A rotary regenerative air preheater

An air preheater, regenerative technology, applied in lighting and heating equipment, combustion methods, indirect carbon dioxide emission reduction, etc. Pressure, temperature fluctuations and other problems, to achieve the effect of long service life, large bearing capacity and low running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

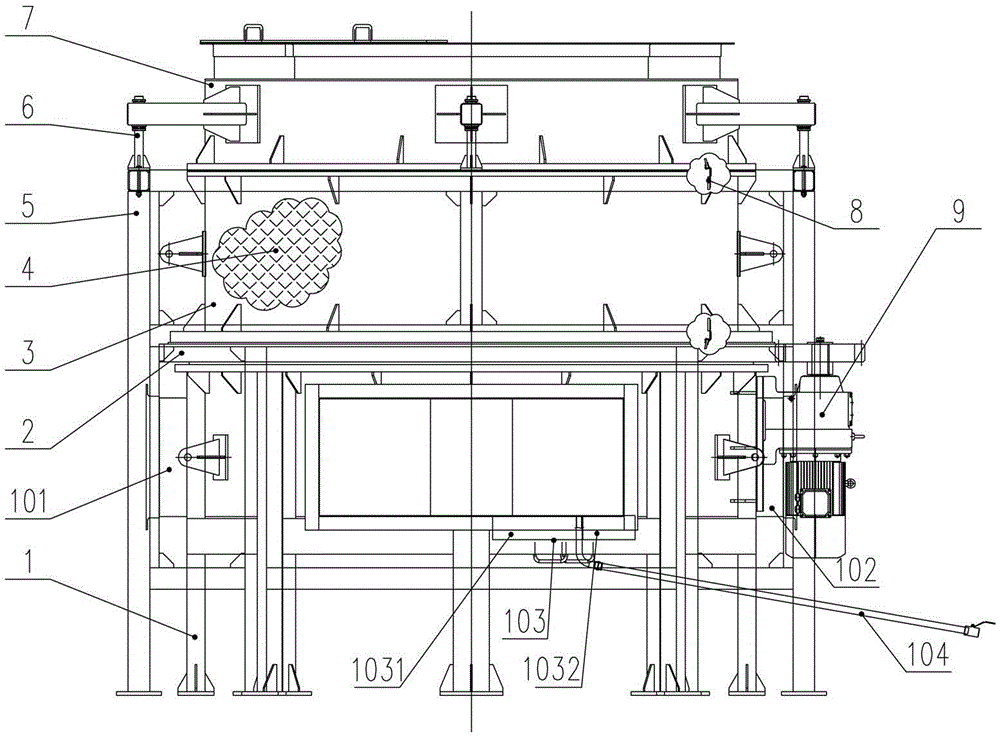

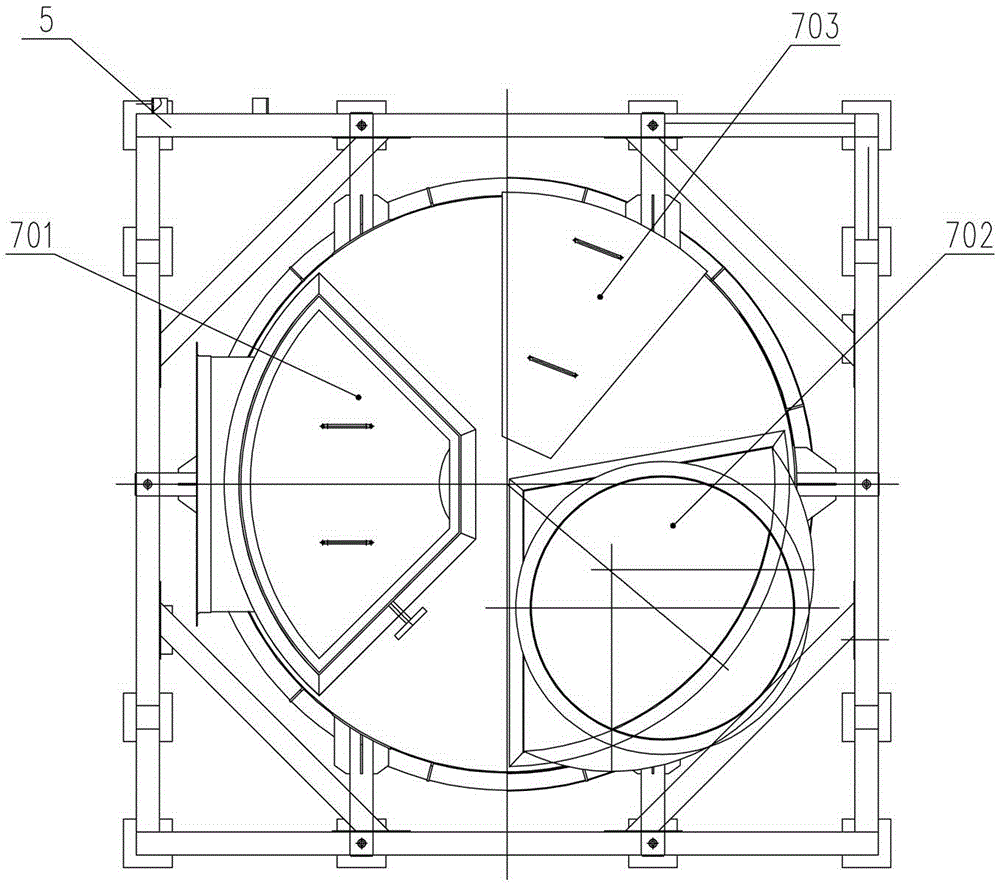

[0019] Such as figure 1 , 2 As shown, the present invention comprises a base 1, a slewing bearing 2, a gyrator 3, a heat storage body 4, a support frame 5, an adjustment device 6, a top cover 7, a seal 8, a reducer 9 and an insulating material; on the base 1 The lower air inlet 101 and the lower flue gas outlet 102 are provided; the top cover 7 is provided with an upper air inlet 701 , an upper flue gas inlet 702 and a maintenance hole 703 .

[0020] Such as figure 1 As shown, the interior of the base 1 is divided into two independent sections of air and smoke, the cold air is input from the lower air inlet 101 , and the cold smoke is discharged from the lower smoke outlet 102 . At the bottom of the base 1, a condensate collection and neutralization device 103 is installed in the flue gas chamber. The condensate collection and neutralization device 103 is composed of a mixed sedimentation chamber 1031 and a heavy metal treatment chamber 1032. The treated condensate is discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com