Flue gas desulfurization and haze reducing tower

A technology for flue gas and desulfurization zones, which is applied in the directions of dispersed particle separation, chemical instruments and methods, combined devices, etc., to achieve the effect of compact structure and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

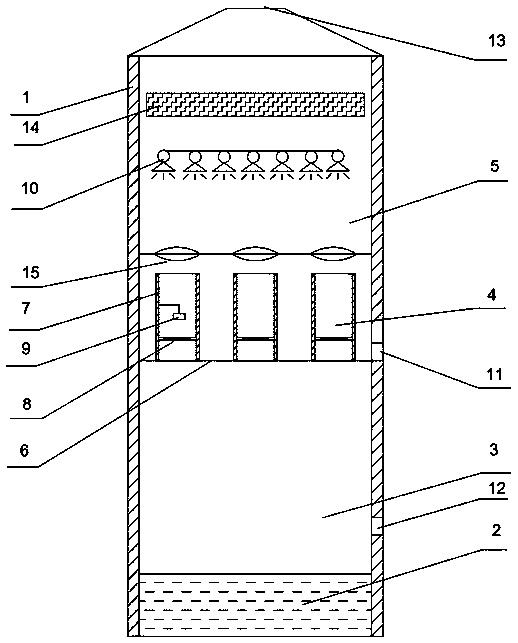

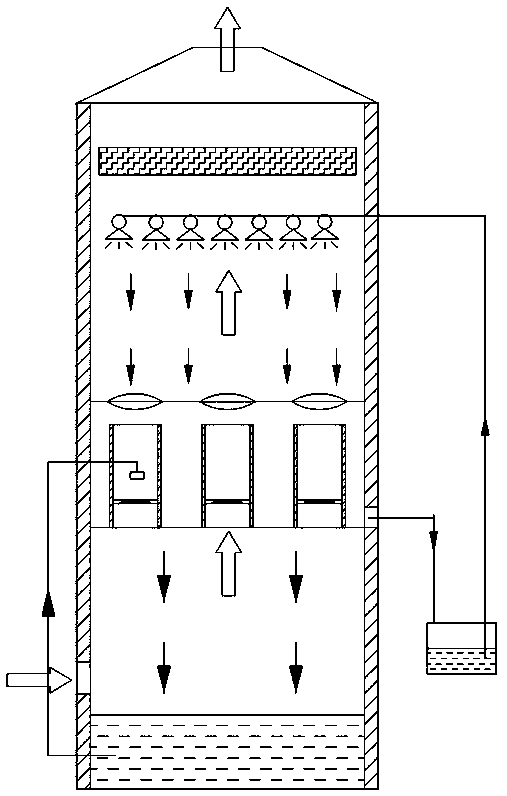

[0022] combine figure 1 , figure 2 , Figure 5 and Figure 6 , the present invention is described as follows:

[0023] A flue gas desulfurization and haze reduction tower, including a tower shell 1 and internal components, the inner cavity of the tower shell 1 is from bottom to top, followed by a slurry area 2, an air intake area 3, a desulfurization area 4 and a washing area 5, and the slurry area 2 communicates with the air intake area 3, a partition 6 is set between the air intake area 3 and the washing area 5, and the partition 6 isolates the air intake area 3 and the washing area 5, and the desulfurization area 4 is in the desulfurization cylinder 7 on the partition 6. The slurry area 2 is the area used to store and collect the desulfurization slurry, also called the slurry pool; the intake area 3 is the area where the flue gas enters the desulfurization haze reduction tower; the desulfurization area 4 is the area where the desulfurization slurry contacts the flue gas...

Embodiment 2

[0030] combine figure 1 , figure 2 , image 3 and Figure 4 , the present invention is described as follows:

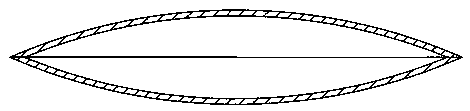

[0031] On the basis of Embodiment 1, in the washing area 5 and above the desulfurization cylinder 7, a shielding device, called a water blocking cap 15, is added to prevent the water sprayed by the scrubber 10 from entering the desulfurization cylinder 7, thereby Drop into final slurry pool. The water blocking cap 15 is arranged on the upper part of the desulfurization cylinder 7 , leaving a gap so that the flue gas enters the washing area 5 from the desulfurization cylinder 7 . In the present embodiment, a double-spherical water blocking cap 15 is adopted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com