A sealing structure and method for a polysilicon reduction furnace

A technology of sealing structure and reduction furnace, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of large number of bolts, high sealing requirements, weakened resilience, etc., to facilitate cleaning and recycling, and reduce costs , the close effect between

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

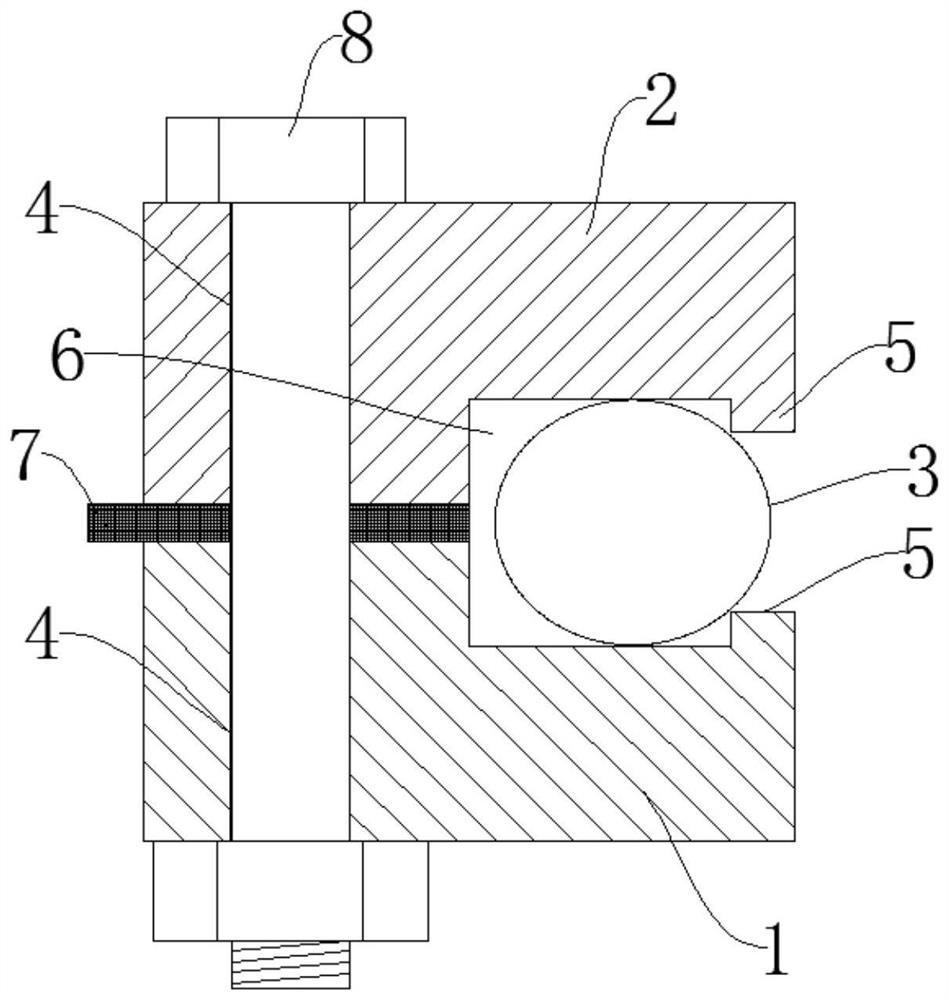

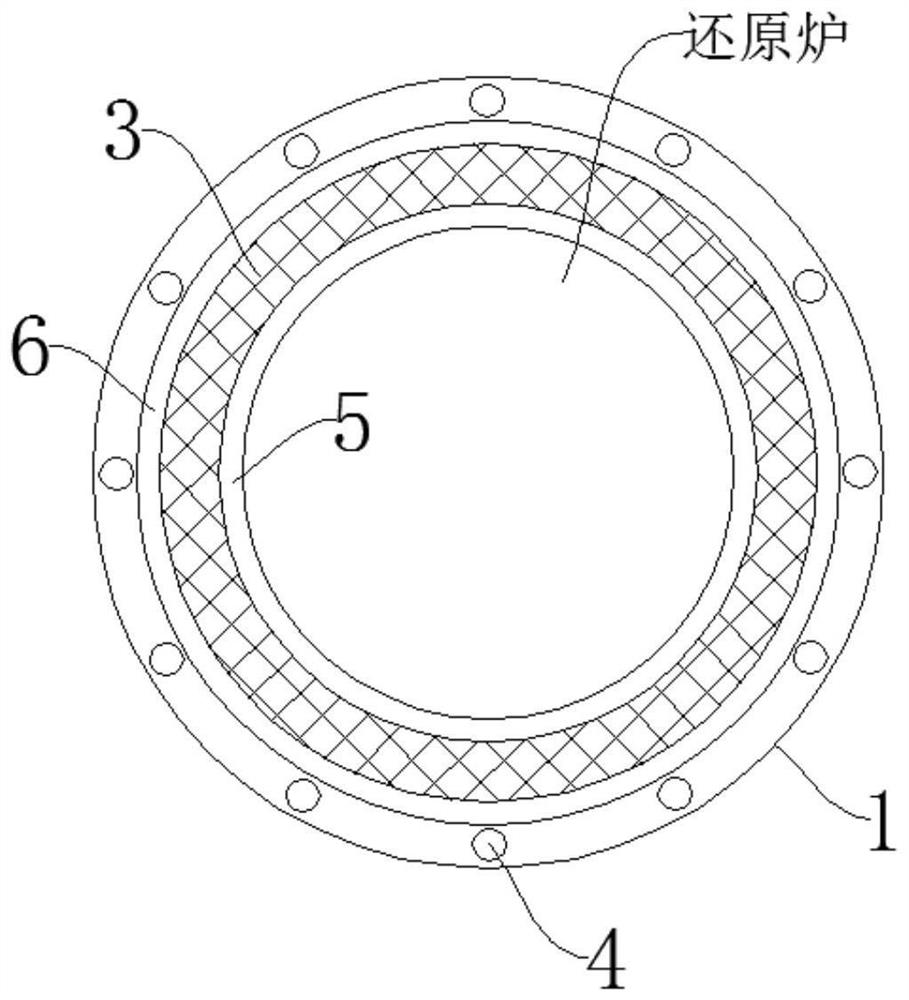

[0027] Embodiment 1, as shown in Figures 1-3, the present invention provides a polysilicon reduction furnace sealing structure, which is characterized in that it includes a reduction furnace chassis flange 1, a bell flange 2 and a flange 1 arranged on the reduction furnace chassis The metal backing ring 3 between the bell jar flange 2, the reduction furnace chassis flange 1 and the bell jar flange 2 are arranged oppositely, and the outer sides of the reduction furnace chassis flange 1 and the bell jar flange 2 are relatively evenly arranged There are bolt fixing holes 4, and the inner sides of the reduction furnace chassis flange 1 and the bell jar flange 2 are oppositely provided with stepped clamping platforms 5, the reduction furnace chassis flange 1, the bell jar flange 2 and the stepped clamping platforms 5 is a backing ring groove 6, the metal backing ring 3 is located in the backing ring groove 6, the metal backing ring 3 has elasticity, and the width of the upper and lo...

