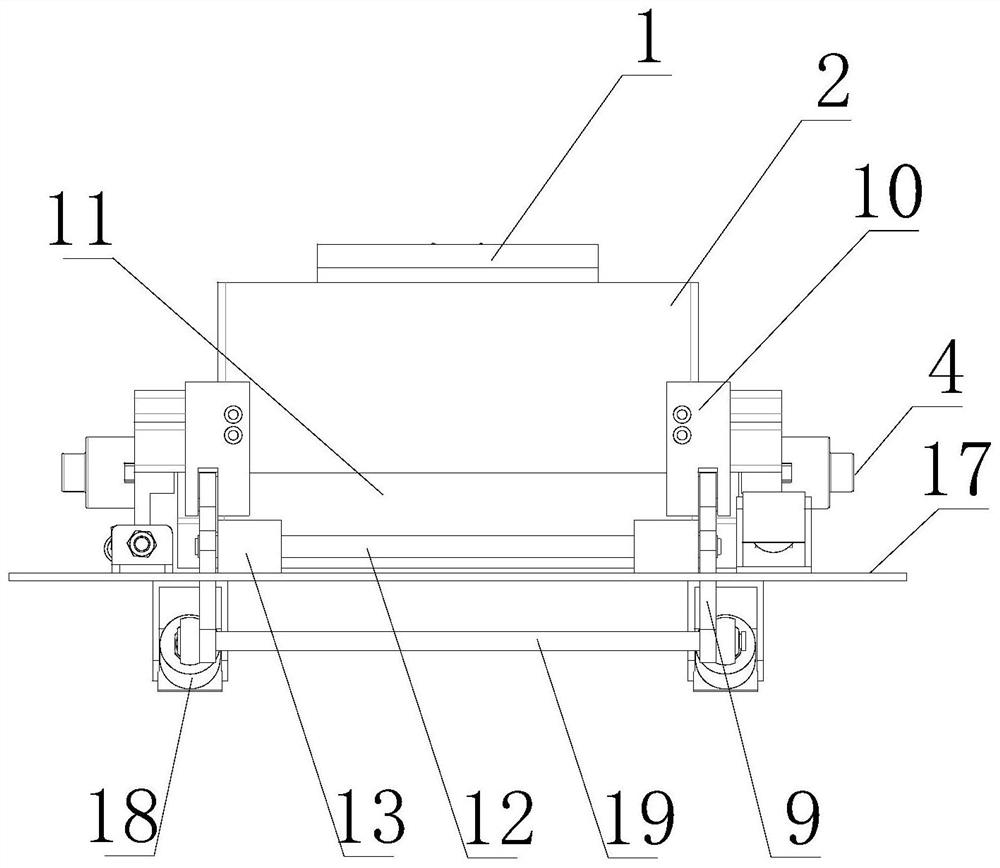

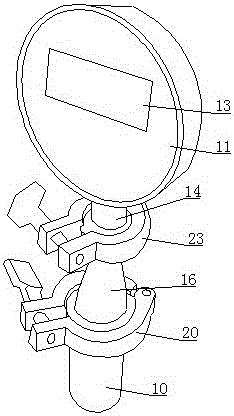

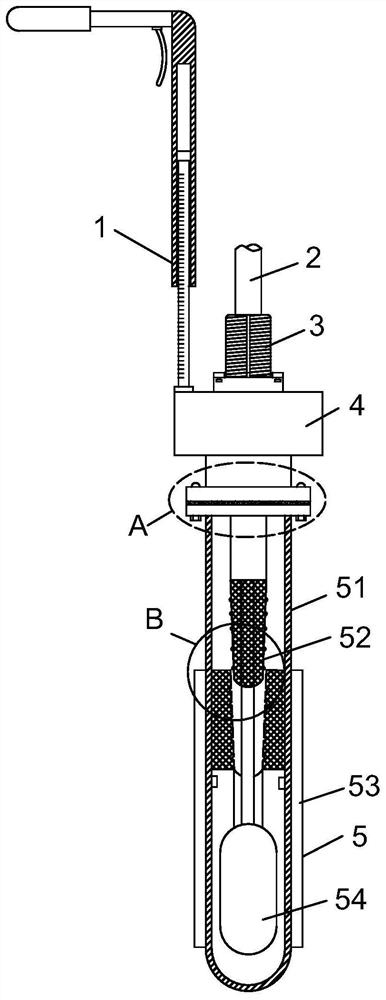

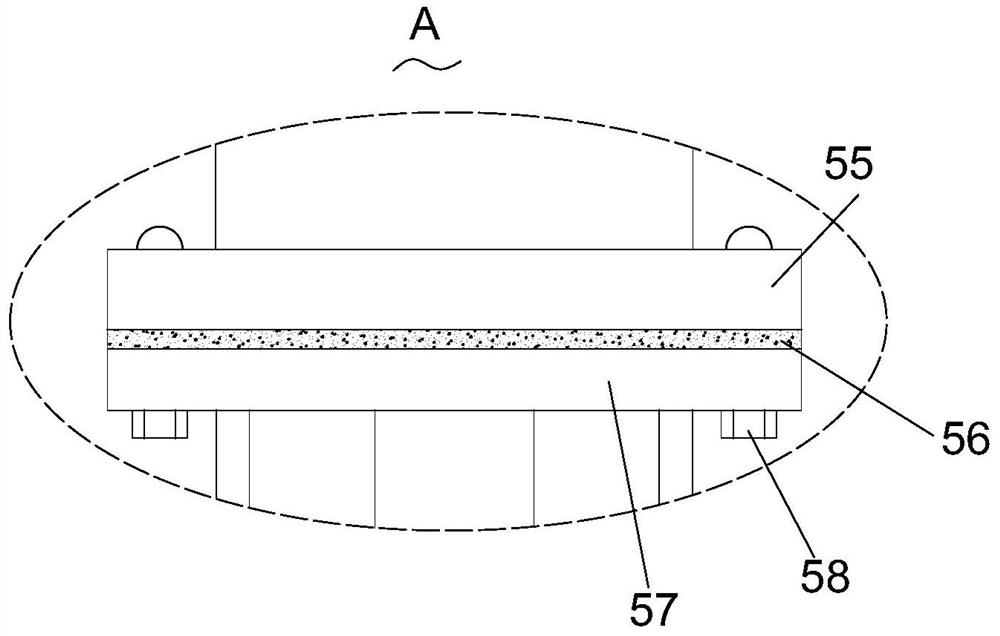

Temperature detection fixer for high-voltage power cable intermediate interface

ActiveCN110967122APrevent falling offConvenient temperature measurementThermometer detailsEngineeringVoltage

The invention discloses a temperature detection fixer for a high-voltage power cable intermediate interface, which comprises a mounting plate, a detector is mounted on the mounting plate, sliding grooves are formed in the end surfaces of the two ends of the mounting plate, one end of a supporting plate is slidably clamped in each sliding groove, the other end of the supporting plate is fixedly connected with a connecting plate, and a tensioning mechanism is mounted between the end surfaces of the connecting plate and the mounting plate. The mounting plate clings to the cable interface; the arc-shaped pressing sheet clings to the outer wall of the interface; the supporting plate slides along the sliding groove. Therefore, the connecting plate is moved to cables at two ends of the interface.The connecting plate is quickly clamped and fixed on cables at two ends of the interface through the clamping sleeve; the mounting plate is fixed firmly, the detector is avoided from falling off, theconnecting plate is pulled through the tensioning mechanism, so that the connecting plate slightly moves towards the mounting plate, the weight of the mounting plate is transmitted to cables at the two ends of the interface through the connecting plate, the middle interface below the mounting plate is in a loose state, the middle interface is prevented from being broken and damaged due to pulling, and the detector can conveniently detect the temperature of the middle interface.

Owner:广东电网有限责任公司汕尾供电局

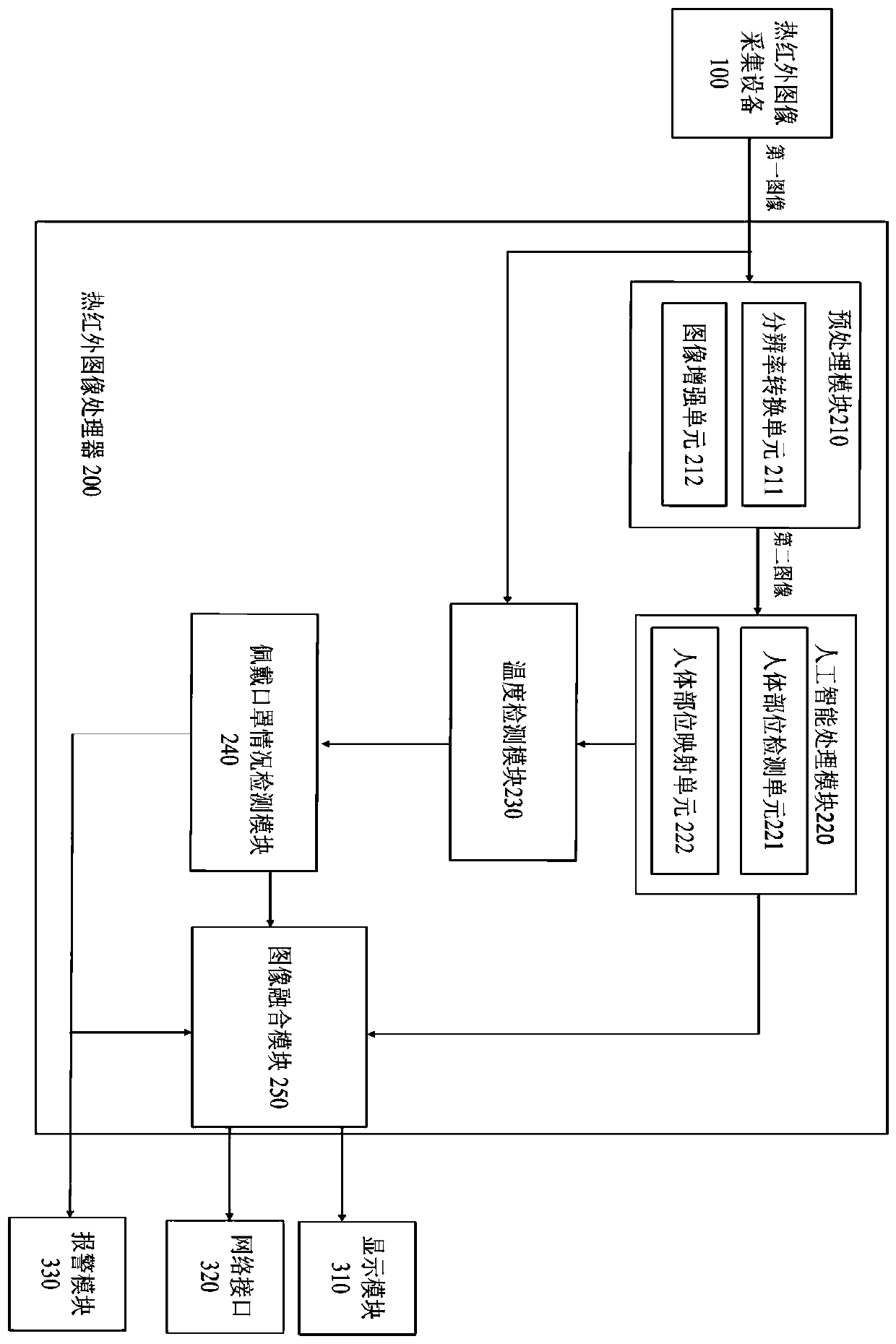

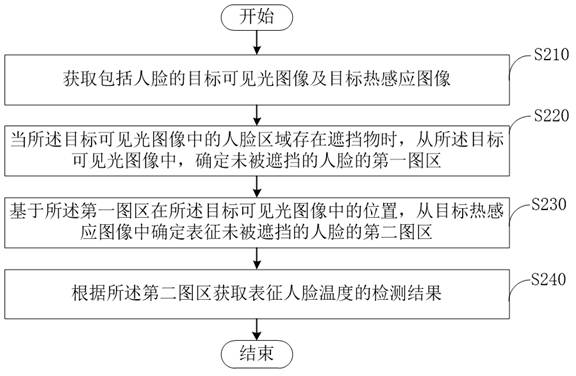

Method for detecting mask wearing condition of target object and thermal infrared image processor

ActiveCN111522073AEasy to determineAccurately determineOptical detectionCharacter and pattern recognitionComputer graphics (images)Thermal infrared

The invention discloses a method for detecting the mask wearing condition of a target object and a thermal infrared image processor. The method comprises the following steps: acquiring a first image acquired by thermal infrared image acquisition equipment; determining a first face image area containing the face of the target object in the first image; determining upper face temperature informationand lower face temperature information of the target object according to the image information of the upper image area and the lower image area of the first face image area; and determining whether the target object wears the mask or not according to the upper face temperature information and the lower face temperature information.

