Patents

Literature

42results about How to "Easy to clean and recycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

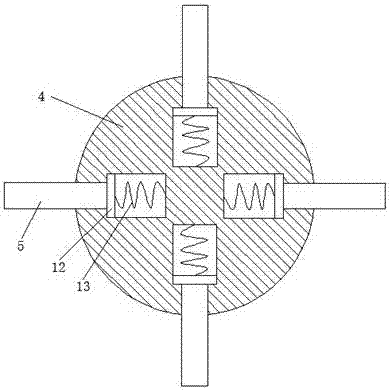

Nano double helix ecological globoid and preparation and application thereof

InactiveCN101239297ALarge wall surface areaWell formedSustainable biological treatmentFiltration separationVoid ratioAir filter

The present invention provides a double helix nanophase ecosphere, having continuous double-helix, the surface is formed by extending of mass bends or each S shaped part. Each part shows radial arrangement to achieve maximal surface area and provide void ratio. This new design provides countless pleats on the surface of the double-helix, so as to have fantastic specific surface and poriness; and it further has stronger impact strength and tensile yield strength. The conglobulation of the invention contains nano ceramics powder, vinyl chloride monomer and all kinds of stabilizing agent and forming agent. The double helix nanophase ecosphere is used for water treatment, air purification, auto air filter, central air condition cycle water treatment, flowers and trees industry, health products industry, industrial filtering material, chemical fillings, catalyst carrier, the invention also provides a preparing method and use of the ecosphere.

