a thermal sensor

A heat-sensitive sensor and connector technology, applied in the field of sensors, can solve the problems of long time required and increased user difficulty, and achieve the effects of precise adjustment position, reduced work difficulty, and reduced bending degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

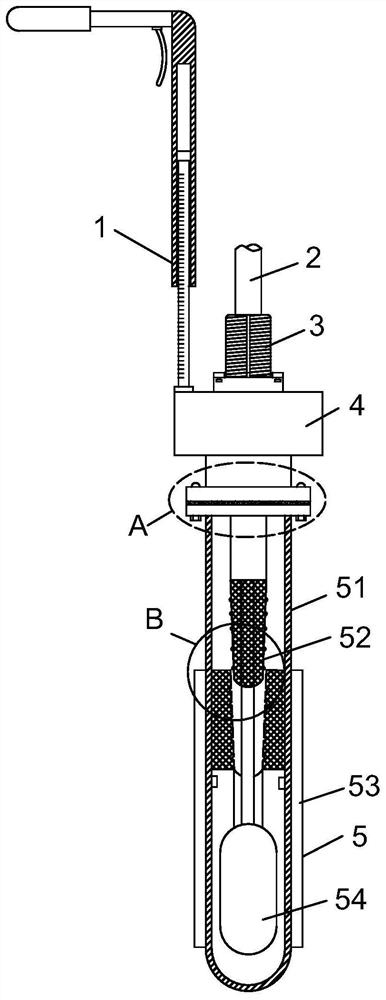

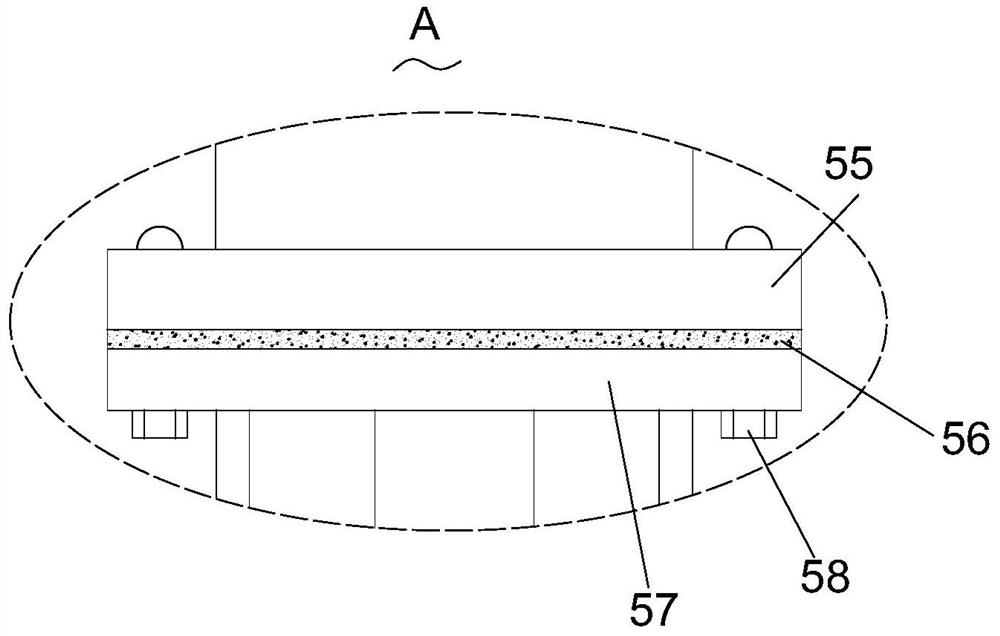

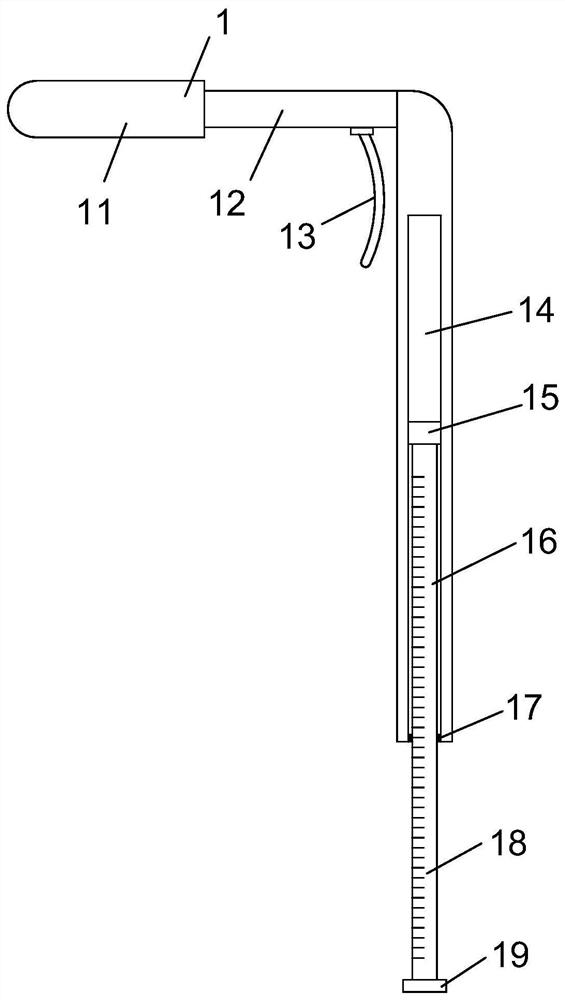

[0024] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , a thermal sensor, including a connector 4, a probe mechanism 5, a handle mechanism 1 and an elastic protection mechanism 3, the connector 4 is connected to the signal line 2; the probe mechanism 5 is connected to the connector 4; the handle The mechanism 1 is connected with the connector 4; the elastic protection mechanism 3 is connected with the connector 4, and the handle mechanism 1 includes a rubber sleeve 11, a handle 12, an internally threaded sleeve 14, an externally threaded block 15, a connecting rod 16 and a connecting block 19, The upper surface of the connector 4 is fixedly connected with a vertically arranged connecting rod 16 through a connecting block 19, and one end of the connecting rod 16 away from the connecting block 19 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com