Bypass type electronic fuel injector

An electronically controlled fuel injection and fuel injector technology, which is applied to machines/engines, fuel injection devices, engine components, etc., can solve the problems of fuel leakage, static pressure difference of fuel injectors, etc., so as to improve the fuel injection process and improve the pressure. Fluctuation, reducing the effect of mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

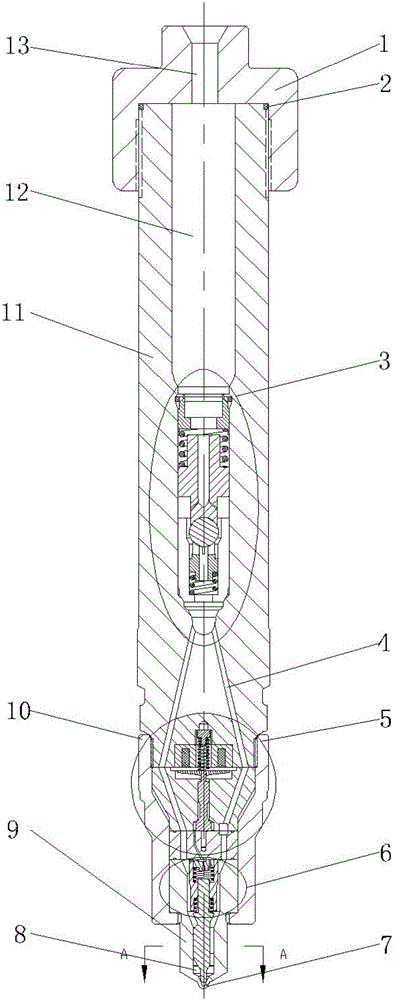

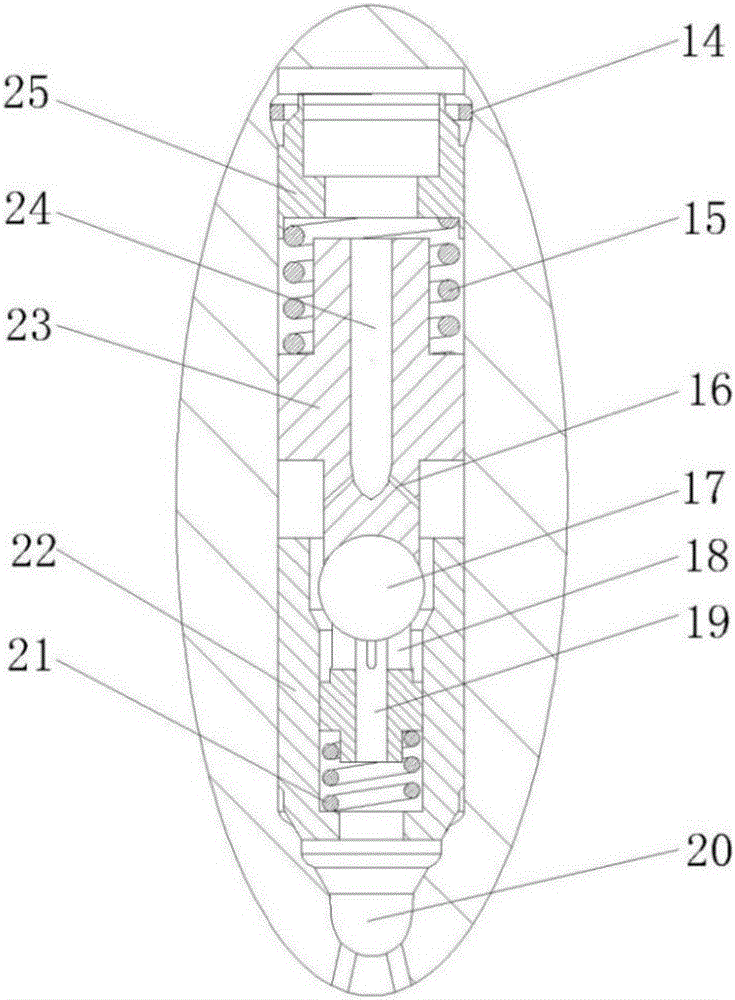

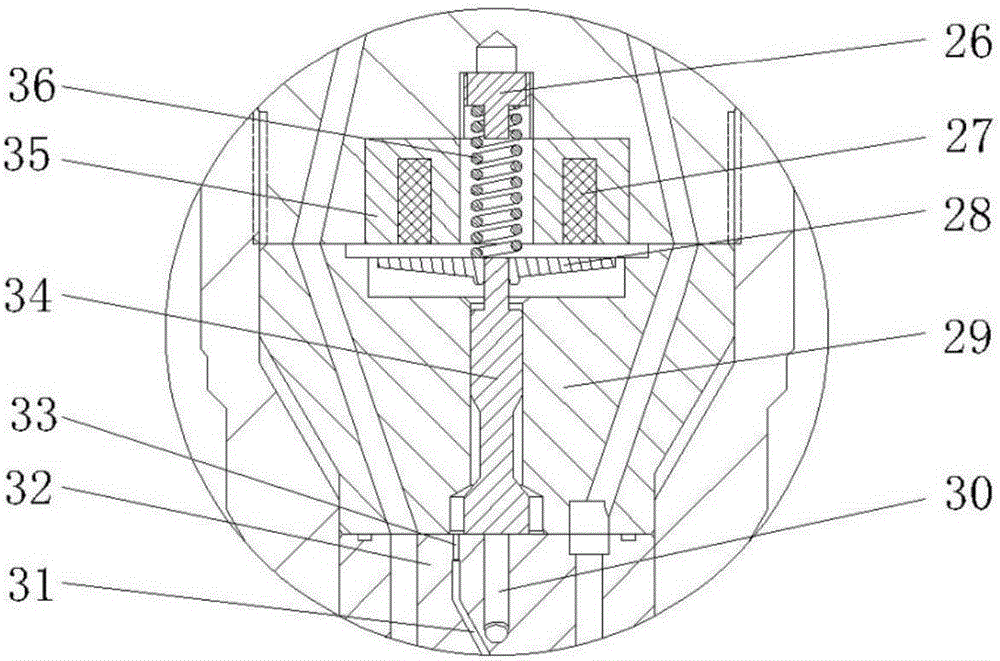

[0021] combine Figure 1-5 , The bypass electronically controlled fuel injector of the present invention includes a fuel injector head 1 , a restrictor valve assembly 3 , a solenoid valve assembly 5 , a needle valve assembly 6 , a nozzle 9 , a tight cap 10 , and a fuel injector body 11 . The fuel injector head 1 is mounted on the fuel injector body 11 through threaded fitting connection, and is sealed by the sealing ring 2 placed on the fuel injector body 11 . A main oil inlet hole 13 is arranged in the injector head 1 and communicates with the pressure accumulator chamber 12 in the injector body 11 . A restrictor valve assembly 3 is arranged below the accumulator chamber 12 . The flow limiting valve assembly 3 is installed inside the fuel injector body 11, and its main structure includes a retaining ring 14, a damping spring 15, a ball valve 17, a support contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com