Owner:北京都是科技有限公司

Temperature sensor

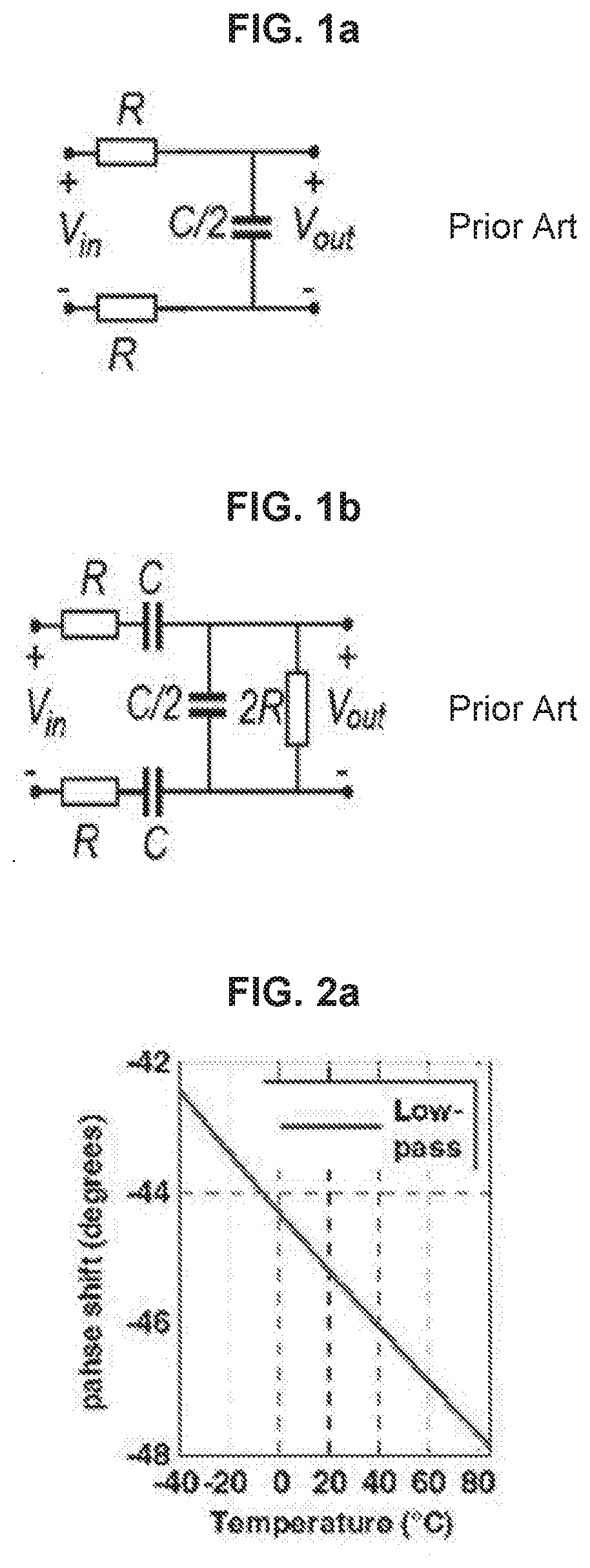

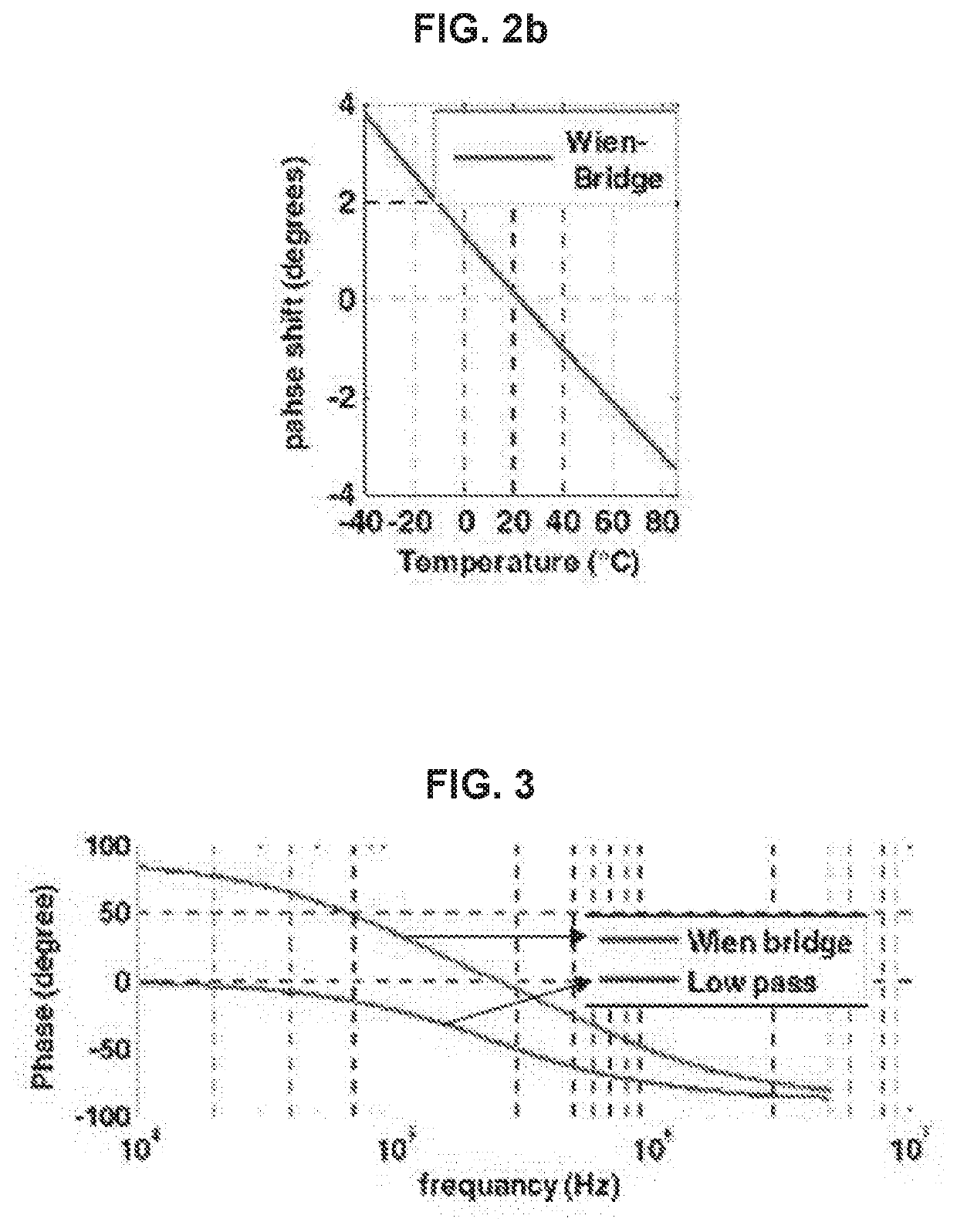

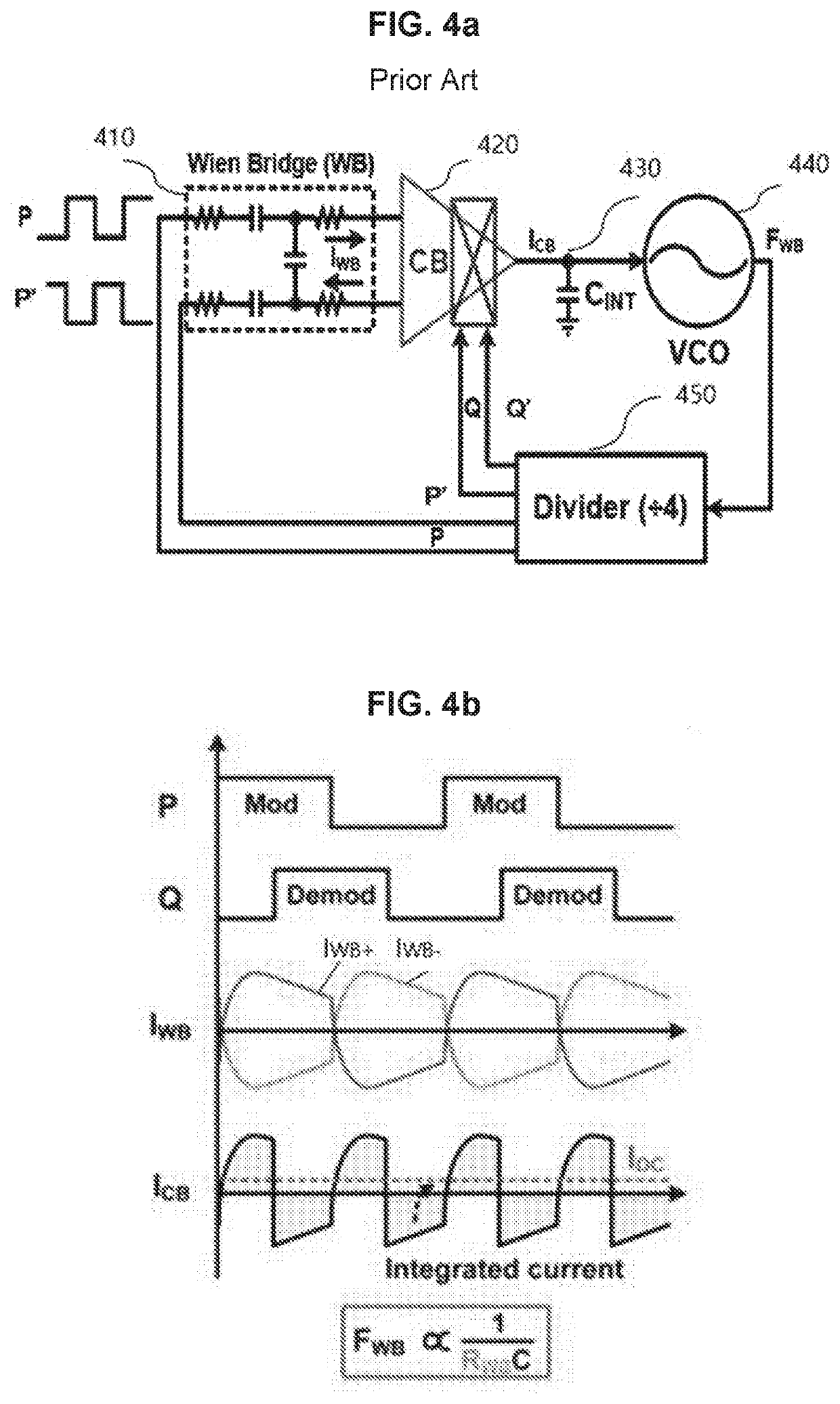

ActiveUS20200191660A1Reduce reading powerBig increaseMultiple-port networksPulse automatic controlCharge currentPhase filter

A temperature sensor using a poly-phase filter may include: a poly-phase filter suitable for receiving a divided clock, and having passive elements coupled to have one or more negative poles and one or more positive zeros; a comparator suitable for generating a reference clock by comparing potentials of first and second filter voltages outputted from the poly-phase filter; a phase frequency detector suitable for outputting an up or down signal by comparing the phase of the reference clock to the phase of a comparison clock; a current supply unit suitable for supplying and integrating a charge current under control of the up or the down signal; an oscillator suitable for outputting an oscillation signal; a divider suitable for generating the divided clock and the comparison clock; and a buffer suitable for inverting and non-inverting the divided clock and outputting the inverted and non-inverted divided clocks.

