Automatic vacuum backflow welding equipment adopting contact type temperature control

A technology of vacuum reflow and welding equipment, applied in welding equipment, metal processing equipment, electric heating devices, etc., can solve the problems of heavy cavity cover, inconvenient operation, low heating efficiency, low heating temperature, etc., to achieve easy cleaning and maintenance, heating speed Fast, high heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

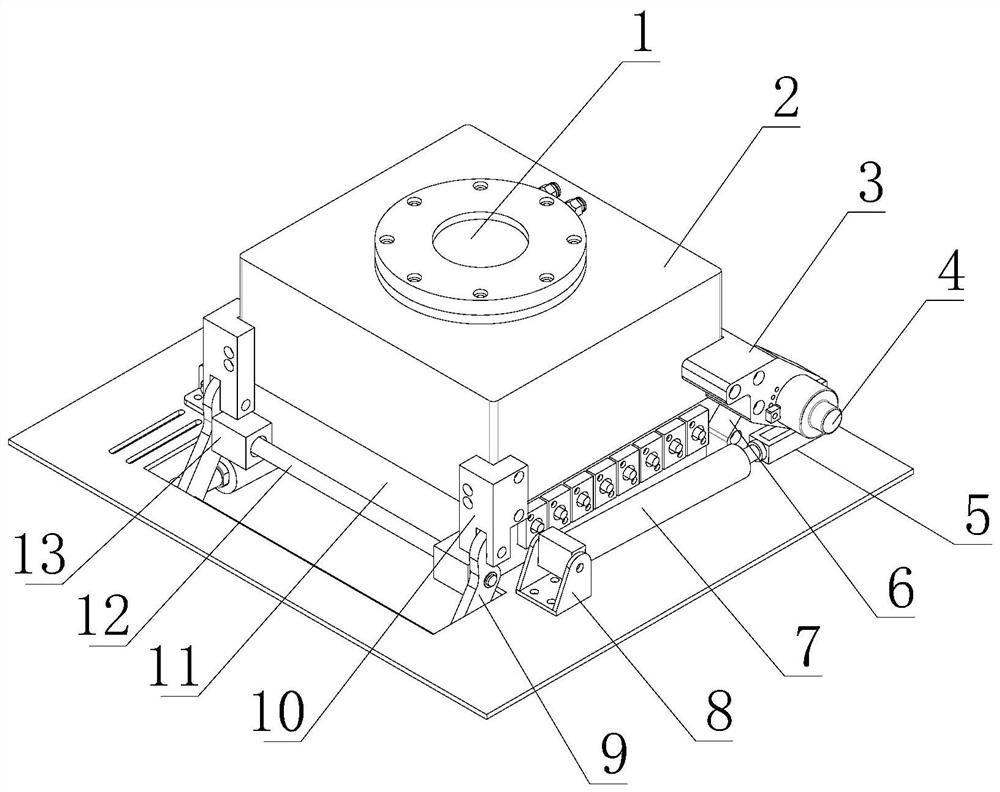

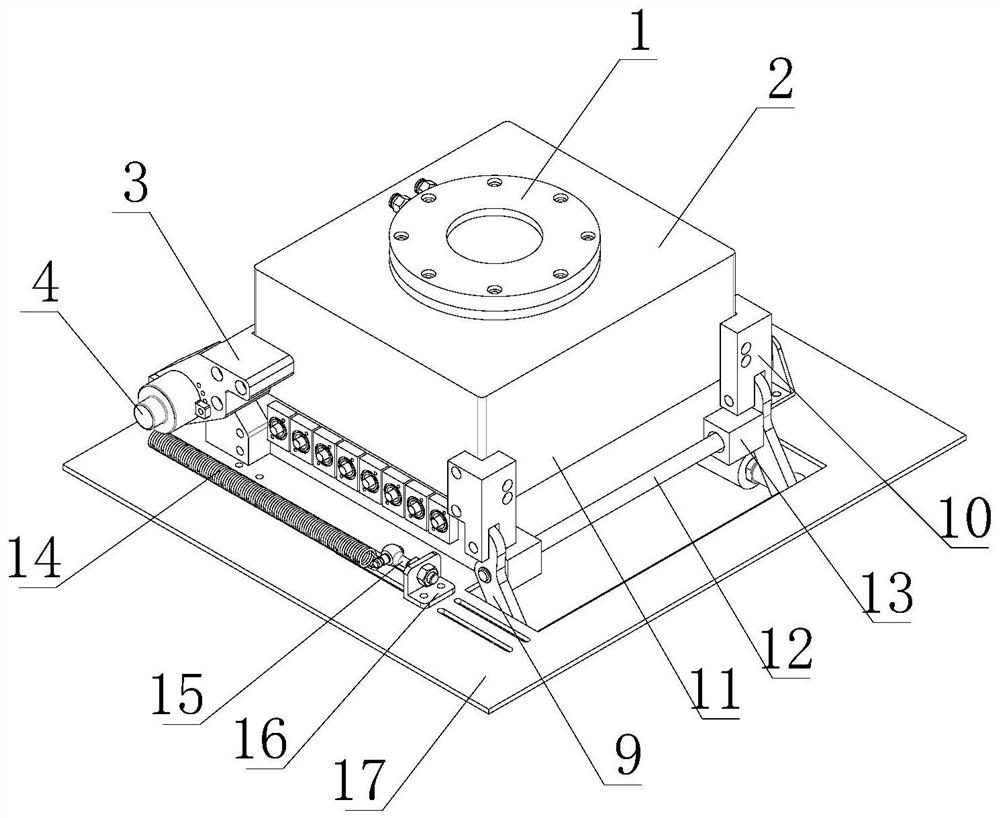

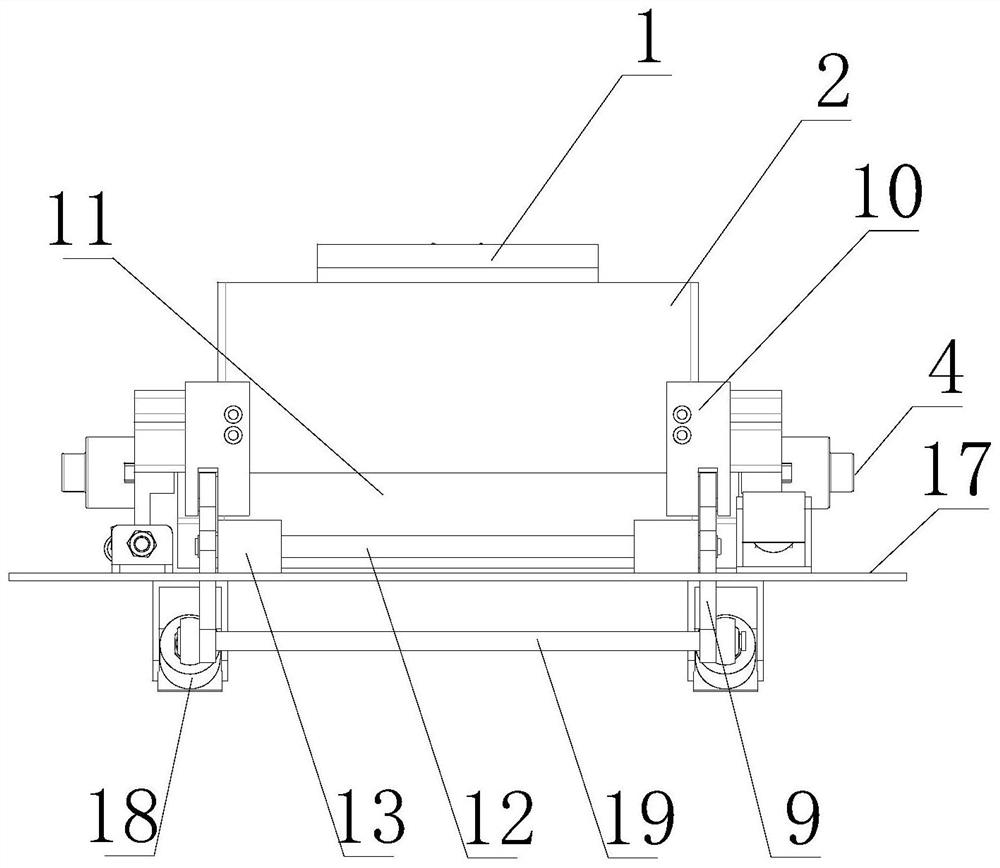

[0037] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0038] See attached Figure 1-6 , a kind of automatic vacuum reflow soldering equipment adopting contact temperature control, comprising a heating chamber 11, a chamber cover 2 forming a sealed cavity with the heating chamber 11, several infrared radiation tubes 27 installed inside the heating chamber 11, located in the infrared radiation tube The heating plate 23 above 27, the contact temperature control mechanism, the vacuuming mechanism and the cooling mechanism connected with the heating chamber 11, the heating chamber 11 and the chamber cover 2 are all made of quartz glass, and one end of the chamber cover 2 is hingedly installed in the heating chamber 11, the other end is detachably sealed with the heating cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com