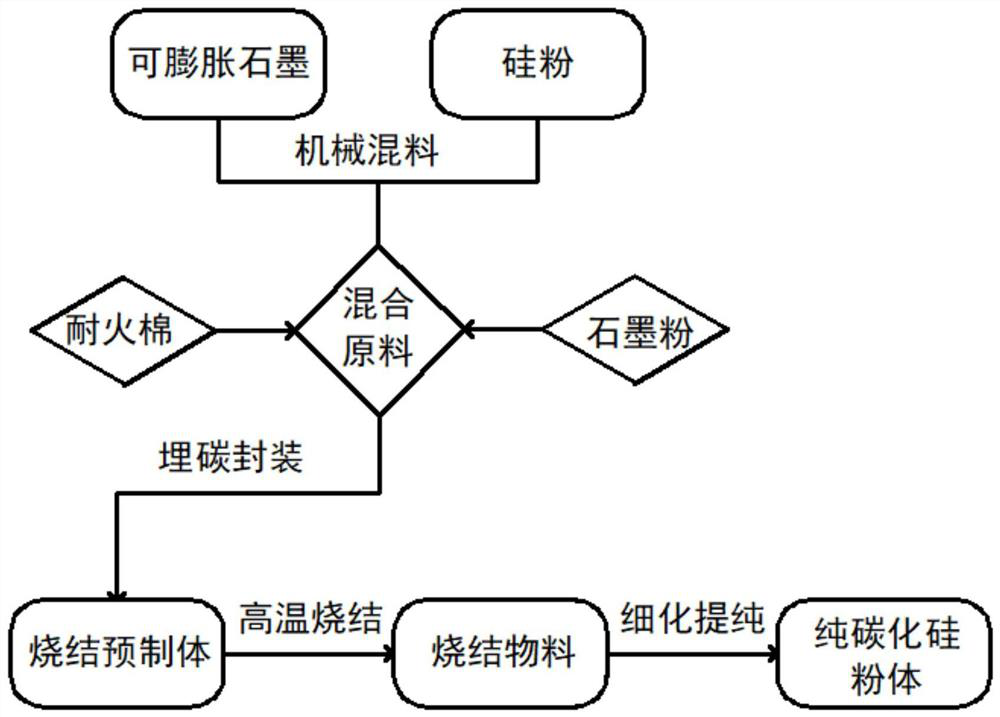

A method for preparing high-purity β-silicon carbide micro-nano powder by carbothermal reduction of high-temperature buried carbon

A technology of micro-nano powder and silicon carbide powder, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems affecting the purity of powder, high equipment requirements, difficult process control, etc., to ensure the output and purity , wide application prospects, the effect of avoiding sintering adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

