Method for treating silicon in waste oil sand generated in silicon ingot cutting process

A treatment method, waste oil sand technology, applied in the direction of chemical instruments and methods, silicon carbide, silicon compounds, etc., can solve the problems of waste residue accumulation environment, complicated process flow, long treatment cycle, etc., achieve huge social and economic benefits, overcome The process is complicated, and the effect of solving waste residue accumulation and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

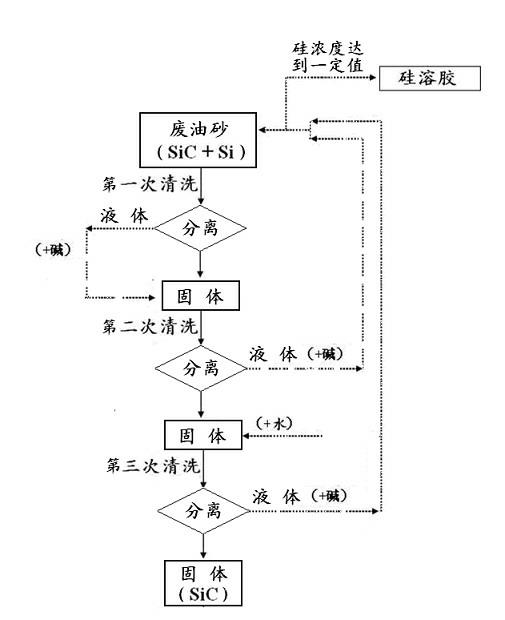

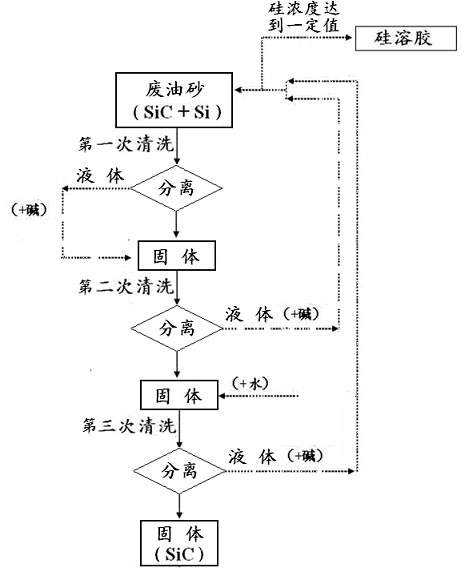

[0027] Add 100g of waste oil sand containing 15.7% silicon, add 2.0% lye (solid-to-liquid ratio 1:1), stir and wash at 65°C for 2 hours, and centrifuge. After separation, the liquid contains 10.2% silicon (silicon conversion rate 65%), iron, copper and other metals and a small amount of PEG. Add solid alkali to the liquid to a concentration of 2%, and repeat the cleaning of the above-separated waste oil sand solid for 3 times. After centrifugation, the liquid contains 15.5% silicon (the total conversion rate of silicon is 99%). Finally, the separated waste oil sand solids are washed with pure water, and the solid SiC is recovered by drying.

[0028] Add solid alkali to the cleaned liquid to a concentration of 2%, and it can still be used as a cleaning liquid to treat waste oil sands. The separated and cleaned liquid is recycled until the silicon concentration is about 30%, and the acidity is adjusted to obtain a stable silica sol.

Embodiment 2

[0030] Add 100g of waste oil sand containing 15.7% silicon, add 2.5% lye (solid-to-liquid ratio 1:3), stir and wash at 85°C for 3 hours, and centrifuge. The separated and cleaned liquid contains 11.9% silicon (silicon conversion rate 76%), iron, copper and other metals and a small amount of PEG. Add solid alkali to the liquid to a concentration of 2.5%, and repeat the cleaning of the above-separated waste oil sand solid twice. After centrifugation, the resulting cleaned liquid contained 15.5% silicon (total conversion of silicon was 99%). The separated solid was washed with pure water and dried to recover SiC. Add solid alkali to the cleaned liquid to a concentration of 2.5%, and it can still be used as a cleaning liquid to treat waste oil sands. The liquid is recycled until the silicon concentration reaches about 30%, and the acidity is adjusted to obtain a stable silica sol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com