Embodiment 2

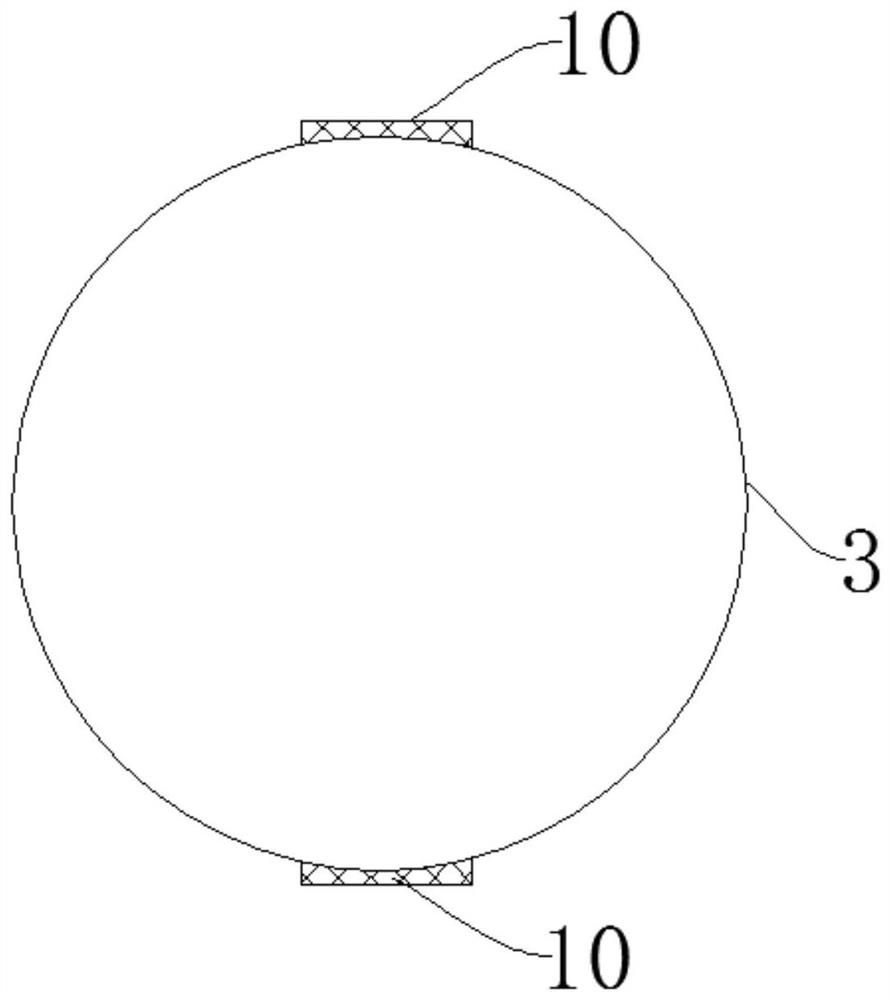

[0034] Embodiment 2, as shown in Figures 4-6, the present invention provides a polysilicon reduction furnace sealing structure, which is characterized in that it includes a reduction furnace chassis flange 1, a bell flange 2 and a flange 1 arranged on the reduction furnace chassis The metal backing ring 3 between the bell jar flange 2, the reduction furnace chassis flange 1 and the bell jar flange 2 are arranged oppositely, and the outer sides of the reduction furnace chassis flange 1 and the bell jar flange 2 are relatively evenly arranged There are bolt fixing holes 4, and the inner sides of the reduction furnace chassis flange 1 and the bell jar flange 2 are oppositely provided with stepped clamping platforms 5, the reduction furnace chassis flange 1, the bell jar flange 2 and the stepped clamping platforms 5 is a backing ring groove 6, the metal backing ring 3 is located in the backing ring groove 6, the metal backing ring 3 has elasticity, and the width of the upper and lo...

Embodiment 3

[0038]Embodiment 3, as shown in Figure 5, the present invention provides a sealing structure for a polysilicon reduction furnace, which is characterized in that it includes a reduction furnace chassis flange 1, a bell flange 2 and a method for setting the reduction furnace chassis The metal backing ring 3 between the flange 1 and the bell flange 2, the reduction furnace chassis flange 1 is set opposite to the bell flange 2, and the outer sides of the reduction furnace chassis flange 1 and the bell flange 2 are opposite Bolt fixing holes 4 are evenly arranged, and the inner sides of the reduction furnace chassis flange 1 and the bell jar flange 2 are oppositely provided with stepped clamping platforms 5, and the reduction furnace chassis flange 1, the bell jar flange 2 and the stepped type Between the decks 5 is a backing ring groove 6, the metal backing ring 3 is located in the backing ring groove 6, the metal backing ring 3 has elasticity, and the width of the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com