Flow sensor using a heat element and a resistance temperature detector formed of a metal film

a flow sensor and metal film technology, applied in the direction of measuring devices, instruments, and measuring the speed of fluids using thermal variables, can solve the problems of degrading the relative high tcr inherent in the metal film cannot be obtained, and the detection sensitivity of the resistance temperature detector is degraded, so as to achieve high tcr inherent, the detection sensitivity of the resistance temperature detector can be improved, and the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

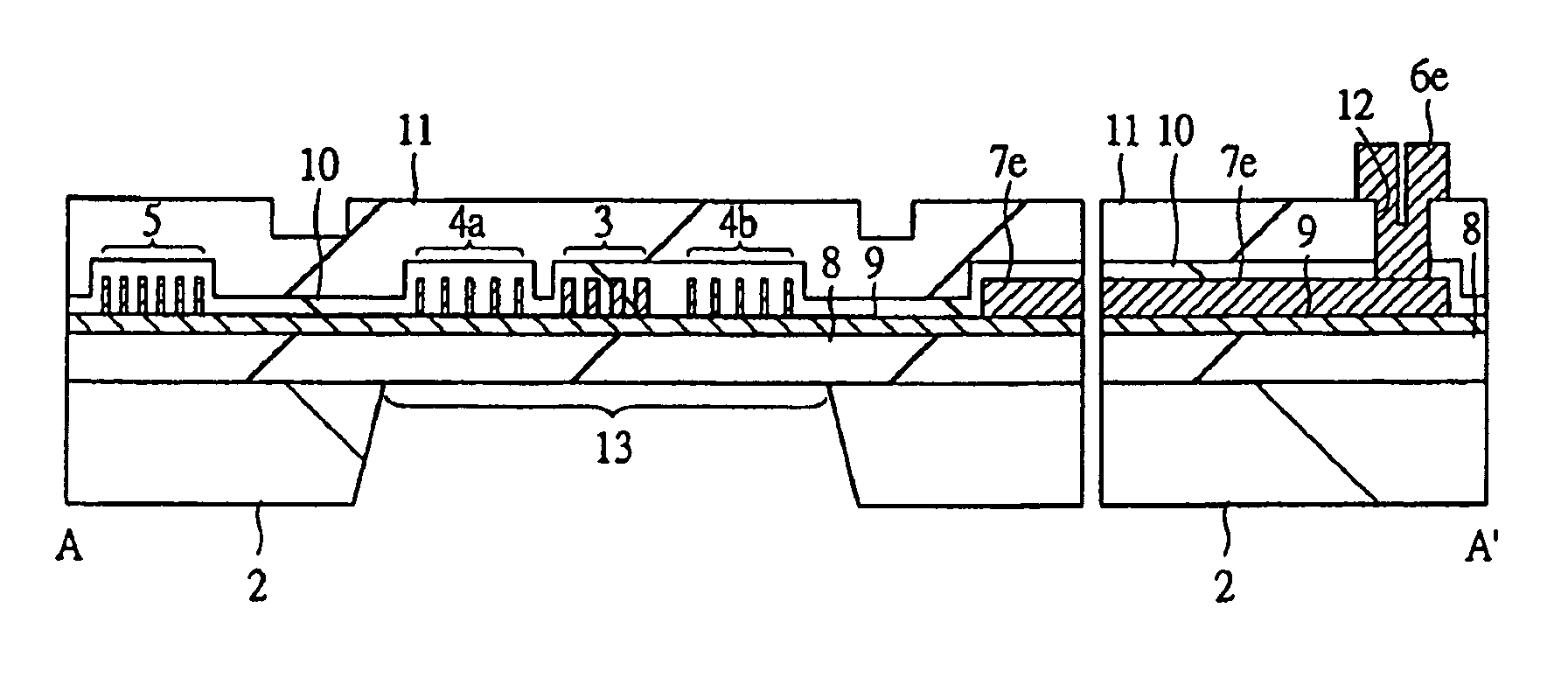

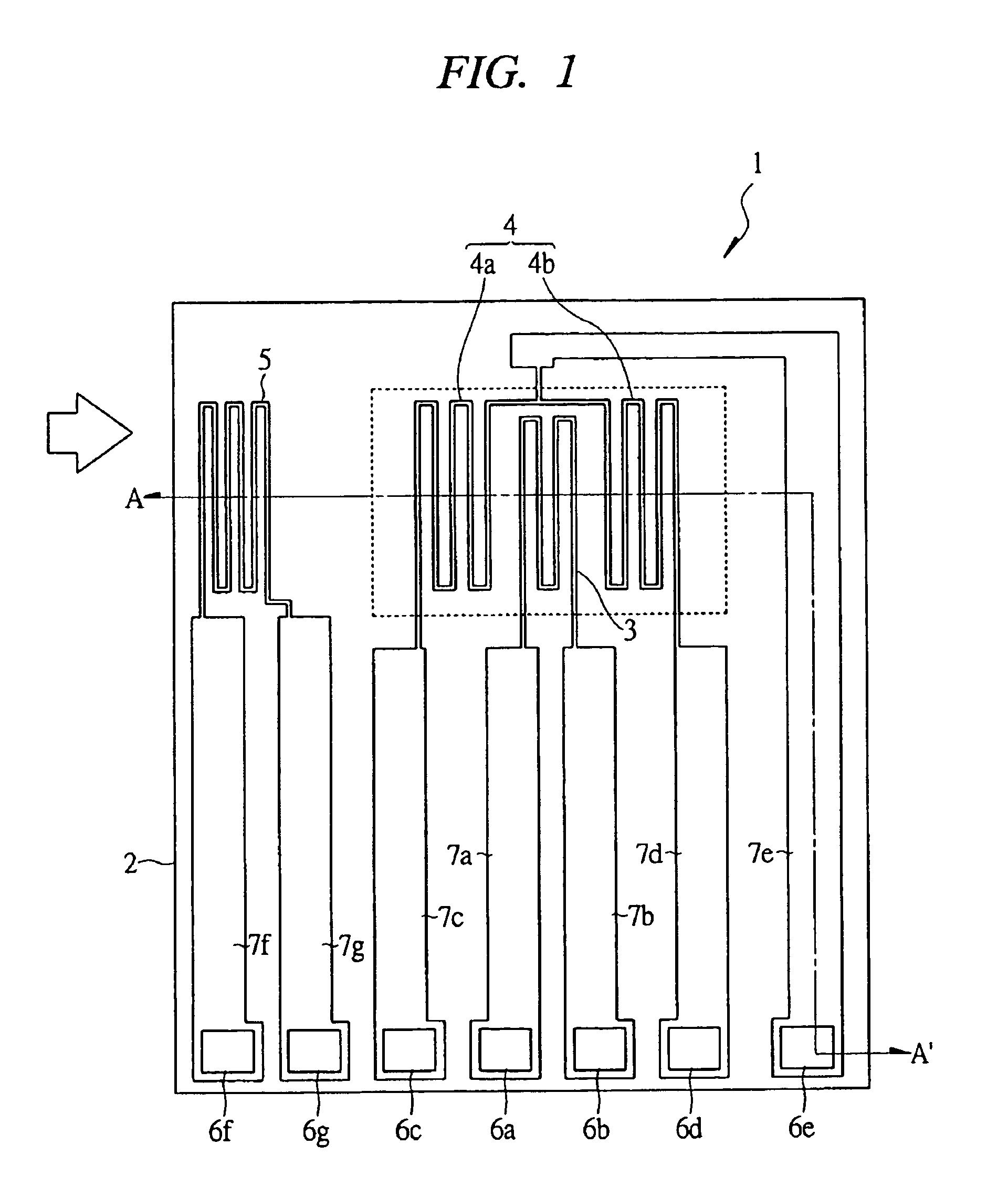

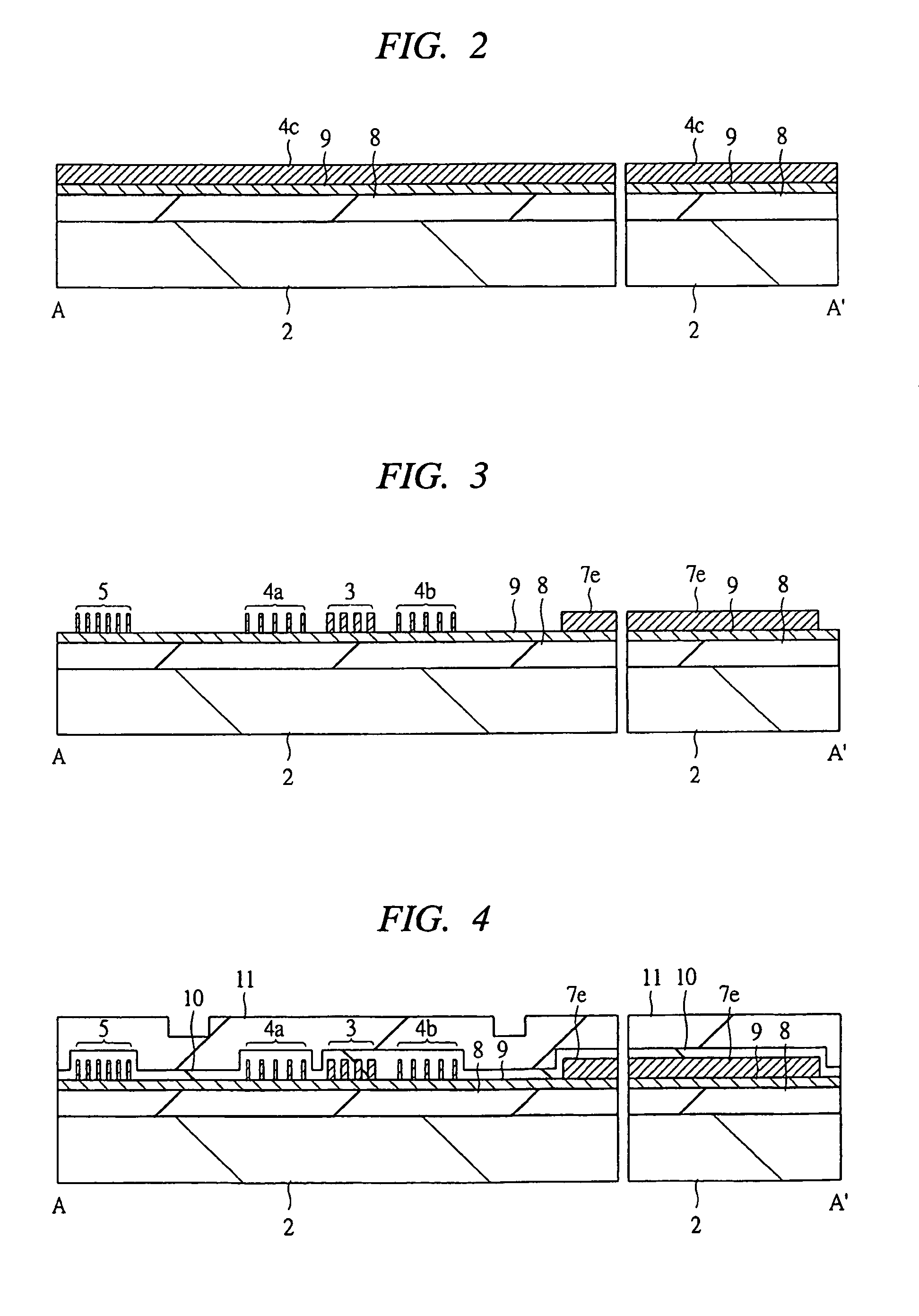

[0032]An example of a plan view of main parts of a thermal fluid flow sensor according to a first embodiment is shown in FIG. 1.

[0033]A measurement device 1, which is a thermal fluid flow sensor, includes a semiconductor substrate 2 made of single crystal Si, a heat element 3 formed on the semiconductor substrate 2 via an insulating film, a resistance temperature detector 4 composed of an upstream-side resistance temperature detector 4a and a downstream-side resistance temperature detector 4b for detecting a temperature of air