Owner:冯英昌

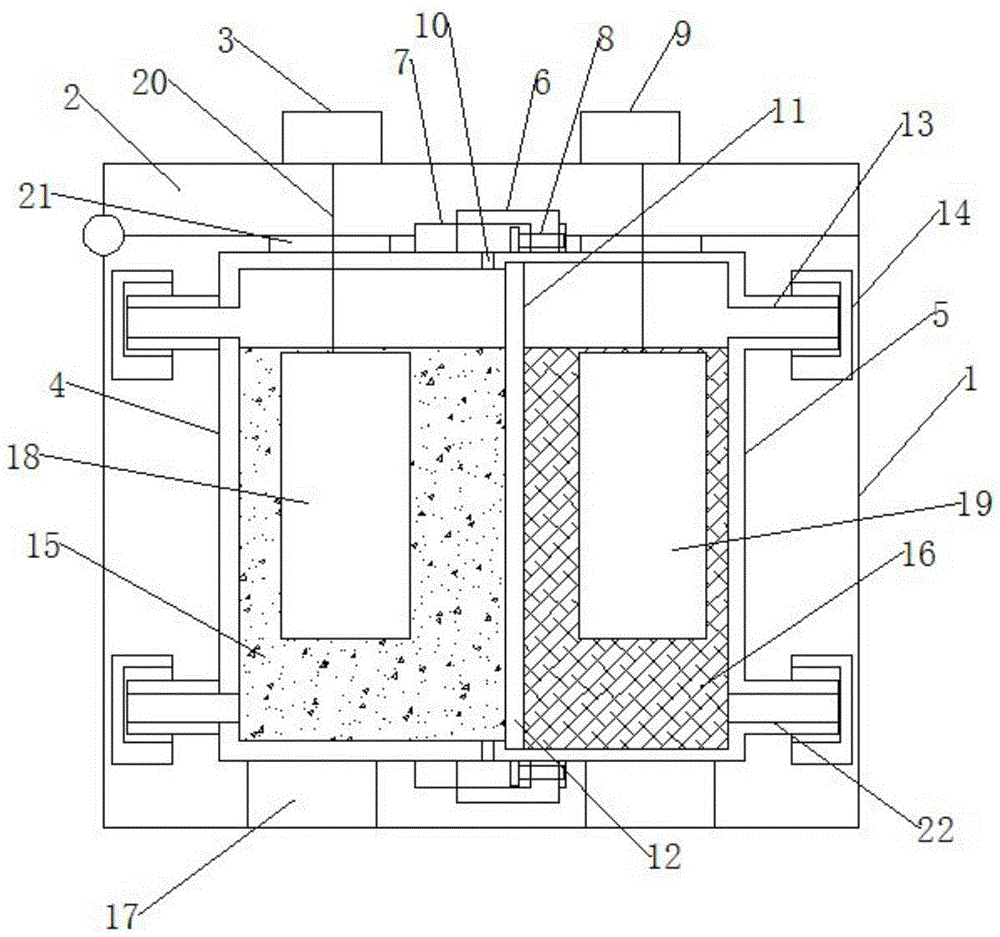

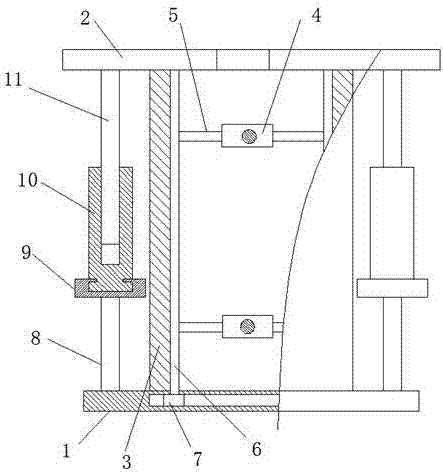

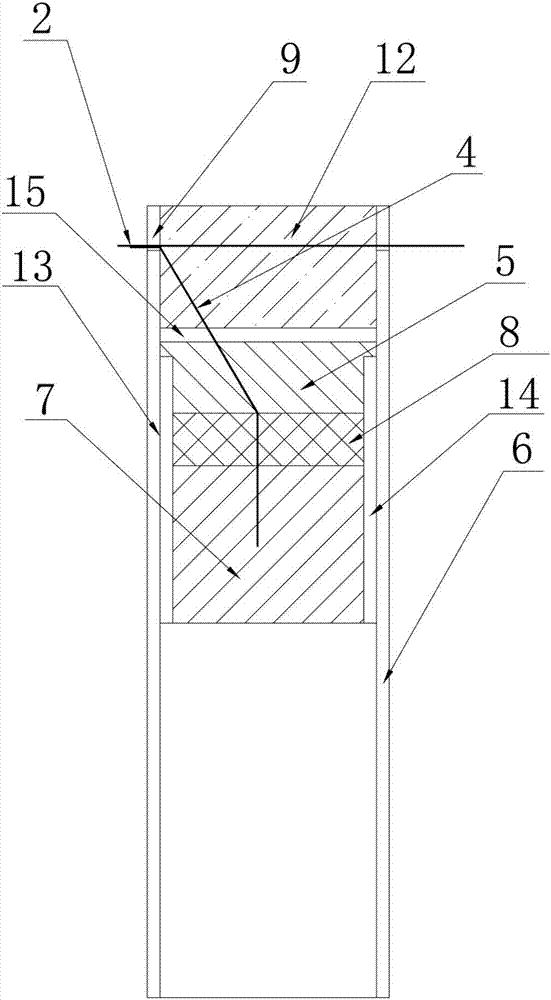

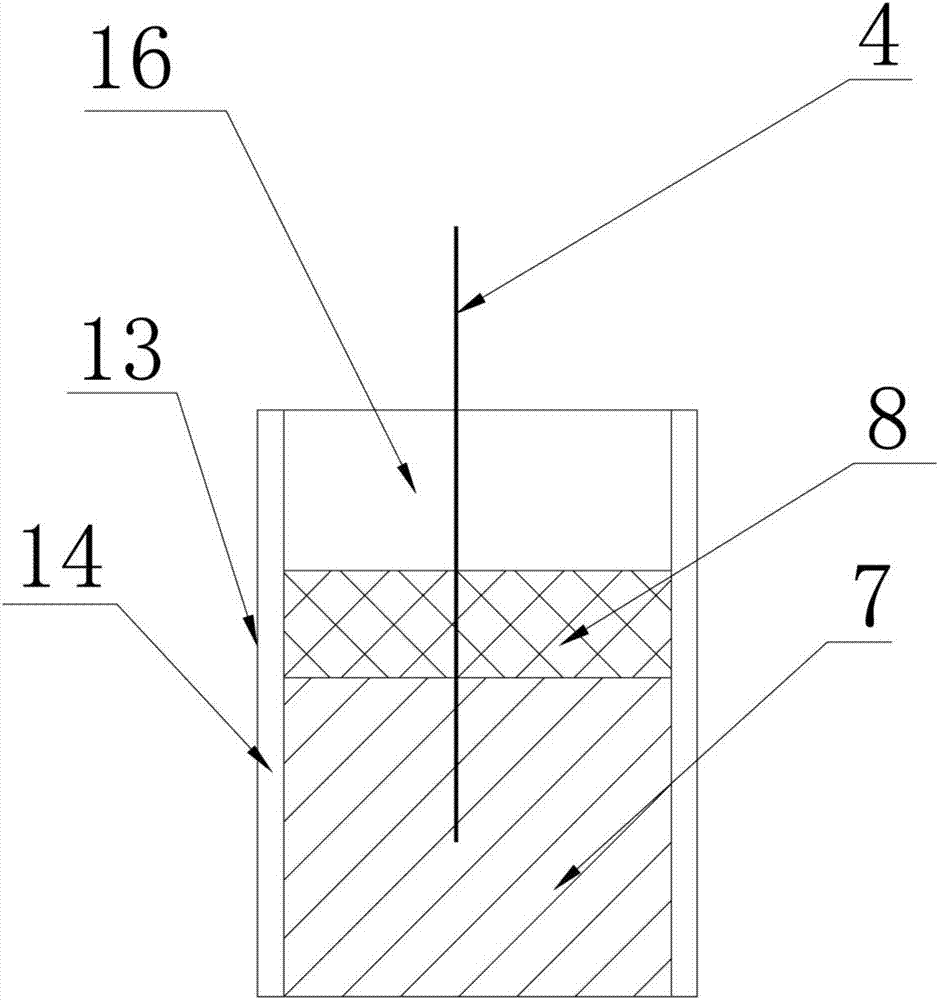

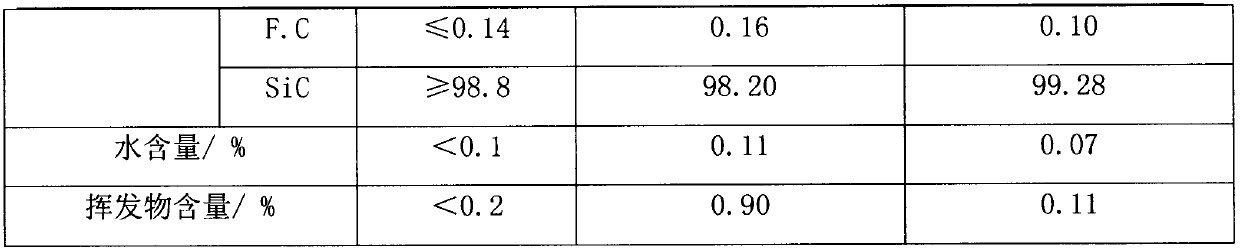

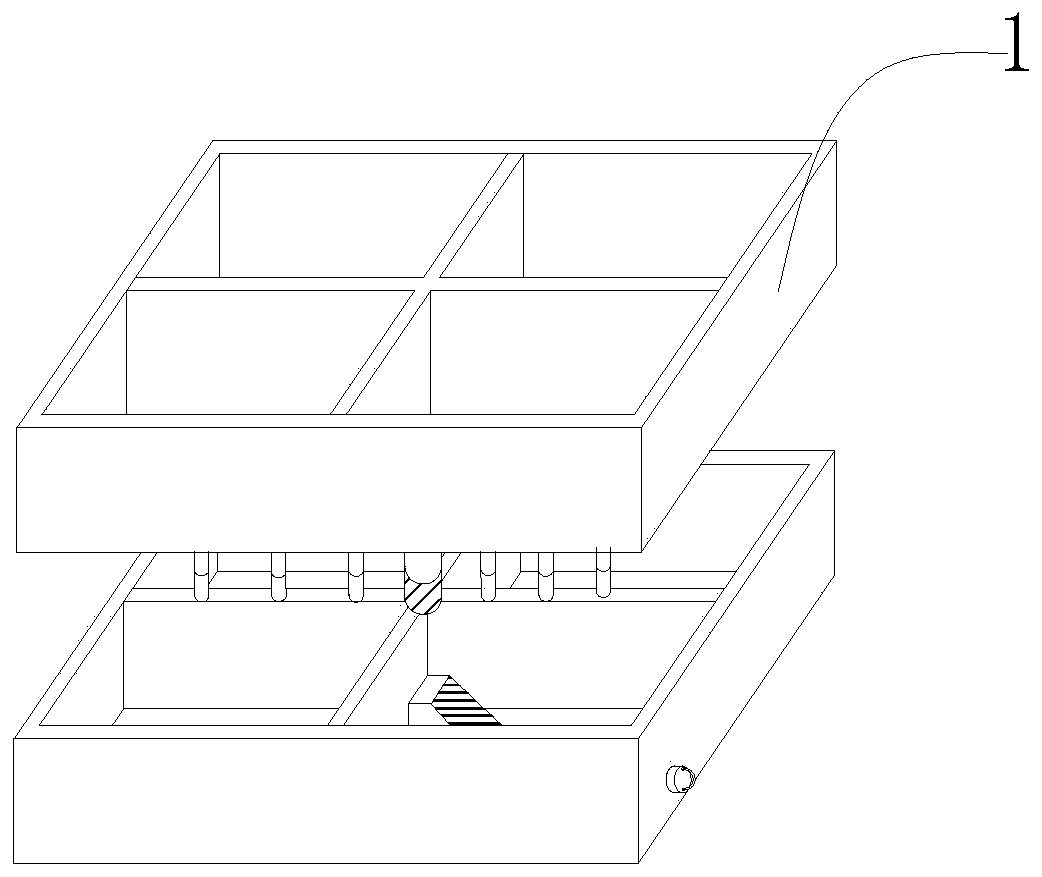

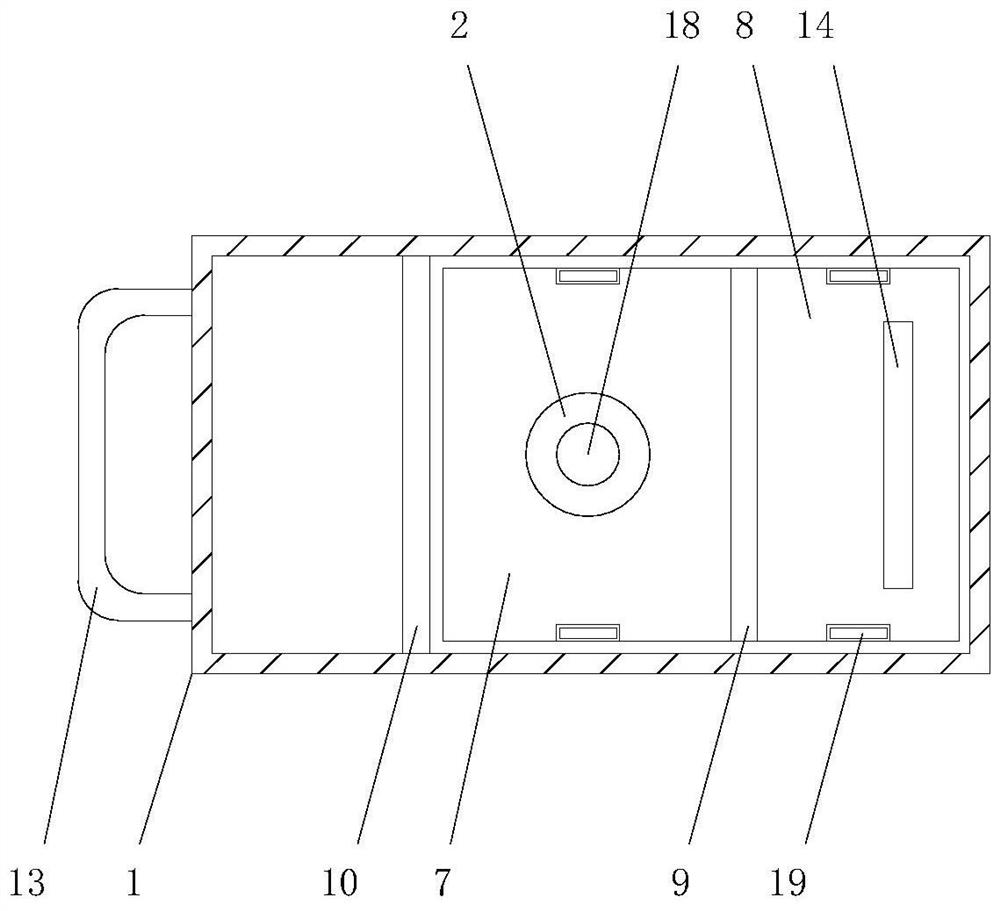

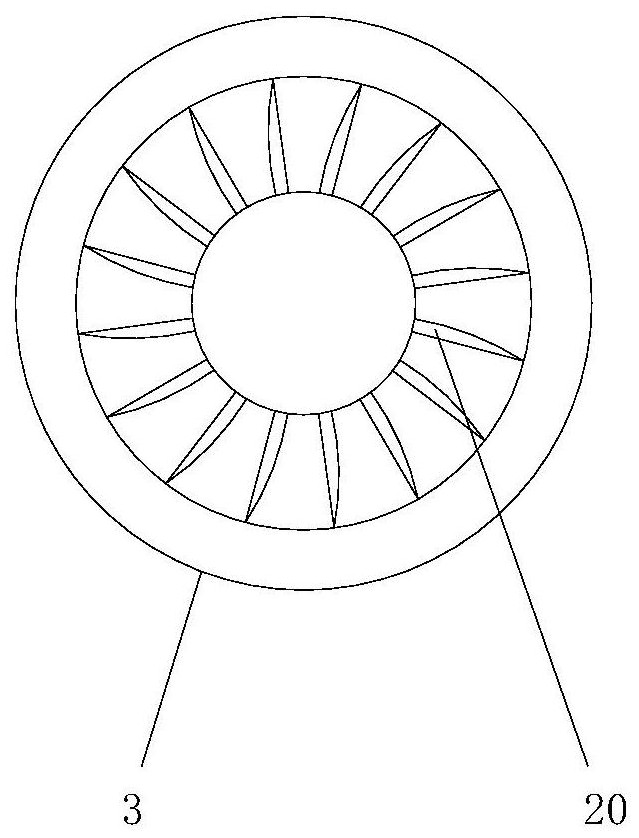

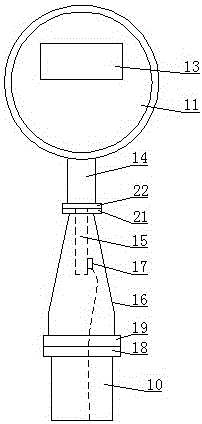

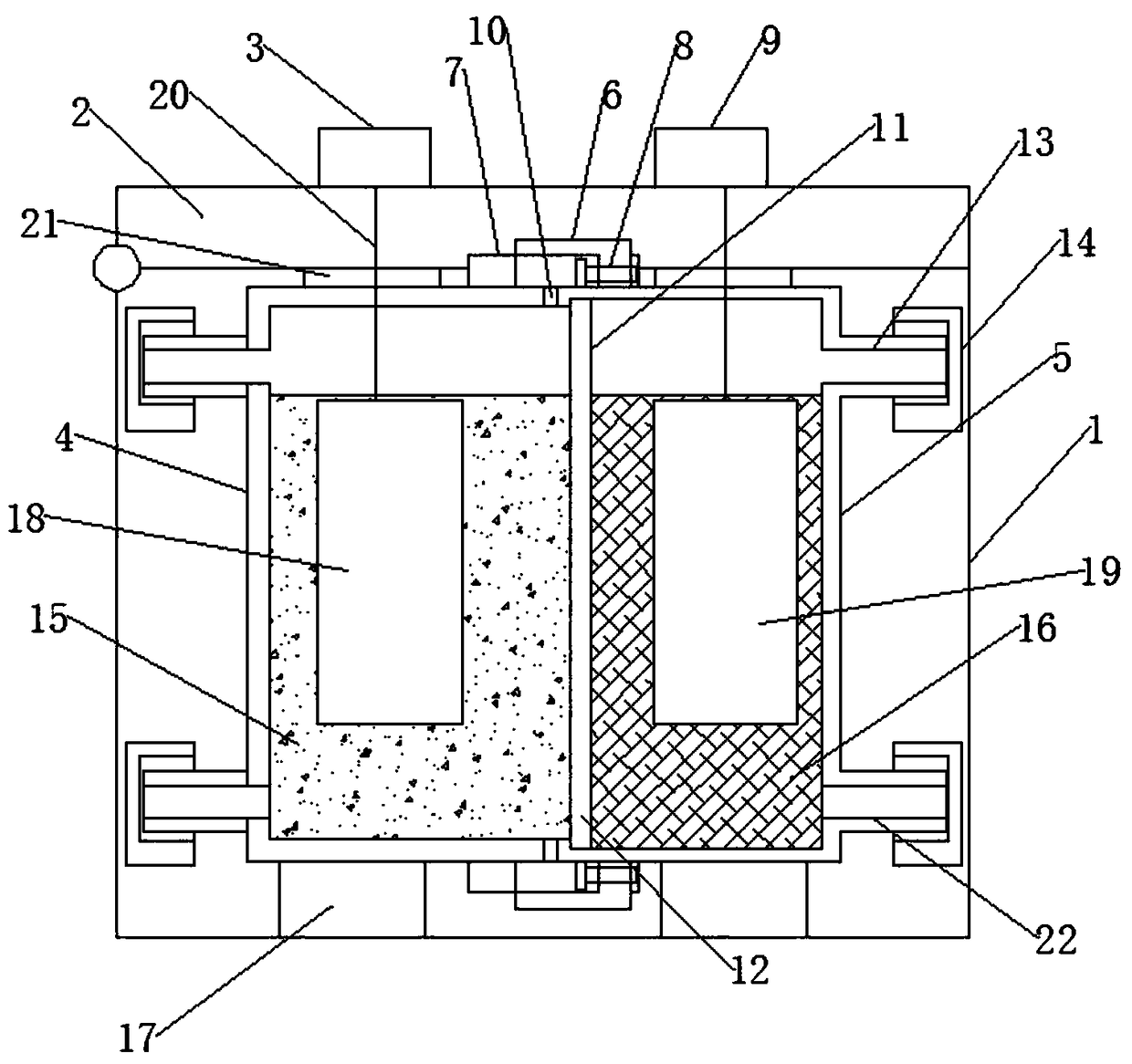

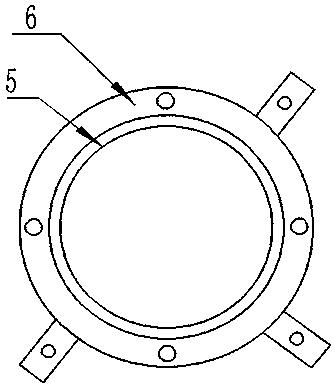

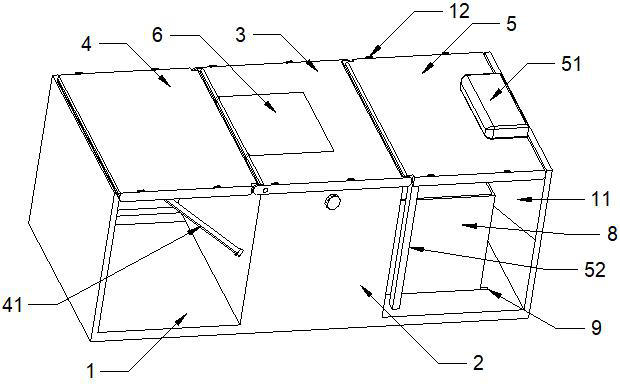

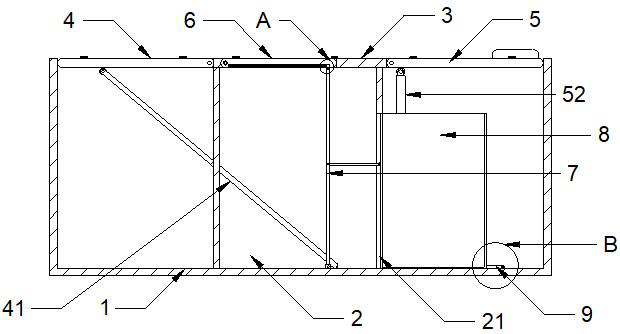

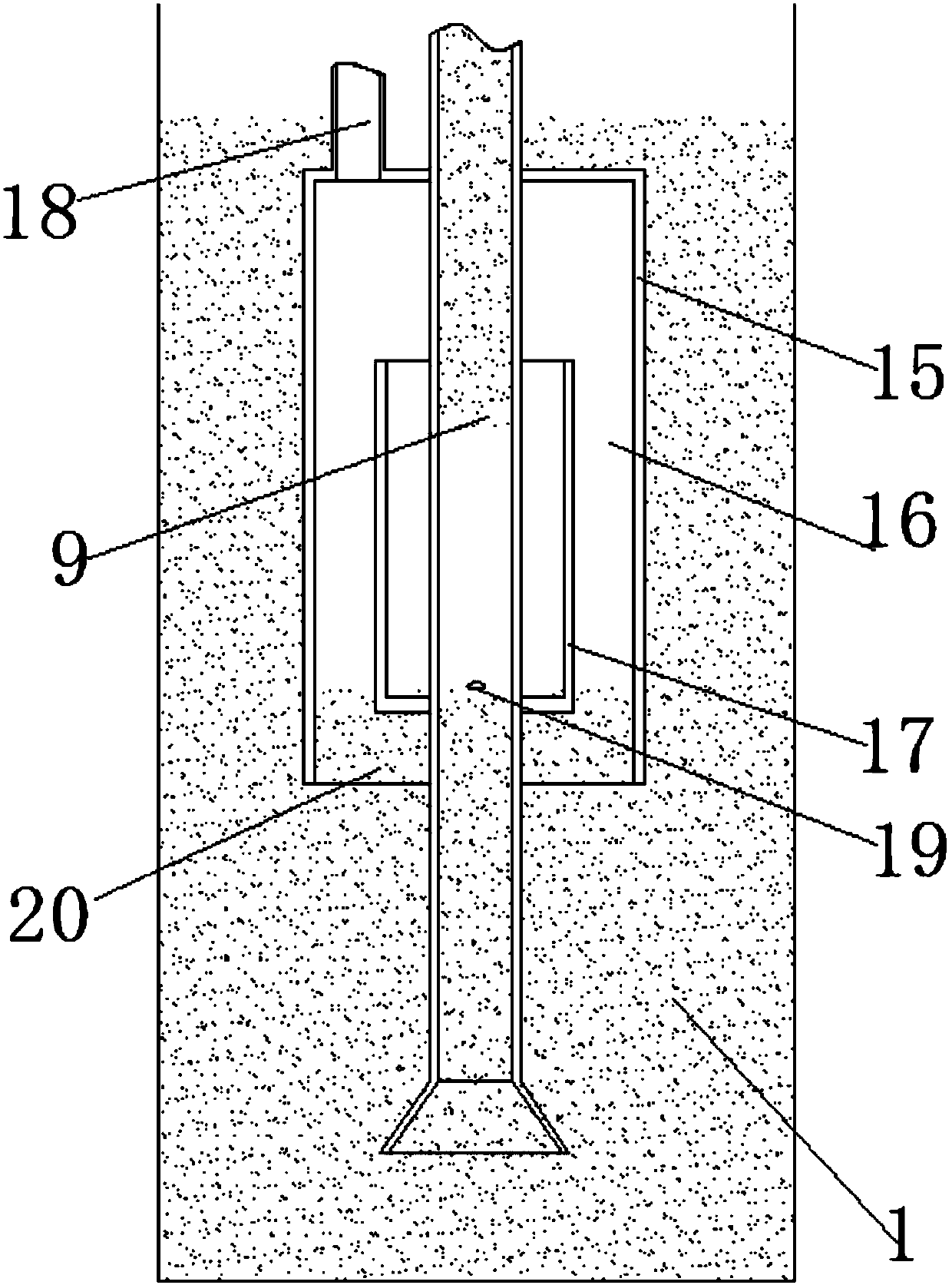

Microbiological fuel battery

ActiveCN105552416AReasonable designNovel structureFuel cell auxillariesBiochemical fuel cellsMicrobial fuel cellElectricity

The invention belongs to the technical field of microbiological batteries, and specifically relates to a microbiological fuel battery. The microbiological fuel battery comprises a box body, a box cover, an anode chamber and a cathode chamber, wherein the box body is provided with the box cover, one end of the box cover is connected with the box body through a rotating shaft, the box cover is provided with an anode terminal and a cathode terminal, the box body is internally provided with the anode chamber and the cathode chamber, the anode chamber and the cathode chamber are spliced together through a snap joint, a neck and a bolt, the spliced part is provided with a sealing ring, a separation neck is arranged at the spliced part of the anode chamber and the cathode chamber, the separation neck is internally provided with a proton exchange membrane, and the proton exchange membrane separates the anode chamber from the cathode chamber. The microbiological fuel battery has the positive effects of being rational in design, being novel in structure, being convenient to dismount and discharge liquid, being convenient to clean and recycle, not only satisfying usage of a experimental stage, but also being usable for daily electricity consumption, and thereby improving utilization rate of biological fuel batteries.

