Safe firework based on axial internal cylinder inverted powder-charging technology and production technology

A technology of upside-down installation and fireworks, which is applied in pyrotechnics, offensive equipment, weapon types, etc. It can solve the problems of user safety hazards, large manpower consumption, and cumbersome operation when setting off fireworks, so as to reduce the probability of blasting and broken tubes, reduce the The effect of labor intensity and time control is accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

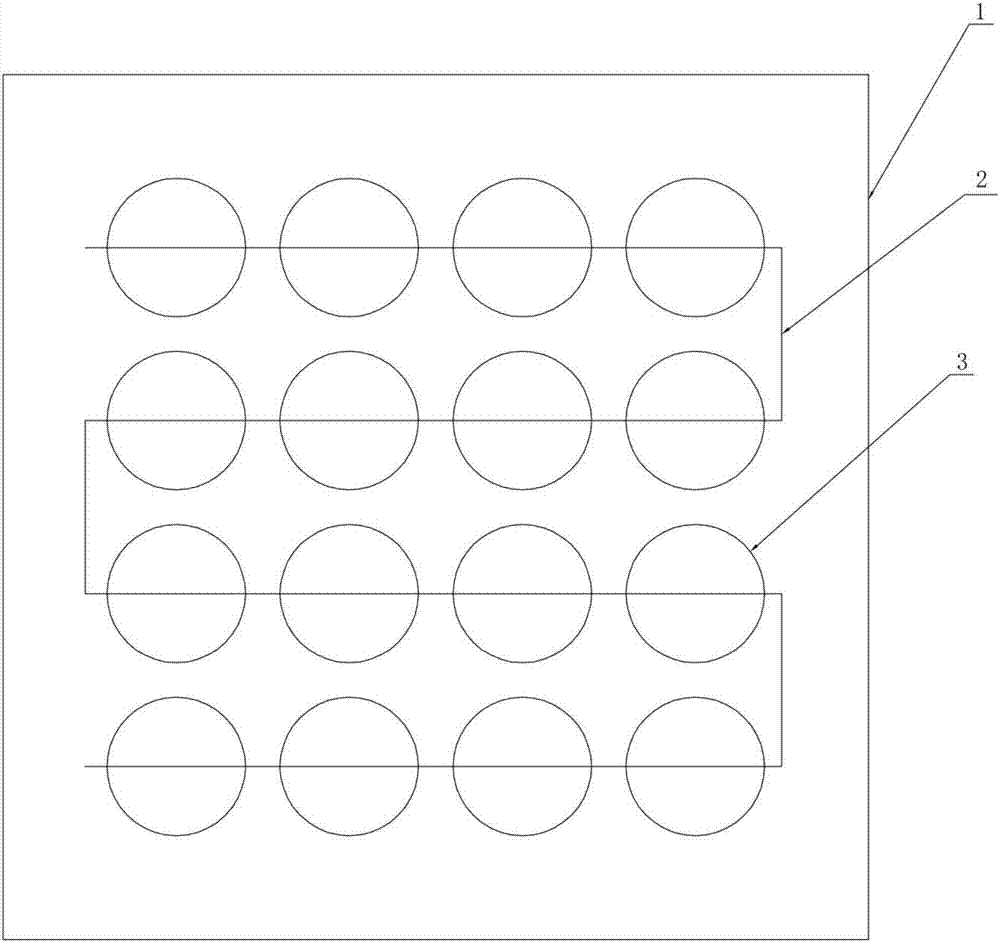

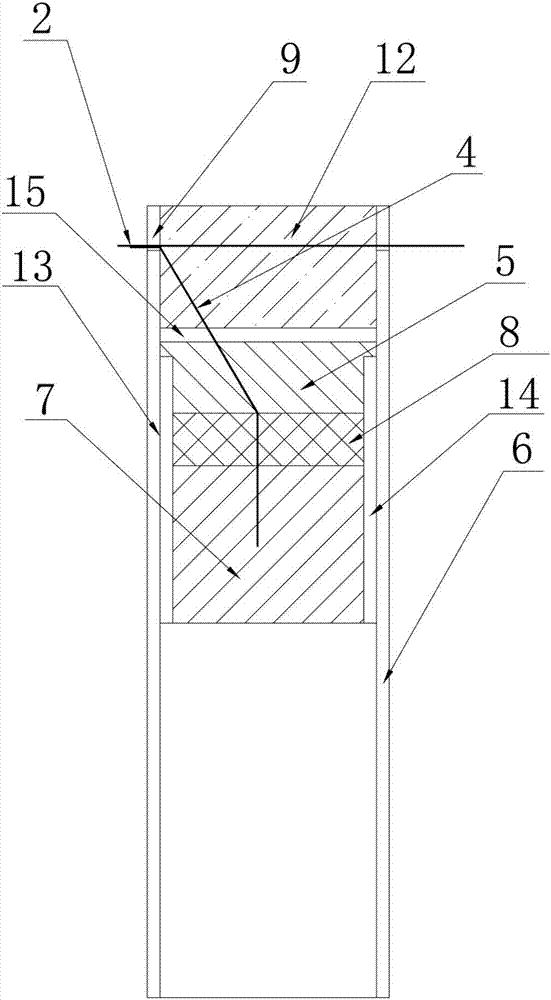

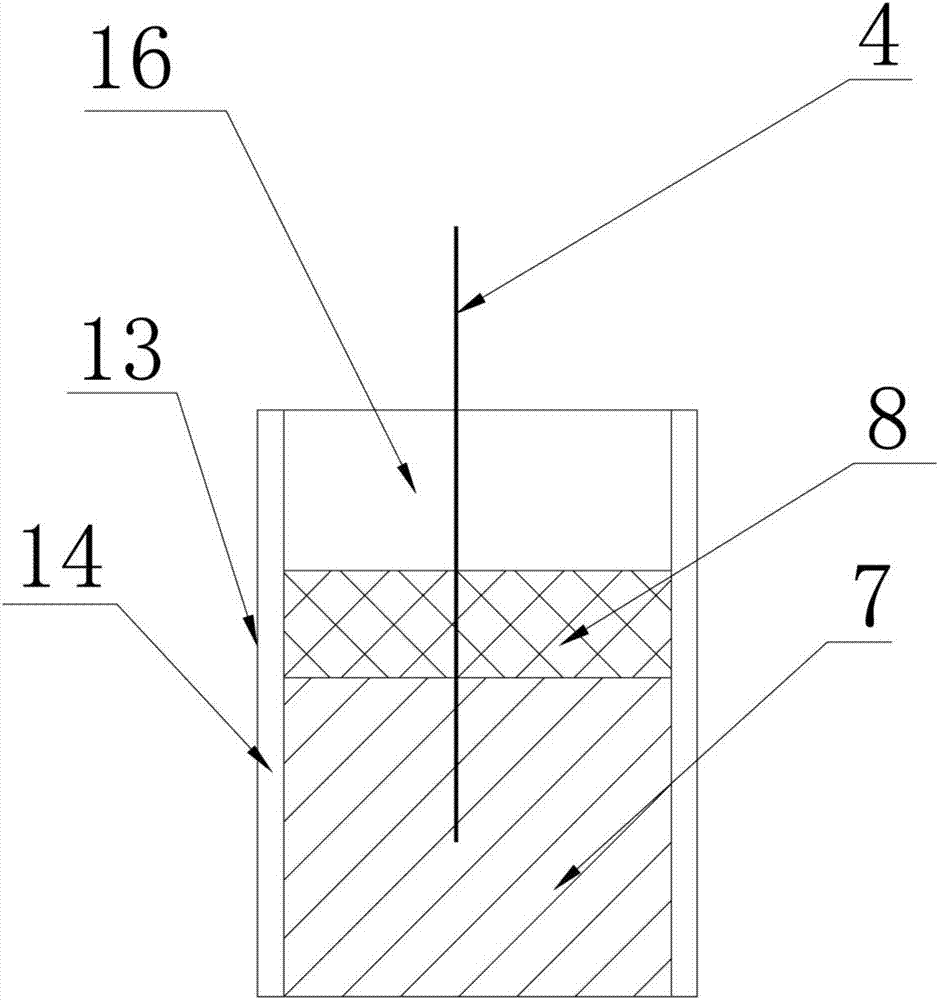

[0037] Use a fast reel to roll out the outer cylinder 6 and bind the outer cylinder 6 together with rubber and tape; at the same time, prefabricate the firework shells 13; arrange the prepared outer cylinder 6 in an array on the base 1; use a slotting machine on the outer cylinder 6 There are lead grooves 9 on both sides of the wall; the firework shell 13 is inserted into the outer tube 6, and the firework lead 4 is clamped in the lead groove 9; the firework lead 4 in each outer tube 6 is connected in turn through the connecting lead 2 Get up; Load the propellant layer 5 and cover the moisture-proof layer 15, install the sealing layer 12 on the top of the moisture-proof layer 15, and fix the fireworks lead 4 and the connecting lead 2 in the sealing layer 12, the time for the sealing layer 12 to solidify It is 11 hours; wrap the entire firework with a special pitot and leave the end of the connecting lead 2 aside to obtain a safe firework based on the technology of inverted charg...

Embodiment 2

[0039] Use a fast reel to roll out the outer cylinder 6 and bind the outer cylinder 6 together with rubber and tape; at the same time, prefabricate the firework shells 13; arrange the prepared outer cylinder 6 in an array on the base 1; use a slotting machine on the outer cylinder 6 There are lead grooves 9 on both sides of the wall; the firework shell 13 is inserted into the outer tube 6, and the firework lead 4 is clamped in the lead groove 9; the firework lead 4 in each outer tube 6 is connected in turn through the connecting lead 2 Get up; Load the propellant layer 5 and cover the moisture-proof layer 15, install the sealing layer 12 on the top of the moisture-proof layer 15, and fix the fireworks lead 4 and the connecting lead 2 in the sealing layer 12, the time for the sealing layer 12 to solidify It takes 10 hours; wrap the entire firework with a special pitot, and leave the end of the connecting lead 2 aside to obtain a safe firework based on the inverted charging techno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com