Owner:SK HYNIX INC +1

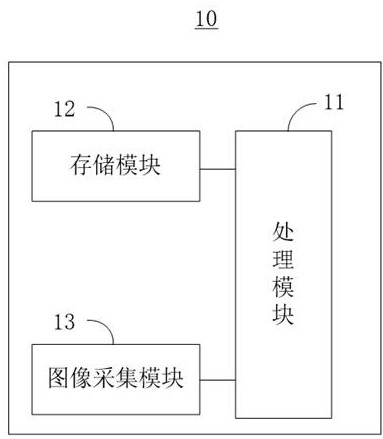

Temperature detection method and device, electronic equipment and readable storage medium

InactiveCN111811667AAffect accuracyImprove accuracyCharacter and pattern recognitionSensing radiation from moving bodiesEngineeringMaterials science

The invention provides a temperature detection method and device, electronic equipment and a readable storage medium. The method comprises the following steps of: acquiring a target visible light image and a target thermal induction image including a human face; when a shielding object exists in a face area in the target visible light image, determining a first image area of an unshielded face from the target visible light image; based on the position of the first image area in the target visible light image, determining a second image area representing an unshielded face from the target thermal induction image; and acquiring a detection result representing the human face temperature according to the second image area. In the scheme, the temperature of the human face is detected by judgingwhether the human face has a shielding object or not and then determining the second image area of the unshielded human face from the thermal induction image, so that the shielding object is prevented from influencing the detection of the temperature of the human face, and the accuracy of temperature detection is improved.

Owner:创新奇智(北京)科技有限公司

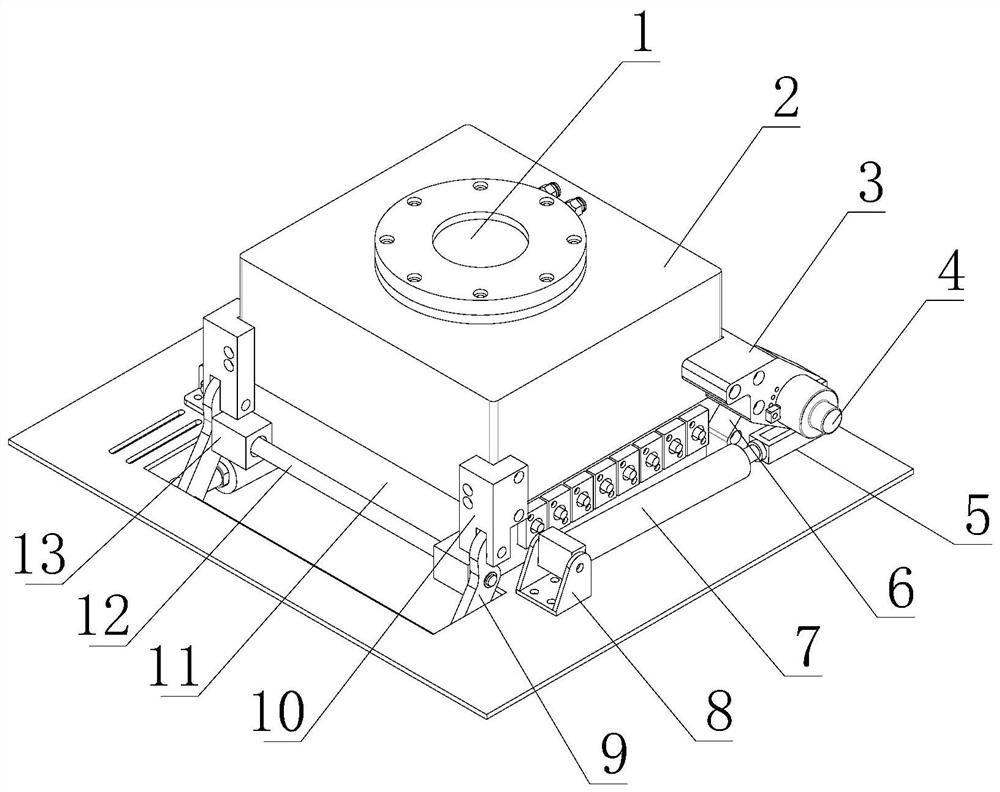

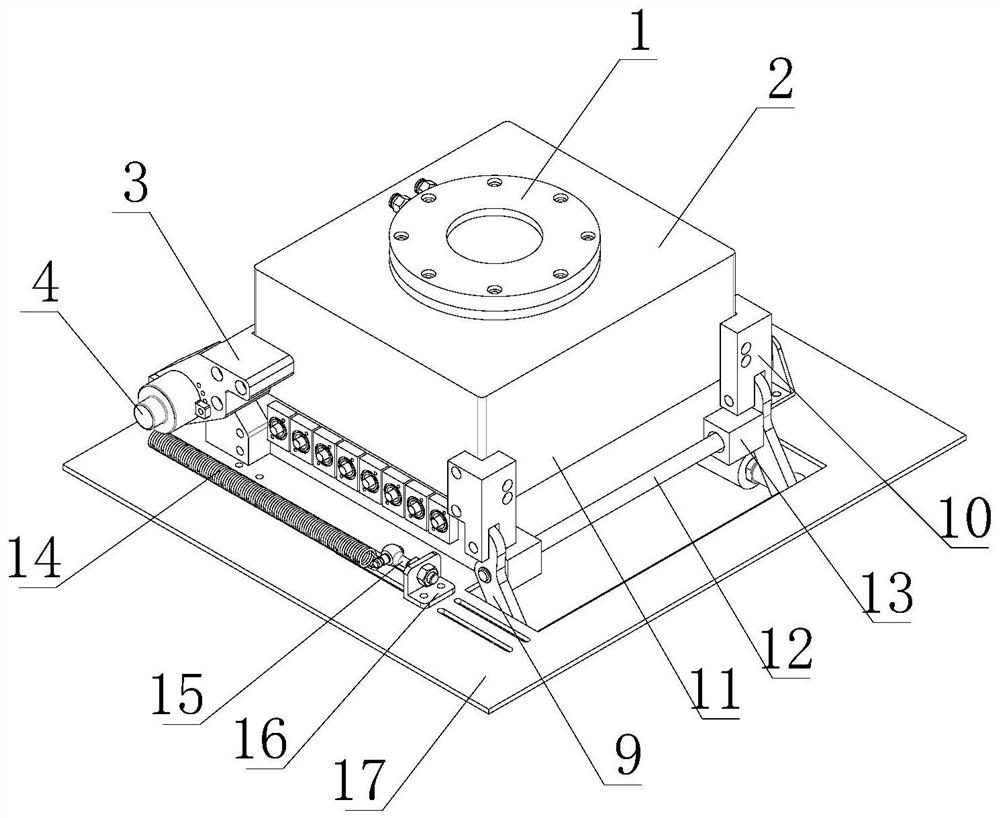

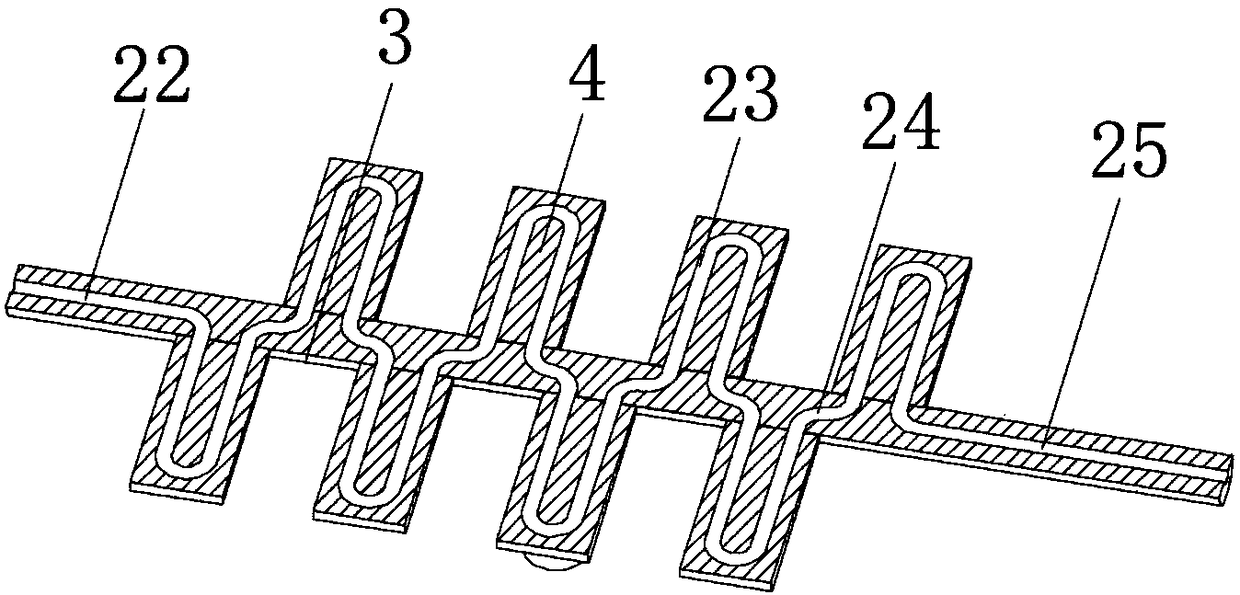

Automatic vacuum backflow welding equipment adopting contact type temperature control

PendingCN111715964AEasy to placeAvoid deformationHeating appliancesMetal working apparatusTemperature controlEngineering

The invention relates to automatic vacuum backflow welding equipment adopting contact type temperature control, and belongs to the technical field of vacuum backflow welding. The automatic vacuum backflow welding equipment adopting contact type temperature control comprises a heating chamber, a cavity cover, infrared radiation tubes, a heating plate located above the infrared radiation tubes, a contact type temperature control mechanism, a vacuumizing mechanism and a cooling mechanism, wherein one end of the cavity cover is hinged to and installed on the heating chamber, and the other end of the cavity cover and the heating chamber are detachably installed in a sealed mode through an automatic opening and closing locking device; a heating cavity is arranged in the heating chamber and internally provided with the multiple infrared radiation tubes; and the contact type temperature control mechanism comprise a main thermocouple and a movable thermocouple, the main thermocouple is installed in the heating cavity and is installed at the bottom of the heating plate in a contact mode, the movable thermocouple is installed on the cavity cover and is installed on the upper surface of the heating plate in a contact mode, and both the main thermocouple and the movable thermocouple are electrically connected with a PID heating controller. The automatic vacuum backflow welding equipment adopting contact type temperature control is used for solving the technical problem of poor product welding quality caused by low heating efficiency, uneven heating and low heating temperature of vacuumreflow welding equipment, and the technical problem that the cavity cover is too heavy to operate.

