High efficient heterogeneous stirring equipment

A mixing equipment and heterogeneous phase technology, which is applied to mixer accessories, mixers with rotating stirring devices, cleaning hollow objects, etc., can solve the problems that the mixing equipment is difficult to clean effectively, and achieve convenience for subsequent operations, balance instability, The effect of increasing surface contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

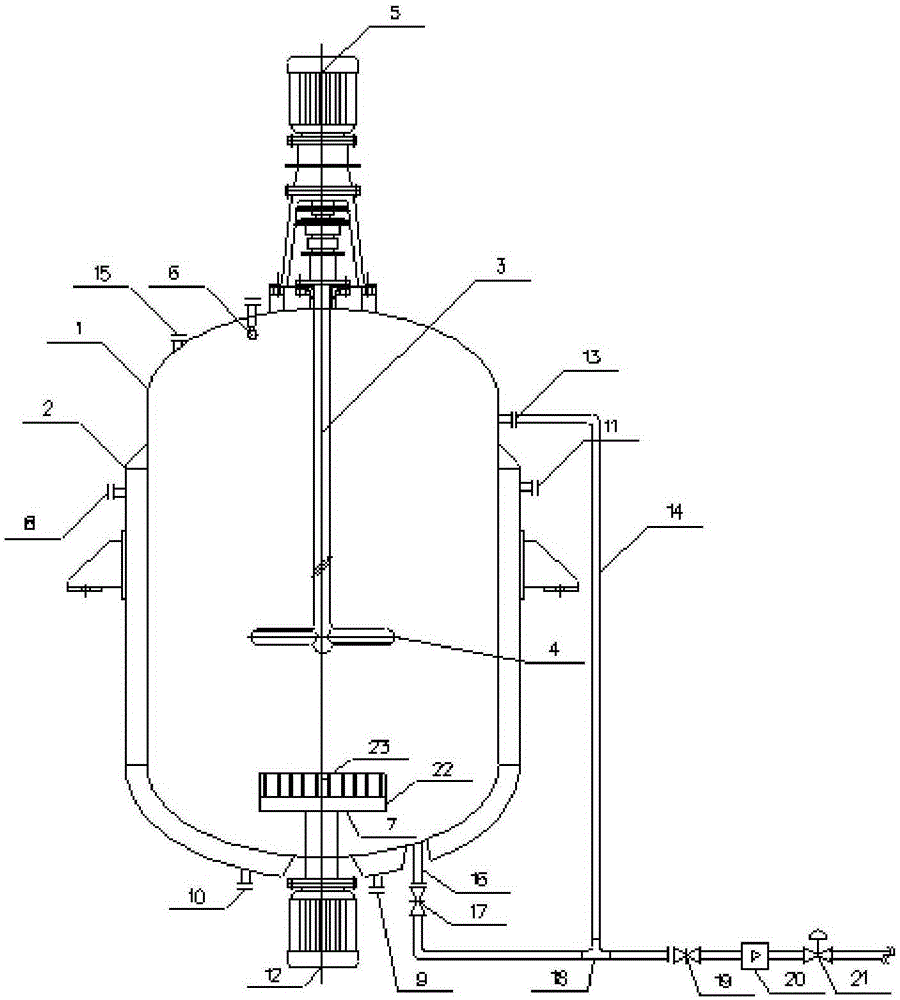

[0026] A high-efficiency heterogeneous mixing equipment, its structure is as follows figure 1 As shown, it is mainly composed of the following components: a kettle body 1, a jacket 2 is provided on the outside to feed steam and refrigerant, the steam inlet 8 is located at the upper part of the jacket 2, the steam condensate outlet 9 is located at the lower part of the jacket 2, and the refrigerant inlet 10 is located at the lower part of the jacket 2, and the refrigerant outlet 11 is located at the upper part of the jacket 2. The stirring shaft 3 controlled by the upper motor 5 is located in the kettle body 1, and the paddle stirrer 4 is connected to the lower end. The still body 1 is also provided with a gear shear agitator 7, which is controlled by a lower motor 12 arranged at the bottom of the kettle body 1 . The tray 22 of the gear shearing agitator 7 is fixed on the kettle body 1, and the inner circumference of the tray 22 is evenly distributed with strip grooves. The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com