Composite material and method for waterproofing maintenance of ballastless track using composite material

A ballastless track and composite material technology, applied in the field of materials, can solve the problems of brittle cracking of the coating surface and concrete vibration, and achieve the effects of resisting concrete vibration, strong shear stress and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

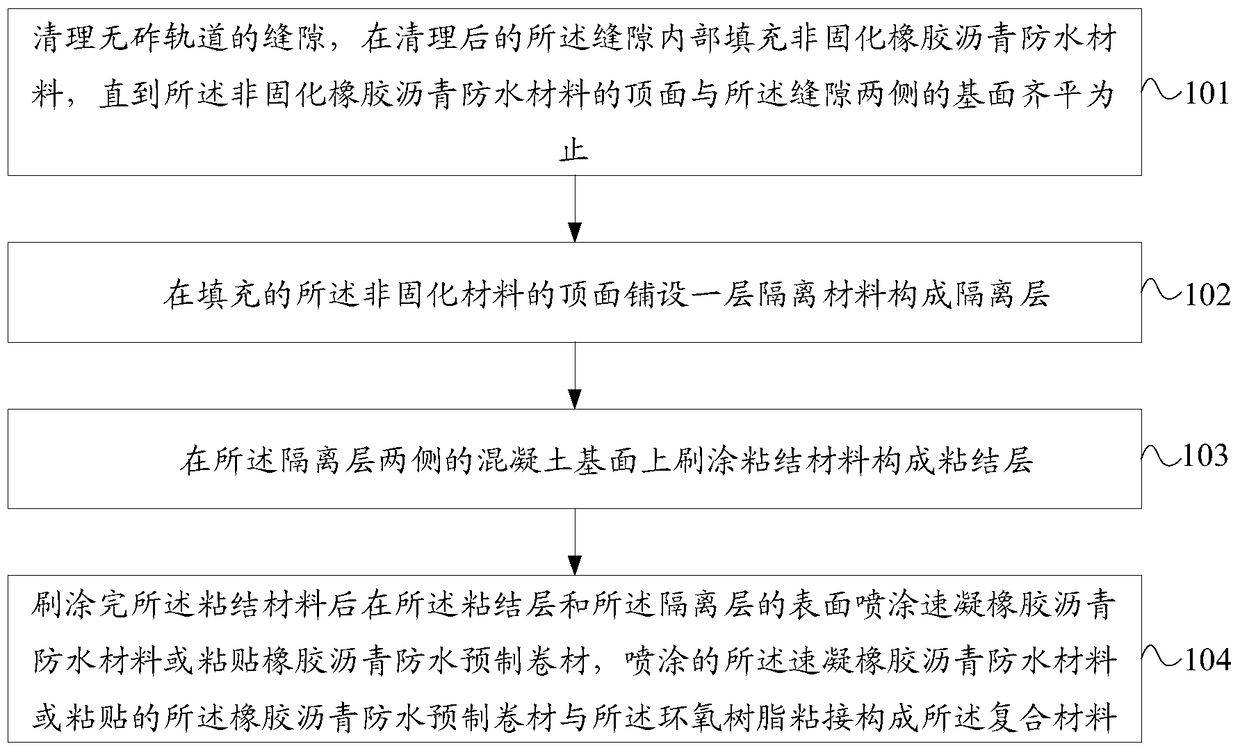

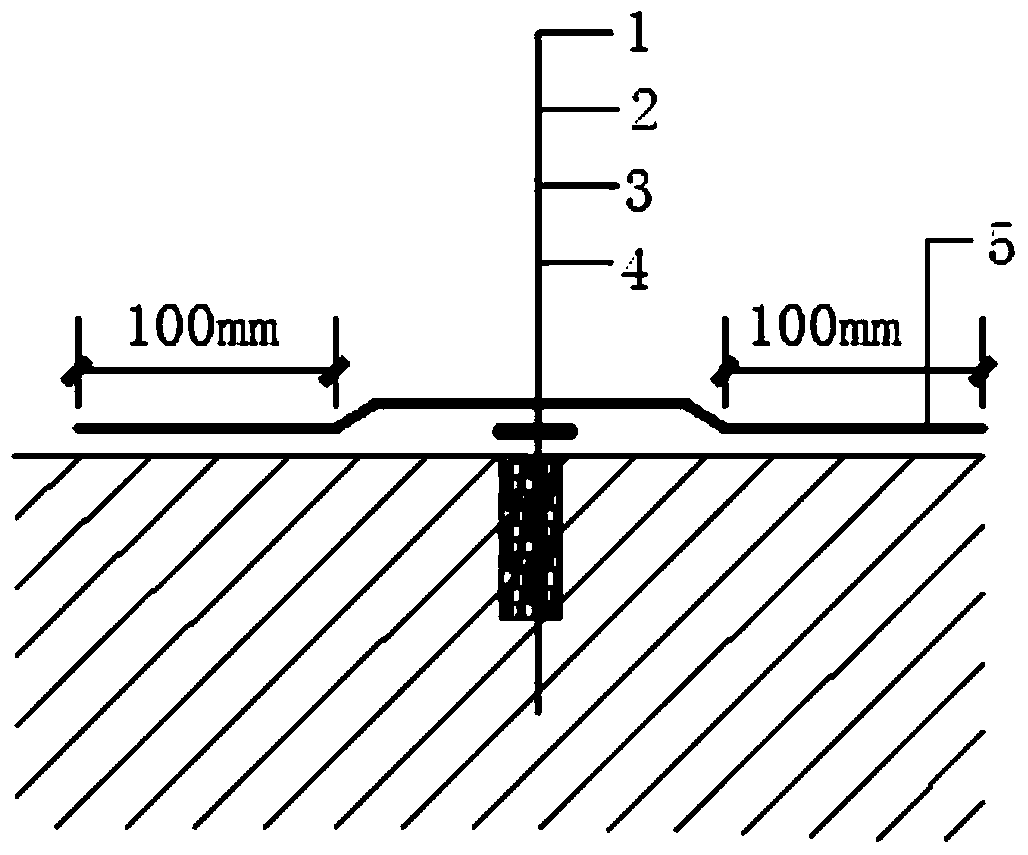

[0089] refer to figure 2 , which shows a schematic diagram of the structure of the crack after the crack is repaired by the method according to the embodiment of the present invention. figure 2 Among them, the black vertical structure at the lower part of the base surface is the crack 4 of the ballastless track. The non-curing rubber asphalt material 3 is added to the crack 4 after cleaning. When the added non-curing rubber asphalt material 3 Addition was stopped when the top surface was flush with the base surfaces on both sides of the crack. After the filling is completed, brush a layer of polyethylene polypropylene fiber 2 with a thickness of 0.7mm on the top surface of the non-cured rubber asphalt material 3 as an isolation layer, and the length and width of the isolation layer are respectively greater than the length of the crack. and wide, figure 2 The protruding part above the middle crack 4 is the isolation layer composed of brushed polyethylene polypropylene fibe...

Embodiment 2

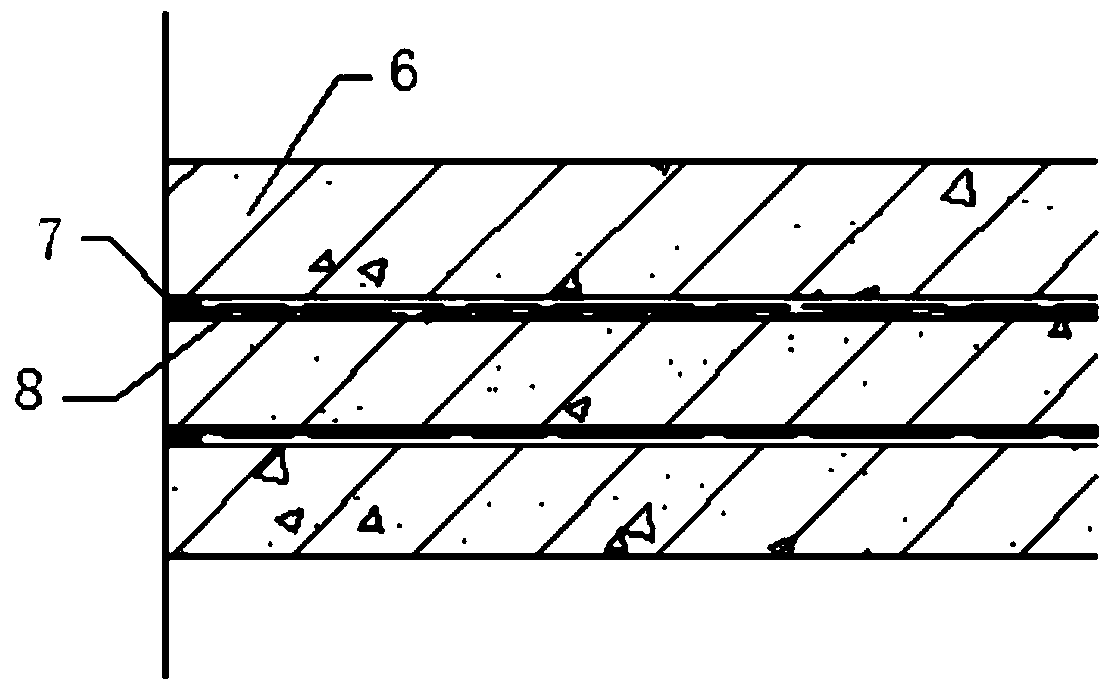

