Method for recycling silicon cutting waste mortar

A waste mortar and silicon cutting technology, applied in the direction of chemical instruments and methods, silicon carbide, silicon compounds, etc., to achieve the effect of improving appearance quality, improving conversion rate, and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

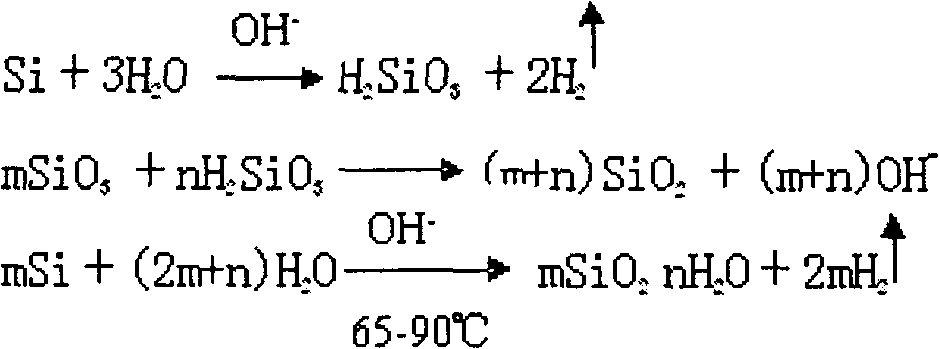

Method used

Image

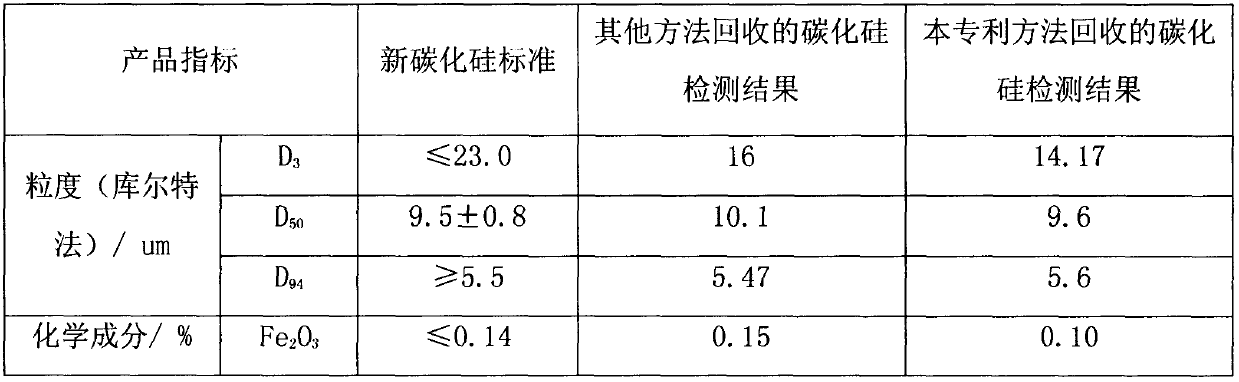

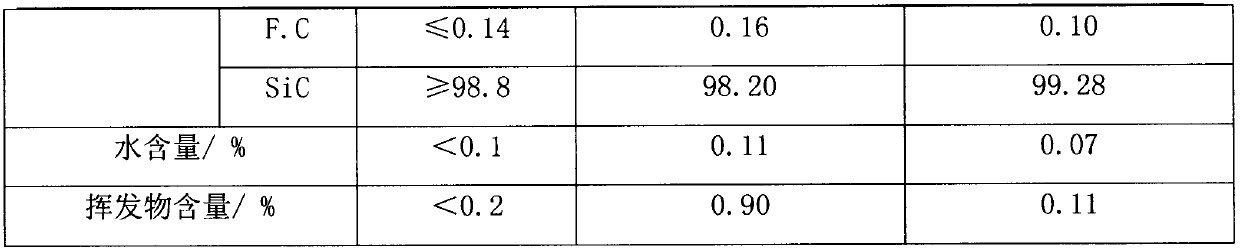

Examples

Embodiment 1

[0052] Step (1): Weigh 2000g of silicon cutting waste mortar, stir evenly, add to a cyclone separator, and separate to obtain 1350g of solid flow and 650g of liquid flow;

[0053] Step (2): wash the separated solid flow with 1000g of water, vacuum filter, dry the obtained solid phase filter cake at a temperature of 110°C and weigh 1200g (silicon carbide content 94%; silicon component ( Si+SiO2) content 5.3%, wherein silicon content 5%, silicon dioxide content 0.3%);

[0054] Step (3): Dissolving 1200 g of the filter cake in 2400 g of deionized water, stirring evenly and fully to obtain a mixed suspension, stirring and activating the reaction at a temperature of 30°C for 40 minutes to remove the inert film on the surface of the silicon powder;

[0055] Step (4): After the activation reaction, add water glass at a temperature of 30°C (water glass is a solution of sodium silicate, the experiment specifically uses sodium silicate nonahydrate, and the density is 0.85g / cm 3 , the s...

Embodiment 2

[0067] Step (1): Weigh 2000g of silicon cutting waste mortar, stir evenly, add into a cyclone separator, and separate to obtain 1355g of solid flow and 645g of liquid flow;

[0068] Step (2): wash the separated solid flow with 2000g of water, vacuum filter, dry the obtained solid-phase filter cake at a temperature of 110°C and weigh 1200g (silicon carbide content 93.9%; silicon component ( Si+SiO 2 ) content of 5.2%, of which silicon content is 4.9%, silicon dioxide content is 0.3%);

[0069] Step (3): Dissolving 1200 g of the filter cake in 600 g of deionized water, stirring evenly and thoroughly to obtain a mixed suspension, stirring and activating the reaction at 30° C. for 30 minutes to remove the inert film on the surface of the silicon powder;

[0070] Step (4): After the activation reaction, add water glass at a temperature of 30°C, the quality of the water glass is 48g, i.e. 4% of the filter cake quality, stir evenly and let stand for 20 minutes;

[0071] Step (5): T...

Embodiment 3

[0082] Step (1): Weigh 4000g of silicon cutting waste mortar, stir evenly, add to a cyclone separator, and separate to obtain 2700g of solid flow and 1300g of liquid flow;

[0083] Step (2): wash the separated solid flow with 4000g of water, vacuum filter, and dry the obtained solid phase filter cake at a temperature of 110°C to obtain a mass of 2400g (silicon carbide content 94.3%; silicon component ( Si+SiO 2 ) content of 5.3%, including 5% silicon content and 0.3% silicon dioxide content);

[0084] Step (3): Dissolving 2400 g of the filter cake in 1200 g of deionized water, stirring evenly and thoroughly to obtain a mixed suspension, stirring and activating at a temperature of 50°C for 35 minutes to remove the inert film on the surface of the silicon powder;

[0085] Step (4): After the activation reaction, add water glass at a temperature of 50°C, the quality of the water glass is 48g, i.e. 2% of the filter cake quality, stir evenly and let stand for 60 minutes;

[0086]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com