A kind of production method of saline heparin sodium

A technology of saline heparin sodium and a production method, which is applied in the production field of saline heparin sodium, can solve the problems of the thermometer being suspended at both ends, inconvenient to operate, easily broken or damaged, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

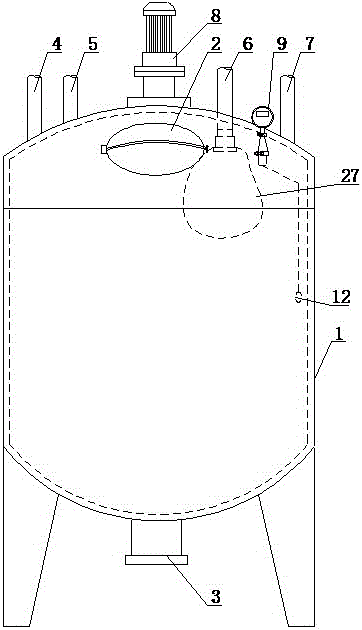

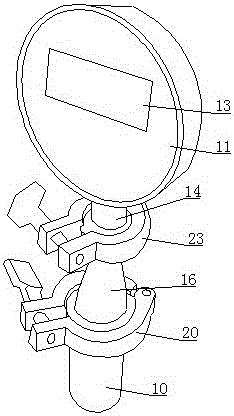

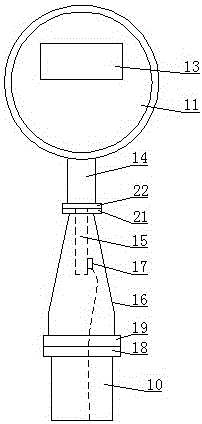

[0057] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0058] When implementing it:

[0059] like Figure 1-Figure 8As shown, a production method of saline heparin sodium includes five major process steps of raw solution acquisition, enzymolysis, adsorption, elution and precipitation; in the adsorption process, first, the enzymolysis solution obtained after the enzymolysis process is sucked into the adsorption tank, Stir the enzymolysis solution, and when the enzymolysis solution is cooled to 55°C~60°C, add adsorption resin, keep warm and stir for 8~10 hours to absorb; in the elution process, the adsorption process Rinse the adsorption resin described in , filter and dry, put it into the elution tank for elution, then add the brine with the same weight as the resin and mix it into a mixture. The brine is a sodium chloride solution with a salinity of 19~23 Mido, heat the mixture to 55-60°C for elution; in the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com