Efficient condensing horizontal film wet dust removal system

A technology of wet dust removal and horizontal membrane, which is applied in membrane technology, steam condensation, and the use of liquid separation agents, etc., can solve the problems of large investment, high operating costs, and difficulty in meeting ultra-low emission requirements, and achieve high dust removal efficiency, Low investment and operating costs, good operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

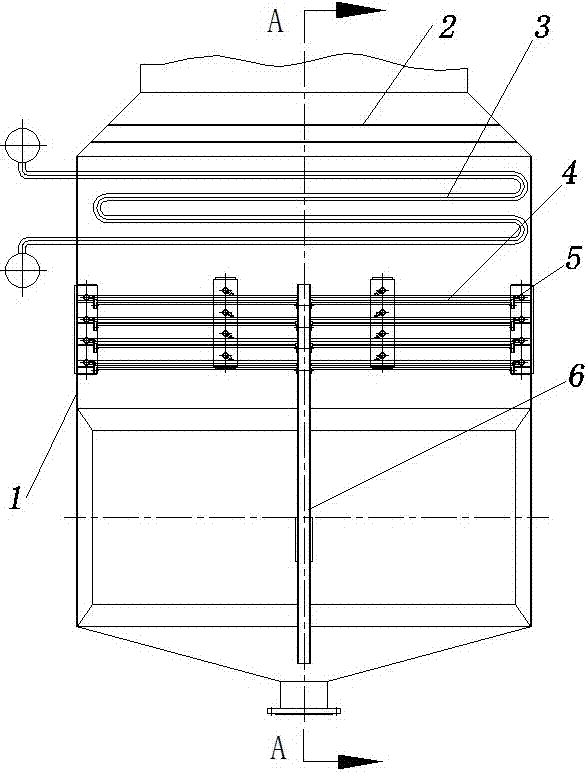

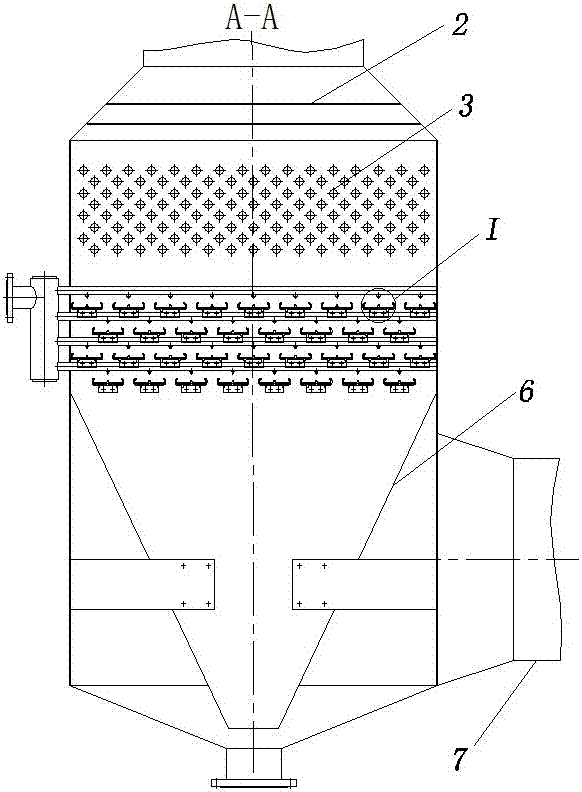

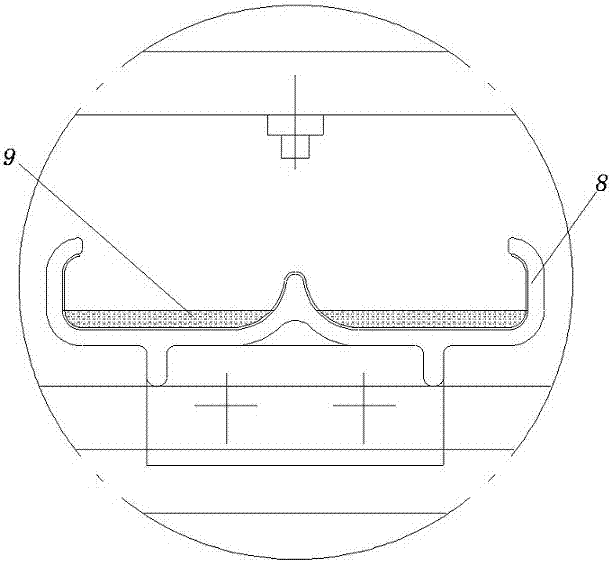

[0020] exist Figure 1 ~ Figure 3 Among them, the high-efficiency condensing horizontal membrane wet dedusting system of the present invention includes a shell 1 connected to the outlet flue of the desulfurization tower at the top, and a flue gas flow equalization device 2 installed above the interior of the shell, located below the flue gas flow equalization device and installed in the shell The flue gas condenser 3 inside the body, several layers of horizontal diaphragm plate demist and dust collectors 4 located below the flue gas condenser and installed inside the shell, several flushing Device 5, the collecting liquid conduit 6 installed in the center of the horizontal membrane plate demister and dust collector, and the smoke exhaust pipe 7 installed on the lower side of the housing; the horizontal membrane plate demist and dust collector includes a "mountain" shaped groove The horizontal membrane plates are arranged horizontally in staggered rows between the upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com