Device and method for avoiding sintering adhesion of magnetic core

A technology of magnetic cores and connectors, applied in magnetic core manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of magnetic core adhesion, bending and deformation, and product qualification rate decline, and achieve low cost and easy The effect of cleaning and recycling, convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

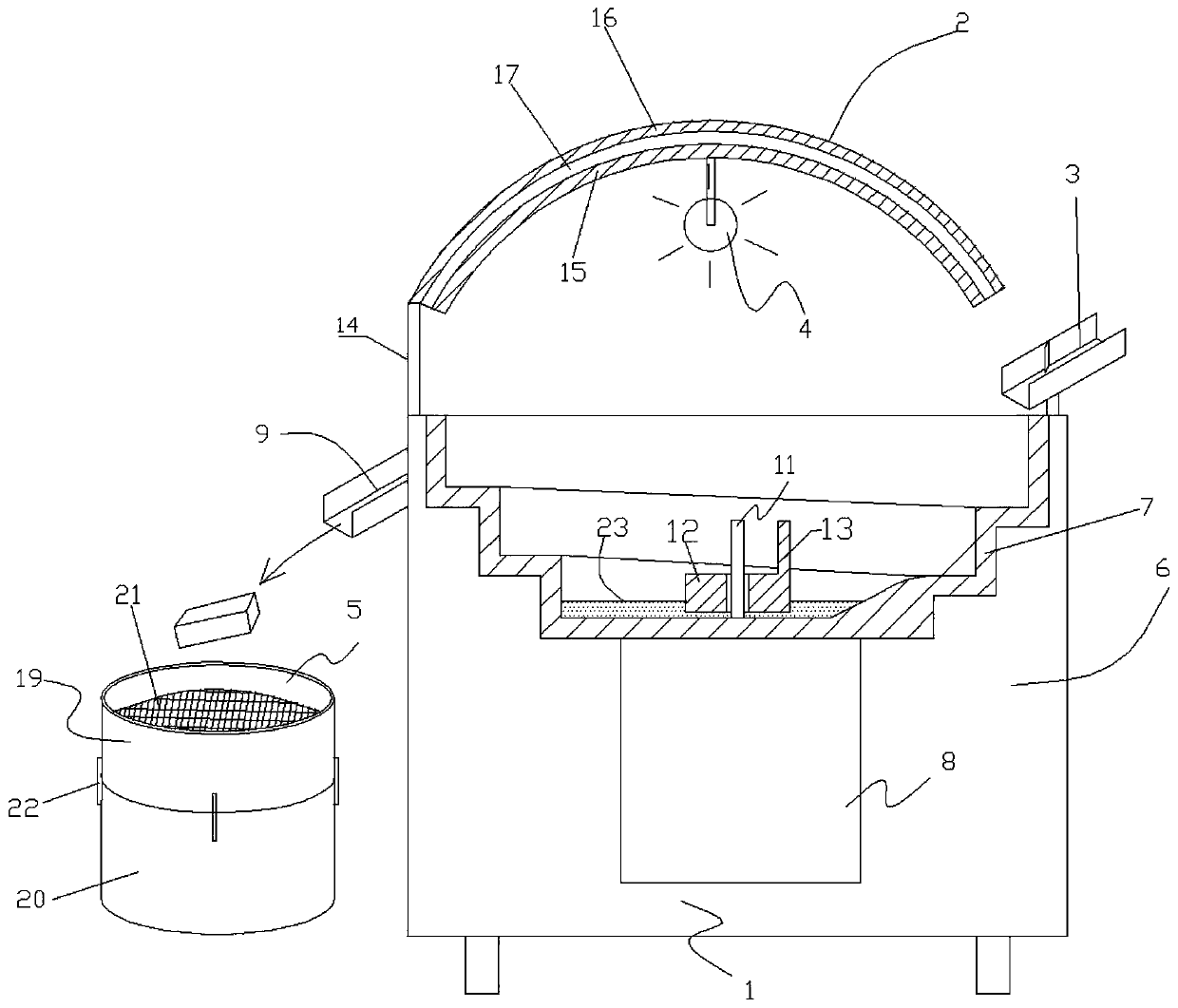

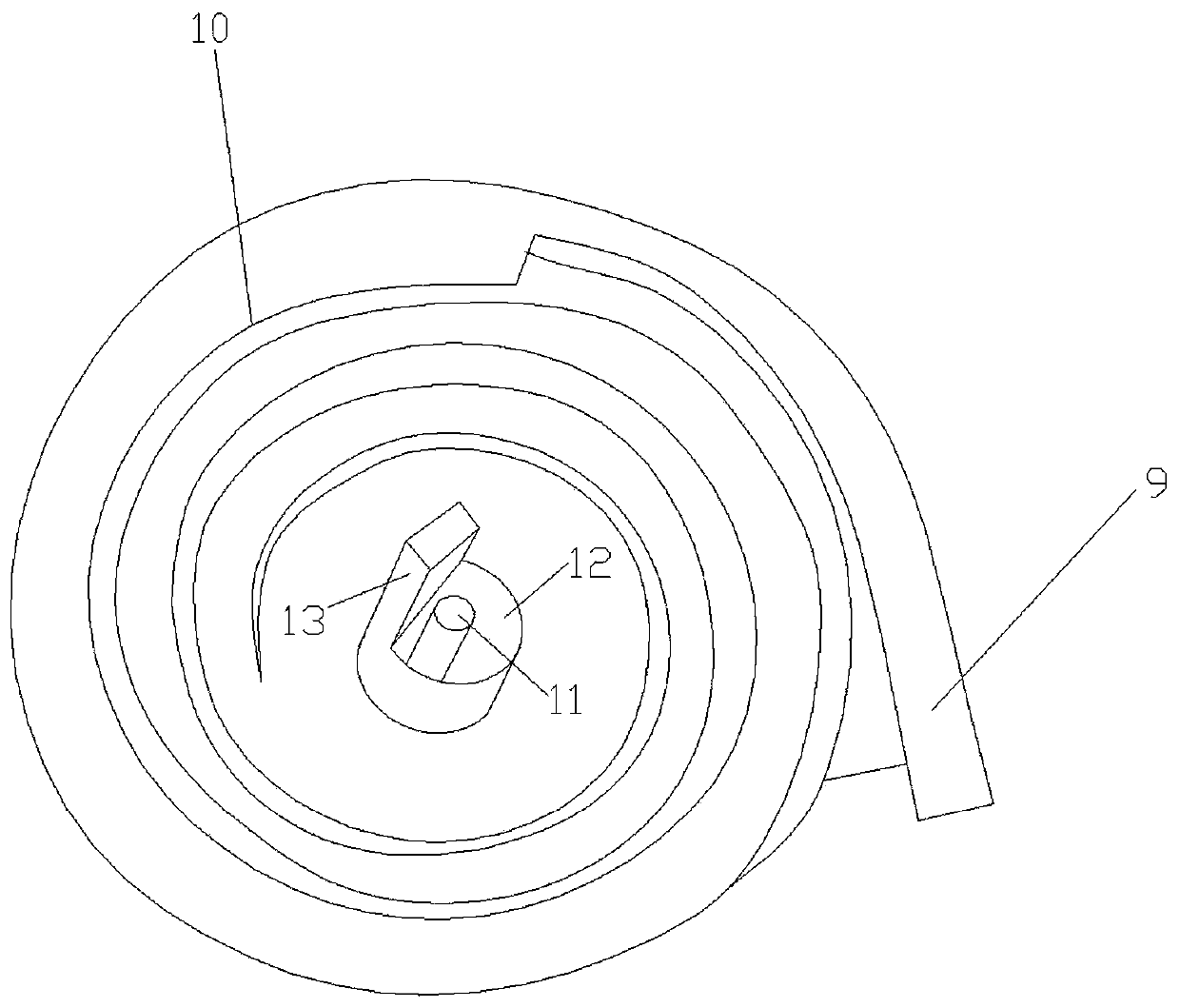

[0021] Such as figure 1 with figure 2 As shown, a device for avoiding magnetic core sintering adhesion, which includes a vibration plate 1, a heat preservation cover 2 located above the vibration plate 1, a material guide groove 3 located on one side of the vibration plate 1, and a heat preservation cover 2 located below The heating lamp 4 and the receiving tube 5; the vibrating plate 1 includes a frame 6, a material pan 7 fixedly installed on the upper end of the frame 6, a vibrator 8 fixedly installed on the lower end surface of the material plate 7, and a vibrator fixedly installed on the The outer side wall of the frame 6 is a discharge chute 9 communicating with the material tray 7; the inside of the material tray 7 is provided with a discharge track 10 that spirals upward from the bottom, and the middle of the material t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com