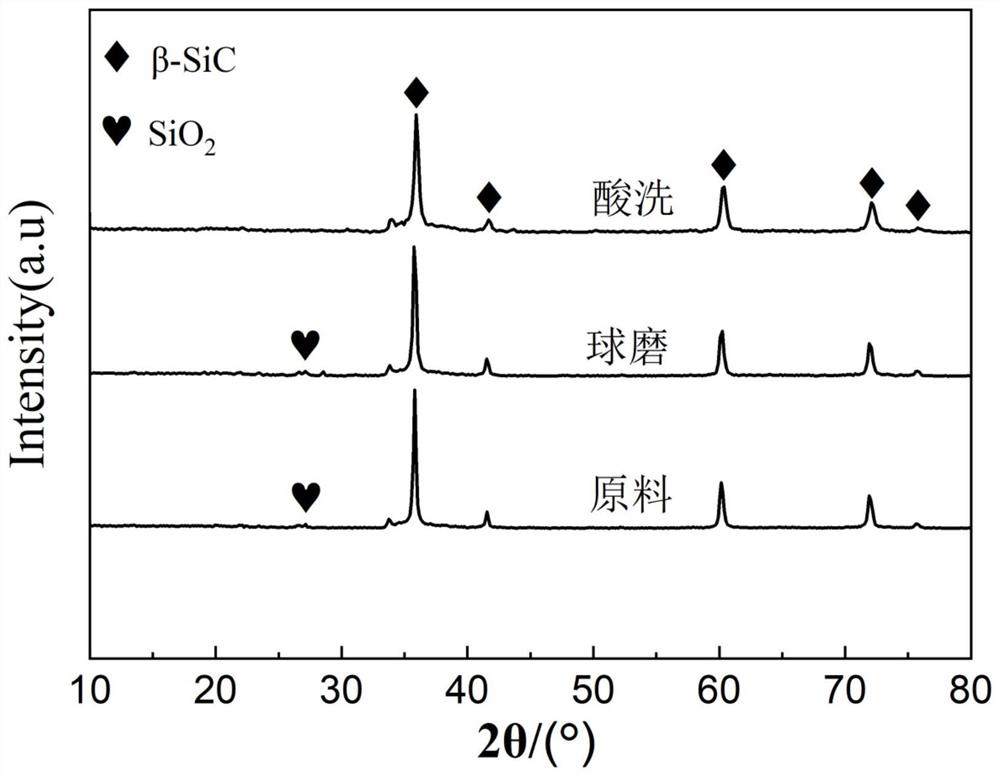

Method used

Image

Examples

Embodiment 1

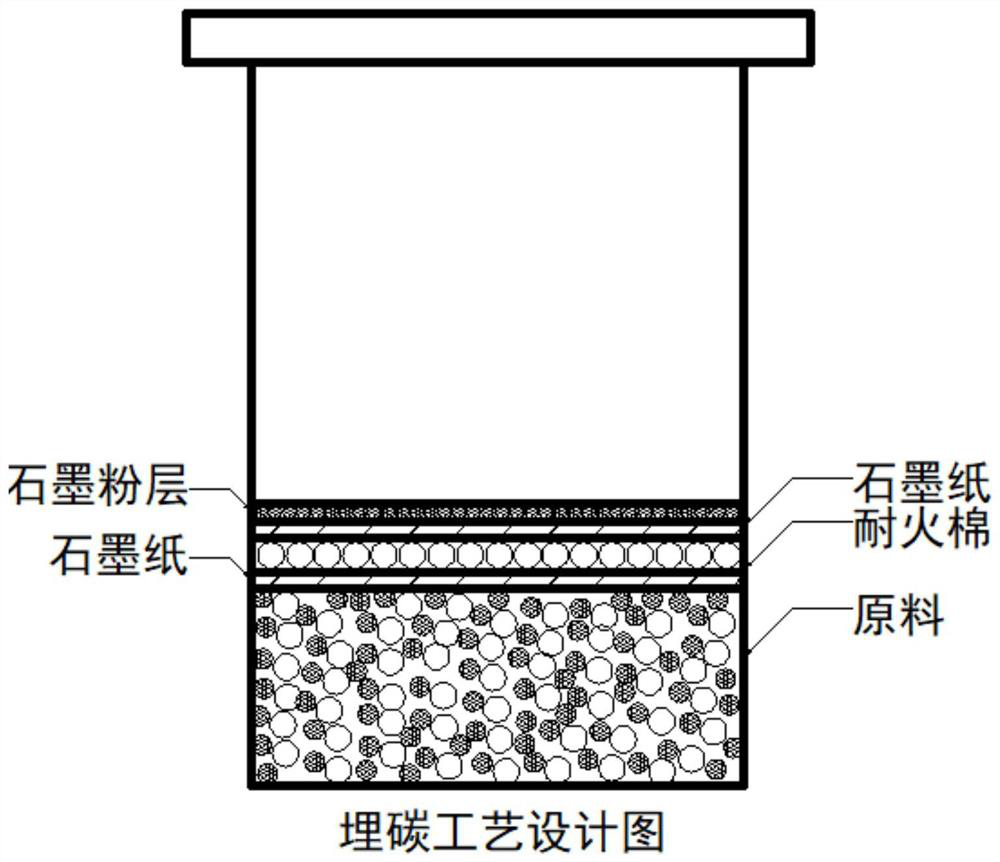

[0036] a. Using silicon powder and expandable graphite as raw materials, proportioning according to the ratio of Si:C=1:1.2, take 524g silicon powder and 259.2g expandable graphite to uniformly mix with a mechanical mixer, and mix the uniformly mixed silicon Put the carbon mixture into a corundum crucible to ensure that the material in the crucible is flat, then put graphite paper, refractory cotton, graphite paper, and graphite powder in sequence, and finally place a corundum cover on the top of the crucible;

[0037] b. Put the crucible in step a into a high-temperature sintering furnace, and the high-temperature sintering furnace controls the temperature stepwise, heats it to 1450° C., and keeps the temperature for 1.5 hours to obtain 783.2 g of silicon carbide powder containing impurities such as silicon dioxide and carbon.

[0038] c. Take 200g of the powder in step b and spread it in the corundum crucible, then put the corundum crucible into the muffle furnace, the muffle...

Embodiment 2

[0042] a. Using silicon powder and expandable graphite as raw materials, the ratio of Si:C=1:1.1 is carried out, and 524g silicon powder and 237.6g expandable graphite are uniformly mixed with a mechanical mixer, and the uniformly mixed silicon Put the carbon mixture into the corundum crucible to ensure that the material in the crucible is flat, then put graphite paper, refractory cotton, graphite paper, and graphite powder in sequence, and finally place a corundum cover on the top of the crucible;

[0043] b. Put the crucible in step a into a high-temperature sintering furnace, and the high-temperature sintering furnace controls the temperature stepwise, heats it to 1450° C., and keeps the temperature for 1.5 hours to obtain 761.6 g of silicon carbide powder containing impurities such as silicon dioxide and carbon.

[0044] c. Take 200g of the powder in step b and spread it in the corundum crucible, then put the corundum crucible into the muffle furnace, the muffle furnace tempe...

Embodiment 3

[0049] a. Using silicon powder and expandable graphite as raw materials, proportioning according to Si:C=1:1 ratio, take 524g silicon powder and 216g expandable graphite to uniformly mix with a mechanical mixer, and mix the uniformly mixed silicon carbon Put the mixture into a corundum crucible to ensure that the material in the crucible is flat, then put graphite paper, refractory cotton, graphite paper, and graphite powder in sequence, and finally place a corundum cover on the top of the crucible;

[0050] b. Put the crucible in step a into the high-temperature sintering furnace, and the high-temperature sintering furnace controls the temperature stepwise, heats it to 1450° C., and keeps the temperature for 1.5 hours to obtain 660.41 g of silicon carbide powder containing impurities such as silicon dioxide and carbon.

[0051] c. Take 200g of the powder in step b and spread it in the corundum crucible, then put the corundum crucible into the muffle furnace, the muffle furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com