Owner:临沂星火知识产权服务有限公司

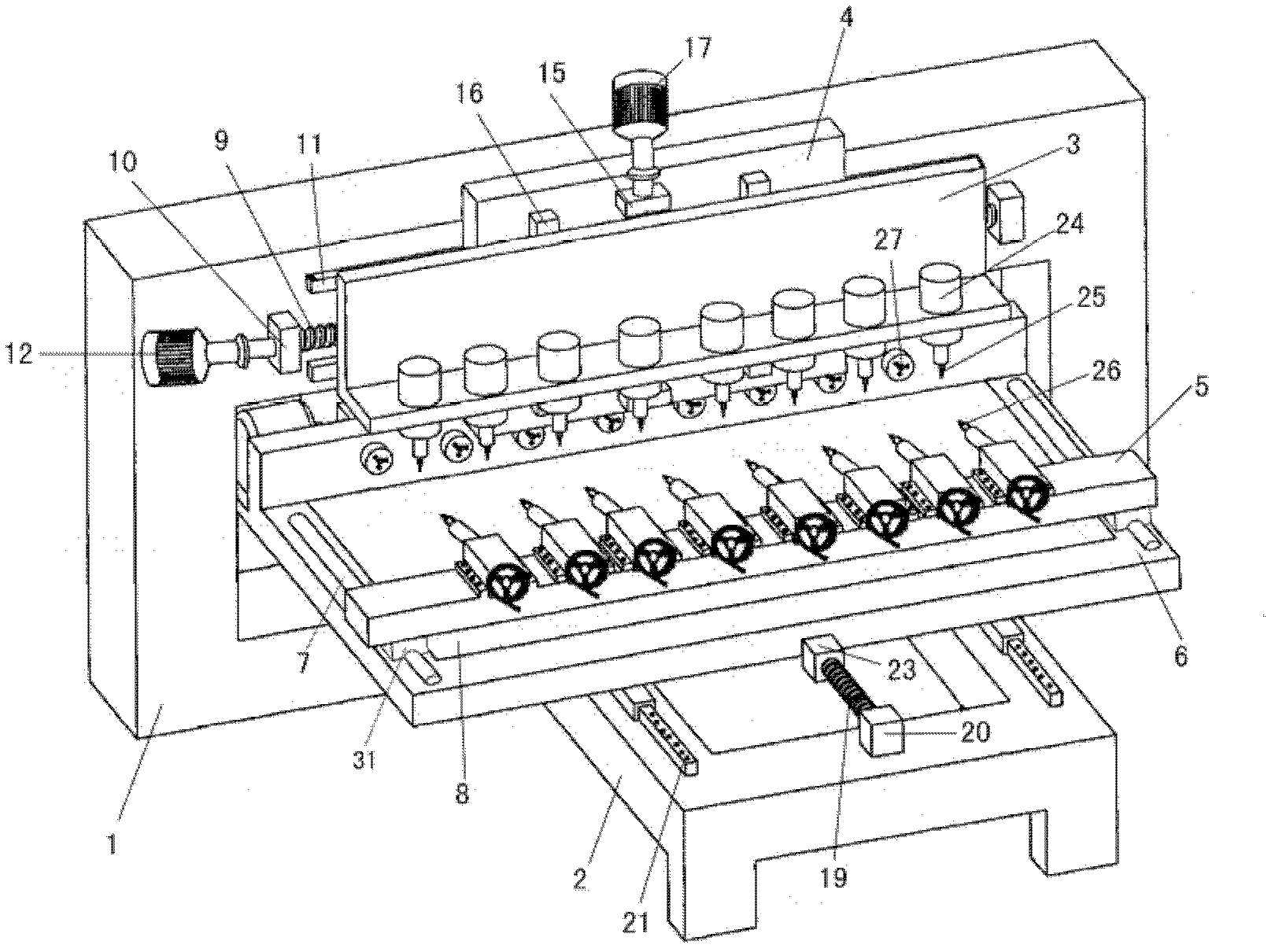

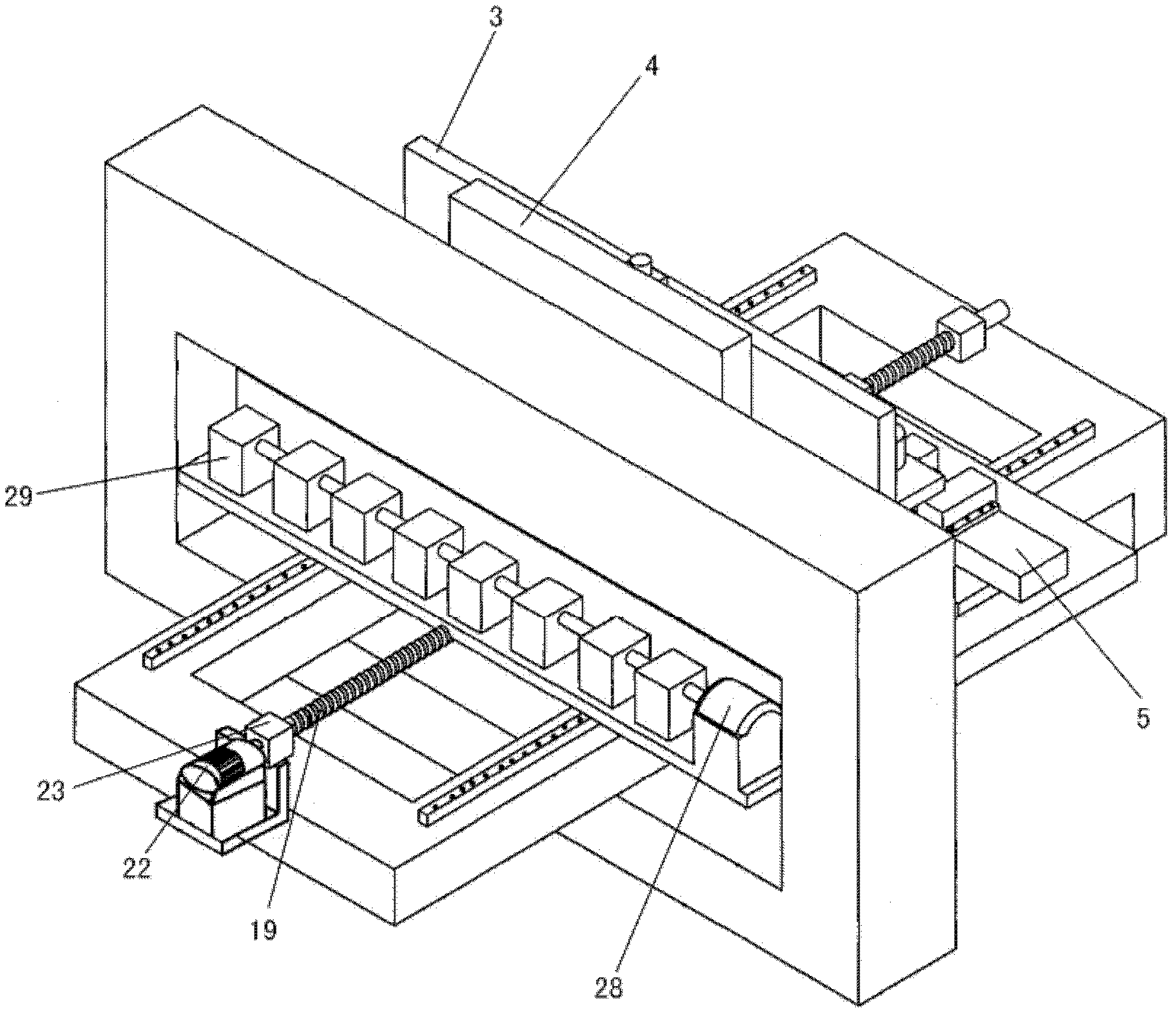

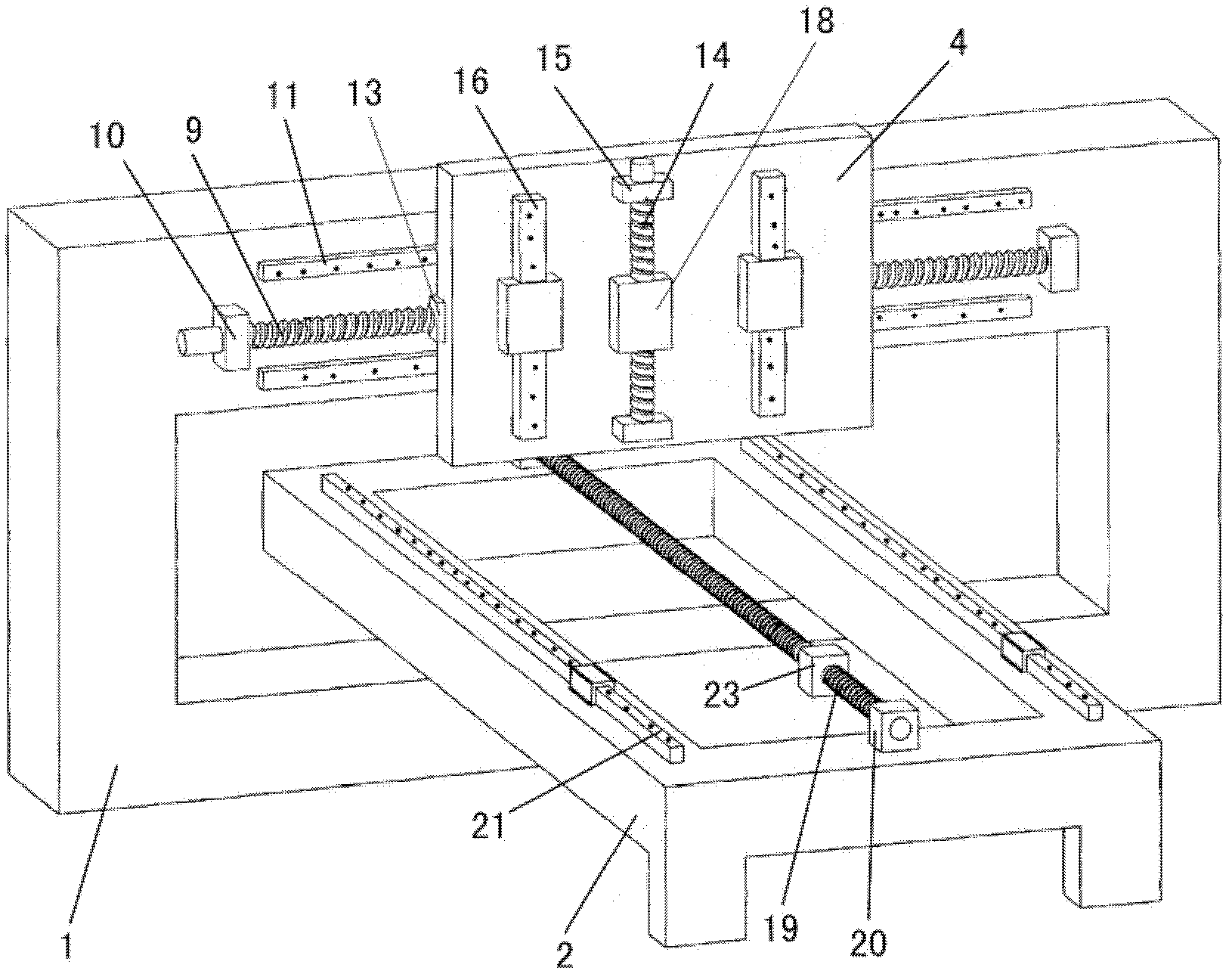

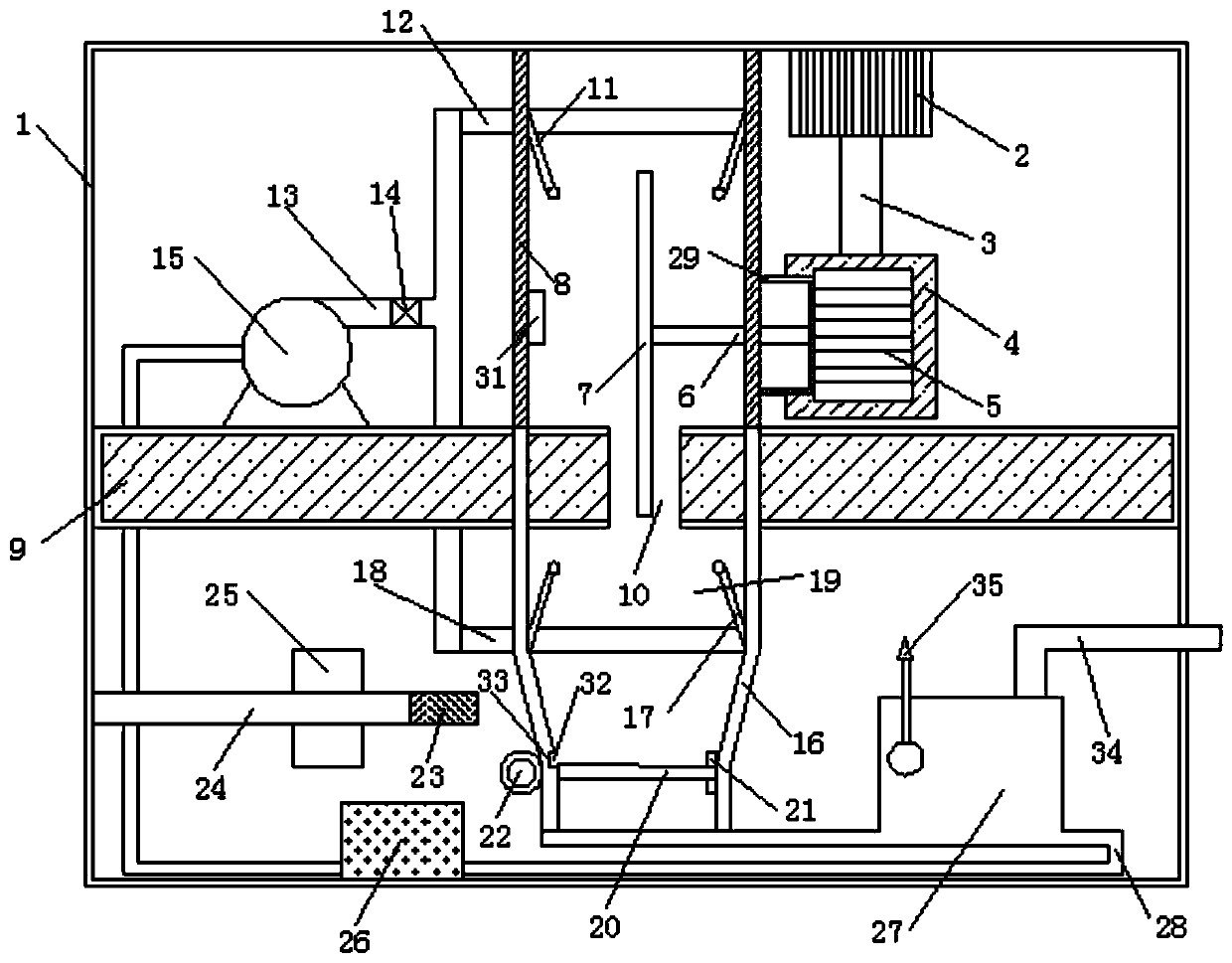

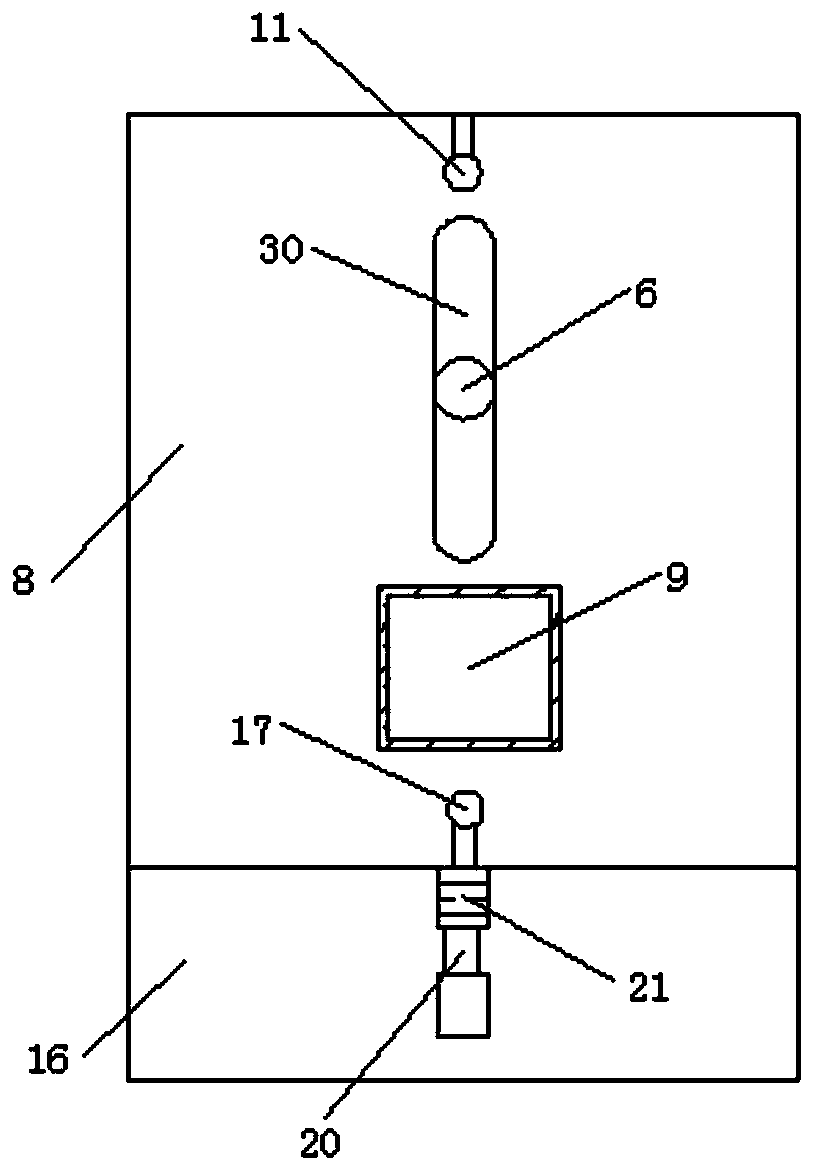

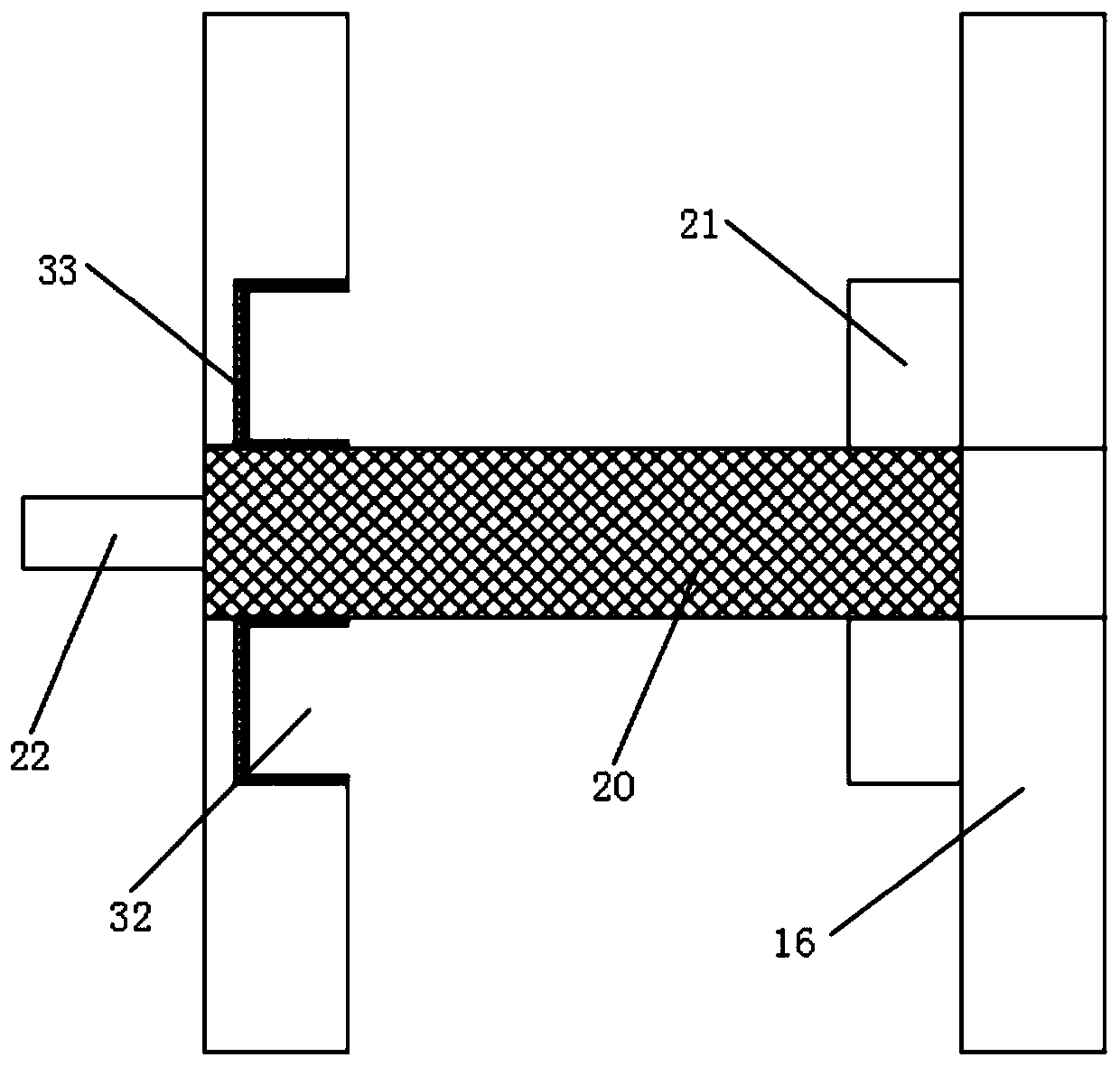

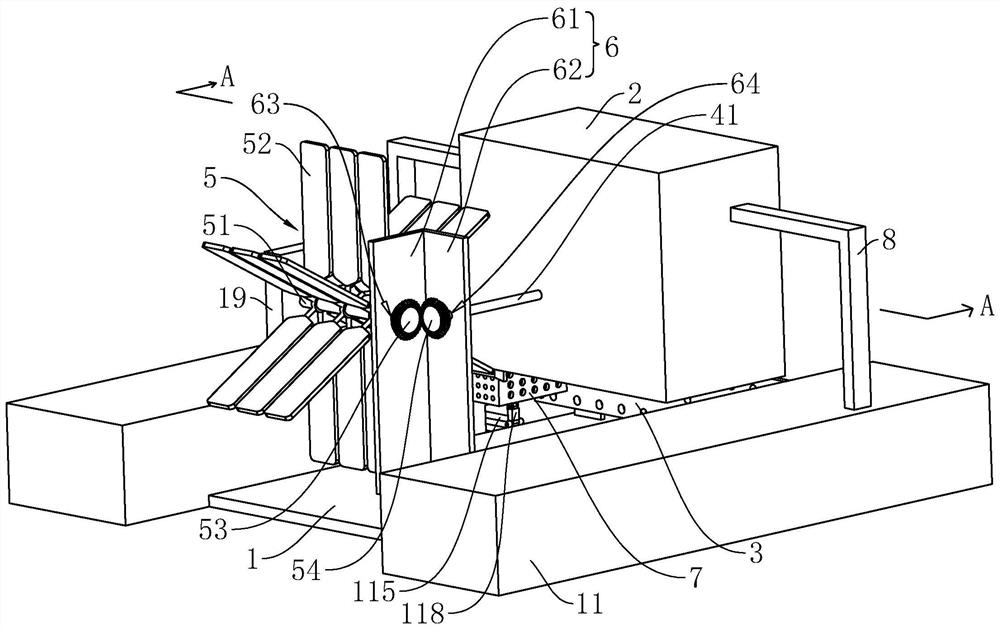

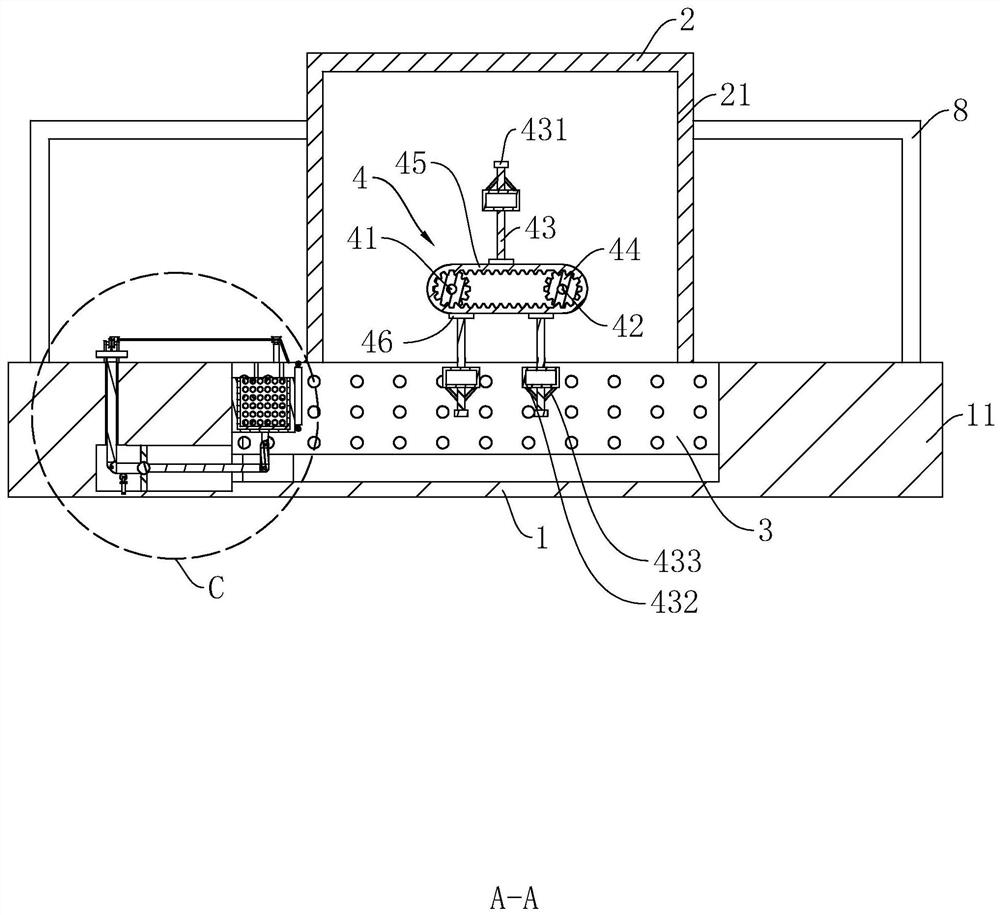

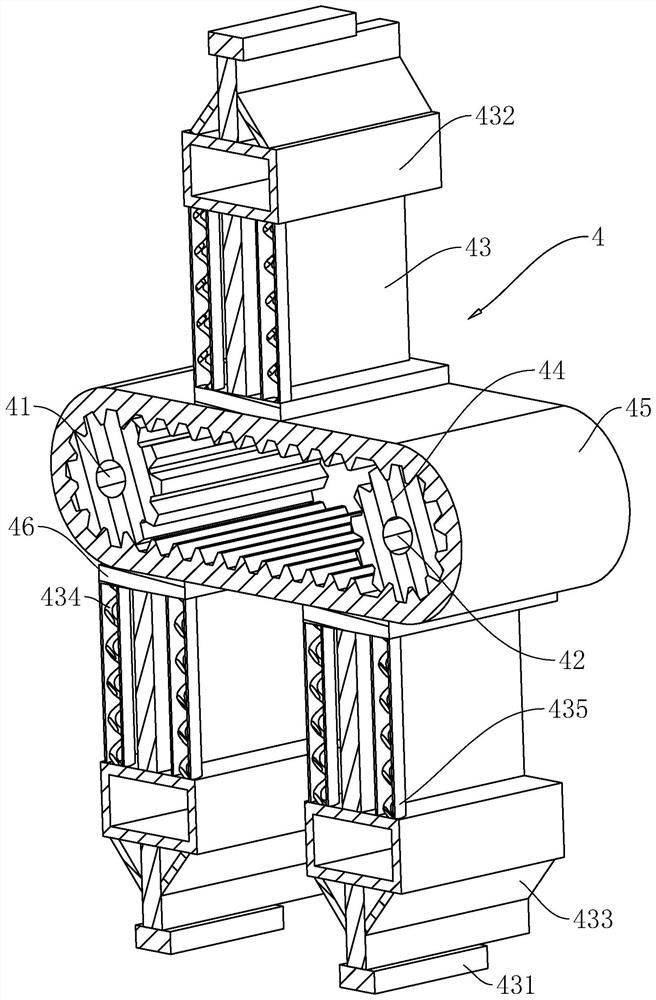

Three-dimensional carving machine

The invention provides a three-dimensional carving machine and belongs to the field of the carving machines. The three-dimensional carving machine comprises a rack, a base, a tool frame, a transverse support plate, a plate strip, a working table and cylindrical guide rails. Tools are arranged on the tool frame. The working table is fixed on the base through a longitudinal moving mechanism. The tool frame is fixed on the transverse support plate through a vertical moving mechanism. The transverse support plate is fixed on the rack through a transverse moving mechanism. The plate strip is arranged on the cylindrical guide rails in a sliding mode. The cylindrical guide rails are arranged on two sides of the working table. A baffle for separating and blocking processed debris is arranged on the working table. The three-dimensional carving machine can effectively prevent sawdust or dust generated by workpieces in the processing process from directly falling on the cylindrical guide rails and the longitudinal moving mechanism so as to influence sliding of the cylindrical guide rails and motion of the longitudinal moving mechanism, and further improves processing accuracy of the workpieces. Meanwhile, the three-dimensional carving machine can conveniently carry out cleaning and uniform recycling on the sawdust or the dust, reduce potential safety hazards and improve the environment of a workshop.

