Large container interior cleaning and sprinkling device and using method

A technology for spraying devices and large containers, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of waste, bad working environment, and heavy labor, and achieve light and convenient portability and improve work Environment, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

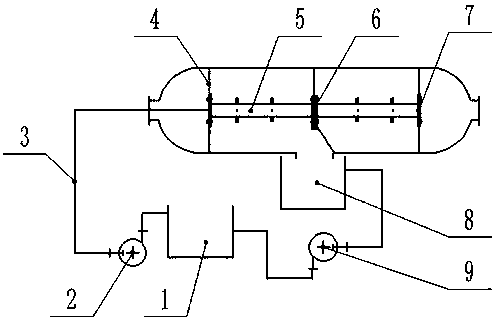

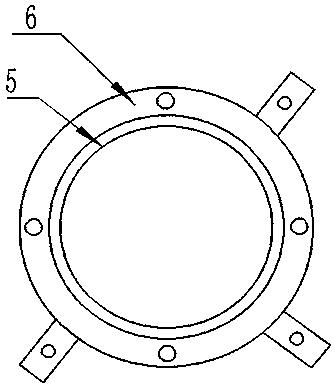

[0025] The specific embodiments of the present invention will be further described with reference to the drawings, such as figure 1 As shown, a spray device for cleaning the inside of a large container has the following structures: acid preparation tank 1, circulating pump 2, acid-resistant hose 3, support structure 4, spray pipe 5, connecting flange 6, blind plate 7, Recovery tank 8, recovery pump 9; wherein the circulation pump 2 is placed in the acid preparation tank 1, and its outlet is connected to the spray pipe 5 with an acid-resistant hose 3 through a connecting flange 6; the recovery pump 9 is placed in the recovery In the tank 8, its outlet is connected to the acid preparation tank 1 with an acid-resistant hose 3; the spray pipe 5 is fixed by the supporting structure 4, and the spray pipe 5 has evenly distributed spray holes on its circumference, and each spray hole The opening positions are misaligned with each other; according to the length of the cleaning container,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com