Owner:烟台华创智能装备有限公司

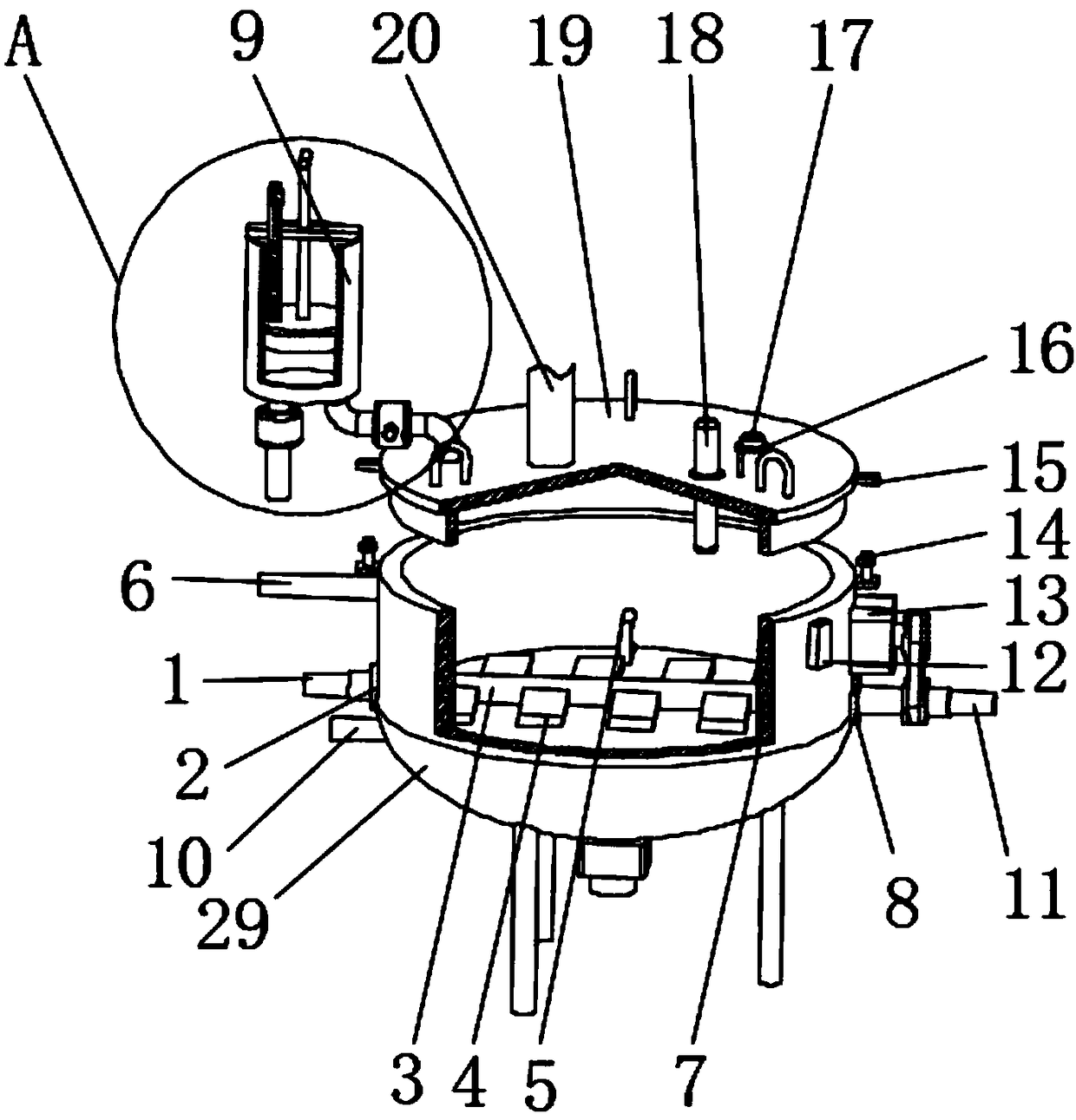

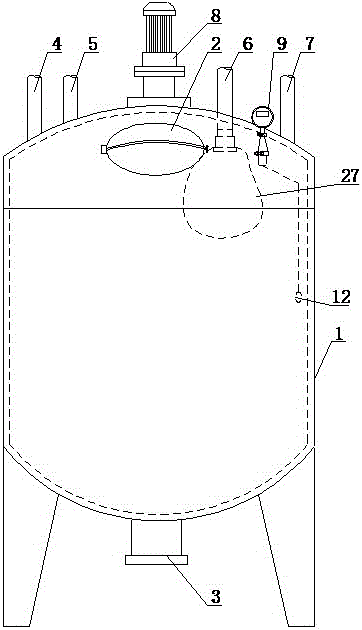

Continuous synthesis device of polyurethane elastomer prepolymer

InactiveCN108579646AImprove cooling effectQuality assuranceChemical/physical/physico-chemical stationary reactorsFeed devicesPolyurethane elastomerRubber ring

The invention discloses a continuous synthesis device of a polyurethane elastomer prepolymer, which comprises a reaction kettle, wherein mounting holes are formed at the left end and the right end ofthe middle of the outer side face of the reaction kettle; a first sealing bearing and a second sealing bearing are fixed in the two mounting holes respectively; an inner ring of the first sealing bearing is fixedly connected with the left end of the side face of a rotating shaft; an inner ring of the second sealing bearing is fixedly connected with the right end of the side face of the rotating shaft; and heat conduction rotating blades are mounted on the front side and the rear side of the side face of the rotating shaft in a staggered manner. The continuous synthesis device of the polyurethane elastomer prepolymer has a good refrigeration effect, is uniform in refrigeration, removes much reaction heat, and ensures the quality of the prepolymer; a single addition level of diisocyanate isaccurate; at the beginning, an annular rubber ring is connected with a rubber stopper in a clamping manner; a worker separates the rubber stopper from the annular rubber ring and inserts a thermometerinto the annular rubber ring; gas in the reaction kettle is not exhausted from the annular rubber ring; and the safety of the worker is ensured.

