A single gun oil gas recovery separator

A separator, oil and gas technology, applied in the field of single-gun oil and gas recovery separator, can solve the problems of oil tank area and gas station safety hazards, oil and gas have not been recovered, eliminate safety hazards, etc., to reduce engineering costs, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

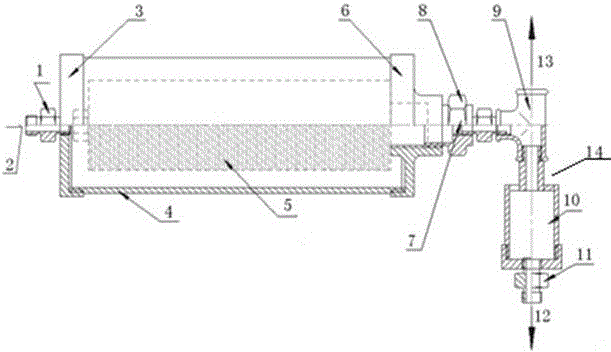

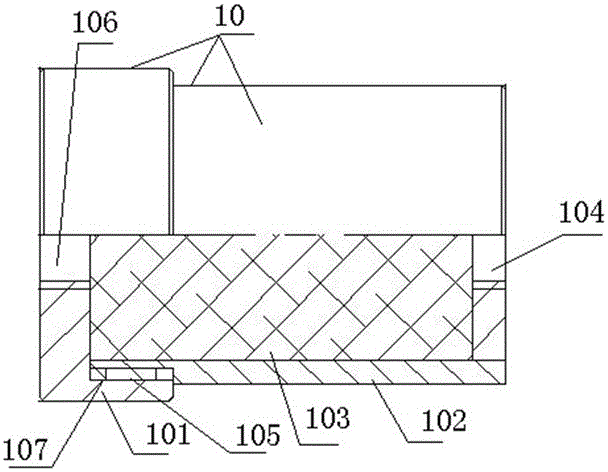

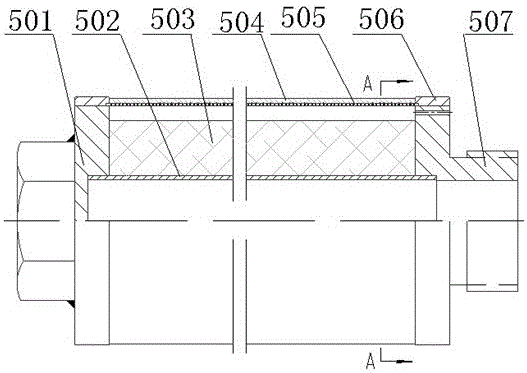

[0025] like figure 1 As shown, a single-gun oil and gas recovery separator is characterized in that it at least includes: a filter cartridge 4, an air inlet joint 1 and a connecting joint 7, a fixed gathering filter unit 5 in the filter cartridge 4, and two ends of the filter cartridge 4 The aggregation filter unit 5 is encapsulated in the filter cartridge 4 by the upper cover 3 and the lower cover 6, the upper cover 3 is connected to the air inlet joint 1, and the lower cover 6 is connected to the connection joint 7; the air intake joint 1 and the connection joint 7 are in the filter cartridge At both ends of 4, the air inlet joint 1, the filter cartridge 4, the aggregation filter unit 5 and the connecting joint 7 constitute the first filter body;

[0026] The connecting joint 7 is connected with a reducing joint 8, and the connecting joint 7 is connected with the three-way joint 9 through the reducing joint 8; one of the two openings directly connected by the three-way joint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com