Worm wheel

A worm gear and gear tooth technology, applied in the field of transmission, can solve the problems of being unsuitable for the installation and use of high-precision instruments, and the volume of the transmission is large, and achieve the effects of light weight, improved transmission efficiency, and large torque output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

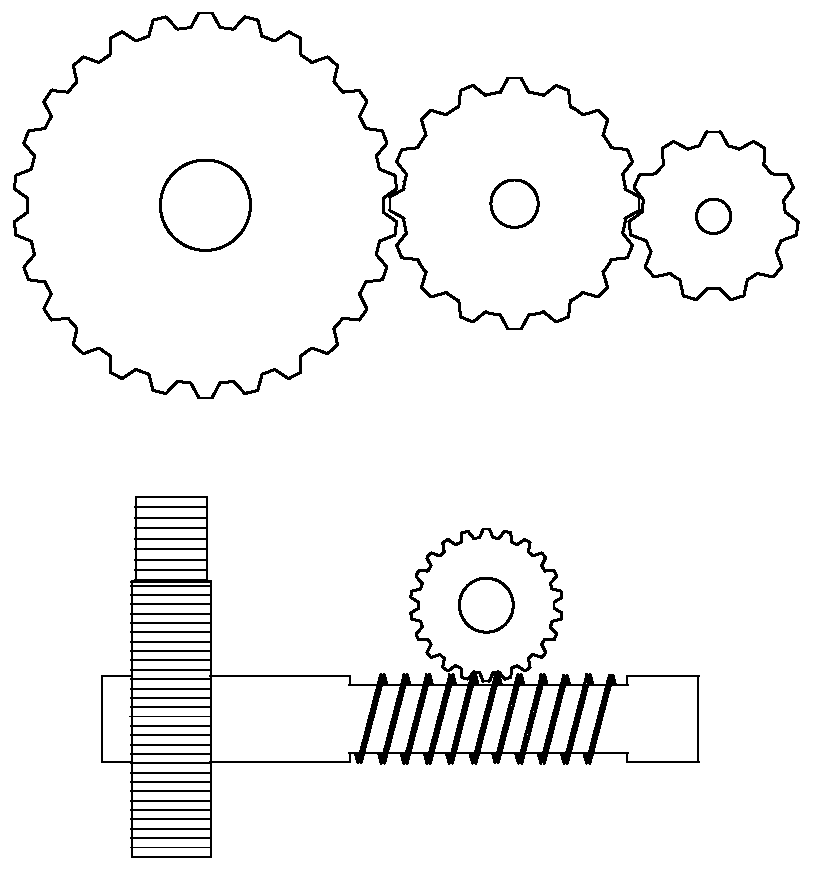

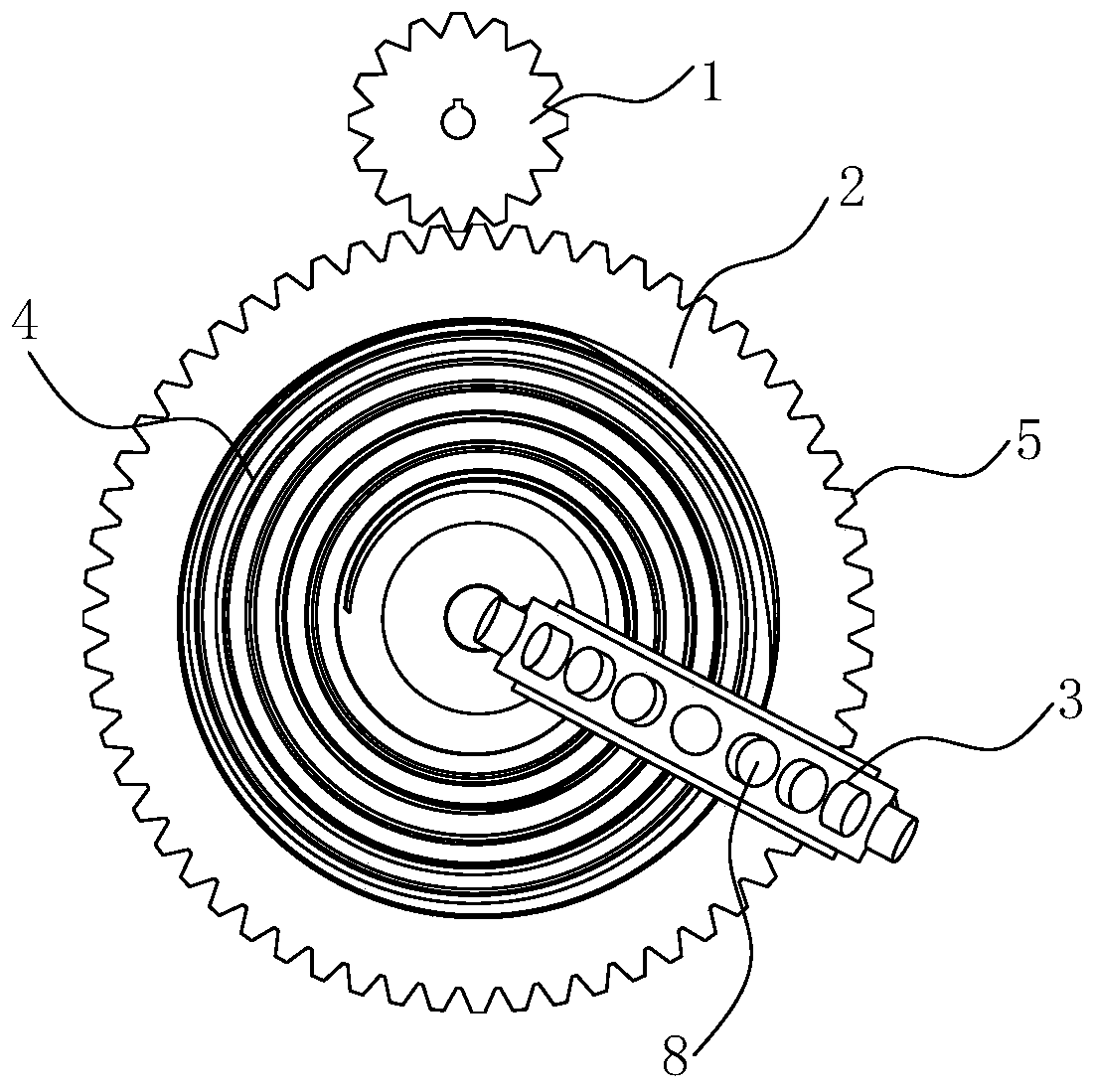

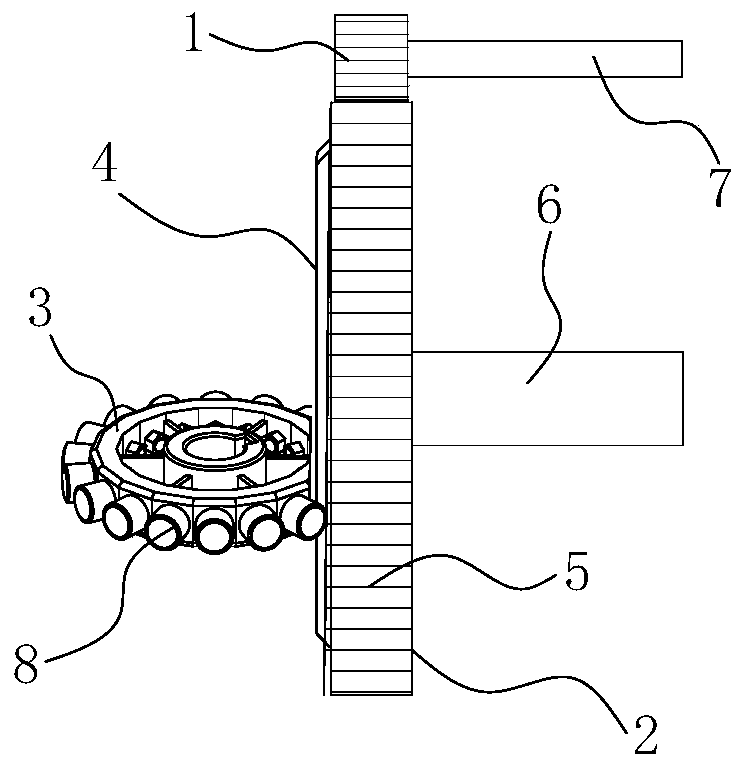

[0027] combine Figure 2-8 A new type of face transmission device with two-stage reduction function is shown, including pinion 1, transmission wheel 2 and worm wheel 3. The pinion 1 is connected with the power input shaft 7 for inputting power to the device. The worm gear 3 is connected with the power output shaft for outputting decelerated power. combine figure 2 and 3 As shown, the middle part of one end surface of the transmission wheel 2 is provided with a helical tooth 4 , the end surface of the worm wheel 3 is perpendicular to the end surface of the transmission wheel 2 , and the worm wheel 3 meshes with the helical tooth 4 . A circle of first gear teeth 5 is arranged on the peripheral surface of the transmission wheel 2 , and the first gear teeth 5 can be formed by machining, of course, can also be formed by direct die forging. The pinion 1 meshes with the first gear teeth 5, and the pinion gear 1 and the first gear teeth 5 realize the first deceleration during tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com