High-temperature and low-temperature gas-phase composite desulfurization and denitration method

A desulfurization and denitrification, high and low temperature technology, applied in the field of desulfurization and denitrification, can solve the problems of complex structure, large floor area, high power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

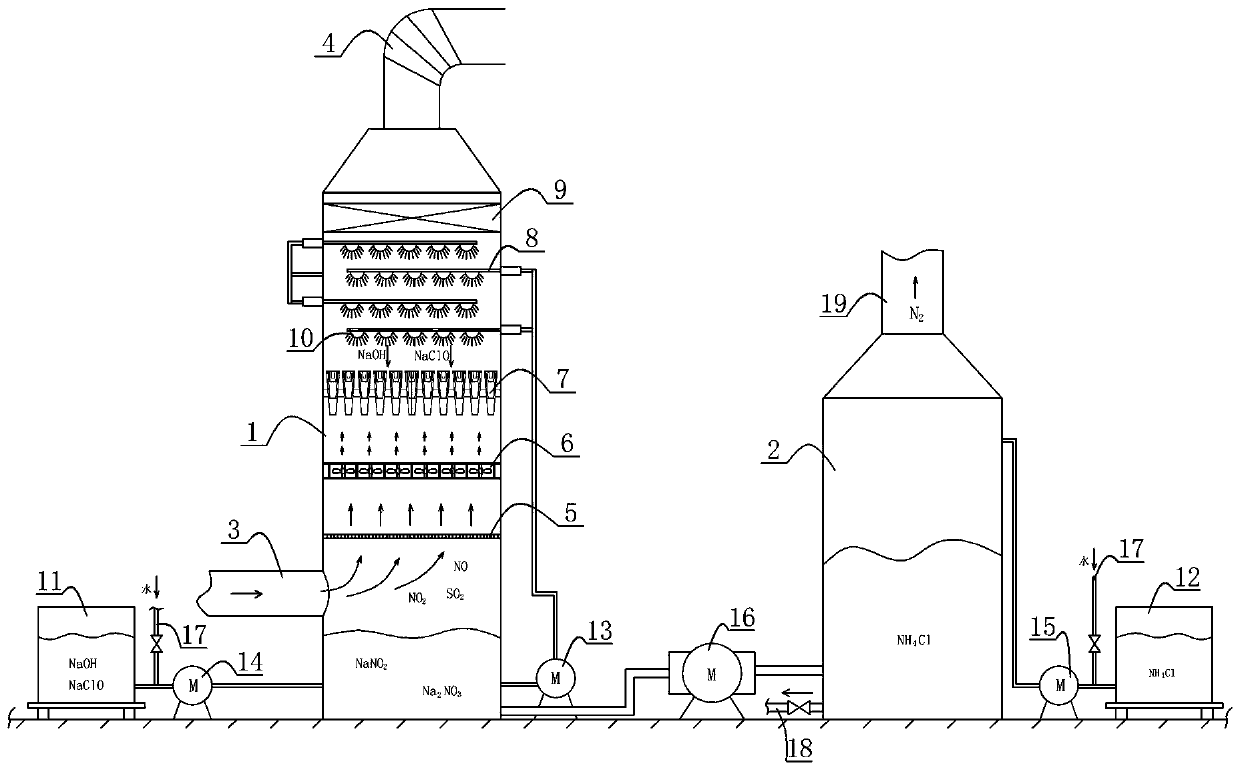

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] The high-low temperature gas-phase composite desulfurization and denitrification method of the present invention is realized by the following methods:

[0028] a). Flue gas is introduced, and the flue gas discharged from combustion is passed into the desulfurization and denitrification tower through the intake pipe;

[0029] b). The flue gas is evenly distributed. After the flue gas enters the desulfurization and denitrification tower, it first passes through the uniform distribution plate with holes at the bottom to achieve uniform distribution on the cross section of the desulfurization and denitrification tower;

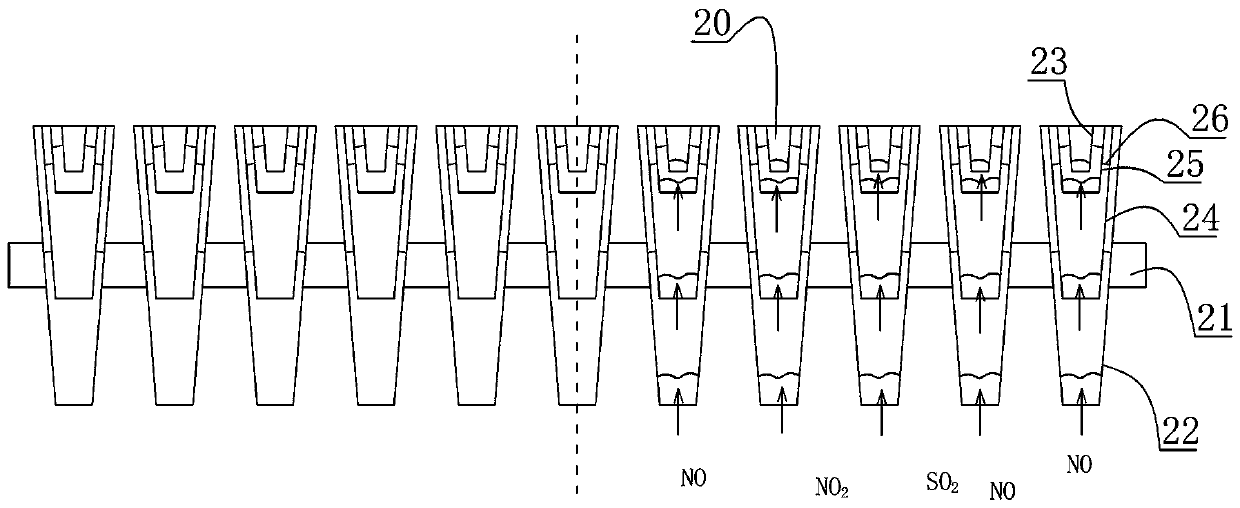

[0030] c). Flue gas turbulence. During the process of flue gas flow through the turbulence device, the upward flow speed of the flue gas will be accelerated under the impeller of the turbulence device; the flue gas meets the catalyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com