Owner:马鞍山久特新材料科技有限公司

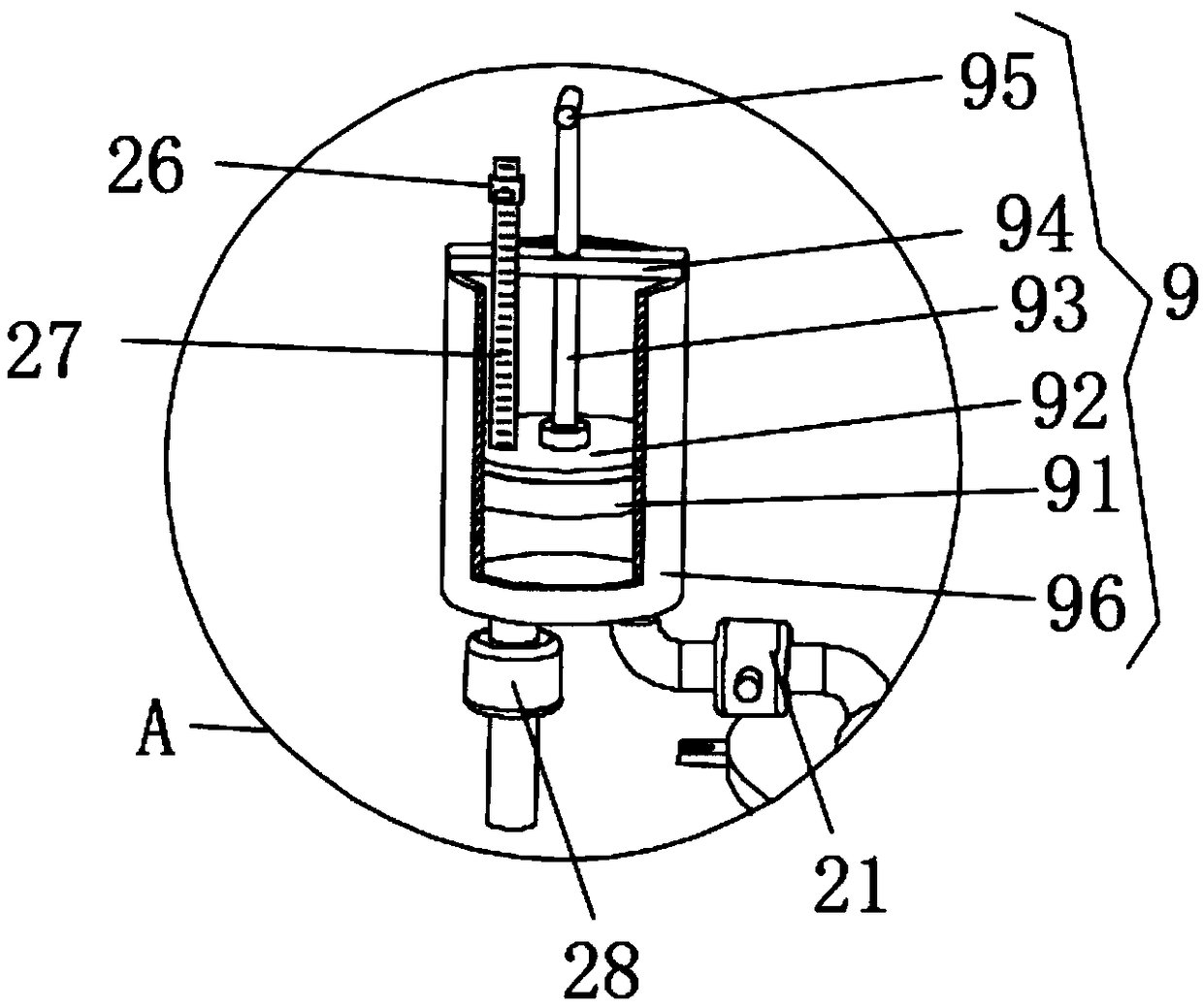

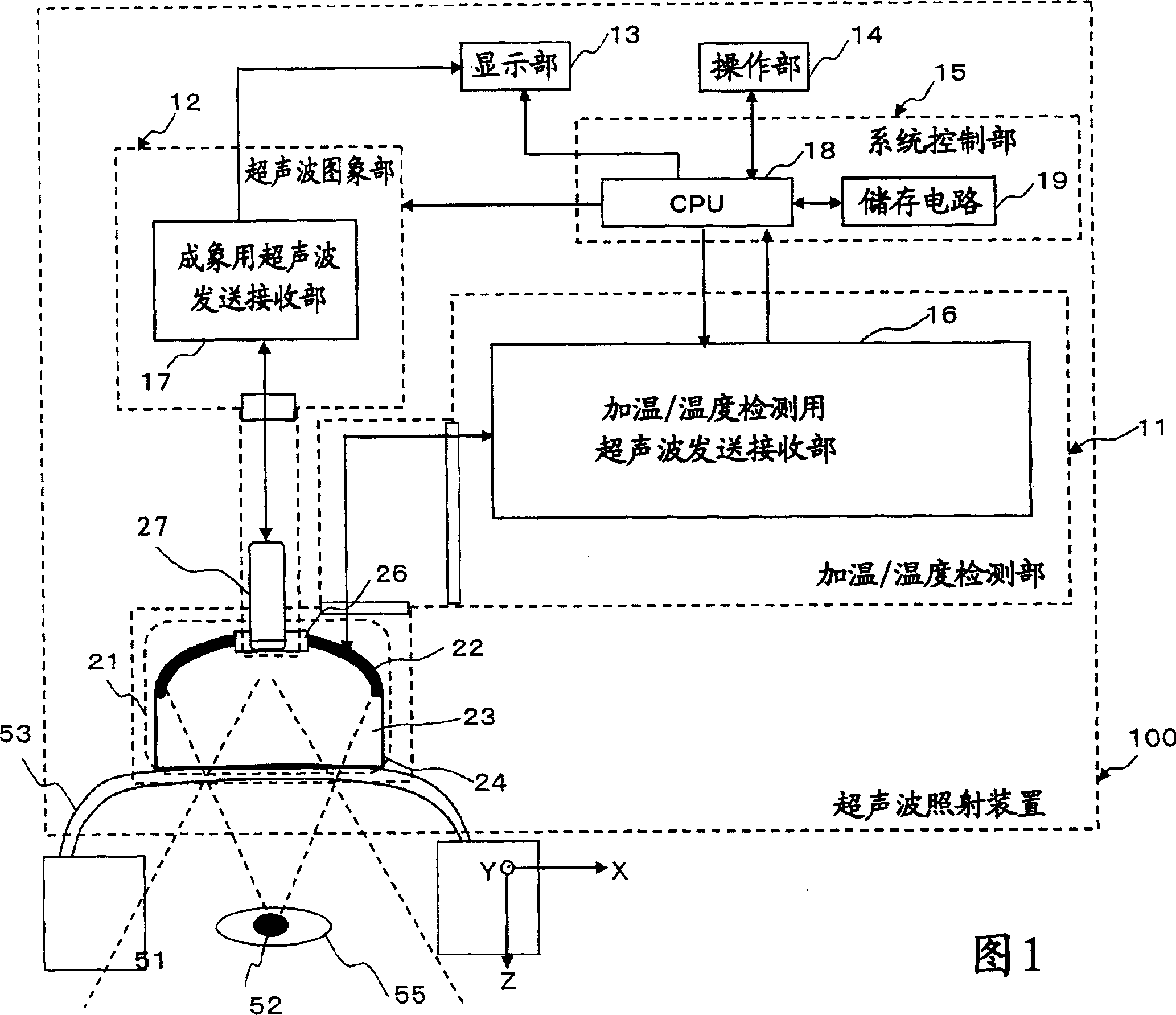

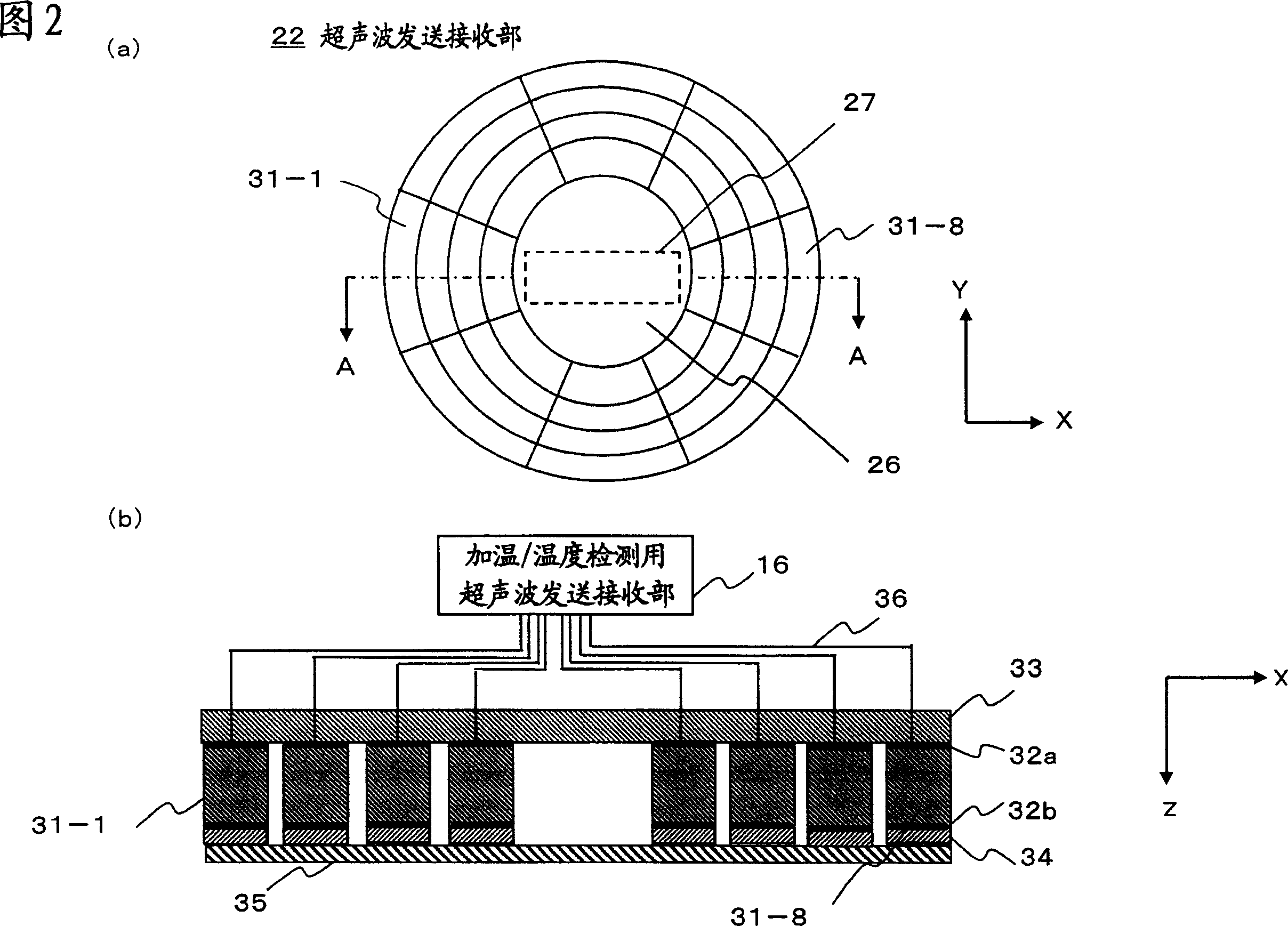

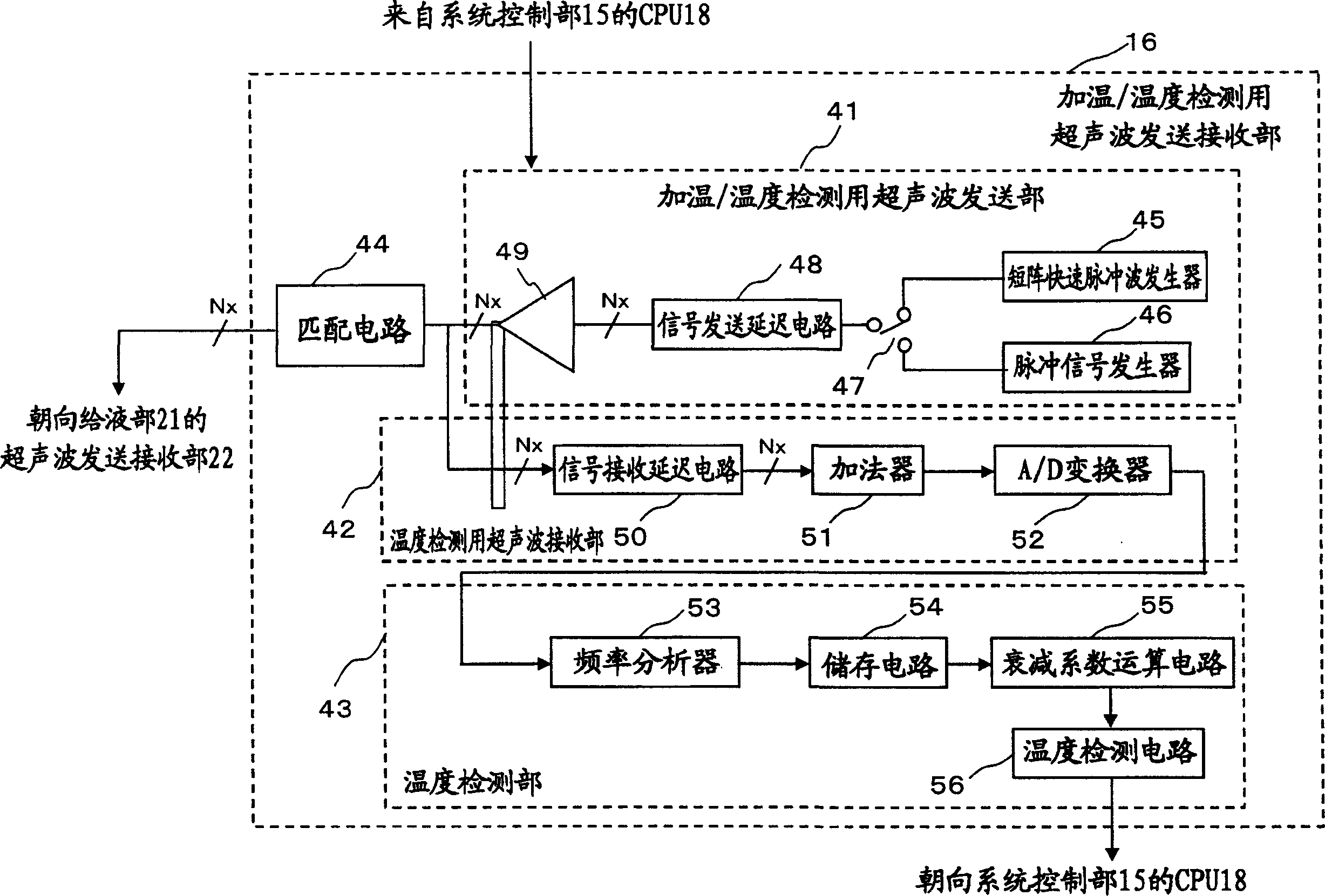

Ultrowave radiation device and its method

InactiveCN1600387AConvenient for temperature detectionUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyElectricityRadiation

This invention provides an ultrasonic wave irradiation device and an ultrasonic wave irradiating method allowing for measuring the temperature of the heated area simply and accurately in a treatment using strong ultrasonic wave. The ultrasonic wave irradiation device 100 provides the transmitting / receiving member 16 for heating and measuring temperature which supplies driving signals to the transmitter / receiver 22 on which piezoelectric oscillation elements are arranged to heat a tumor 55 of the subject 51 and transmits / receives the ultrasonic wave for measuring temperature using the transmitter / receiver 22 to measure the temperature of the heated area. The device also provides the ultrasonic probe 27 to collect ultrasonic wave images in the heated area 52 and the transmitting / receiving member 12 for ultrasonic wave for imaging. The temperature information of the heated area 52 is displayed on the display 13 being superimposed on ultrasonic wave data.