heated by the heat element 3, a resistance temperature detector for air 5 for measuring an air temperature, terminal electrodes 6a, 6b, 6c, 6d, 6e, 6f, and 6g for connecting signals from the measurement device 1 to an external circuit, lead wirings 7a and 7b for connecting both ends of the heat element 3 to the terminal electrodes 6a and 6b, lead wirings 7c and 7d for connecting both ends of the resistance temperature detector 4 to the terminal electrodes 6c a...

second embodiment

[0060]In a second embodiment, a Mo (molybdenum) film is used as a metal film which forms a heat element and resistance temperature detectors included in a measurement device which is a thermal fluid flow sensor. FIG. 12 is a cross-sectional view of main parts of one example of the thermal fluid flow sensor according to the second embodiment, which shows the same portions (main parts taken along the line A-A′ in FIG. 1) as those shown in FIG. 6 of the above-described first embodiment.

[0061]An insulating film 31 is formed on a semiconductor substrate 30 made of single crystal Si, and a heat element 32, a resistance temperature detector (upstream-side resistance temperature detector 33a and downstream-side resistance temperature detector 33b), a resistance temperature detector for air 34, and a lead wiring 35 which are all made of a third metal film made of, for example, Mo are formed on the insulating film 31. The insulating film 31 is provided so as to insulate the semiconductor subs...

third embodiment

[0067]In a third embodiment, an example in which a measurement device including a heat element and resistance temperature detectors is applied to an acceleration sensor will be described.

[0068]FIG. 14 is a plan view showing main parts of one example of an acceleration sensor according to the third embodiment.

[0069]An acceleration sensor 41 includes a heat element 42, terminal electrodes 43a and 43b for electrically connecting the heat element 42 and an external circuit, resistance temperature detectors 44a, 44b, 44c, and 44d having the same length (same resistance value) disposed so as to be spaced a predetermined distance apart in four directions from the heat element 42, and terminal electrodes 45a, 45b, 45c, 45d, 45e, and 45f for electrically connecting the resistance temperature detectors 44a, 44b, 44c, and 44d and the external circuit, which are all formed on a semiconductor substrate made of single crystal Si via an insulating film and the like. In the external circuit, a brid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com