Owner:吴善旺

Preparation method for superfine zirconium powder

InactiveCN104289709AReduce surface activityInhibition of growth behaviorCoatingsZirconium hydrideMicro nano

The invention relates to a preparation method for superfine zirconium powder, in particular to a technical method utilizing a sodium salt and / or potassium salt to coat zirconium hydride to prepare micro-nano-scale zirconium powder, and belongs to the technical field of superfine metal powder. The technical method comprises the following steps: taking the sodium salt as a coating agent, mixing the zirconium hydride particles with the coating agent according to a mass ratio of (5-15):1, conducting wet grinding and vacuum drying to obtain the superfine zirconium powder of which surface is coated with the coating agent uniformly, dehydrogenizing in a vacuum environment at 550-680 DEG C, and conducting wet grinding dispersion and elution on the product to remove the coating agent so as to obtain the superfine zirconium powder, wherein the vacuum degree is controlled at 0.05-0.1 Pa in the dehydrogenation process. The preparation method disclosed by the invention is simple in preparation technology, convenient to control, and safe in operation technology; the obtained product is good in quality; the preparation method facilitates industrialized application.

Owner:CENT SOUTH UNIV

Recoverable dust removal filter cloth bag

PendingCN107126785AEasy to replaceQuick releaseDispersed particle filtrationDust controlScrew thread

The invention discloses a recoverable dust removal filter cloth bag, which comprises a connecting base and a top cover positioned above the top of the connecting base, wherein a filter bag main body is arranged between the connecting base and the top cover; fixing rods arranged at equal intervals around the filter bag main body are arranged at the outer side of the filter bag main body; one end of each fixing rod is vertically fixed at the top of the connecting base; the other end of each fixing rod is fixedly provided with a connecting groove block; the top of the connecting groove block is provided with an installing groove with a T-shaped cross section; a rotating sleeve is rotationally connected into the installing groove in a sleeving way; a second fixing rod is connected with the inner side of the rotating sleeve through screw threads. The recoverable dust removal filter cloth bag has the advantages that through the matched use of springs, a connecting rod, a support rod, the rotating sleeves, the second fixing rods, the top cover and the like, filter bag main bodies in different sizes can be installed; meanwhile, all components can be fast dismounted or separated; further, the filter bag main body can be conveniently replaced; the recovery and the cleaning are further convenient; the use is flexible.

Owner:JIANGSU XINKEDA FILTER BAG

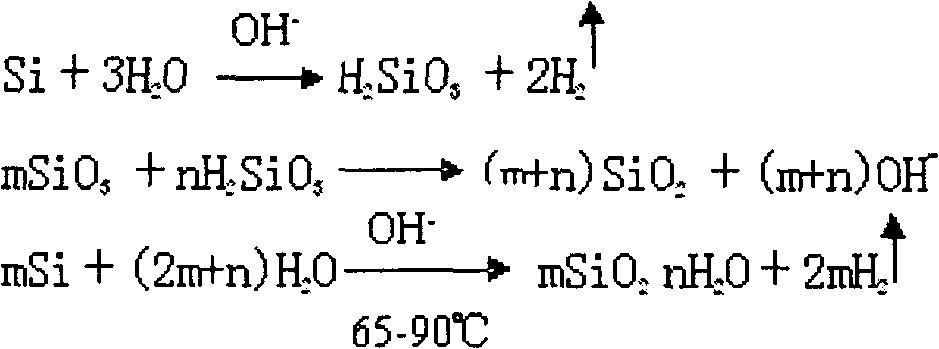

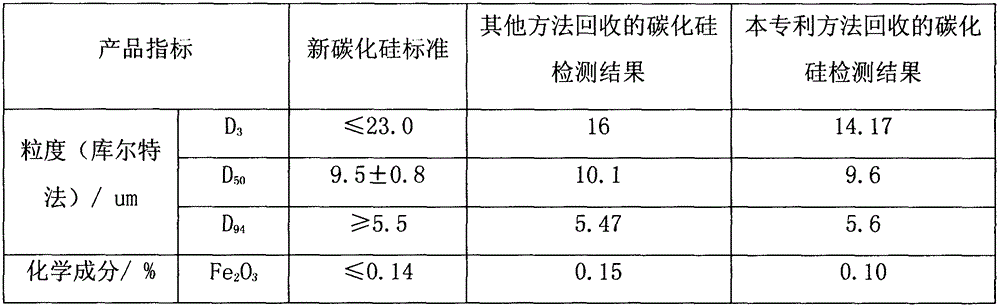

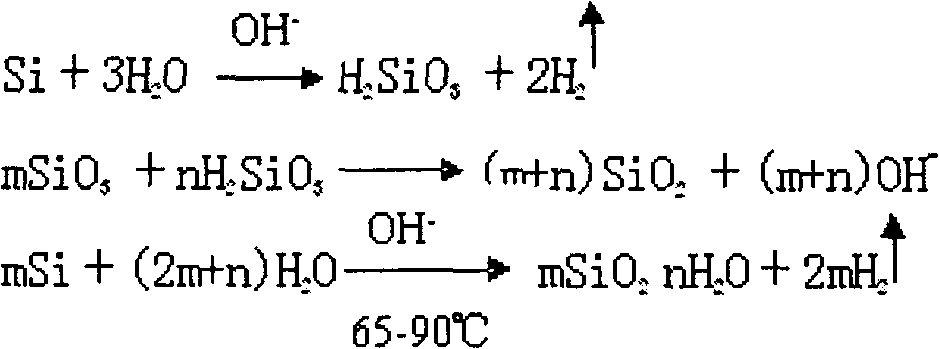

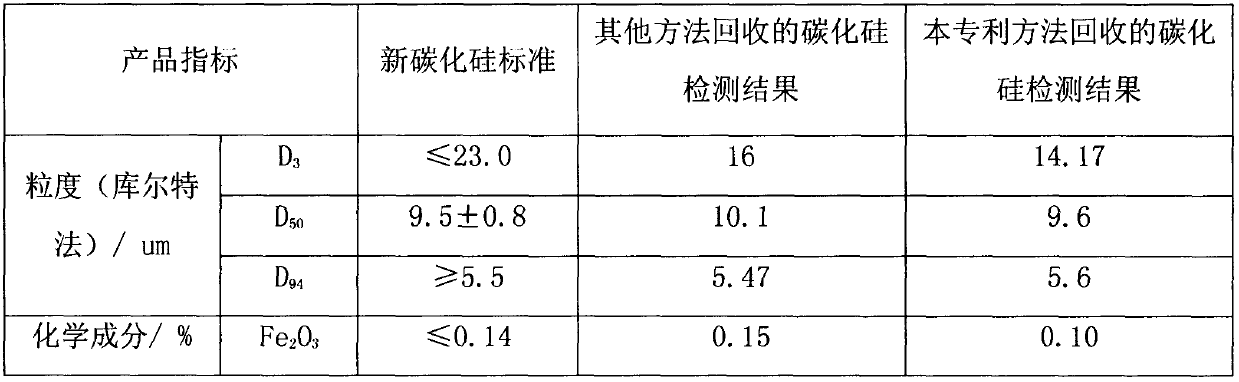

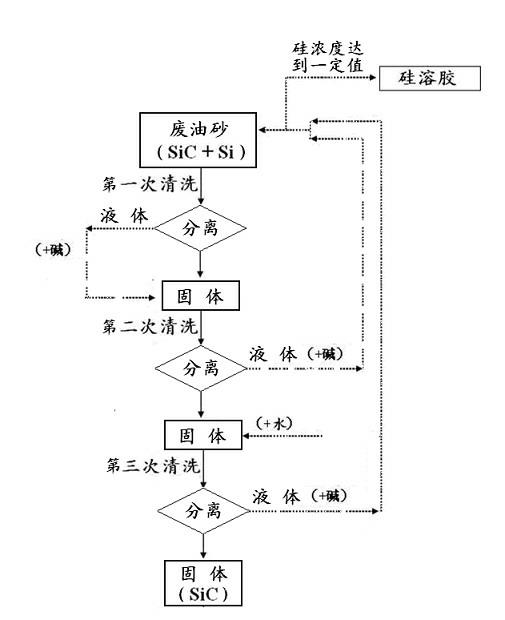

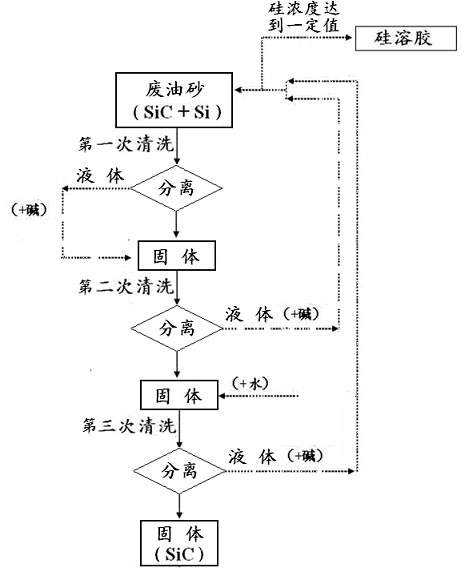

Method for recycling silicon cutting waste mortar

ActiveCN102746935AReduce dosageReduce cost investmentSilicon carbideSilicon compoundsDistillationPolyethylene glycol

Disclosed is a method for recycling silicon cutting waste mortar. The method comprises the steps of performing solid-liquid separation of the waste mortar; performing solid flow washing and vacuum filtration; drying the obtained filter cake, mixing with deionized water and performing activation reaction; adding water glass and sodium hydroxide successively and performing heating reaction, performing solid-liquid separation of the obtained product, performing ion exchange resin decolorization and distillation of the liquid phase to obtain silica sol, and performing solid phase washing and drying to obtain a silicon carbide raw material; and performing ultra precision filter of obtained liquid phase after solid-liquid separation of the waste mortar, adding a decoloring agent a filter aid to perform solid-liquid separation, reducing the conductivity, and heating and evaporating water to obtain finished polyethylene glycol cutting liquid. According to the technical scheme of the method, the flow line production is achieved, the silicon cutting waste mortar is recycled, the silica sol is prepared effectively, and the environmental pollution is reduced.

Owner:山东网金资源再利用发展有限公司

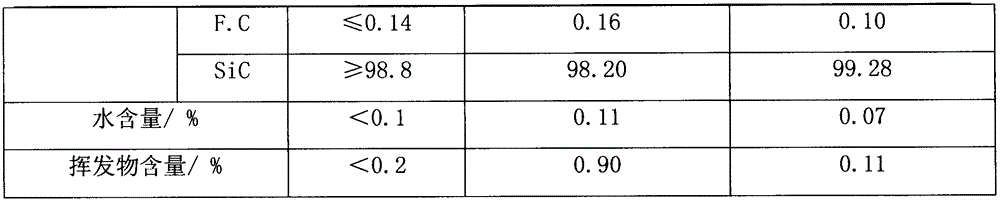

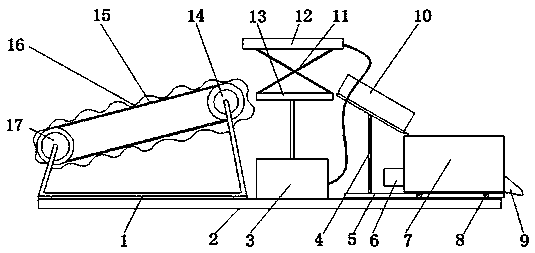

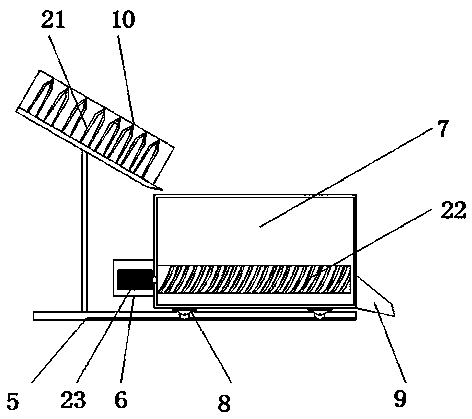

Smashing and washing device for waste plastic recycling

InactiveCN107825624ASolve sewer blockageEasy to clean dirtPlastic recyclingMechanical material recoverySewerageEngineering

The invention discloses a smashing and washing device for waste plastic recycling. The smashing and washing device for waste plastic recycling comprises a base and a collection box. A conveyer belt support is welded to the part, on one side, of the outer wall of the base. The inner wall of the top of the conveyer belt support is connected with a driving wheel and a driven wheel through bearings. The outer wall of the driving wheel and the outer wall of the driven wall are sleeved with the same conveyer belt in a connected manner. The driving wheel and the driven wheel form transmission cooperation through the conveyer belt. A groove belt is fixed to the part, on one side, of the outer wall of the conveyer belt through screws. A water tank is welded to the side, close to the conveyer belt support, of the outer wall of the top of the base. According to the smashing and washing device for waste plastic recycling, the problem that a sewer is blocked can be solved through a spraying devicewith circulated filtration, dirt can be removed conveniently, water resources can be utilized repeatedly, the cost is reduced, a reaming breaking box and the collection box can carry out polishing after reaming breaking, a smashing device is not blocked, the smashing efficiency is improved, the service life of the device is prolonged, waste plastic can be retrieved and washed by the conveyer beltwith the groove belt, and the efficiency of washing and the efficiency of smashing of the device are improved.

Owner:江苏名欧高分子科技有限公司

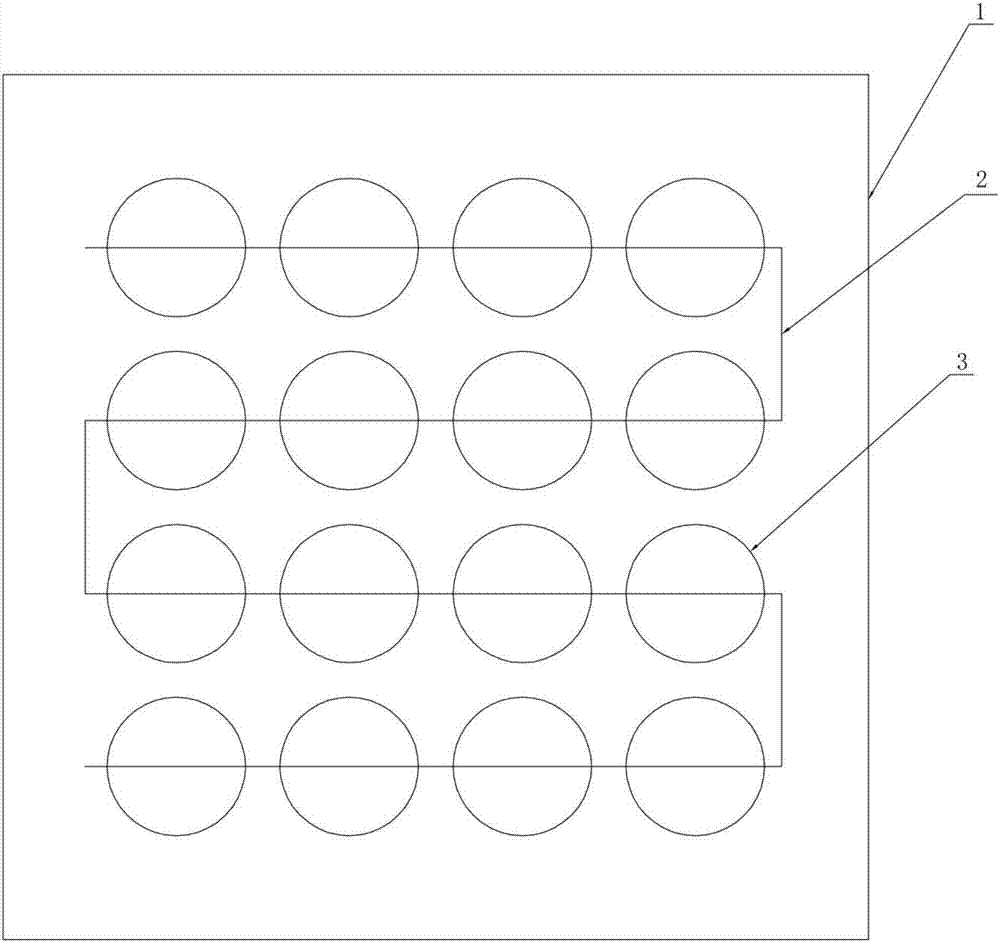

Safe firework based on axial internal cylinder inverted powder-charging technology and production technology

The invention discloses safe firework based on axial internal cylinder inverted powder-charging technology. The firework comprises a base, a connecting lead wire and monomer firework cylinders, wherein the monomer firework cylinders are distributed on the base in an array mode; firework shells in all monomer firework cylinders are sequentially connected by the connecting lead wire; each monomer firework cylinder comprises an external cylinder, a firework shell, a propellant powder layer, a moistureproof layer and a power sealing layer; the firework shell, the propellant powder layer, the moistureproof layer and the power sealing layer are arranged inside the external cylinder; a propellant powder groove is formed in the upper part of the firework shell; the moistureproof layer is arranged on the upper part of the propellant powder layer; the power sealing layer is arranged on the upper part of the moistureproof layer; the firework shell comprises a firework powder layer, an over-fire mud bottom layer, the propellant powder groove, a wrapping layer and a firework shell lead wire; and the firework shell lead wire is connected with the connecting lead wire. The technology of the invention is simple, and by adopting the internal-external cylinder inverted powder-charging technology, the labor efficiency of preparation is improved, the materials are saved, the labor intensity is reduced, and the production of fireworks and the safety of setting off fireworks are increased.