Owner:KK TOSHIBA +1

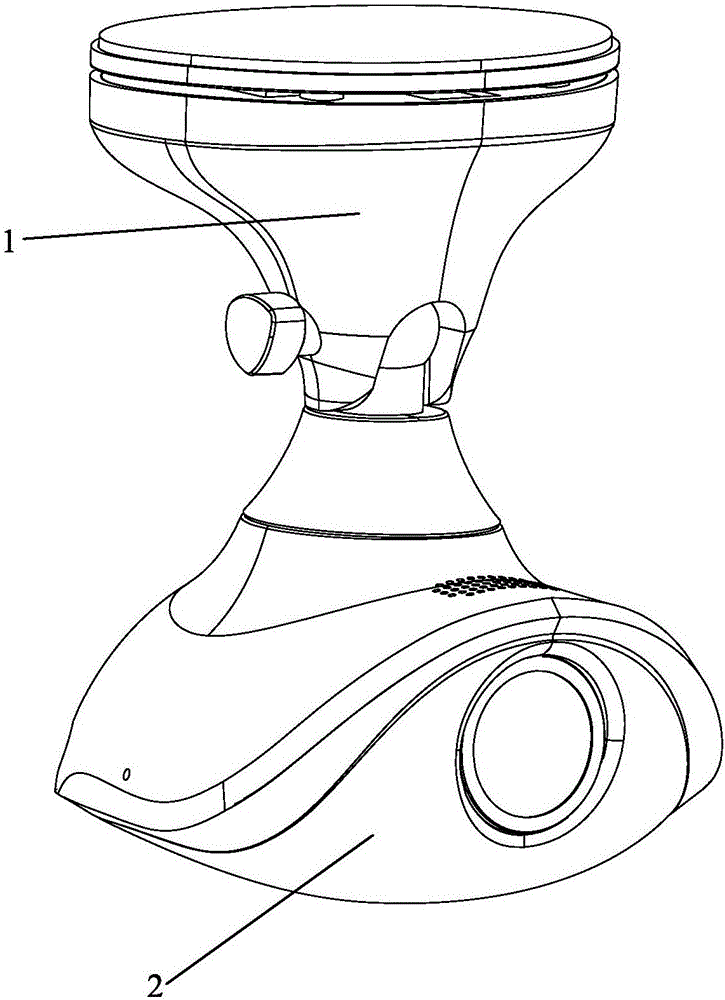

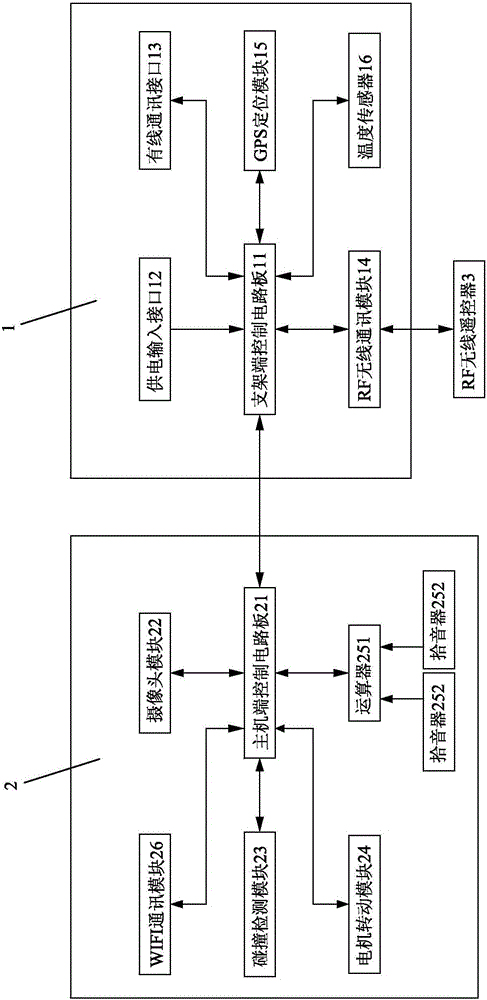

Automobile data recorder apparatus

InactiveCN106097478AConvenient for video shootingEasy to turn shooting controlsRegistering/indicating working of vehiclesElectricityWired communication

The invention discloses an automobile data recorder apparatus. The apparatus comprises a support and a recorder host movably connected to the support, the recorder host is provided with a host control circuit board, the host control circuit board is electrically connected with a camera module, a bump detection module and a motor rotating module used for driving the recorder host to rotate relative to the support under the control of the host control circuit board, the support is provided with a support control circuit board electrically connected with the host control circuit board, and the support control circuit board is connected with a power supply input interface and a wired communication interface. The apparatus has the advantages of simple structure, easy realization, and convenience in use.

Owner:GUANGDONG CHANGHONG RIDIAN TECH

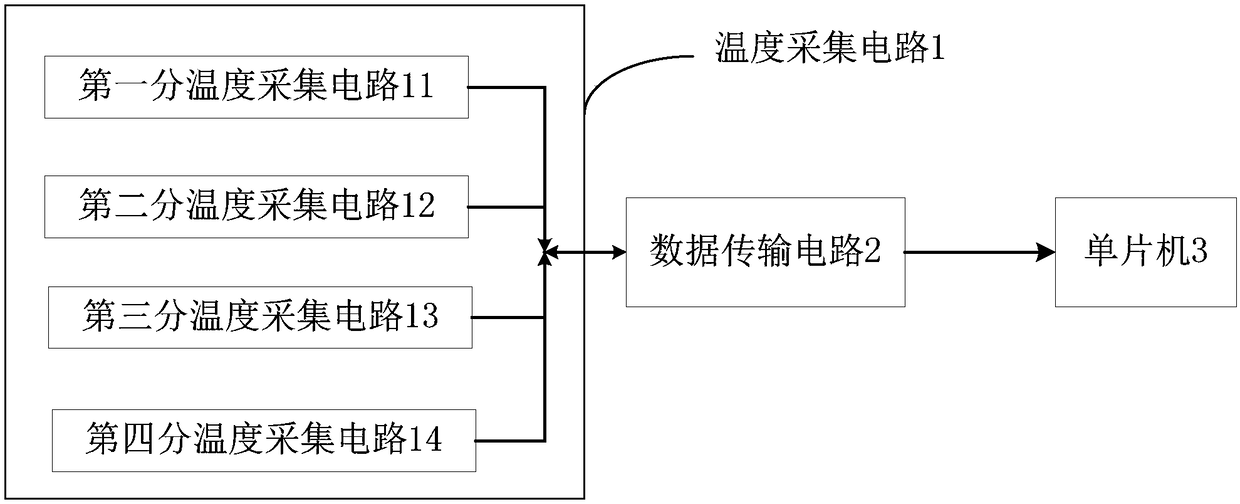

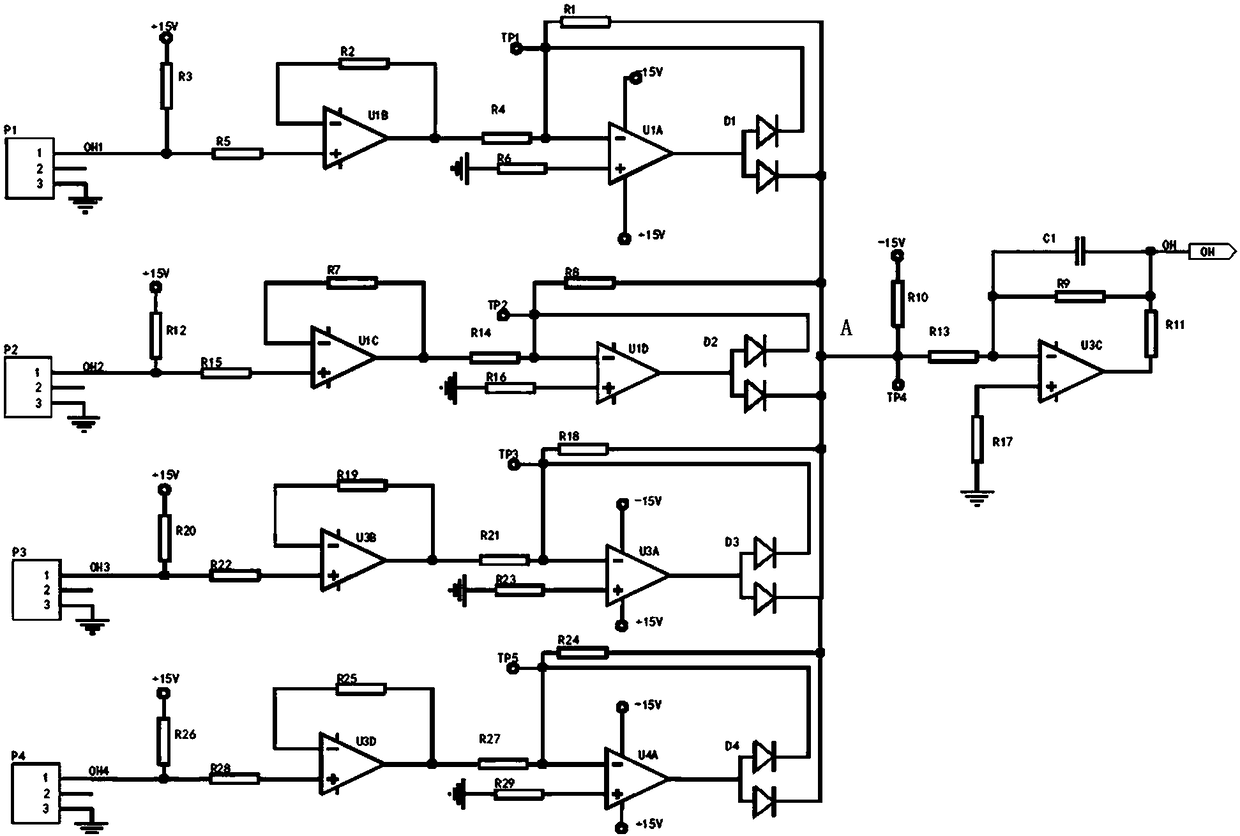

Temperature detection circuit of frequency converter

PendingCN108303192AConvenient for temperature detectionSave resourcesThermometers using electric/magnetic elementsUsing electrical meansMicrocontrollerFrequency changer

The invention provides a temperature detecting circuit of a frequency converter. The temperature detecting circuit comprises a temperature collecting circuit and a data transmitting circuit. The temperature collecting circuit comprises a plurality of branch circuits. The input end of each of the branch circuits is connected to multiple temperature switches for temperature detection and / or thermistors distributed in the frequency converter, and the temperature collecting circuit compares the voltage of the output end of each of the branch circuits and outputs voltage Umax of a maximum value. The output end of the data transmitting circuit is connected to a single-chip microcomputer of the frequency converter by an AD interface and transmits a processed voltage signal to the single-chip microcomputer, thus the single-chip microcomputer calculates the highest temperature in the multiple temperature switches and / or thermistors according to the voltage signal. According to the temperature detecting circuit of a frequency converter, a detection mode with the temperature switches and / or thermistors as detection components is satisfied, the highest temperature in the frequency converter can be determined, thus overheat protection is facilitated, and the occasion of application is wide.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

Dual waveband temperature detector

ActiveUS9335219B2Reduce system costImprove installationRadiation pyrometryThermometers using electric/magnetic elementsBeam splitterMetal forming

Owner:EXERGEN CORPORATION

Flow sensor using a heat element and a resistance temperature detector formed of a metal film

ActiveUSRE43660E1Convenient for temperature detectionHigh TCR inherentVolume/mass flow by thermal effectsFluid speed measurement using thermal variablesElectrical resistance and conductanceMeasurement device

The present invention provides a technology capable of achieving a highly-sensitive flow sensor, by forming a metal film having a relatively high TCR on a semiconductor substrate via an insulating film. A measurement device which is a thermal fluid flow sensor includes a heat element, resistance temperature detectors (upstream-side resistance temperature detector and downstream-side resistance temperature detector), and a resistance temperature detector for air which are all formed of a first metal film. The first metal film is formed of an α-Ta film having a resistivity lower than three times the resistivity of a Ta ingot and obtained by deposition through sputtering on an amorphous film containing metal.