[0092] refer to Figure 4 , which shows a schematic diagram of the crack structure of the ballast bed slab after the crack treatment is performed by the method according to the embodiment of the present invention. Figure 4 The two black vertical structures at the lower part of the base surface of the middle groove are cracks 4, and the non-curing rubber asphalt material 3 is added to the cracks 4 after cleaning. When the top of the added non-curing rubber asphalt material 3 When the surface is flush with the base surfaces of the grooves on both sides of the crack 4, stop adding, use silicone sealant to seal the crack 4, and then paint a layer of non-curing rubber asphalt material 3 with a thickness of 0.7mm polyethylene polypropylene fiber 2 is used as the isolation layer, and epoxy resin 5 with a thickness of 0.2 mm and a width of 100 mm is brushed on both sides of the isolation layer. After spraying experiments, it is found that when spraying directly, there is no way to a...

Embodiment 3

[0094] When repairing the expansion joints of the high-speed rail ballastless track, among the expansion joints after cleaning, the expansion joints are first sealed with silicone sealant, and then the non-curing rubber asphalt material is added. Stop adding when the top surface of the non-cured material is flush with the base surfaces of the grooves on both sides of the crack, and then lay a layer of silicone oil paper with a thickness of 0.3mm on the surface of the added non-cured material as an isolation layer, and brush on both sides adjacent to the isolation layer Epoxy resin with a thickness of 0.15mm and a width of 100mm, after brushing the bonding layer, quickly paste rubber asphalt waterproof prefabricated rolls on the surface of the isolation layer and the bonding layer, and then use butyl tape to seal the adjacent The lap joints of the above-mentioned rubber asphalt waterproof prefabricated coils are processed, that is, the maintenance of the entire expansion joint i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com