Owner:孔为乐

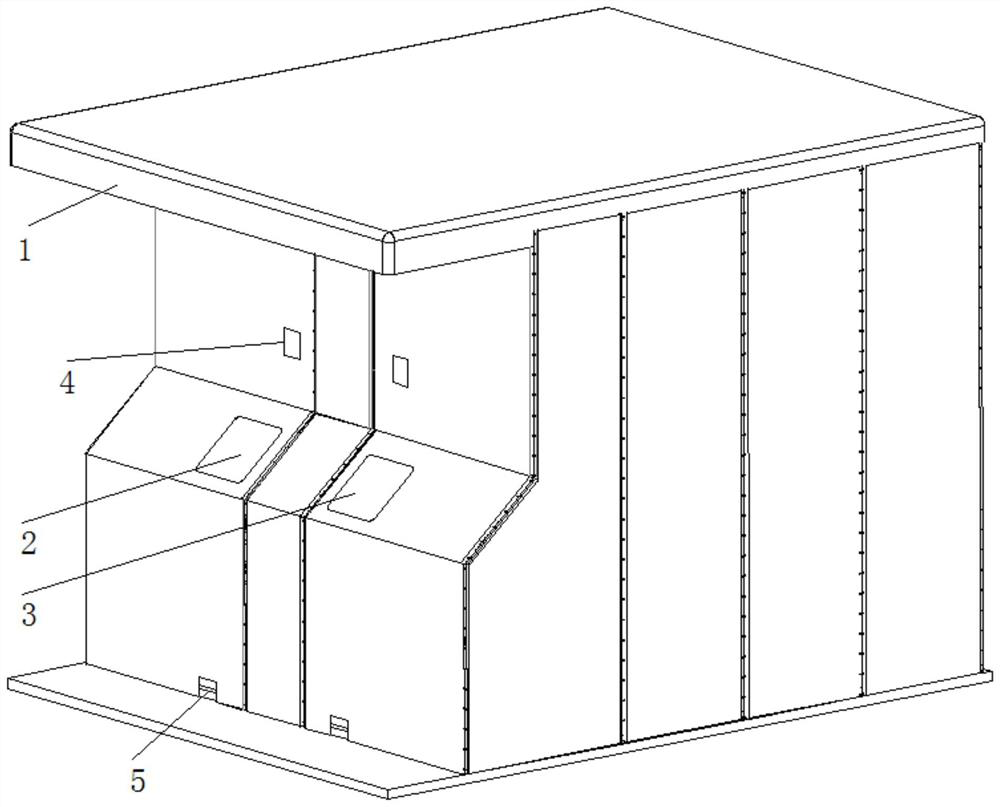

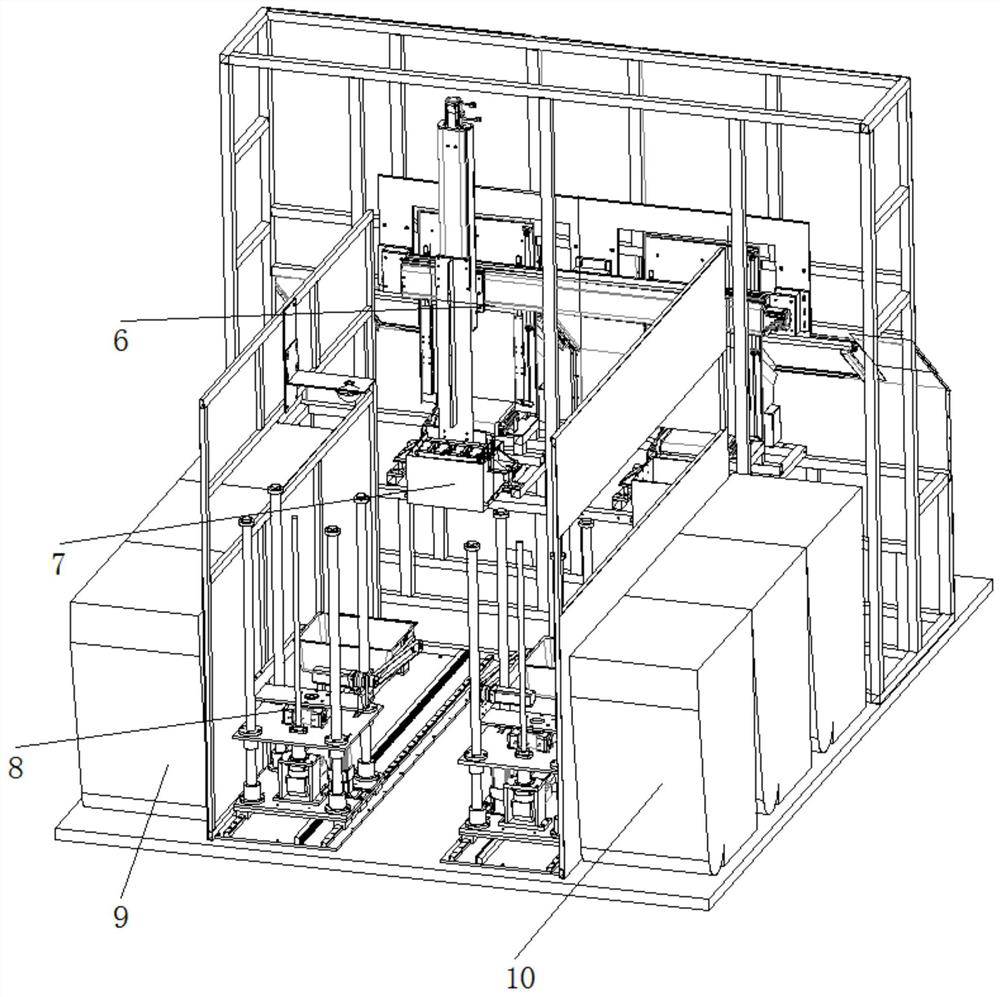

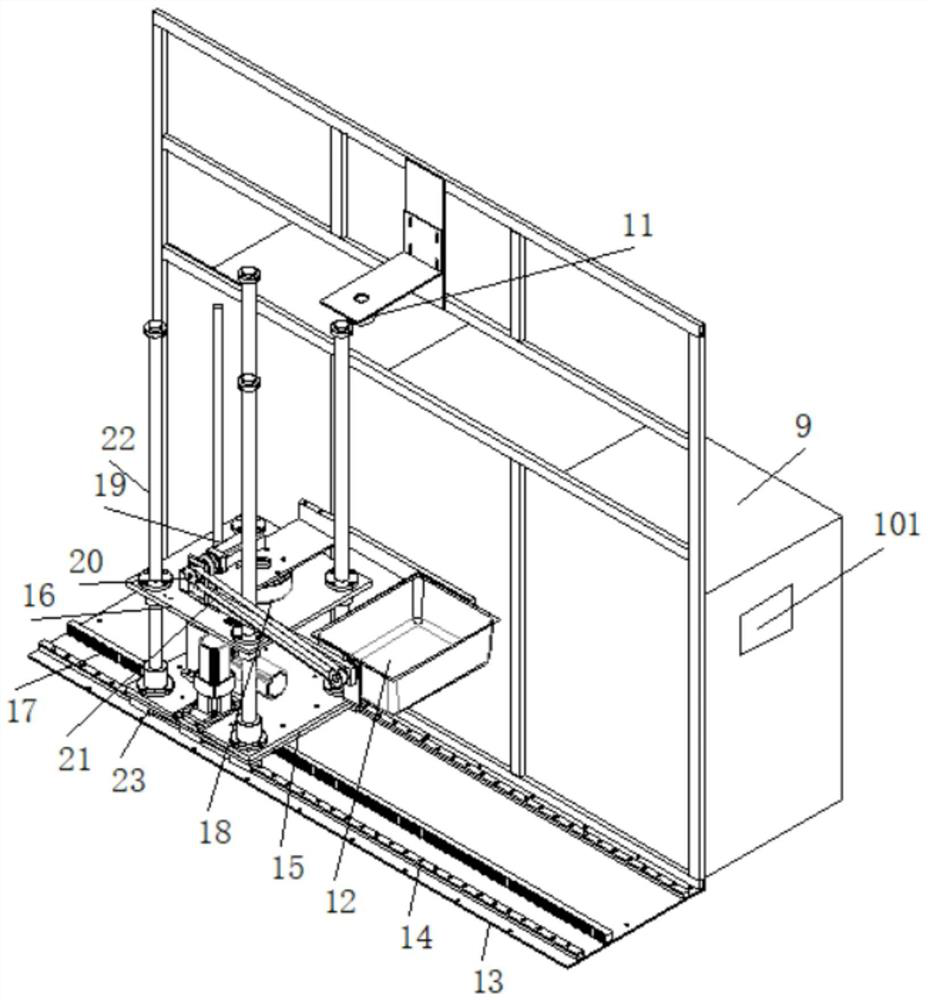

Full-automatic garbage classification and recovery equipment

PendingCN111940340AMaximizeAchieving Zero Landfill GoalWaste collection and transferRefuse receptaclesProcess engineeringIndustrial engineering

The invention belongs to the technical field of garbage classification and recovery, and particularly relates to full-automatic garbage classification and recovery equipment. The full-automatic garbage classification and recovery equipment comprises an equipment body, an automatic bag breaking and taking mechanism, a clamp mechanism, an automatic photographing recognition mechanism and an automatic classification and conveying mechanism. Infrared induction devices are arranged above the top of a perishable garbage inlet and the top of an other garbage inlet, skirting induction devices are arranged below the bottom of the perishable garbage inlet and the bottom of the other garbage inlet, bag taking moving mechanisms are arranged at the inner side end of the perishable garbage inlet and theinner side end of other garbage inlet, and a bag breaking hopper is arranged below a clamp. A receiving hopper is arranged below the bag breaking hopper, a camera is installed above an automatic conveying mechanism, and other garbage cans and perishable garbage cans are distributed on the two sides of the automatic conveying mechanism, so that the functions of automatic bag breaking and taking, automatic photographing recognition and automatic classification throwing of garbage are achieved, and therefore the garbage classification efficiency and classification quality are improved; and the garbage resource utilization is realized.

Owner:嘉兴市智鹏科技有限公司

Suspension cable steel structure large power plant coal transporting trestle stay cable construction method

ActiveCN106348034AReduce pollutionEasy to clean and recycleBridge structural detailsStorage devicesArchitectural engineeringWinch

The invention discloses a suspension cable steel structure large power plant coal transporting trestle stay cable construction method. A steel strand of a stay cable is drawn by a winch, the steel strand and a sleeve are fed and lifted on a bridge floor, construction cost and safety risk are reduced, a steel structure is simplified by stay cable bridge construction of a coal transporting trestle, the weight of the steel structure is greatly reduced, and engineering cost is reduced. Two sides of the coal transporting trestle are symmetrically tensioned, the influence of lateral tension on the trestle is reduced, and construction is accelerated. An equal tension method is used for tension, single cable force is ensured within the allowable range of design errors, construction speed is increased, and construction quality is guaranteed. The sleeve is welded inside the trestle, the steel strand is fed inside the trestle, the influence of environmental factors is less, waste caused by construction is easily cleaned and recycled, and environmental pollution is less.

Owner:中能建建筑集团有限公司

Method for recycling silicon cutting waste mortar

ActiveCN102746935BGood dispersionImprove stabilitySilicon carbideSilicon compoundsDistillationPolyethylene glycol

Disclosed is a method for recycling silicon cutting waste mortar. The method comprises the steps of performing solid-liquid separation of the waste mortar; performing solid flow washing and vacuum filtration; drying the obtained filter cake, mixing with deionized water and performing activation reaction; adding water glass and sodium hydroxide successively and performing heating reaction, performing solid-liquid separation of the obtained product, performing ion exchange resin decolorization and distillation of the liquid phase to obtain silica sol, and performing solid phase washing and drying to obtain a silicon carbide raw material; and performing ultra precision filter of obtained liquid phase after solid-liquid separation of the waste mortar, adding a decoloring agent a filter aid to perform solid-liquid separation, reducing the conductivity, and heating and evaporating water to obtain finished polyethylene glycol cutting liquid. According to the technical scheme of the method, the flow line production is achieved, the silicon cutting waste mortar is recycled, the silica sol is prepared effectively, and the environmental pollution is reduced.

Owner:山东网金资源再利用发展有限公司

Spraying treatment method of mobile phone shell

InactiveCN105772358AEvenly distributedHigh Scratch StrengthPretreated surfacesCoatingsTemperature controlEngineering

The invention provides a spraying treatment method of a mobile phone shell. The method comprises the following steps: step one, cleaning the mobile phone shell; step two, heating a mobile phone glass shell to 150-400 DEG C, reducing specific resistance and conducting; step three, spraying powder coating on the inner wall of the mobile phone shell by using an inner spraying machine of a static spraying gun with more than 16 stations, wherein the adjustable voltage is 50-70KV, the adjustable speed is 6-20 r / min, the powder suction airflow of the spraying gun is 0.23-0.28Mpa and the powder spraying airflow is 0.18-0.2Mpa; and step four, heating the sprayed mobile phone shell, curing the coating powder to be a film, and spraying for at least three times by using the spraying gun, wherein a chain type temperature control curing machine with more than 48 stations is used for curing the coating powder to be the film; the sprayed film is carbonized at 300-350 DEG C, so that the glass shell can be conveniently washed and recycled; no harmful gas is discharged in the recycling process.

Owner:LIUZHOU YIJIAN TECH

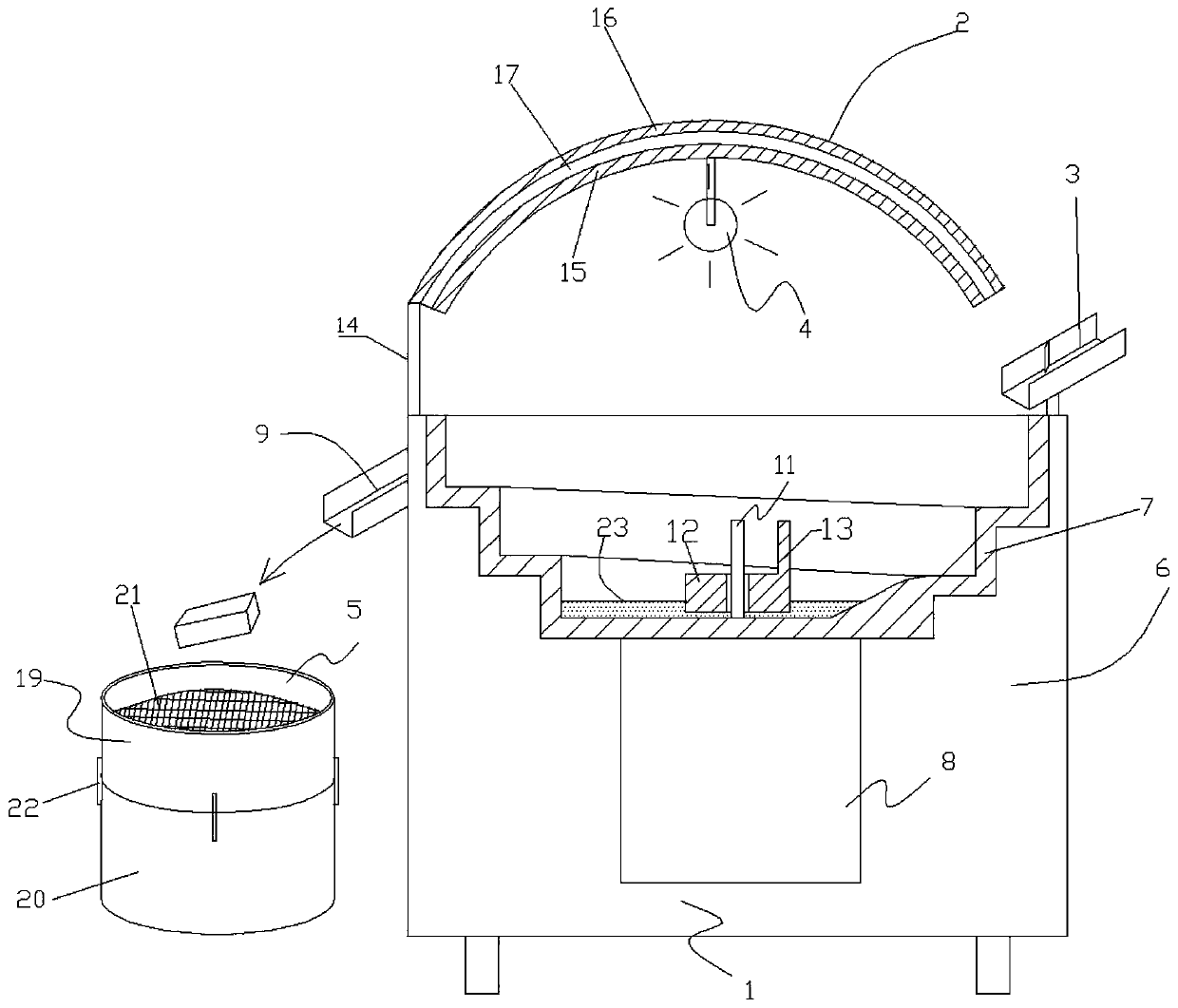

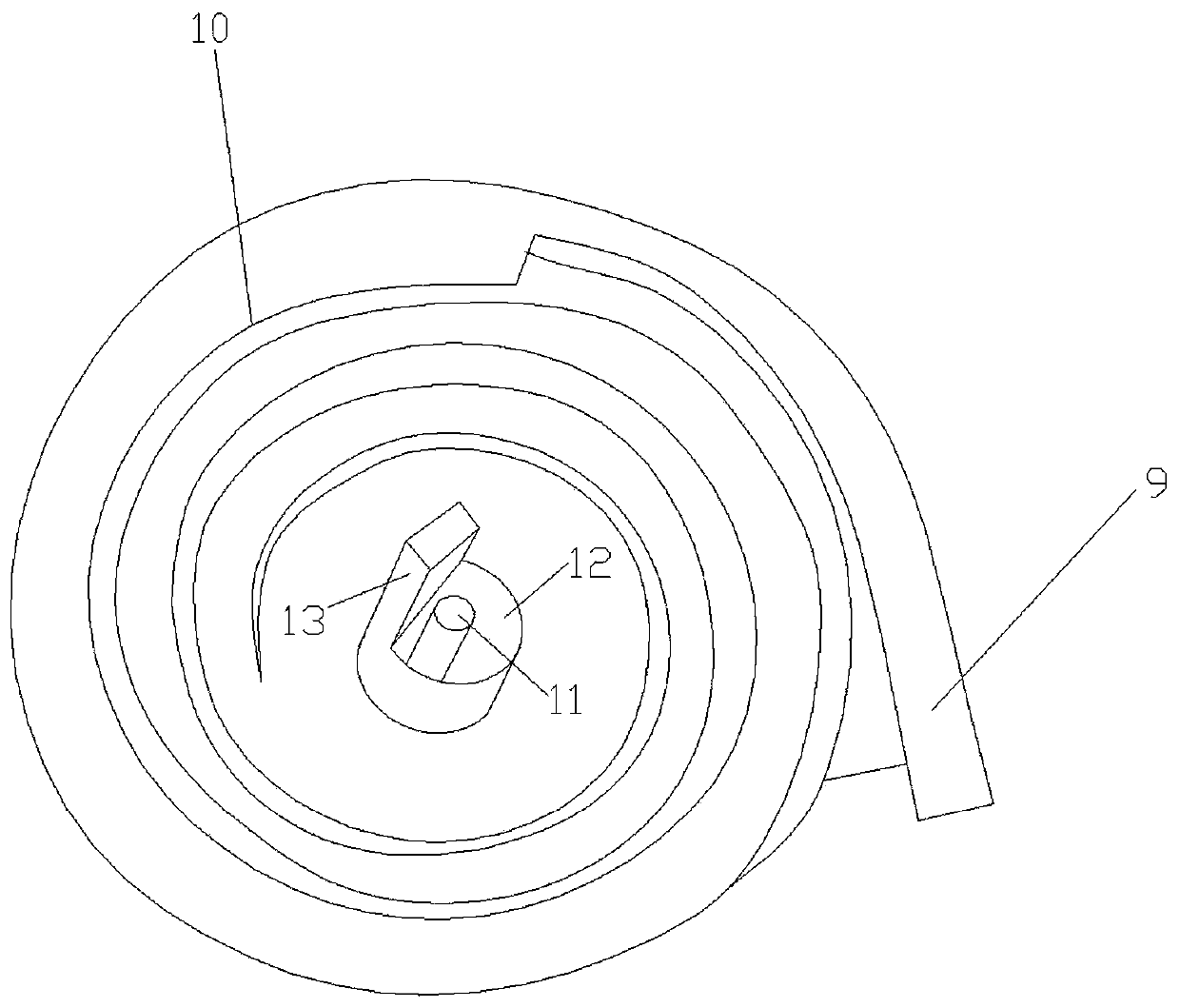

Environment-friendly bamboo rat breeding device specific to breeding dead angle cleaning of bamboo rats

ActiveCN110214705AGood cleaning effectClean recycling goodHollow article cleaningAnimal housingEngineeringFiltration

The invention provides an environment-friendly bamboo rat breeding device specific to breeding dead angle cleaning of bamboo rats. The breeding device comprises a device body, a feces cleaning device,a partition plate and a filtration collector, feces can move upwards along a bevel edge by enabling the feces to be conducted by a cleaning rod in the cleaning process through the active connection of a rotating wheel, the problem that the feces are accumulated and thus are difficult to clean is completely eradicated, a better cleaning effect is achieved, by arranging a rotor, water flows out ofa water outlet slowly to dilute accumulated feces, the feces are better cleaned and recycled, meanwhile, a large quantity of accumulated water appearing in the breeding device is further avoided in the cleaning process, dryness in the breeding device is maintained, by arranging a cleaning surface of which the shape is of an externally expanded arc, the cleaning area of a dead angle is increased, meanwhile, a cleaning solution extrusion ejector is arranged in the middle of the cleaning surface of the dead angle, inward extruding force can be brought about to extrude a cleaning solution out to be sprayed on the cleaning surface when the cleaning surface cleans, and the dead angle can be better cleaned.

