Desulphurization and dust removal integrating flue gas purification device and method

A flue gas purification, desulfurization and dust removal technology, applied in the field of flue gas purification, can solve the problems of high cost, large area occupied by flue gas desulfurization and dust removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the drawings.

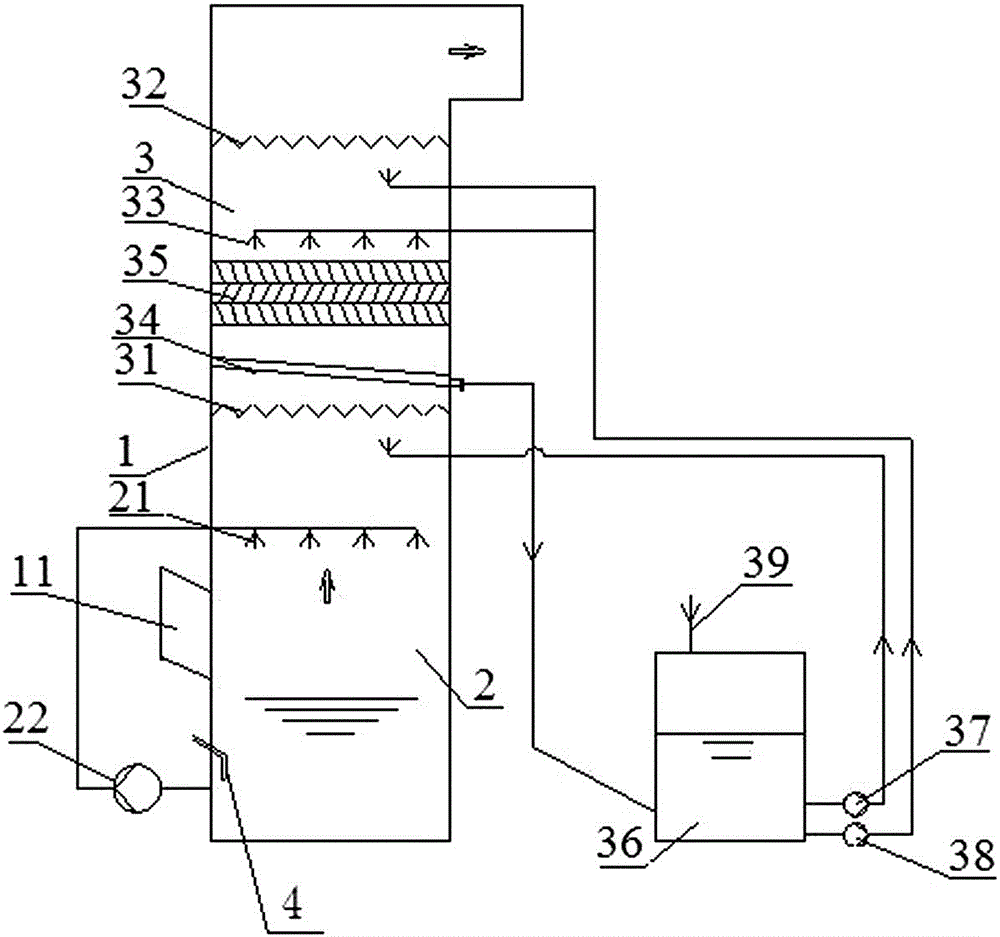

[0021] figure 1 It is a schematic structural diagram of an integrated desulfurization and dust removal flue gas purification device provided by an embodiment of the present invention. The direction of the hollow arrow in the figure is the flow direction of the flue gas. As shown in the figure, the embodiment of the present invention provides an integrated flue gas purification device for desulfurization and dust removal, including an absorption tower 1 in which a wet desulfurization system 2 and a water washing deep dust removal system 3 are sequentially arranged in the flue gas flow direction in the absorption tower 1. The flue gas enters the absorption tower 1, after passing through the absorption tower inlet 11, it first passes through the wet desulfurization system 2, and then enters the water washing deep dust removal system 3, and the flue gas is deeply cleaned and was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com