Owner:HITACHI ASTEMO LTD

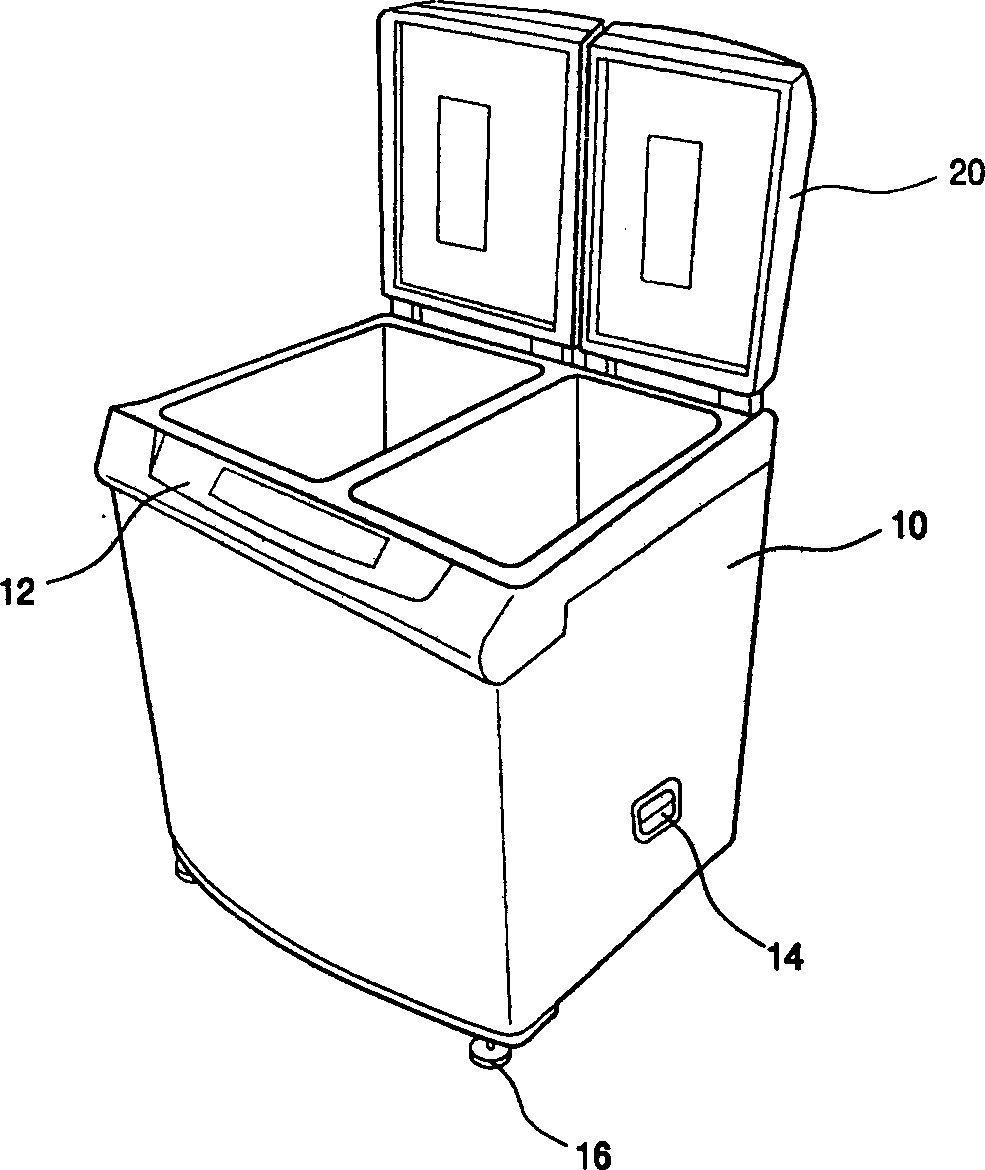

Pickles refrigerator

InactiveCN1862165AAvoid deformationEliminate deformationLighting and heating apparatusDomestic refrigeratorsRefrigerantRefrigerated temperature

The present invention discloses a pickled vegetables refrigerator. It includes the following several portions: external box formed into appearance of refrigerator; internal box placed in the interior of external box for storing various foods; refrigerant tube which is coiled on the external side surface of internal box and whose interior can allow the refrigerant to flow and make heat exchange; cooling unit formed from cooling sensor for detecting internal box coaling temperature; and heating unit which is coiled and set on lower side of cooling unit, in the heating unit interior are set a heater capable of releasing a certain heat quantity to raise internal box temperature and a heating sensor for detecting internal box temperature.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

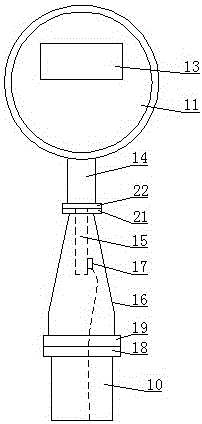

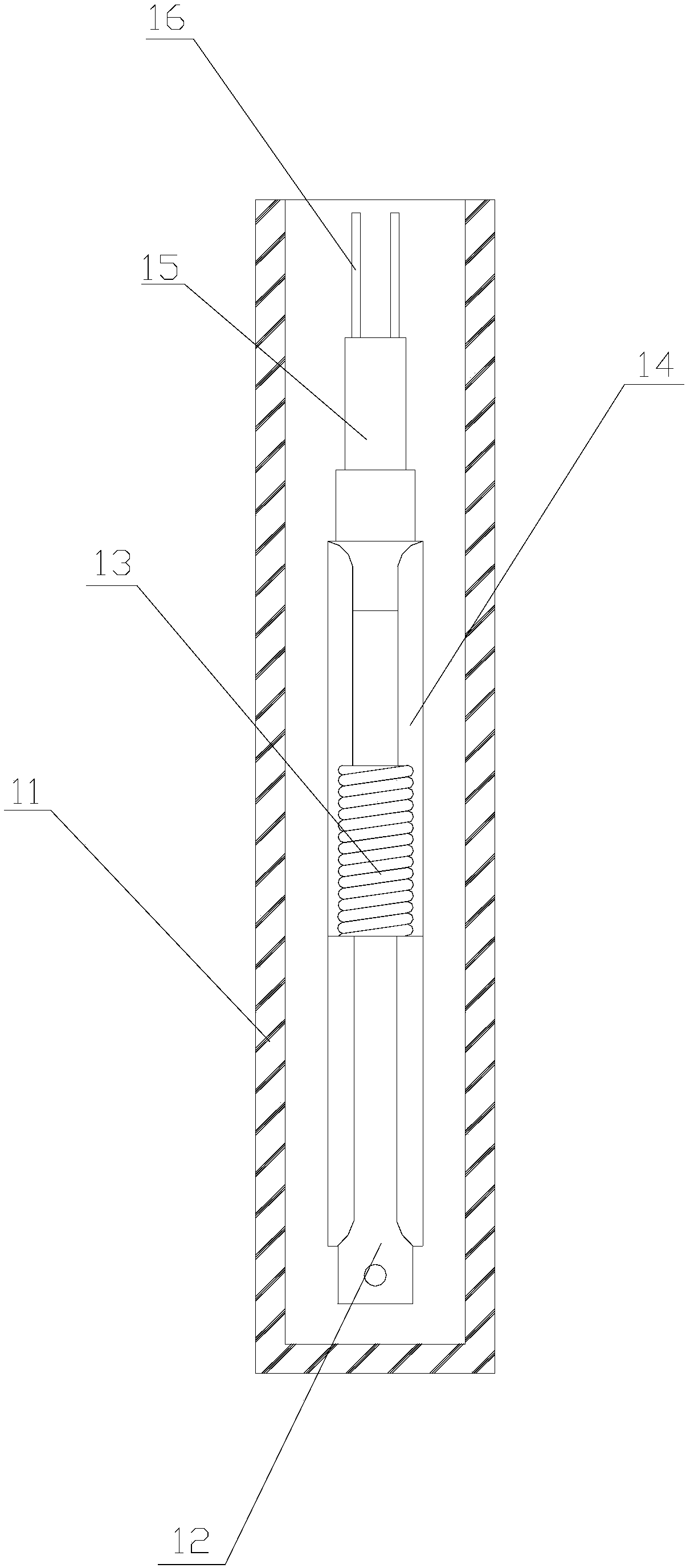

Heat-sensitive sensor

ActiveCN111854993AConvenient for temperature detectionEase of workThermometer detailsThermometers using electric/magnetic elementsEngineeringScrew thread

The invention relates to the field of sensors, in particular to a heat-sensitive sensor, which comprises a connector, a probe mechanism, a handle mechanism and an elastic protection mechanism, and ischaracterized in that the connector is connected with a signal line; the detection head mechanism is connected with the connector; the handle mechanism is connected with the connector; the handle mechanism comprises a rubber sleeve, a handle, an internal thread sleeve, an external thread block, a connecting rod and a connecting block; a vertically-arranged connecting rod is fixedly connected to the upper surface of the connector through a connecting block, an outer threaded block is fixedly connected to the end, away from the connecting block, of the connecting rod, the outer threaded block isin threaded connection with the interior of an inner threaded sleeve, a handle is fixedly connected to the side face of the upper end of the inner threaded sleeve, and a rubber sleeve is fixedly connected to the handheld section of the handle; and the elastic protection mechanism is connected with the connector. The heat-sensitive sensor provided by the invention has the advantages that the detection position is convenient to adjust, the service life is long, and the detection precision is high.

Owner:浙江力夫传感技术有限公司

A kind of production method of saline heparin sodium

The invention discloses a production method of brine heparin sodium. The production method comprises the following five steps: preparation of a stock solution; enzymolysis; adsorption; elution; and precipitation. The production method is characterized in that in the step of preparing the stock solution, a raw material is originated from brine for treating a semi-finished product casing; parameter adjustment is carried out in the enzymolysis step to guarantee correspondence with components of the stock solution so as to ensure the enzymolysis effect. The method disclosed by the invention is suitable for producing the brine heparin sodium, wherein the raw material is originated from casing processing brine. The heparin component in the small intestine of a pig can be fully extracted to avoid waste on raw materials, so that the extraction efficiency and the production efficiency of the brine heparin sodium can be improved.

Owner:广东华赢医疗科技有限公司

a thermal sensor

ActiveCN111854993BConvenient for temperature detectionEase of workThermometer detailsThermometers using electric/magnetic elementsScrew threadThermal sensors

The invention relates to the field of sensors, in particular to a thermal sensor, comprising a connector, a probe mechanism, a handle mechanism and an elastic protection mechanism. The connector is connected with a signal line; the probe mechanism is connected with the connector; the The handle mechanism is connected with the connector, and the handle mechanism includes a rubber sleeve, a handle, an inner thread sleeve, an outer thread block, a connecting rod and a connecting block, and the upper surface of the connector is fixedly connected with a vertically arranged connecting rod through the connecting block , the end of the connecting rod away from the connecting block is fixedly connected with an external thread block, the external thread block is threadedly connected in the internal thread sleeve, and the upper end side of the internal thread sleeve is fixedly connected with a handle, and the hand-held section of the handle is fixedly connected with a rubber sleeve; The elastic protection mechanism is connected with the connector. The thermal sensor provided by the invention has the advantages of convenient adjustment of the detection position, long service life and high detection accuracy.