Owner:佛山市嘉沃农业科技合伙企业(有限合伙)

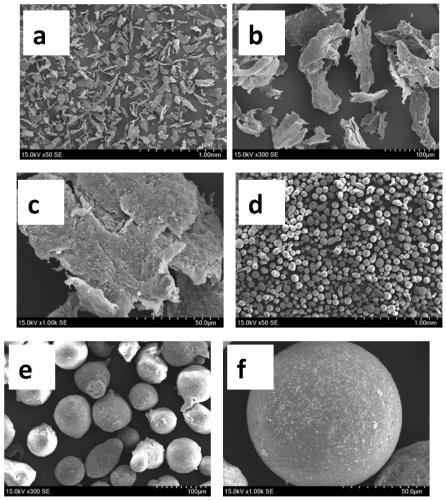

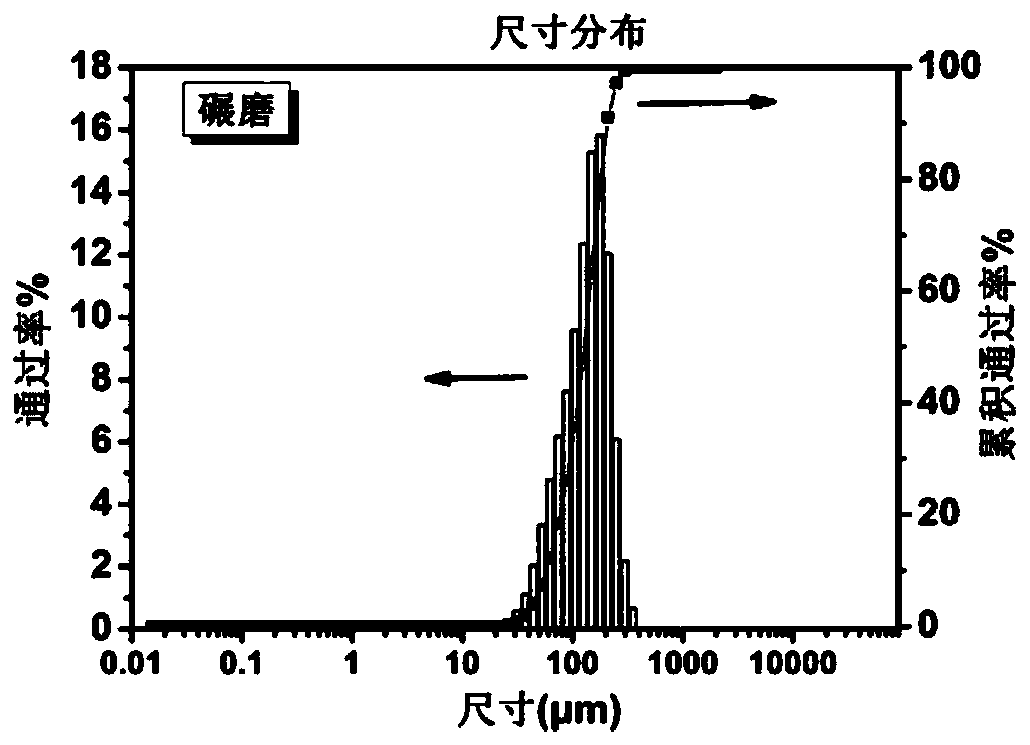

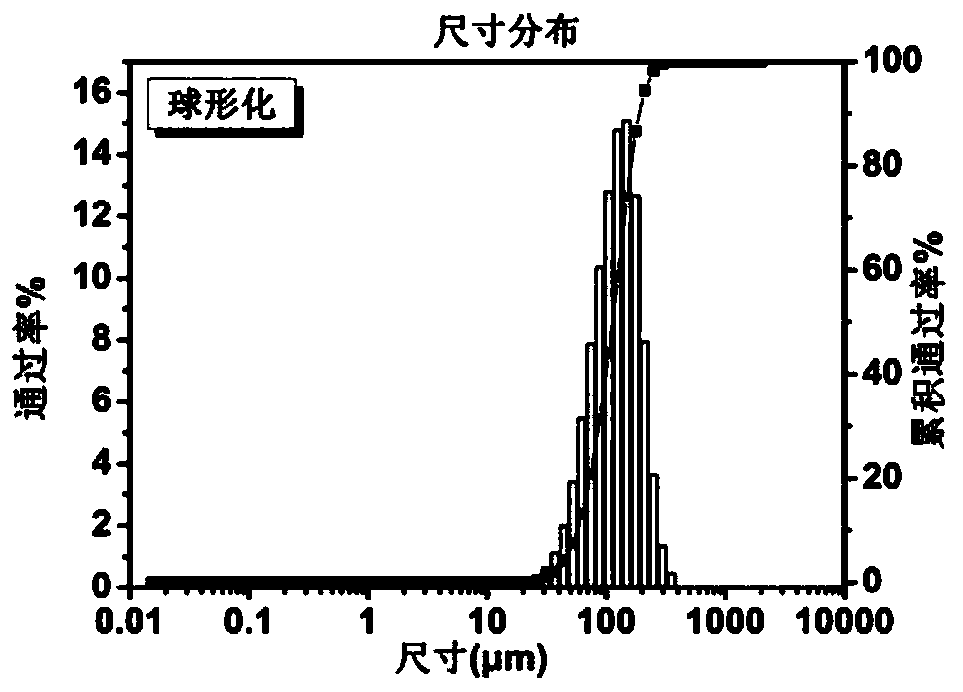

Polymer-based micro/nano functional composite spherical powder and preparation method thereof

The invention belongs to the field of macromolecules, and particularly relates to polymer-based micron / nano functional composite spherical powder and a preparing method thereof. According to the method, polymer-based micron / nano functional composite ultrafine powder compact in combination and uniform in scattering is obtained through solid-phase shearing grinding, and the powder grain size rangesfrom 30 microns to 200 microns; the above functional composite powder is evenly scattered in a scattering agent to be heated to the temperature above the heating deformation temperature of the functional composite powder for spheroidization treatment; and then heated suspension liquid is cooled, filtered, washed, dried and screened, and the functional composite spherical powder is obtained. The method is simple in operation, economical and environment-friendly, and large-scale preparing of the polymer-based micron / nano functional composite spherical powder can be achieved. The beneficial effects that the degree of sphericity is high, size distribution is narrow, the inner structure is uniform, and mobility and stacking density are high are achieved. The functional composite powder preparedthrough the method can meet the selective laser sintering requirement and can also be applied to the fields of the biomedical engineering, super capacitors, coatings, cosmetics and the like.

Owner:SICHUAN UNIV

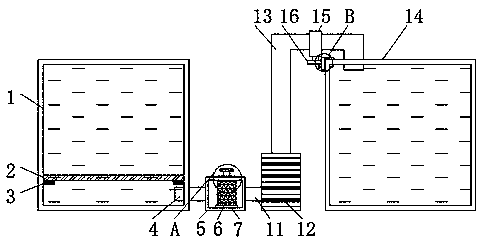

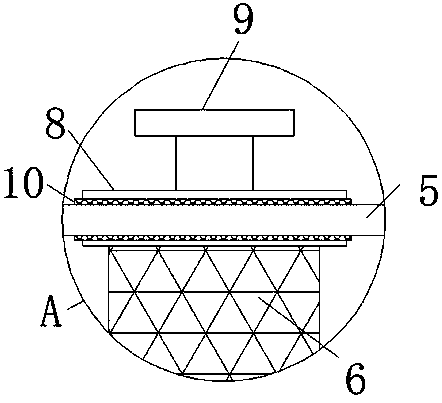

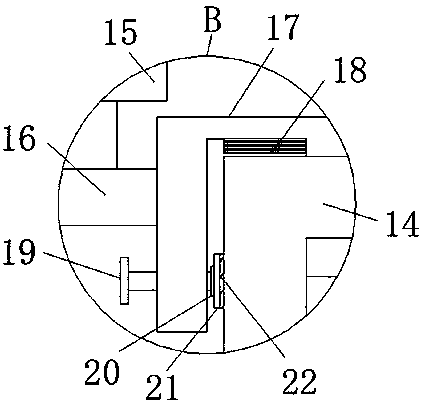

Water tank water resource recycling device

InactiveCN109744182AEasy to clean and recycleSolve the problem of wasting a lot of water resourcesPisciculture and aquariaEngineeringWater quality

The invention relates to the technical field of environment protection equipment, and discloses a water tank water resource recycling device, which comprises a first water tank. A filter screen is movably connected to the bottom of the inner wall of the first water tank, a filter chamber is fixedly connected to the bottom of the side face of the first water tank through a water guiding pipe, a filter element is clamped into the filter chamber, a water suction pump is fixedly connected to one side of the filter chamber through a water suction pipe, a water outlet pipe is fixedly connected to the top of the water suction pump, and the end, away from the water suction pump, of the water outlet pipe extends into a second water tank and is movably connected with the second water tank. The filter screen is used for filtering fish scales and impurities in the first water tank, the filter element is used for purifying and filtering water discharged from the first water tank so that water withthe water quality can be secondarily used, the purified water is guided into the second water tank to be collected for standby use through the water suction pump, the advantage of cleaning and recycling water discharged from the water tanks conveniently is achieved, and the problem of waste of a large amount of water resources due to direct discharging of water in the water tanks is solved.

Owner:江都区小纪镇恺胜体育用品厂

Fallen leaf recovery device for garden engineering

InactiveCN112359762AAvoid damageEfficient dischargeRoad cleaningGrain treatmentsAgricultural engineeringMechanical engineering

The invention discloses a fallen leaf recovery device for garden engineering. The fallen leaf recovery device comprises a recovery device body, a main absorption device is movably installed in the center of the inner side of the front face of a protective shell, a smashing box is movably installed at the top end of the front face of the protective shell, and a smashing device is movably connectedto the bottom end of the front face of an inner shaft. A first fallen leaf recycling box and a second fallen leaf recycling box are arranged on the inner side of the front face of the recycling devicebody. A first partition plate and a second partition plate are movably installed at the two ends of the front faces of the first and second fallen leaf recycling boxes. According to the fallen leaf recovery device for garden engineering, by starting a second driving motor, a secondary absorption device movably installed at the bottom end of the right side of the front face of the recovery devicebody absorbs fallen leaves on the ground, the secondary absorption device movably installed at the bottom end of the right side of the front face of the recovery device body is cuboid, and the bottomend is subjected to chamferring treatment; the second fallen leaf recovery box penetrates through the inner side of the front surface of the recovery device body, is hollow and can store the absorbedfallen leaves in the second fallen leaf recovery box.

Owner:浙江古思建筑科技有限公司

A kind of production method of saline heparin sodium

The invention discloses a production method of brine heparin sodium. The production method comprises the following five steps: preparation of a stock solution; enzymolysis; adsorption; elution; and precipitation. The production method is characterized in that in the step of preparing the stock solution, a raw material is originated from brine for treating a semi-finished product casing; parameter adjustment is carried out in the enzymolysis step to guarantee correspondence with components of the stock solution so as to ensure the enzymolysis effect. The method disclosed by the invention is suitable for producing the brine heparin sodium, wherein the raw material is originated from casing processing brine. The heparin component in the small intestine of a pig can be fully extracted to avoid waste on raw materials, so that the extraction efficiency and the production efficiency of the brine heparin sodium can be improved.

Owner:广东华赢医疗科技有限公司

Method for treating silicon in waste oil sand generated in silicon ingot cutting process

InactiveCN102689905AOvercome complicated processSolve waste accumulation and environmental pollutionSilicon carbideSilicon compoundsSilica fumeChemistry

The invention provides a method for treating silicon in waste oil sand which is generated in a silicon ingot cutting process. The method comprises the following steps of: washing the waste oil sand in alkali liquor for a certain period of time in a countercurrent mode to dissolve silicon powder, a small amount of iron, copper and residual polyethylene glycol (PEG) in the waste oil sand; separating the mixture to obtain waste oil sand solid and liquid which is obtained after washing; adding alkali into the liquid which is obtained after washing till the solution reaches a certain concentration; washing the waste oil sand once again; repeating the steps of adding the alkali and washing the waste oil sand for several times; washing the waste oil sand by using pure water; separating to obtain silicon carbide (SiC) solid and liquid which is obtained after washing; drying the SiC, and recycling; adding the alkali into the liquid which is obtained after washing to obtain a washing solution for washing other waste oil sand; and when the concentration of the silicon in the liquid which is obtained after washing reaches the needed concentration, collecting, and thus obtaining silica sol. In the whole treatment process, materials are recycled in a closed mode, and the method is pollution-free, environment-friendly (waste water cannot be generated and discharged), low in consumption and economic. By the method, the defects of complex process flows, low efficiency, high energy consumption, long treatment cycle, severe environmental pollution and the like which commonly exist in the prior art of recycling the silicon are overcome, and the problems of the accumulation of waste residues and environmental pollution in industries are solved effectively.

Owner:JIANGNAN UNIV +1

A microbial fuel cell

ActiveCN105552416BReasonable designNovel structureFuel cell auxillariesBiochemical fuel cellsMicrobial fuel cellElectricity

The invention belongs to the technical field of microbiological batteries, and specifically relates to a microbiological fuel battery. The microbiological fuel battery comprises a box body, a box cover, an anode chamber and a cathode chamber, wherein the box body is provided with the box cover, one end of the box cover is connected with the box body through a rotating shaft, the box cover is provided with an anode terminal and a cathode terminal, the box body is internally provided with the anode chamber and the cathode chamber, the anode chamber and the cathode chamber are spliced together through a snap joint, a neck and a bolt, the spliced part is provided with a sealing ring, a separation neck is arranged at the spliced part of the anode chamber and the cathode chamber, the separation neck is internally provided with a proton exchange membrane, and the proton exchange membrane separates the anode chamber from the cathode chamber. The microbiological fuel battery has the positive effects of being rational in design, being novel in structure, being convenient to dismount and discharge liquid, being convenient to clean and recycle, not only satisfying usage of a experimental stage, but also being usable for daily electricity consumption, and thereby improving utilization rate of biological fuel batteries.

Owner:临沂星火知识产权服务有限公司

A hot saw device for metal processing with self-cleaning function

ActiveCN108544016BEasy to moveAchieve reductionMetal sawing devicesMetal sawing accessoriesDrive shaftMetal machining

The invention discloses a metal machining hot sawing device with a self-cleaning function. The metal machining hot sawing device comprises a device body, an air cylinder is installed in the device body, a base is connected to the air cylinder through a pushing rod, a motor is installed on the upper portion of the base, and a cutting sheet is rotatably connected to one side of the motor through a driving shaft; a guiding groove is formed in the lower portion of a baffle, and a penetrating hole is formed in the middle of the guiding groove; first spray heads are installed on the inner wall of the baffle, and a mother pipe is connected to the corresponding sides of the first spray heads through a first water feeding pipe; an oblique plate is installed on the lower portion of the guiding groove, the oblique plate and the guiding groove jointly form a containing cavity, and filter screens are arranged in the containing cavity; and a water replenishing tank is connected to an outlet of the oblique plate and connected with a water pump through a water return pipe. According to the metal machining hot sawing device with the self-cleaning function, fragments generated at high temperature can be easily and conveniently removed and recycled in the hot sawing machining process, cooling water treatment is achieved, cooling water recycling is achieved, and the service life of the device is prolonged.

