Integrated sub master cylinder wire control hydraulic brake system

A hydraulic braking, wire-controlled technology, applied in the direction of brakes, wire-controlled brakes, brake transmission devices, etc., can solve the problems of brake pressure fluctuation, large pressure build-up accuracy, slow brake pressure, etc., to achieve weight reduction and stability. The effect of good sex and convenient layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention is described in detail below in conjunction with accompanying drawing:

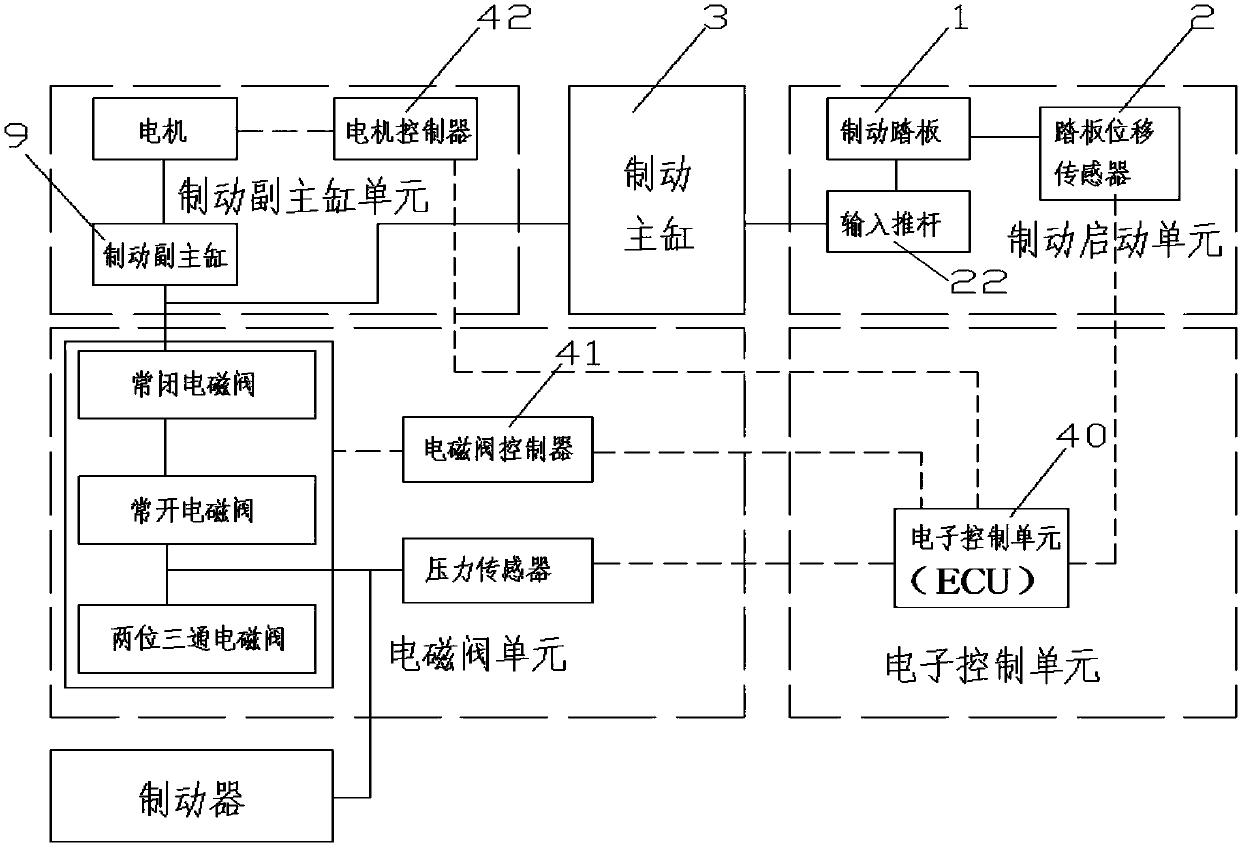

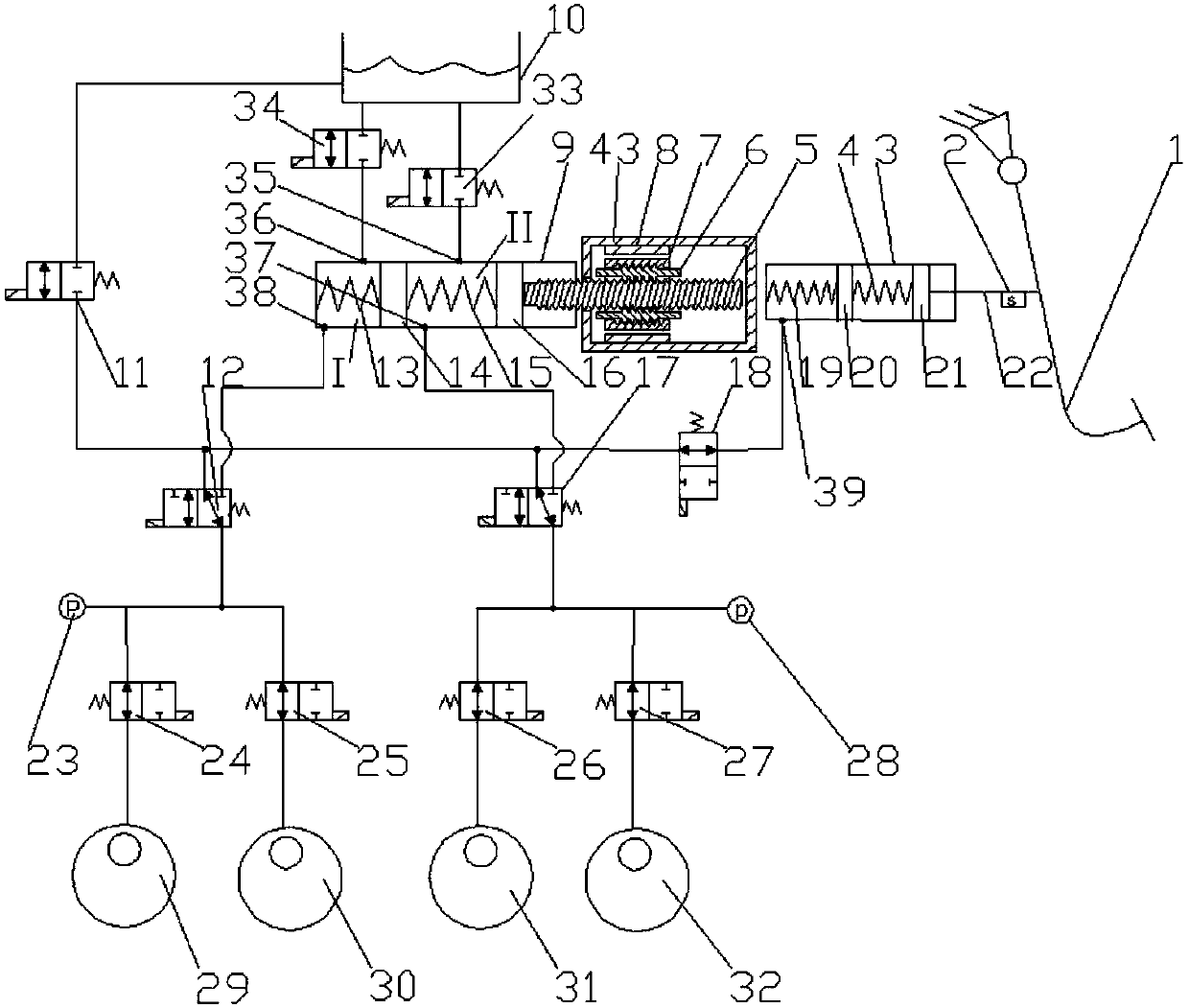

[0051] refer to figure 1 , the present invention includes a brake start unit, a brake master cylinder 3, a brake sub-master cylinder unit, a solenoid valve unit, an electronic control unit and a brake.

[0052] refer to figure 2 , the brake activation unit includes a brake pedal 1 , a pedal displacement sensor 2 , and an input push rod 22 .

[0053] The pedal displacement sensor 2 can be selected as a potentiometer type displacement sensor or a Hall type displacement sensor.

[0054] The right end of the brake pedal 1 and the input push rod 22 is connected by a pin shaft, so that the input push rod 22 can move with the rotation of the brake pedal 1 . The input push rod 22 is fixedly connected with the first piston 21 of the master cylinder in the brake master cylinder unit through threads.

[0055] The pedal displacement sensor 2 is fixedly installed on the input push rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com