Negative pressure waste gas discharge disinfection sterilizer and manufacturing method thereof

A technology for disinfection and sterilizers and exhaust gas discharge, which is applied to chemical instruments and methods, separation methods, manufacturing tools, etc., and can solve the problems of difficult welding of protective covers and increase the pressure bearing capacity of protective covers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

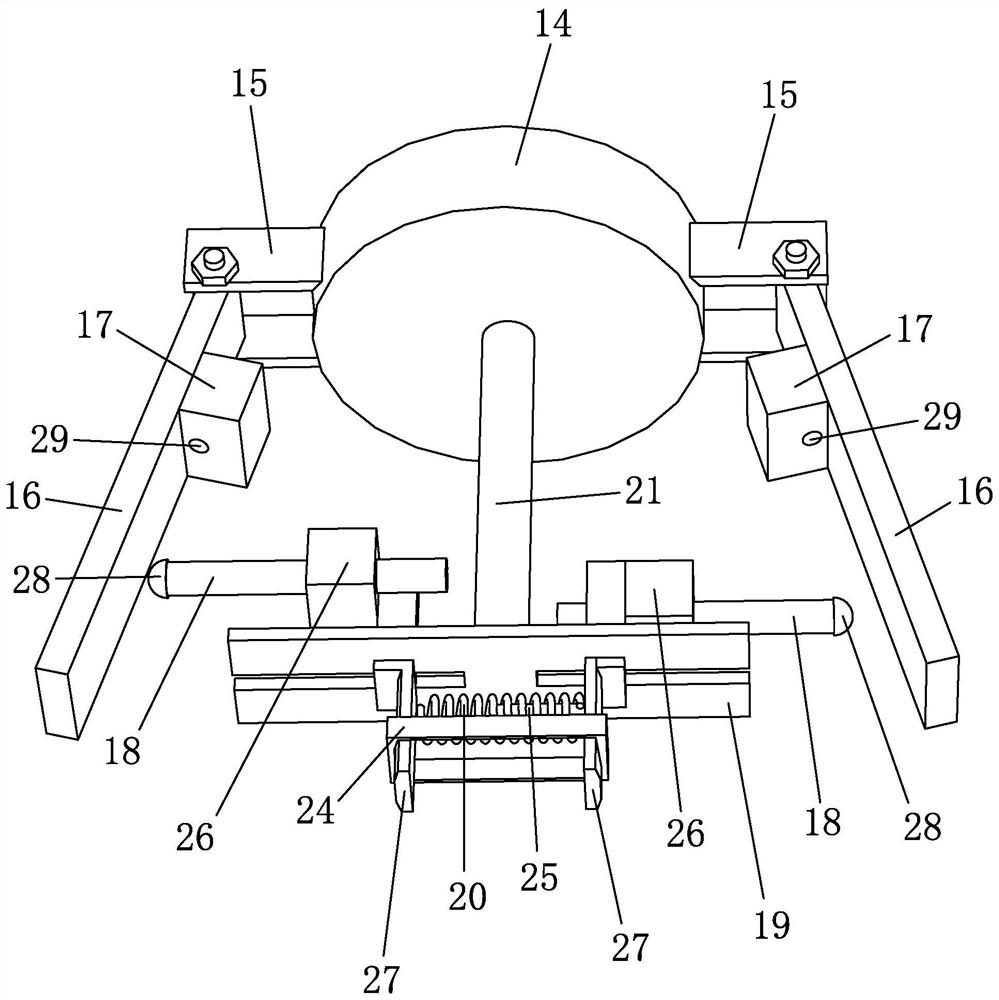

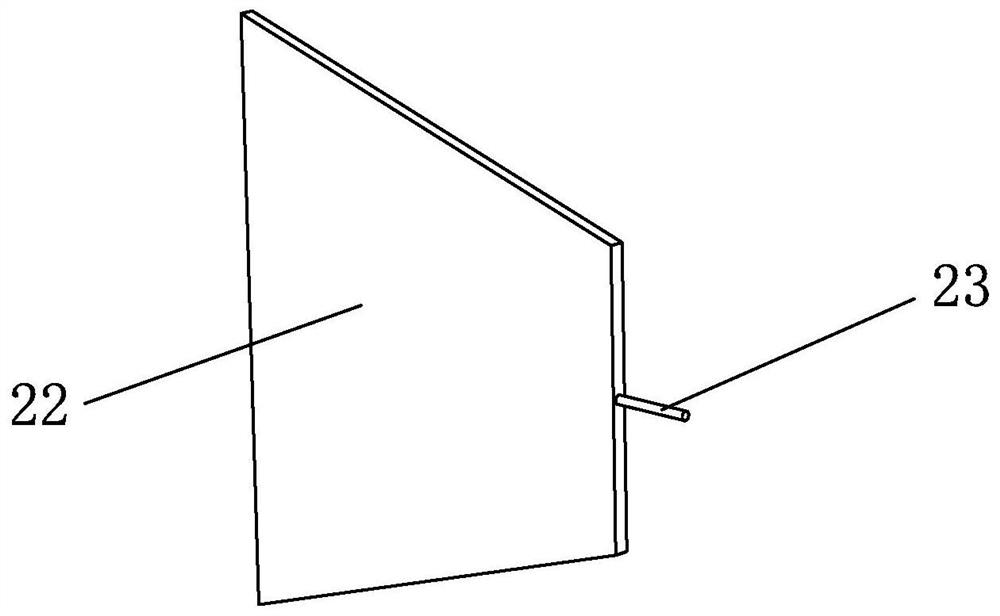

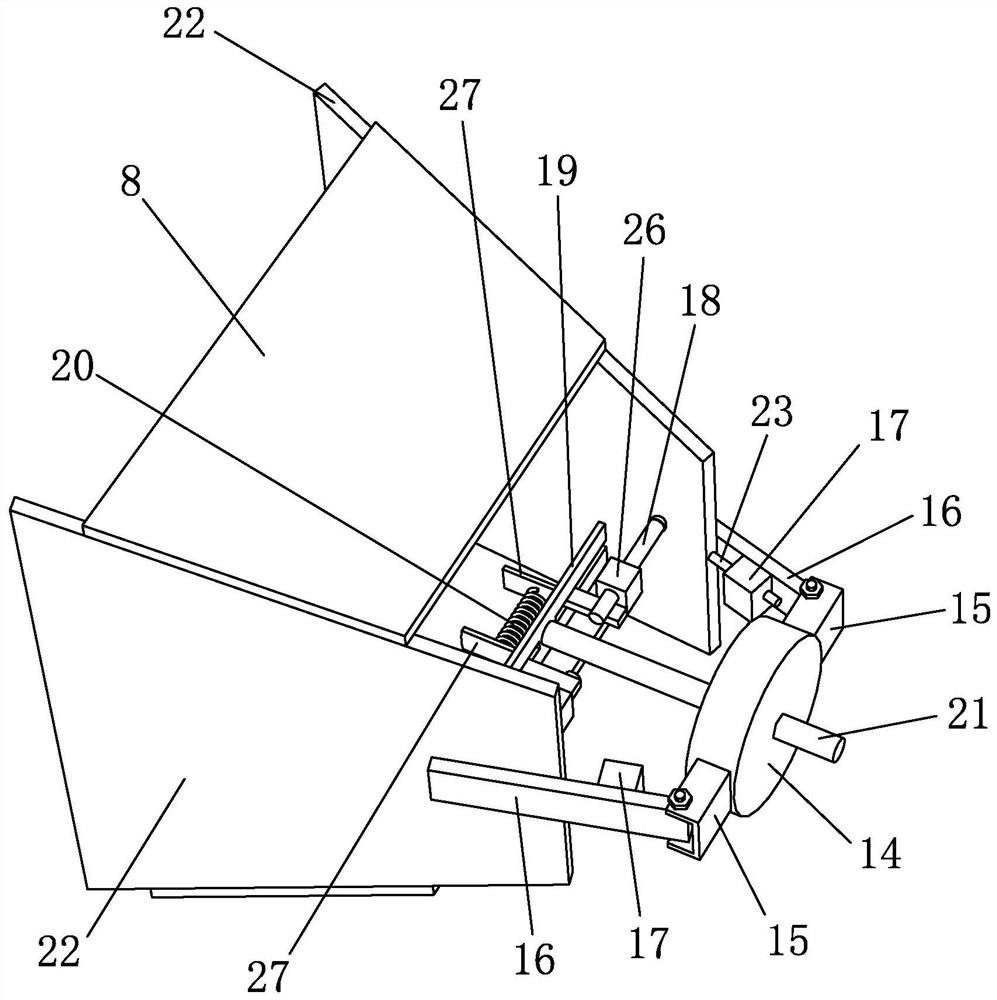

[0057] like Figure 1 to Figure 10 As shown, it is a negative pressure exhaust gas discharge disinfection and sterilizer according to the present invention, which includes a housing 1 and a gas pipeline 2, a junction box 3 is provided on the top of the housing 1, a heating element 4 is arranged in the housing 1, and the heating element 4 Protruding into the housing 1 , the junction box 3 supplies power to the heating element 4 . After the power is turned on, the heating element 4 can be heated to 110°C~200°C, the system differential pressure is ≤2kPa, and the processing air volume is 500m 3 / h, killing efficiency > 99.99%.

[0058] The gas pipeline 2 is mainly an intake pipe and an exhaust pipe, and the intake pipe is connected with the vacuum pump system. If the exhaust port of the exhaust pipe is set in the basement, the exhaust port should be led to the outside; if the exhaust port is set outside or newly led to the outside, the exhaust port should not be at the same heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com