Polymer-based micro/nano functional composite spherical powder and preparation method thereof

A nano-functional, spherical powder technology, applied in the polymer field, can solve the problems of inability to prepare high-filling composite powder, unsatisfactory particle size, uneven dispersion of inorganic particles, etc., achieving easy implementation, breaking through technical bottlenecks, The effect of short spheroidization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of polymer-based micro / nano functional composite spherical powder comprises the following steps:

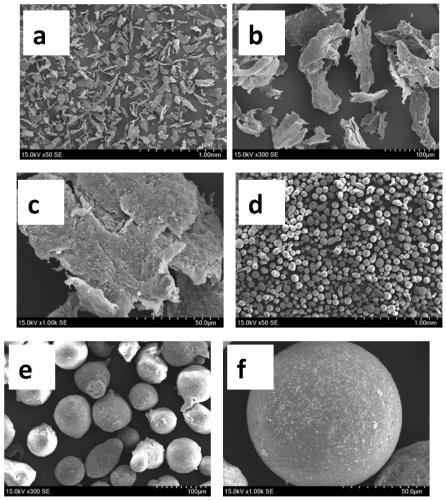

[0043] A. The first milling: Use a disc-type mechanochemical reactor to mix and mill the polymer pellets and inorganic functional particles to refine and mix the raw materials uniformly to obtain primary composite powders;

[0044] B. Melt extrusion: The primary composite powder is melt-extruded and pelletized to obtain composite particles; this step makes the polymer and inorganic functional particles bond together; but the particle size of the composite particles obtained in this step is millimeter-level, which cannot meet the requirements Use requirements, so it needs to be further pulverized and then spheroidized;

