Ammonia recovery device

A recovery device and ammonia gas technology, applied in ammonia compound, inorganic chemistry, use of liquid separation agent, etc., can solve the problems of non-recovery of ammonia, environmental pollution, waste of resources, etc., achieve high recovery efficiency, meet environmental protection standards, occupy land small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

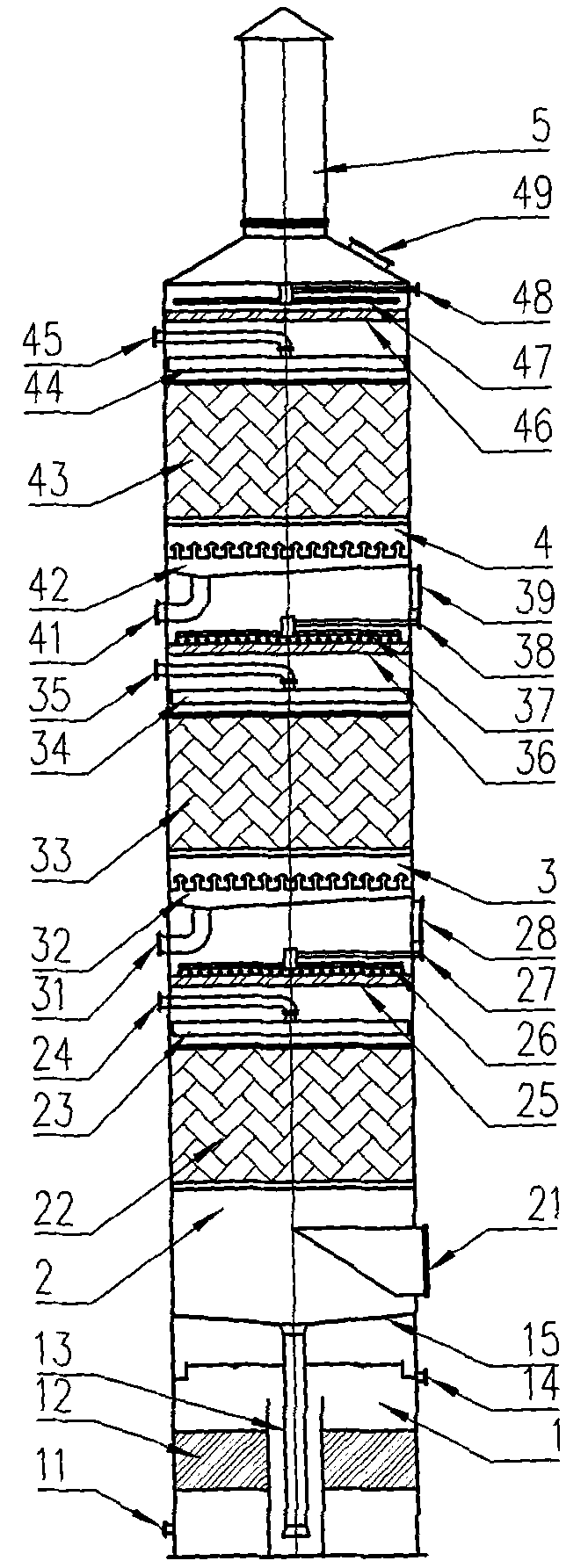

Image

Examples

Embodiment Construction

[0008] The tail gas from polyacrylamide production enters the ammonia gas recovery device of the present invention from the tail gas inlet 21, then flows upwards, passes through the washing area 2, the primary absorption area 3, and the secondary absorption area 4 in sequence, and finally is discharged into the atmosphere through the chimney 5.

[0009] Water is used as the washing liquid, the polyacrylamide dust in the tail gas dissolves into the water, the oil in the tail gas and water form an emulsion, in the washing liquid circulation separation tank 1, the oil and water are separated, the oil floats to the water surface, and the water is used as the washing liquid through the washing The cleaning liquid inlet pipe 27 in the washing area is added, which is not only used for cleaning the demister 25 in the washing area, but also for replenishing the washing liquid in the washing liquid circulation separation tank 1, replacing the washing liquid and overflowing the oil floatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com