Owner:南理工泰兴智能制造研究院有限公司

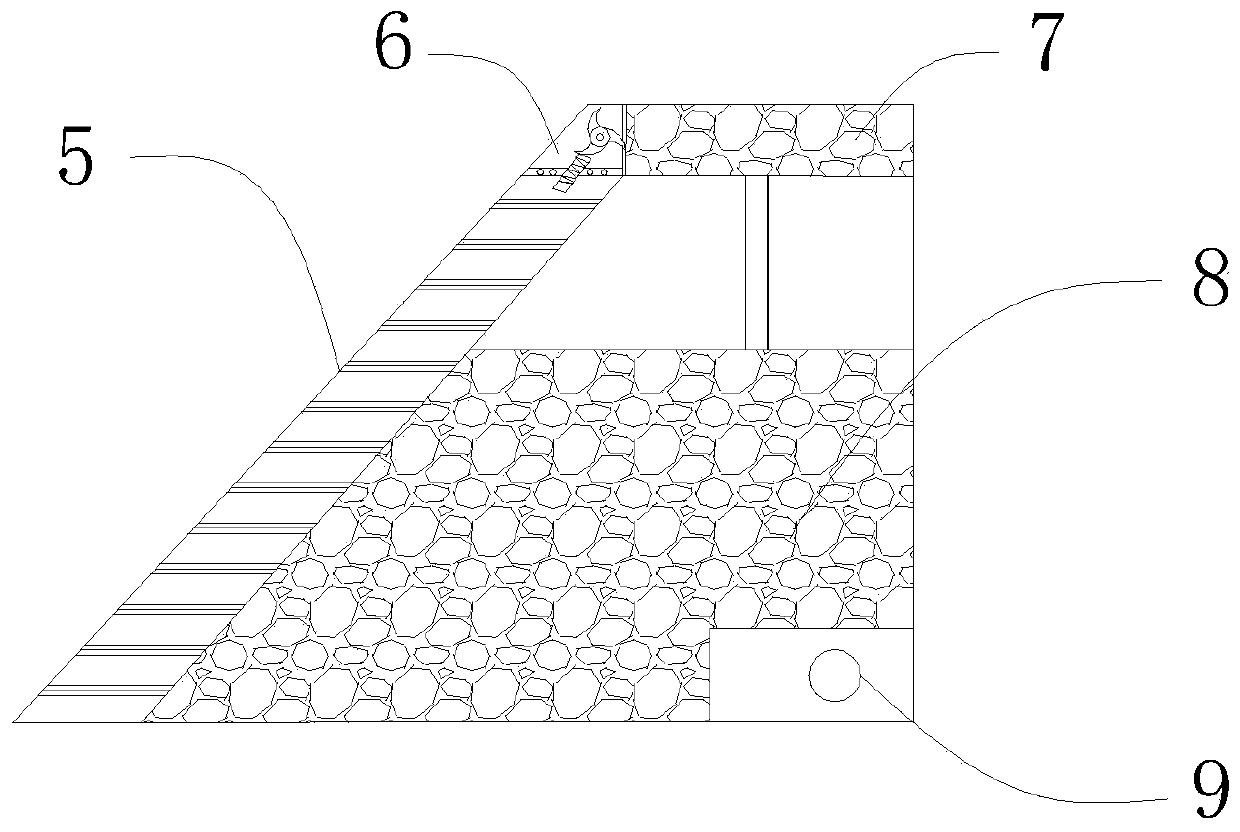

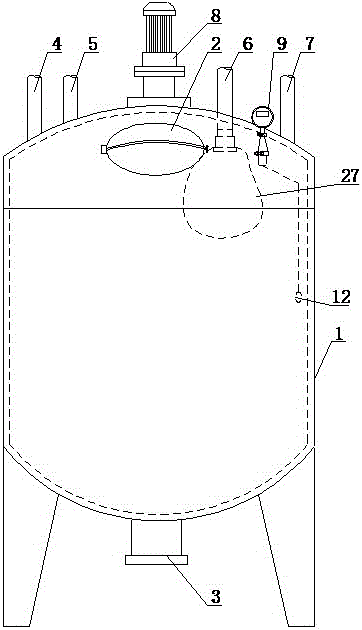

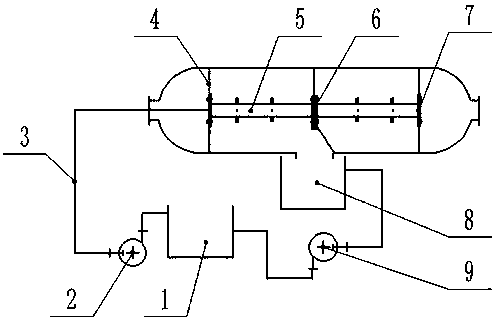

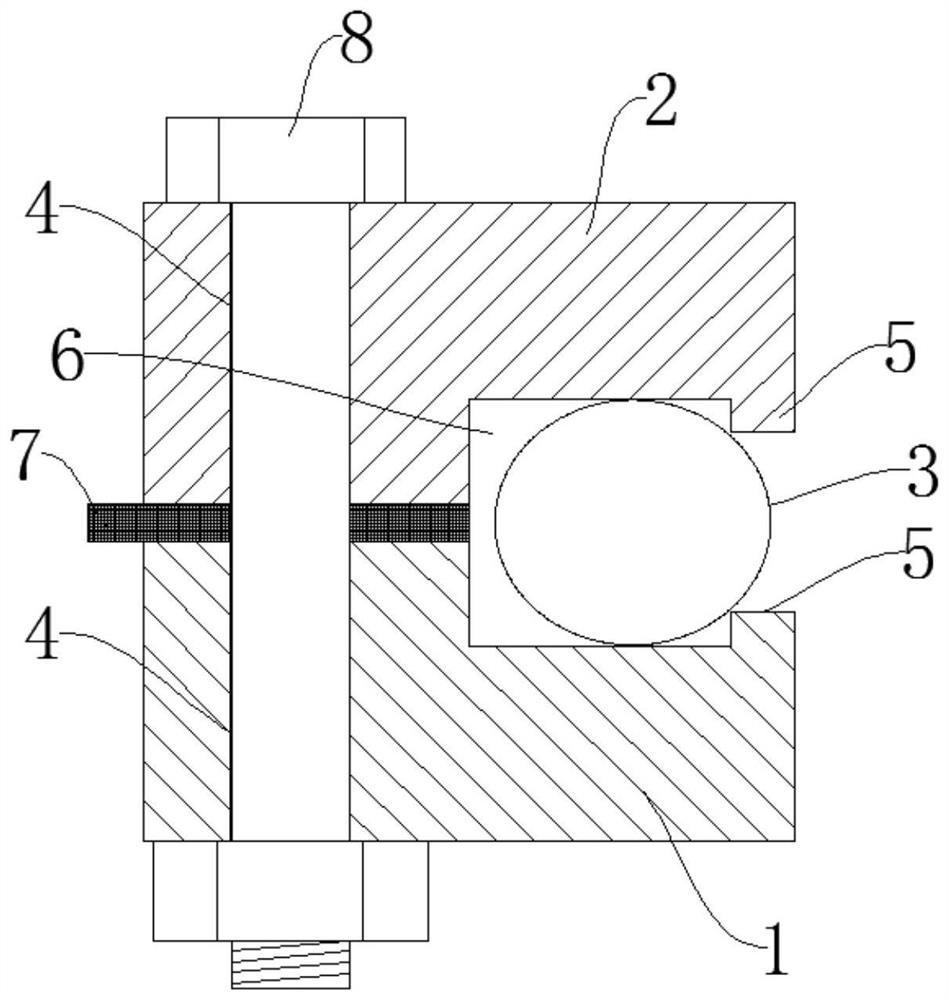

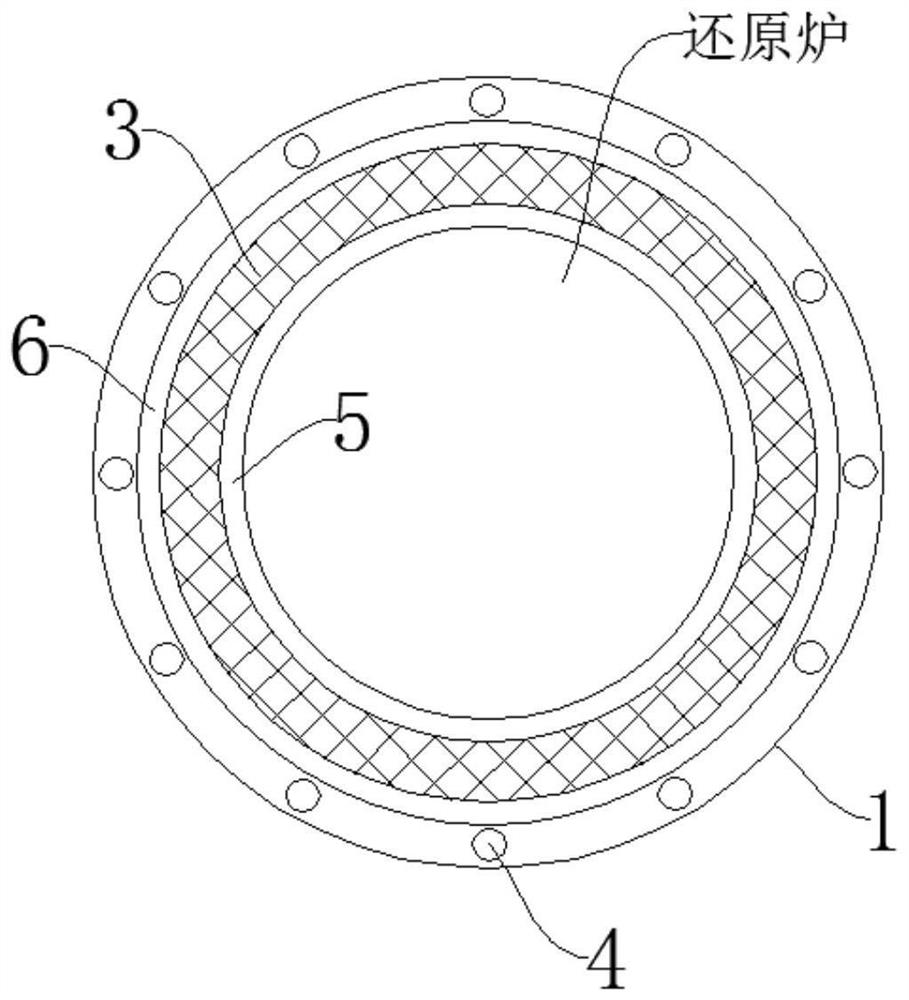

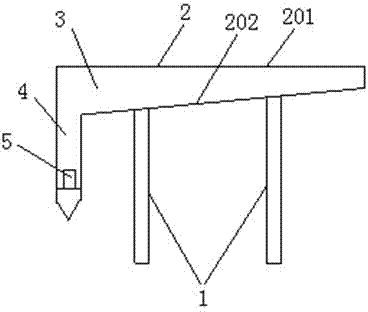

Large container interior cleaning and sprinkling device and using method

InactiveCN108941102AImprove working environmentReduce labor intensityHollow article cleaningWorking environmentLarge vessel

The invention discloses a large container interior cleaning and sprinkling device and a using method and relates to cleaning of large containers, and the problems that the work environment is poor, and cleaning liquid cannot be recycled in the prior art are solved. The large container interior cleaning and sprinkling device structurally comprises an acidic liquid preparing groove (1), a circulating pump (2), an acid-resistant hose (3), a supporting structure (4), a sprinkling pipe (5), a connecting flange (6), a blind plate (7), a recycling groove (8) and a recycling pump (9), wherein the circulating pump (2) is arranged in the acidic liquid preparing groove (1), and an outlet of the circulating pump (2) is connected to the sprinkling pipe (5) through the connecting flange (6) by using theacid-resistant hose (3); the recycling pump (9) is placed in the recycling groove (8), and an outlet of the recycling pump (9) is connected with the acidic liquid preparing groove (1) by using the acid-resistant hose (3); the sprinkling pipe (5) is fixed by the supporting structure (4), the circumference of the sprinkling pipe (5) is provided with uniformly distributed sprinkling holes, and the hole forming positions of the sprinkling holes are staggered; the handle head tail end of the sprinkling pipe (5) is blocked by using the blind plate (7); and all materials are acid-resistant materials. Cleaning liquid can be supplemented in time in the running process. Due to the large container interior cleaning and sprinkling device, the labor intensity is lowered, the work efficiency is high, and the large container interior cleaning and sprinkling device is environment-friendly and saving and especially suitable for cleaning of ultra-large type containers.

Owner:LANZHOU LS HEAVY EQUIP

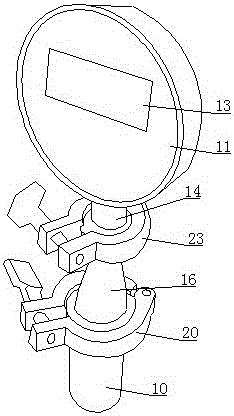

Supporting device for neurosurgery operation

InactiveCN114569390AEasy to useEasy to sitOperating tablesWaste collection and transferSurgical operationEngineering

The invention relates to the technical field of medical instruments, and discloses a neurosurgery operation supporting device which comprises a cabinet body and a bed board, the bed board comprises a first supporting plate, the two ends of the first supporting plate are rotationally connected with a second supporting plate and a third supporting plate respectively, and a containing cavity is fixedly connected between the bottom of the first supporting plate and the inner bottom of the cabinet body; a first hydraulic rod used for supporting the second supporting plate is installed on the containing cavity, a second hydraulic rod used for supporting the third supporting plate is installed at the bottom of the cabinet body, a rotating plate is arranged on the first supporting plate in a penetrating mode, one end of the rotating plate is rotationally connected with the first supporting plate, and a through groove is formed in one side of the containing cavity in a penetrating mode. A garbage can is arranged on the through groove in a sliding fit mode, and an adjusting assembly connected with the rotating plate in an assembled mode is installed in the containing cavity. Clean placement of a patient can be achieved, the whole structure is flexible and convenient to use, use by the patient is facilitated, and cleaning and recycling are more convenient.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

Construction method of cable-stayed cable-stayed bridge for large-scale coal-handling trestle in power station with steel structure

ActiveCN106348034BReduce pollutionEasy to clean and recycleBridge structural detailsStorage devicesPower stationCable stayed

Owner:中能建建筑集团有限公司

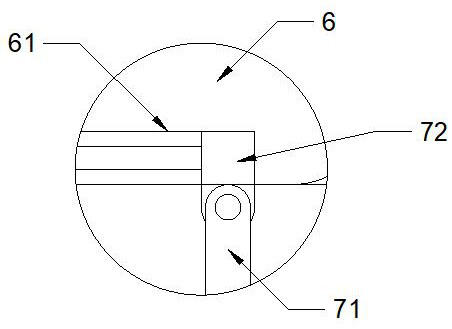

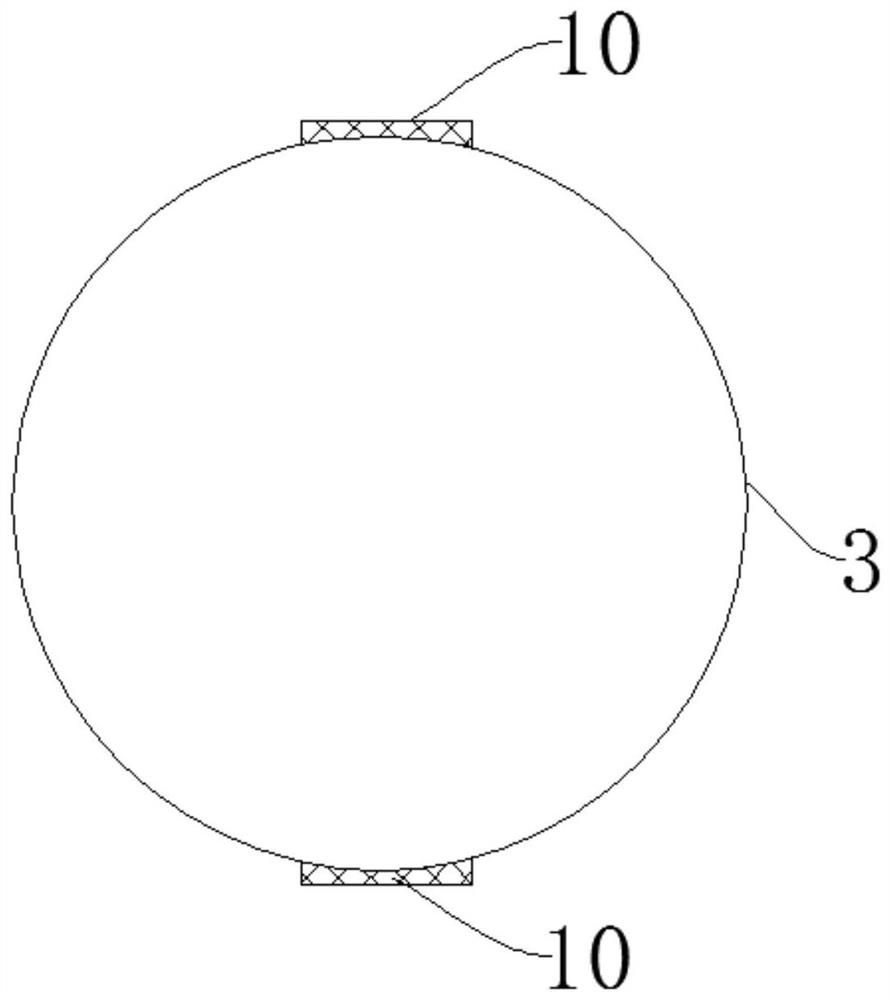

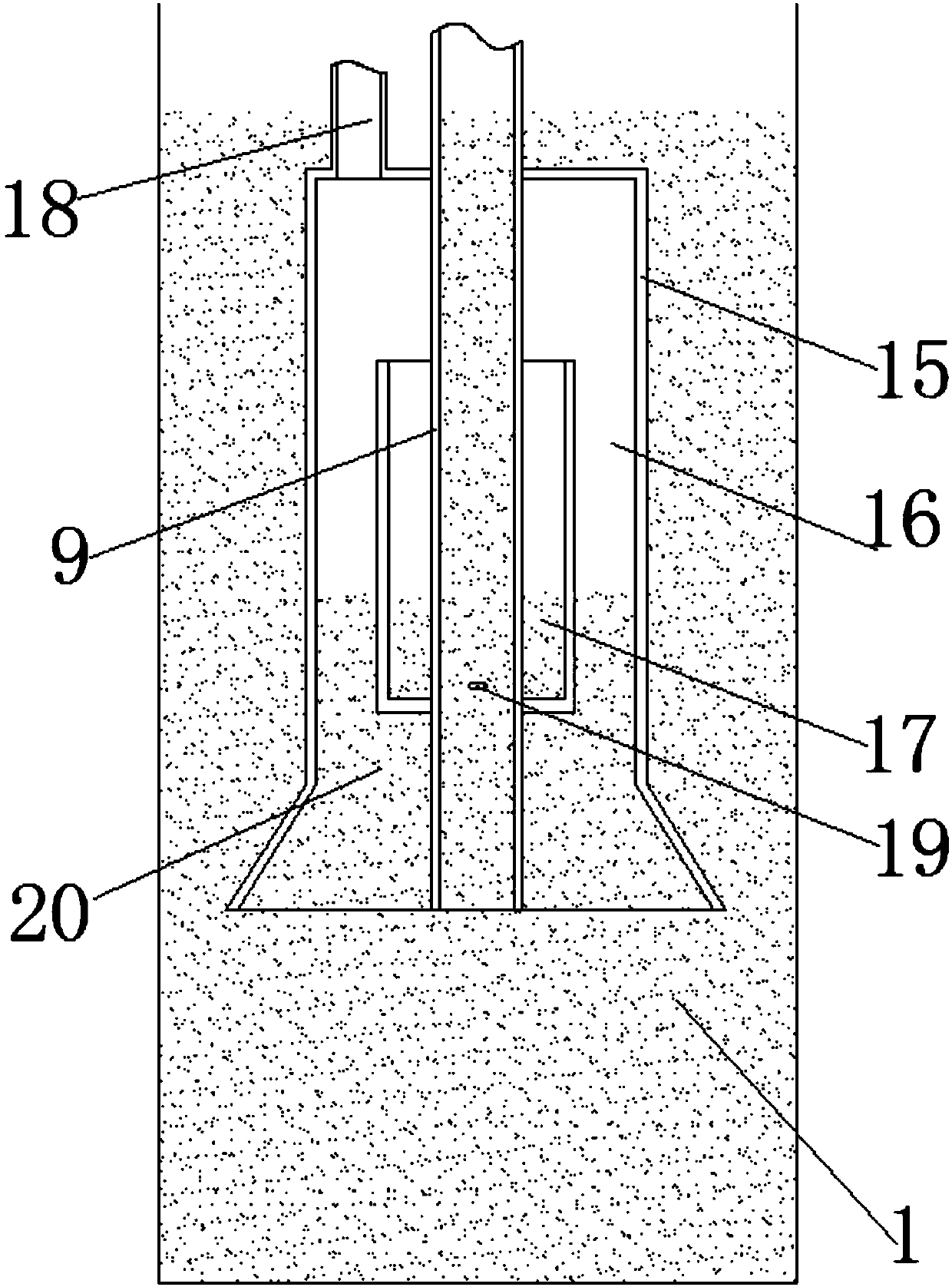

A sealing structure and method for a polysilicon reduction furnace

ActiveCN109879288BEasy to clean and recycleImprove sealingSilicon compoundsMetallic materialsNatural state

The invention discloses a polycrystalline silicon reduction furnace sealing structure and method. The sealing structure comprises a reducing furnace base plate flange, a bell jar flange and a metal pad rings, wherein the metal pad rings are arranged between the reducing furnace base plate flange and the bell jar flange; the reducing furnace base plate flange and the bell jar flange are in oppositearrangement; screw bolt fixing holes are uniformly formed in the outer sides of the reducing furnace base plate flange and the bell jar flange oppositely; step type clamp tables are arranged on the inner sides of the reducing furnace base plate flange and the bell jar flange oppositely; pad ring grooves are formed among the reducing furnace base plate flange, the bell jar flange and the step typeclamp tables; the metal pad rings are positioned in the pad ring grooves; the metal pad rings are elastic; in the natural state, the width of the upper and lower ends of the metal pad rings is greater than the height of the pad ring grooves. The rebounding force is provided through the self toughness of the metal materials; the sealing performance of the reducing furnace can be effectively ensured; through the inside and outside pressure differences, the surface of the metal rings is stressed from inside to outside; the rebounding force effect of the pad rings is further ensured; the sealingeffect is good; the cleaning is easy; the operation is convenient; the cyclic utilization can be realized.

Owner:ASIA SILICON QINGHAI +1

Device and method for avoiding sintering adhesion of magnetic core

PendingCN110491667AAvoid Sinter StickingAvoid wastingMagnetic core manufactureEngineeringMagnetic core

The invention discloses a device and a method for avoiding sintering adhesion of a magnetic core. The device for avoiding sintering adhesion of the magnetic core comprises a vibration disc, a heat preservation cover located above the vibration disc, a material guide groove located in one side of the vibration disc, a heater located below the heat preservation cover and a material collecting barrel. The vibration disc comprises a rack, a tray fixedly installed at the upper end of the rack, a vibrator fixedly installed on the lower end face of the tray, and a discharging groove fixedly installedon the outer side wall of the rack and communicated with the tray. And a buffer piece is arranged in the middle of the tray. The method for avoiding sintering adhesion of a magnetic core comprises the following steps: 1) pouring aluminum powder into the vibration disc; 2, conveying the magnetic core to the middle part of the tray to be in contact with aluminum powder; 3, vibrating and dischargingby the magnetic core through the vibrating disc; 4, entering sintering furnace for sintering. The device and method for avoiding sintering adhesion of the magnetic core have the advantages of being simple in structure, convenient to operate, low in cost, high in efficiency and high in product percent of pass.

Owner:ZHUHAI JIACI ELECTRONICS

A kind of preparation method of superfine zirconium powder

InactiveCN104289709BReduce surface activityInhibition of growth behaviorCoatingsMicro nanoZirconium hydride

The invention relates to a preparation method for superfine zirconium powder, in particular to a technical method utilizing a sodium salt and / or potassium salt to coat zirconium hydride to prepare micro-nano-scale zirconium powder, and belongs to the technical field of superfine metal powder. The technical method comprises the following steps: taking the sodium salt as a coating agent, mixing the zirconium hydride particles with the coating agent according to a mass ratio of (5-15):1, conducting wet grinding and vacuum drying to obtain the superfine zirconium powder of which surface is coated with the coating agent uniformly, dehydrogenizing in a vacuum environment at 550-680 DEG C, and conducting wet grinding dispersion and elution on the product to remove the coating agent so as to obtain the superfine zirconium powder, wherein the vacuum degree is controlled at 0.05-0.1 Pa in the dehydrogenation process. The preparation method disclosed by the invention is simple in preparation technology, convenient to control, and safe in operation technology; the obtained product is good in quality; the preparation method facilitates industrialized application.

