Gas-liquid mixed multi-stage high-speed ejection device

An ejection device, gas-liquid mixing technology, applied in the direction of fluid pressure actuation device, servo motor, mechanical equipment, etc., can solve the problems of difficult ejection output effect, high energy consumption, low energy utilization rate, etc., to achieve energy storage and transfer. The effect of high density, reduced relative movement speed, easy and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

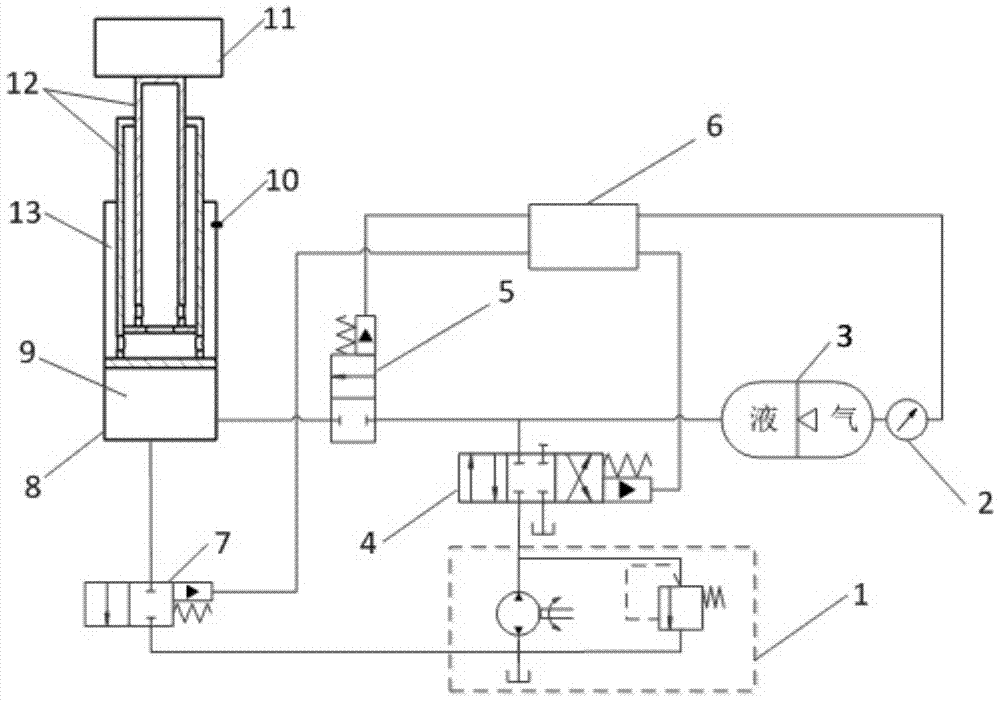

[0019] combine figure 1 :

[0020] A gas-liquid mixed multi-stage high-speed ejection device, including a hydraulic oil source 1, a control valve 4, a large flow switch valve 5, a common switch valve 7, an accumulator 3, a controller 6, a multi-stage ejection cylinder 8 and a load 11, The multi-stage ejection cylinder 8 is provided with a multi-stage sleeve type piston cylinder 12, the bottom of the multi-stage sleeve type piston cylinder 12 is in sliding and sealing cooperation with the multi-stage ejection cylinder 8, and the open end of the multi-stage ejection cylinder 8 is in contact with the multi-stage sleeve. The multi-stage ejection cylinder 8 is divided into a lower chamber 9 and an upper chamber 13 by the bottom of the multi-stage sleeve type piston cylinder 12. The upper chamber 13 is filled with oil, and the multi-stage sleeve type piston cylinder 12 is a two-layer sleeve structure, the inner sleeve is connected with the load, mainly the inner sleeve pushes the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com