Owner:浙江力夫传感技术有限公司

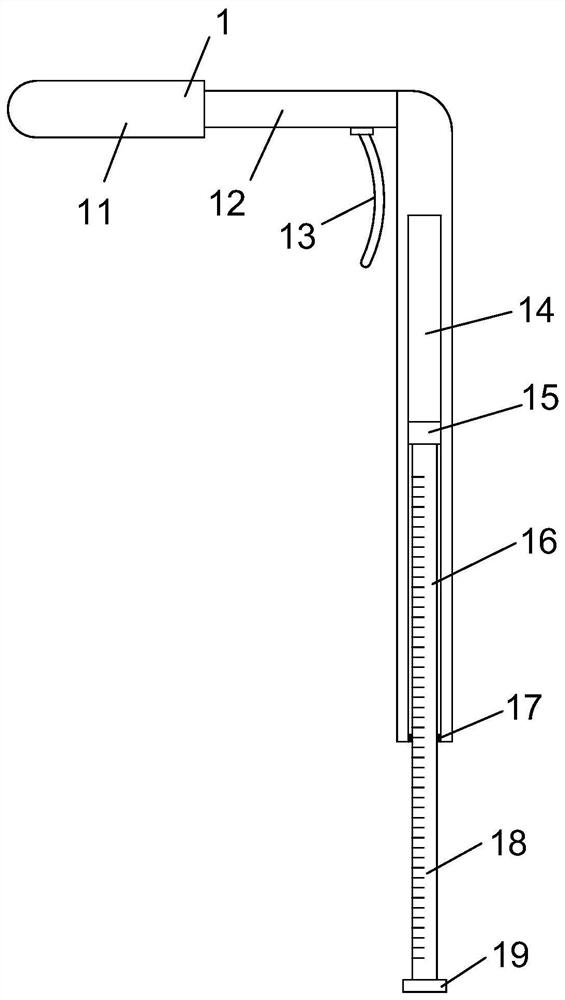

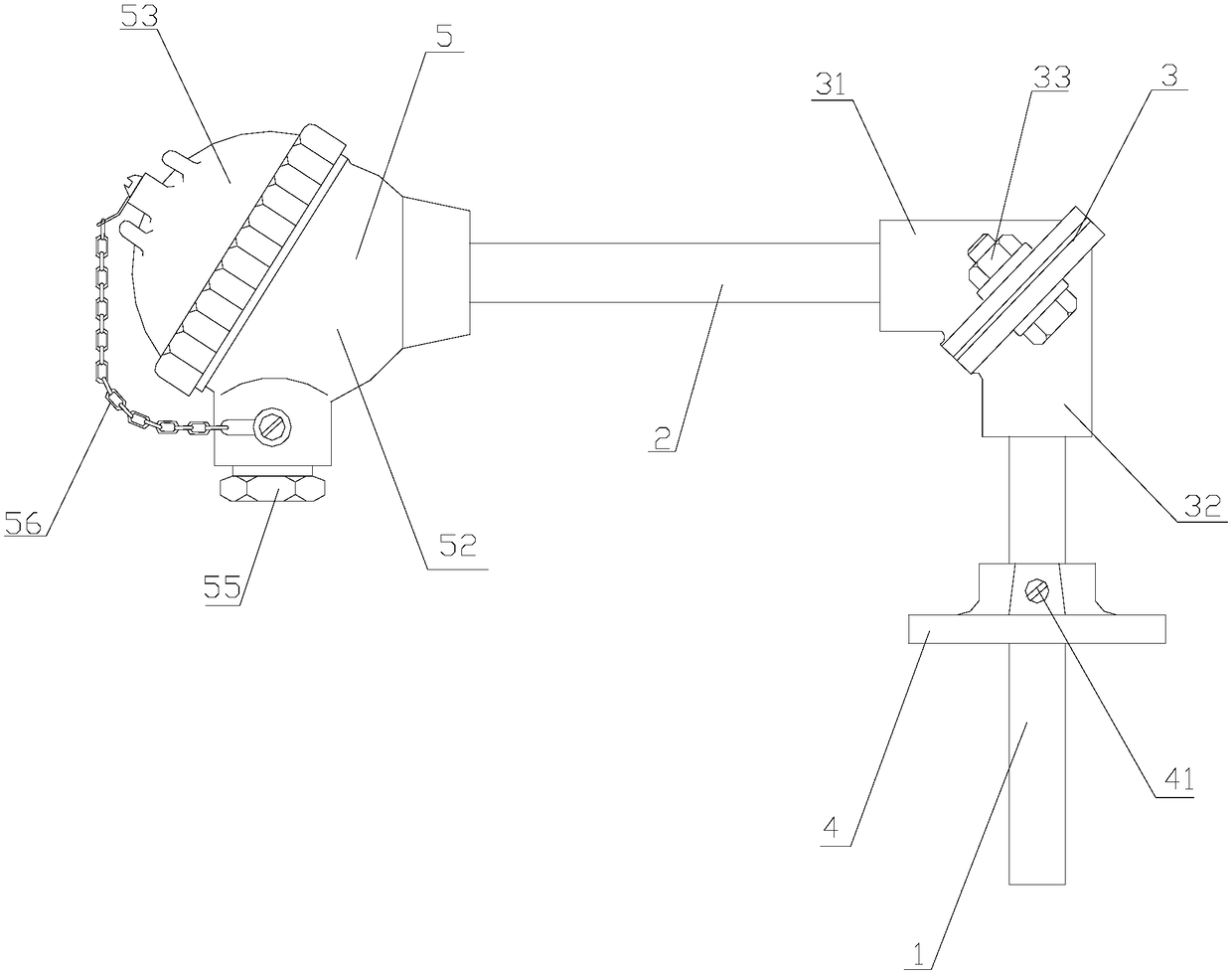

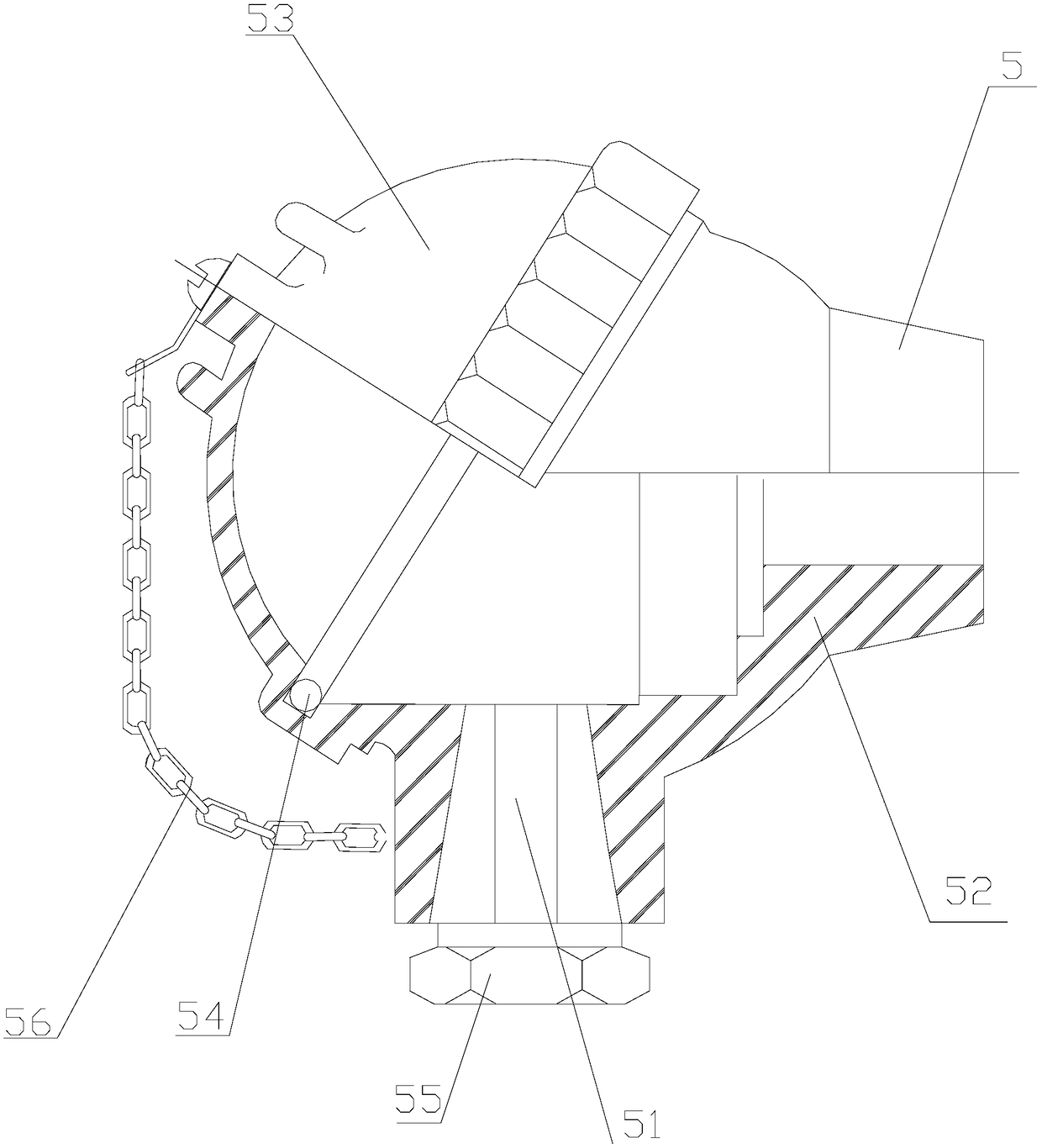

Waterproof movable flange angle-ruler-shaped thermal resistor

PendingCN109443566AEasy to fixConvenient for temperature detectionThermometer detailsThermometers using electric/magnetic elementsFlangeResistive element

The invention discloses a waterproof movable flange angle-ruler-shaped thermal resistor. The waterproof movable flange angle-ruler-shaped thermal resistor comprises a thermal resistance element, a thermal resistance element connecting rod, a connecting flange, a clamping sleeve flange plate and a waterproof junction box, wherein the thermal resistance element is detachably connected with the thermal resistance element connecting rod through the connecting flange, the thermal resistance element is relatively perpendicular to the thermal resistance element connecting rod, the thermal resistanceelement is provided with the clamping sleeve flange plate, and the clamping sleeve flange plate is movably connected with the thermal resistance element. The waterproof movable flange angle-ruler-shaped thermal resistor has the advantages that the thermal resistance element is in right-angle connection with the thermal resistance element connecting rod through the connecting flange, so that the thermal resistance element and the waterproof junction box are arranged in a right angle, thereby providing convenience for performing temperature detection on some small space or special environments;the arrangement of the waterproof junction box can effectively prevent water, thereby protecting circuit components; the clamping sleeve flange plate can perform limiting protection on the thermal resistance element and facilitate the fixation of the thermal resistance element.

Owner:海盐县秦山热工仪表厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com