Self-buffering gas-liquid mixing multi-stage ejection mechanism

A gas-liquid mixing and self-buffering technology, which is applied in the direction of fluid pressure actuation devices, can solve the problems of poor sealing effect, easy damage to ejection devices, and difficulty in ensuring sealing performance, so as to reduce relative motion speed, ensure buffering effect, Effects that are easy to precisely control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

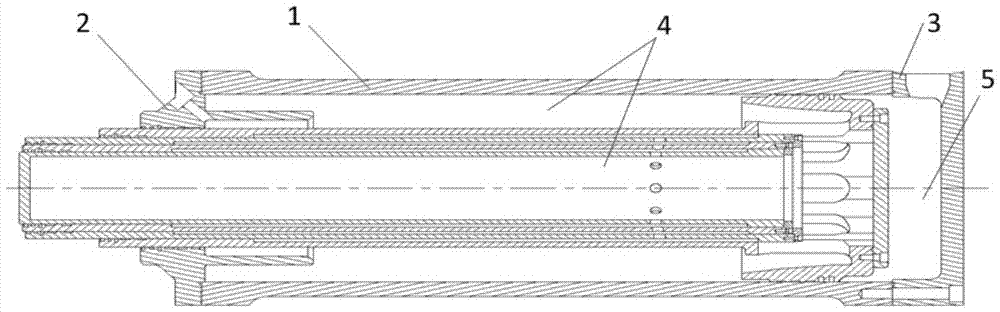

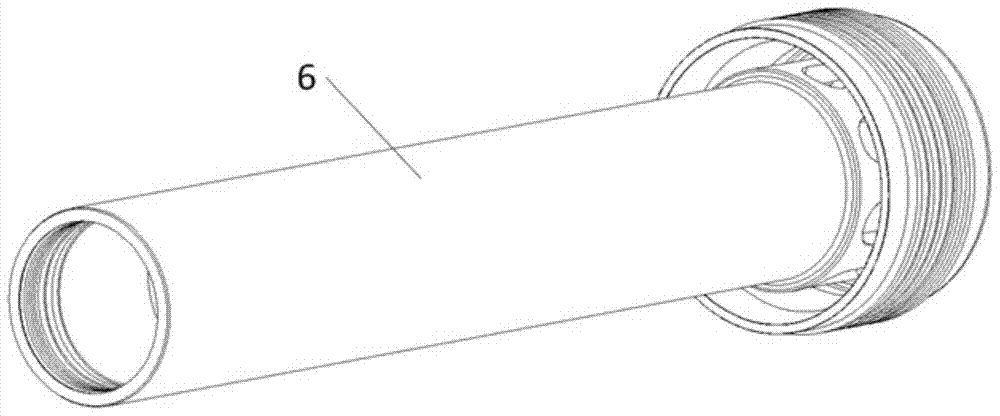

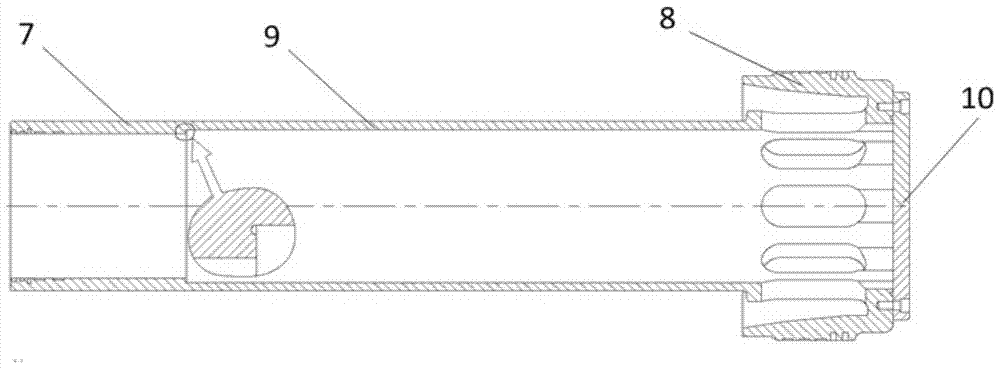

[0027] combine Figure 1 to Figure 5 :

[0028] A self-buffering gas-liquid mixed multi-stage ejection mechanism, including an outer cylinder body 1, an oil-filled end cover 2, an air intake end cover 3 and a four-stage sleeve type piston cylinder, an oil-filled end cover 2 and an air intake end cover 3 They are respectively fixed at both ends of the outer cylinder body 1, the oil-filled end cover 2 and the outer cylinder body 1 are oil-sealed, and the air-intake end cover 3 and the outer cylinder body 1 are air-tight; the outer cylinder of the four-stage sleeve type piston cylinder The layer piston cylinder 6 includes the extension end 7 of the outer layer piston cylinder, the outer layer piston cylinder body 9 and the outer layer piston end 8 in sequence, and the outer layer piston end 8 of the outer layer piston cylinder 6 is adjacent to the end surface of the oil chamber 4 There is a channel communicating with the inner cavity of the outer piston cylinder 6, the channel h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com