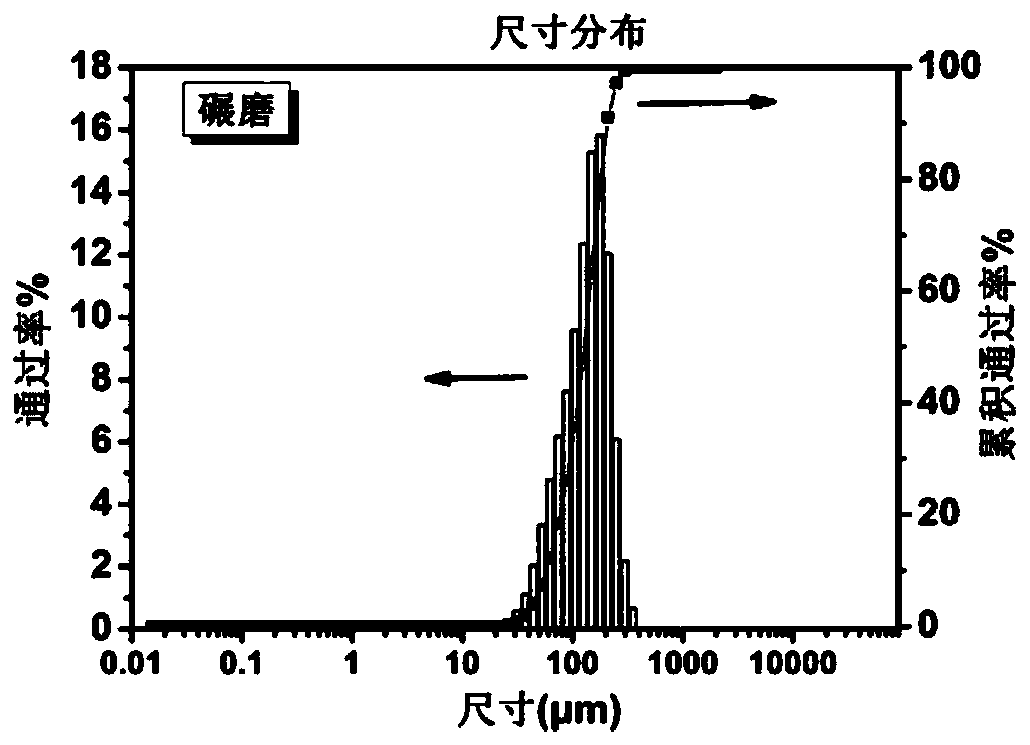

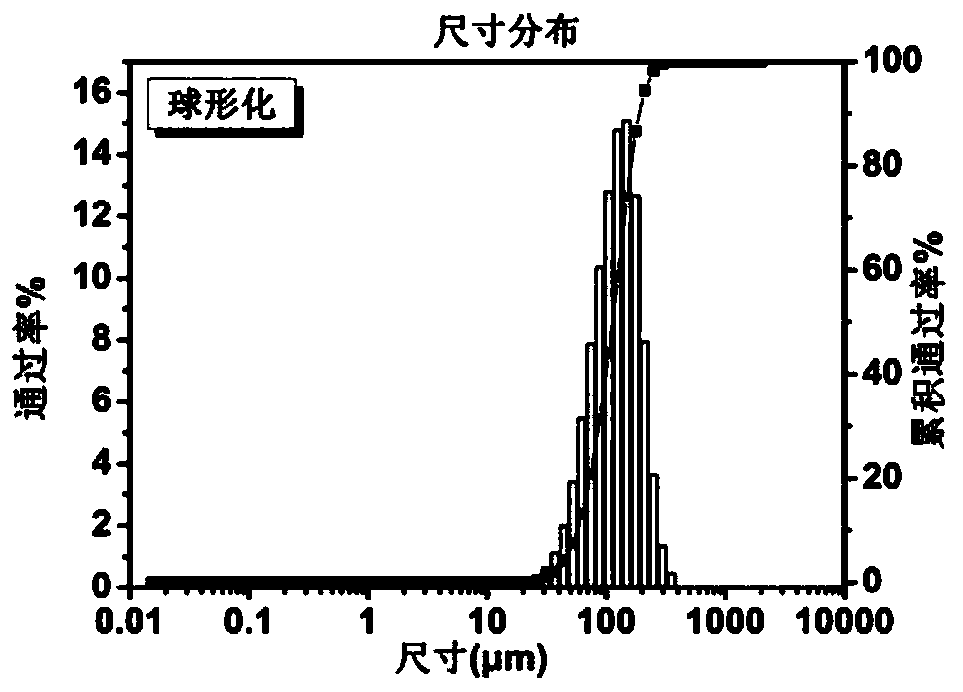

[0045] C. Second milling: Grinding the composite particles with a disc-type mechanochemical reactor to obtain a secondary composite powder with a suitable particle size, so as to finally obtain a micron or nanometer product with a sui...

Embodiment 1

[0058] Example 1: PA11 / BaTiO 3 Preparation of Piezoelectric Nanocomposite Spherical Powder

[0059] 800 g of nylon 11 (PA11) with a particle size of 2 to 5 mm and BaTiO with an average particle size of 500 nm 3 Piezoelectric nanopowder particles 200g and antioxidant 1,3,5-trimethyl-2,4,6(3,5-di-tert-butyl-4-hydroxybenzyl)benzene 9g and 2,2- Add 1 g of ethyl bis(4,6-di-tert-butylphenyl) fluorophosphite into the opened disc-type mechanochemical reactor through the feed port for mixing and grinding, and control the cooling cycle water temperature during the grinding process to 25°C, milling pressure 25MPa, milling speed 500rpm, after 10 times of milling, the first PA11 / BaTiO mixed evenly was obtained 3 Piezoelectric nanocomposite powder;

[0060] The PA11 / BaTiO obtained by grinding 3 The piezoelectric nanocomposite powder is melt-extruded in a twin-screw extruder, the extrusion temperature is controlled at 190-210°C and the extrusion speed is 80rpm, and then pelletized to obt...

Embodiment 2

[0067] Example 2: Preparation of polyvinylidene fluoride / hydroxyapatite nanocomposite spherical powder for biological tissue scaffolds

[0068]600g of polyvinylidene fluoride (PVDF) with a particle size of 2-5mm, 400g of hydroxyapatite nanopowder particles with an average particle size of 60nm, and N,N'-bis(3,5-di-tert-butyl-4 -Hydroxyphenylpropanamide) 8g and tetrakis(2,4-di-tert-butylphenyl) 2g are added into the opened disc type mechanochemical reactor through the feeding port for mixed grinding, and the cooling cycle is controlled during the grinding process The water temperature is 24°C, the grinding pressure is 20MPa, and the grinding speed is 800rpm. After 8 times of grinding, a uniformly mixed polyvinylidene fluoride / hydroxyapatite nanocomposite powder is obtained;

[0069] The polyvinylidene fluoride / hydroxyapatite nanocomposite powder obtained by grinding is melt-extruded in a twin-screw extruder, the extrusion temperature is controlled at 190-200°C and the extrusion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com