Owner:CENT SOUTH UNIV

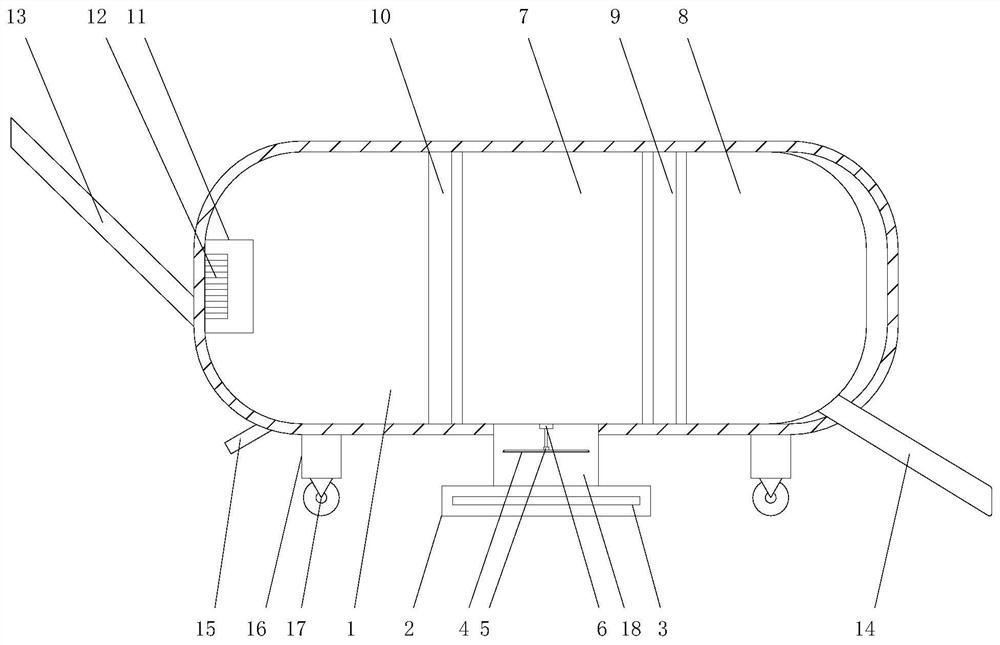

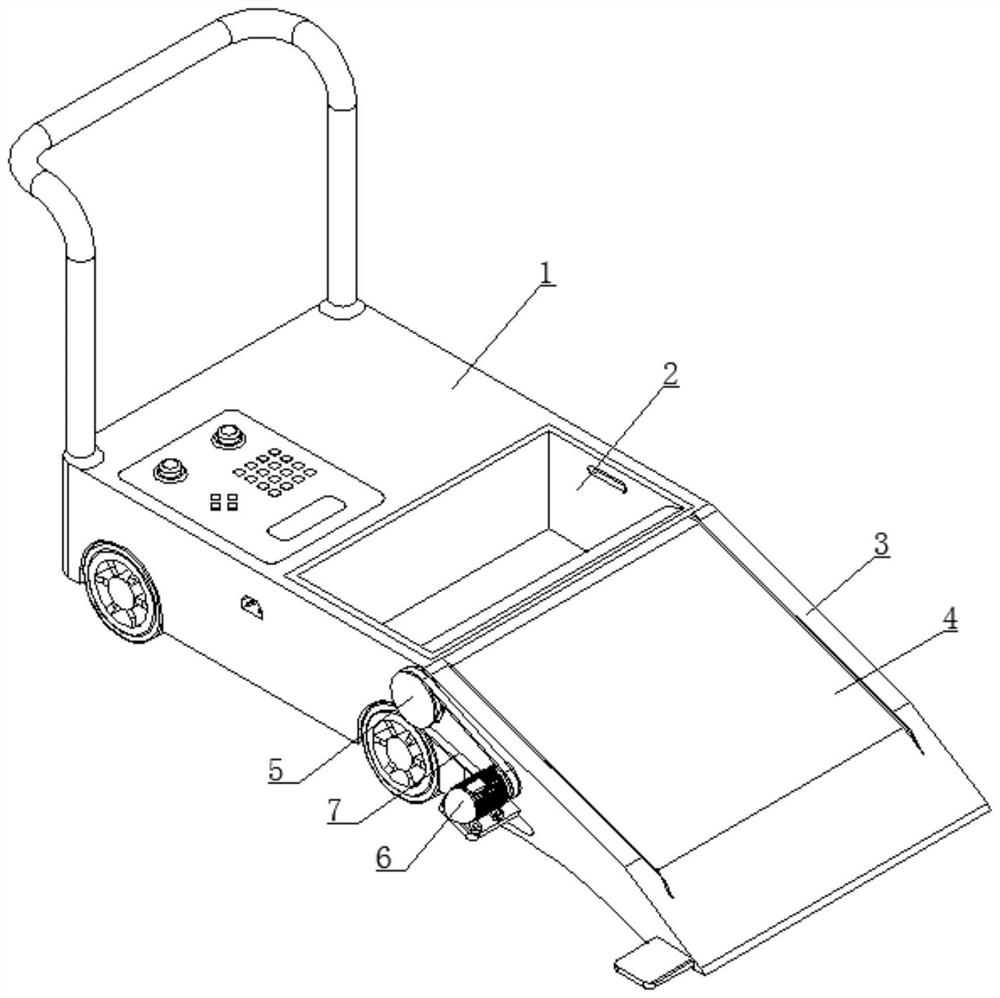

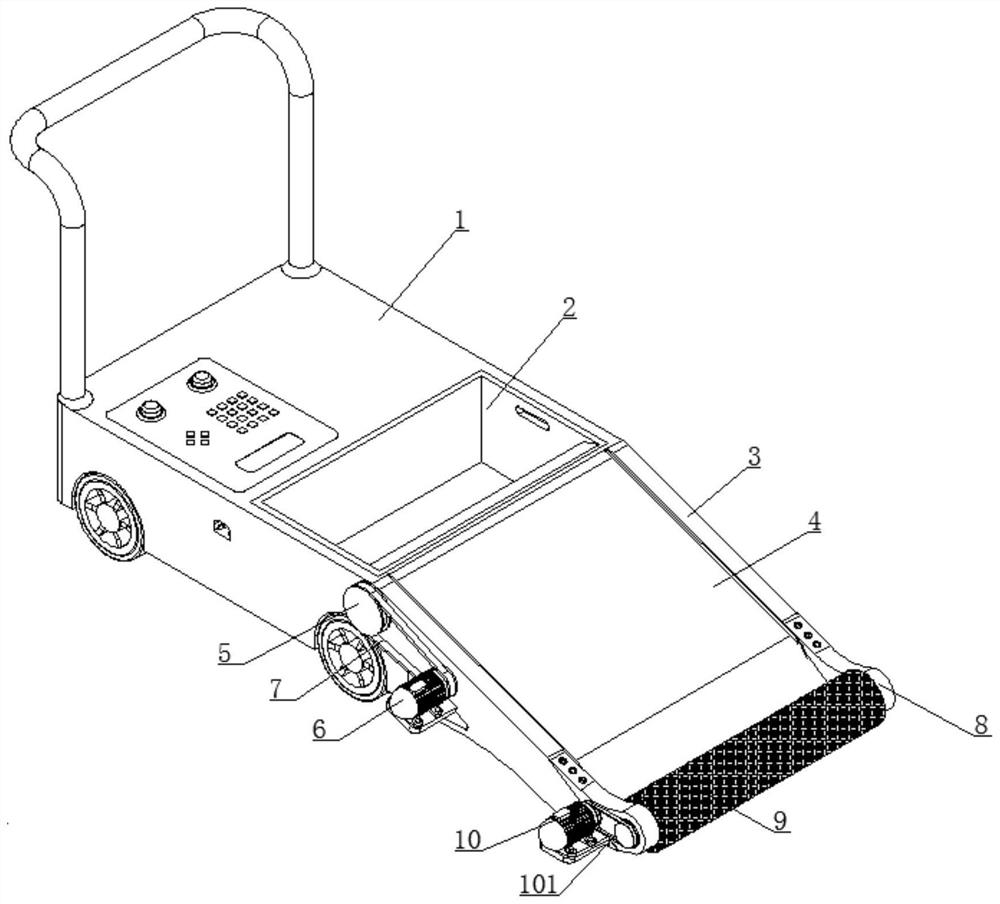

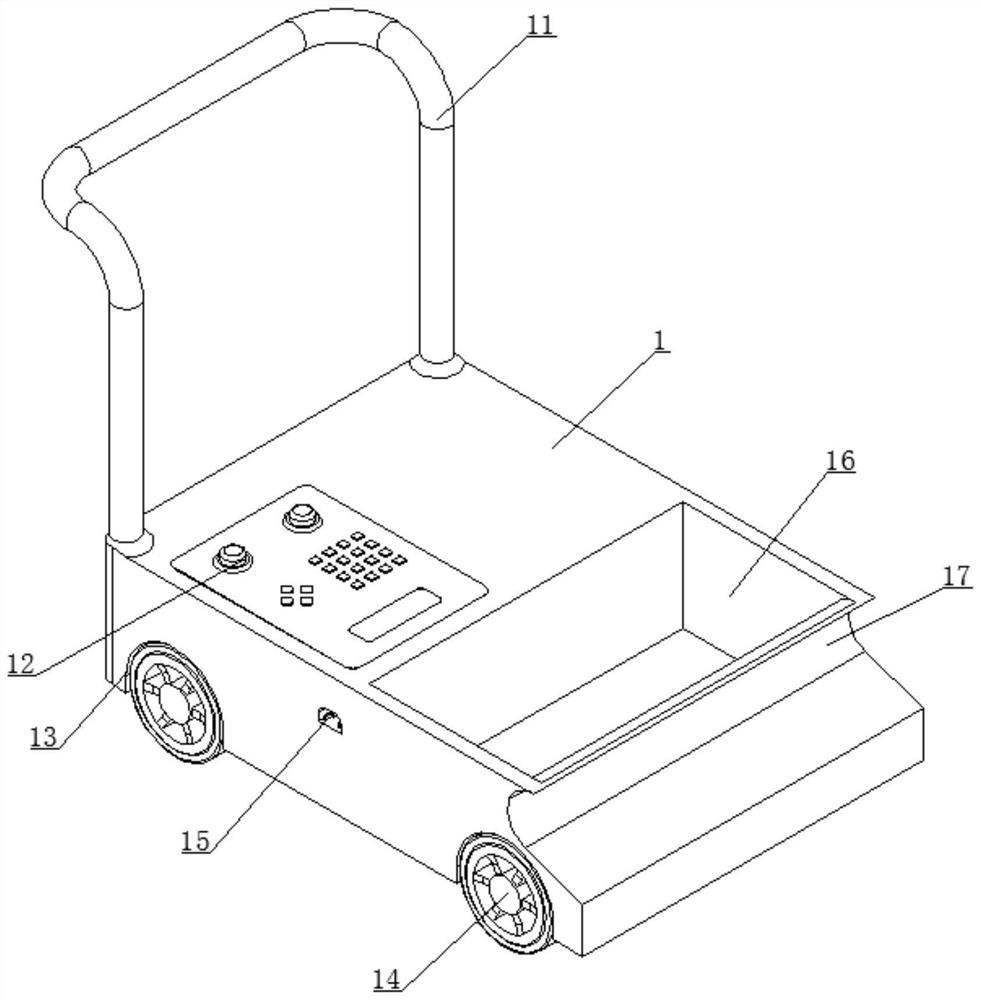

Automatic waste cleaning and recycling device

InactiveCN113026630AEasy to clean and recycleEasy to installRoad cleaningDrive shaftElectric machinery

The invention discloses an automatic waste cleaning and recycling device which comprises a transfer trolley, a storage box is arranged at the position, close to the front end, in the transfer trolley, the automatic waste cleaning and recycling device further comprises a conveying mechanism, the conveying mechanism comprises a mounting frame, a conveying belt, a transmission shaft, a first motor and a first belt, the top end of the mounting frame is against the front of the transfer trolley, the mounting frame and the transfer trolley are connected together through bolts, the conveying belt is arranged on the inner side of the mounting frame, transmission shafts are arranged at the two ends of an output belt, and one end of the transmission shaft arranged at the top end of the conveying belt extends out of the mounting frame. The invention solves the problems that during existing waste material cleaning and recycling, waste materials are manually cleaned, then the waste materials are loaded by a container and transferred, waste material cleaning and recycling efficiency is low and a large amount of manpower is wasted. The structure of the cleaning and recycling device is improved and optimized, so that the cleaning and recycling device can quickly clean the waste materials, and the swept waste materials can be conveyed into a temporary storage container while the waste materials are swept.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

Metal powder recovery device with magnet

The invention discloses a metal powder recovery device with a magnet. The metal powder recovery device comprises a supporting frame and a working table, wherein the bottom of the supporting frame is fixed on the horizontal ground; the working table is fixedly connected with the top of the supporting frame and comprises an upper table plate and a lower table plate; powder recovery holes are uniformly distributed in the upper table plate; the interior of the working table is hollowed to form a cavity; a recovery box is arranged on one side of the working table; the recovery box and the powder recovery holes are respectively communicated with the cavity. In the mode, the metal powder recovery device is used for magnetically recovering metal powder, contributes to cleanness and recovery, and is convenient and practical.

Owner:太仓万冠涂装设备有限公司

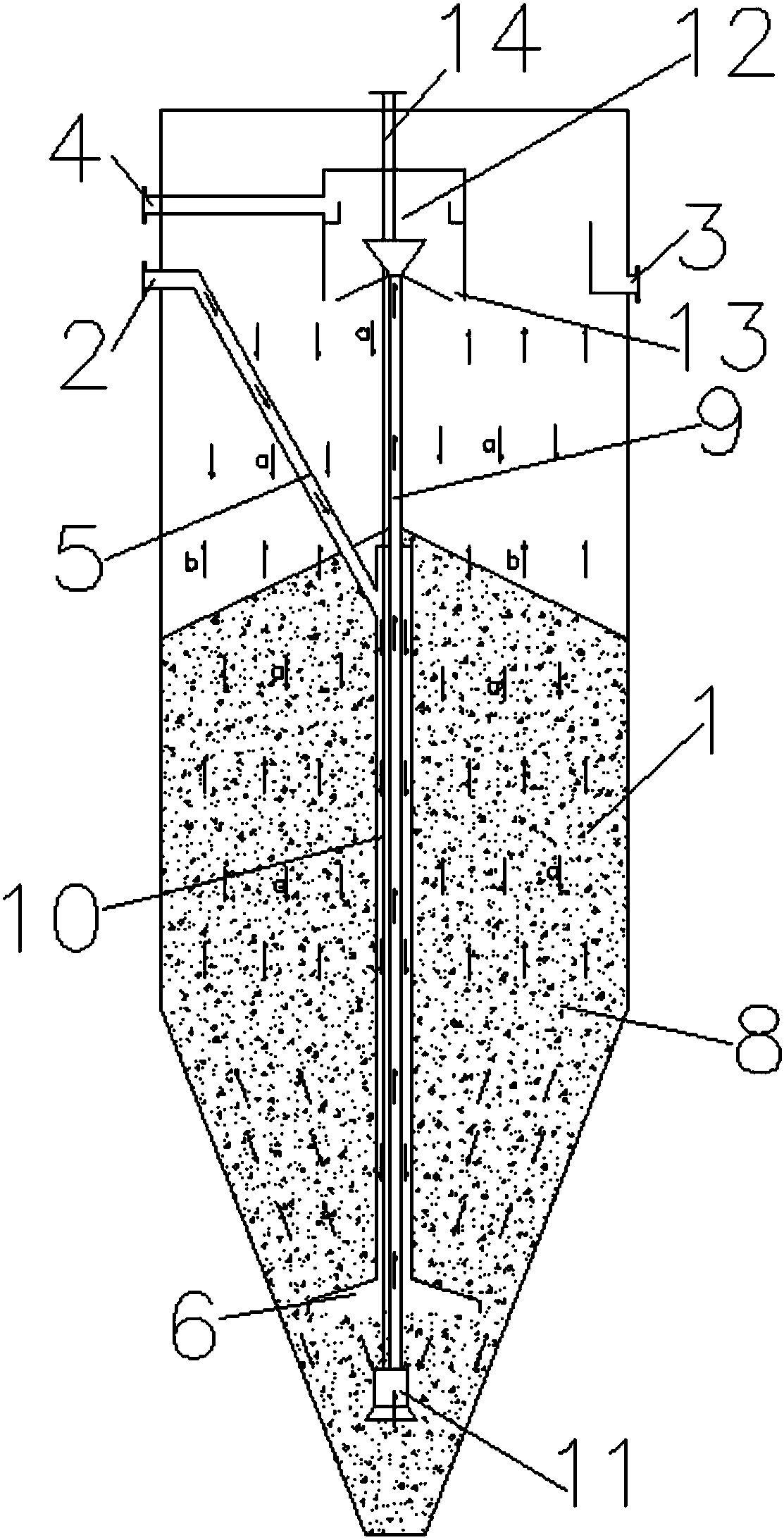

Air inlet type self-circulation filter

PendingCN107694169AEasy to clean and recycleImprove efficiencyLoose filtering material filtersGravity filtersEngineeringSewage

The invention discloses an air inlet type self-circulation filter, which comprises a filter body, a water inlet, a water outlet and an air inlet pipe, wherein a filtering material cabin is arranged atthe bottom of the filter body; the water outlet communicates with the upper side of the filtering material cabin; a water inlet pipe is arranged in the filter body and communicates with a vertical pipe; the vertical pipe is arranged at the middle part of the filter body; a water distributor is arranged at the bottom of the vertical pipe; a filtering material sucking pipeline is arranged in the vertical pipe in a sleeving way; a pulse type lifting pump is arranged at the bottom of the filtering material sucking pipeline; the top of the filtering material sucking pipeline is provided with a filtering material sucking device and a filtering material outlet; a filtering material cleaner is arranged at the filtering material outlet. The pulse type lifting pump and the filtering material cleaner are arranged in the filter; sewage and filtering materials at the inner bottom of the filter are lifted to the filtering material cleaner at the upper side for cleaning; after the cleaning is completed, filtering materials fall onto the upper part of the filter to continuously operate, so that the filtering materials in the filter are cyclically used and cleaned; the filtering material use efficiency and the filtering material cleaning degree are improved; the water outlet quantity is increased; the water outlet water quality is improved.

Owner:重庆林德科技发展有限公司

Riverway environmental protection and restoration system

The invention relates to a riverway environmental protection and restoration system, which belongs to the field of environmental protection, and comprises a riverway and bank bodies on both sides of the riverway, a support plate is arranged between the bank bodies on both sides, the support plate is arranged above the riverway, the bottom of the support plate is connected with an interception net, and the bottom of the interception net extends into the riverway and is located below the liquid level, a cavity is formed in the bottom wall of the supporting plate, a fishing mechanism is arranged in the cavity and located on the side, facing the upstream of the riverway, of the interception net, the fishing mechanism comprises a first rotating shaft, a second rotating shaft and a fishing plate, the first rotating shaft and the second rotating shaft are rotationally connected to the inner wall of the cavity, and driving gears are fixed to the first rotating shaft and the second rotating shaft, a driving toothed belt is wound on the two driving gears, a plurality of mounting plates are arranged on the driving toothed belt, the fishing plates are arranged on the sides, away from the driving toothed belt, of the mounting plates, and the end, facing the upstream of the riverway, of the first rotating shaft extends out of the supporting plate and is connected with a driving assembly. The system has the effect of improving the safety of salvaging personnel when salvaging garbage.

Owner:深圳贵人生态建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com