Production line of glass wool rock wool composite PU hard foam thermal insulation plate

A technology of thermal insulation board and glass wool, applied in the direction of layered products, lamination devices, lamination auxiliary operations, etc., can solve the problems of long curing and curing period, complicated construction, long construction period, etc., saving overall labor time, shortening Construction period, safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to have a clearer understanding of the technical features, purposes and effects of the invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings, in which the same reference numerals represent the same components. In order to make the drawing concise, the parts related to the present invention are only schematically shown in each drawing, and they do not represent the actual structure of the product.

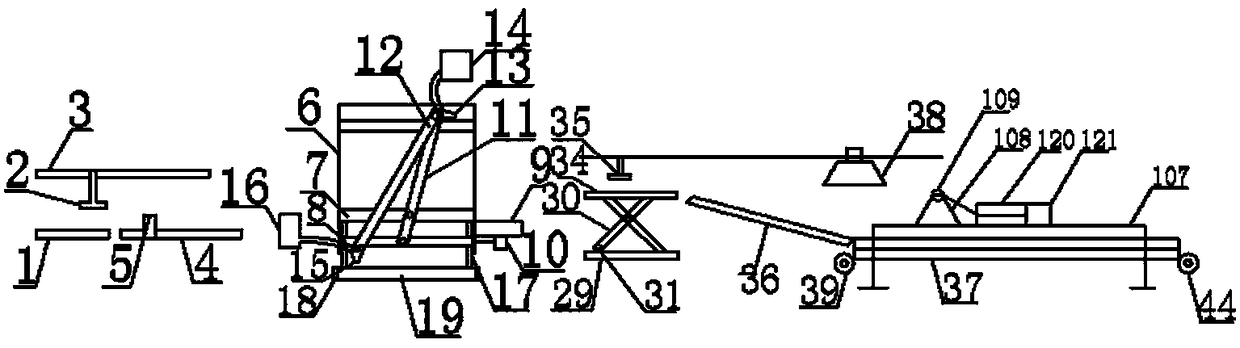

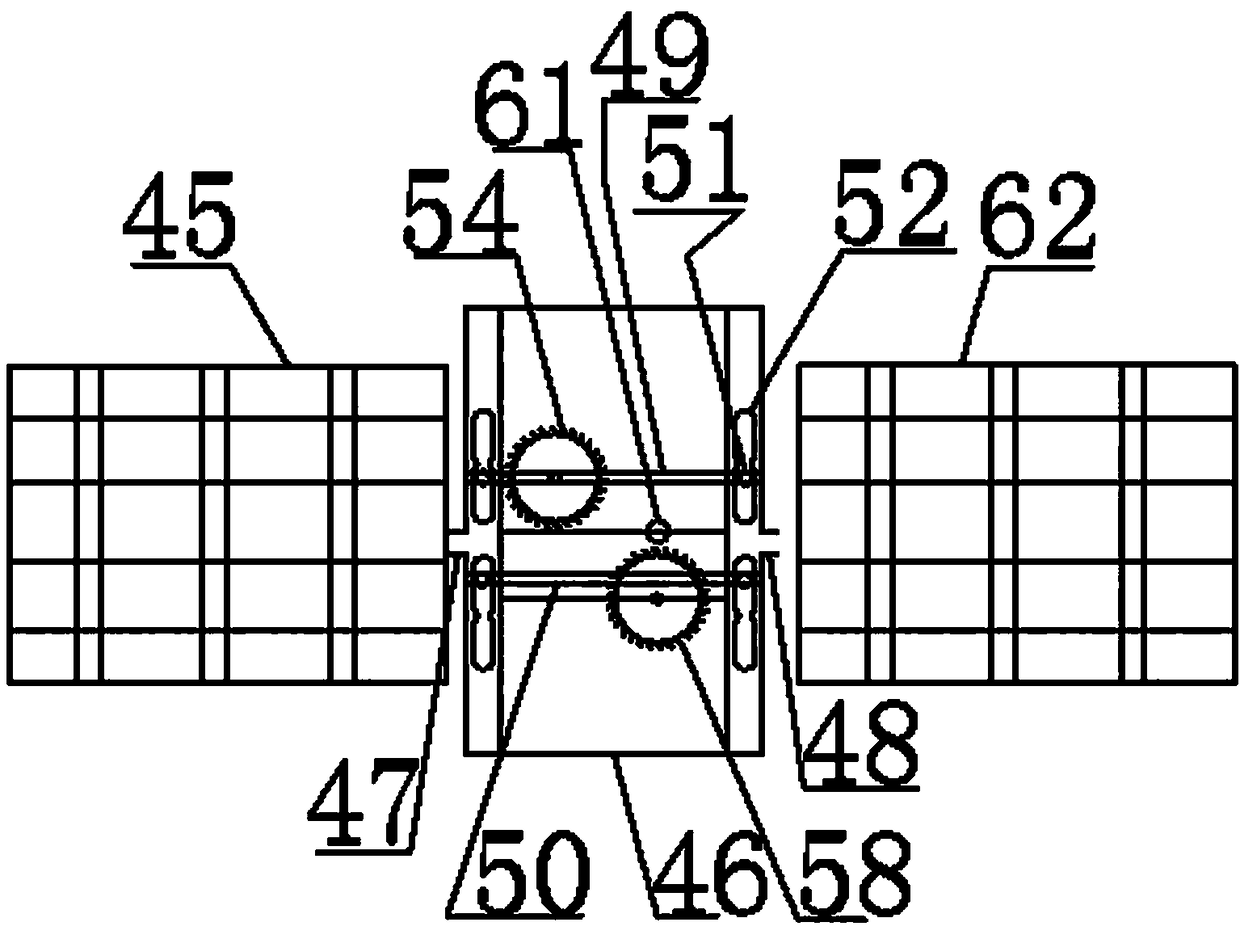

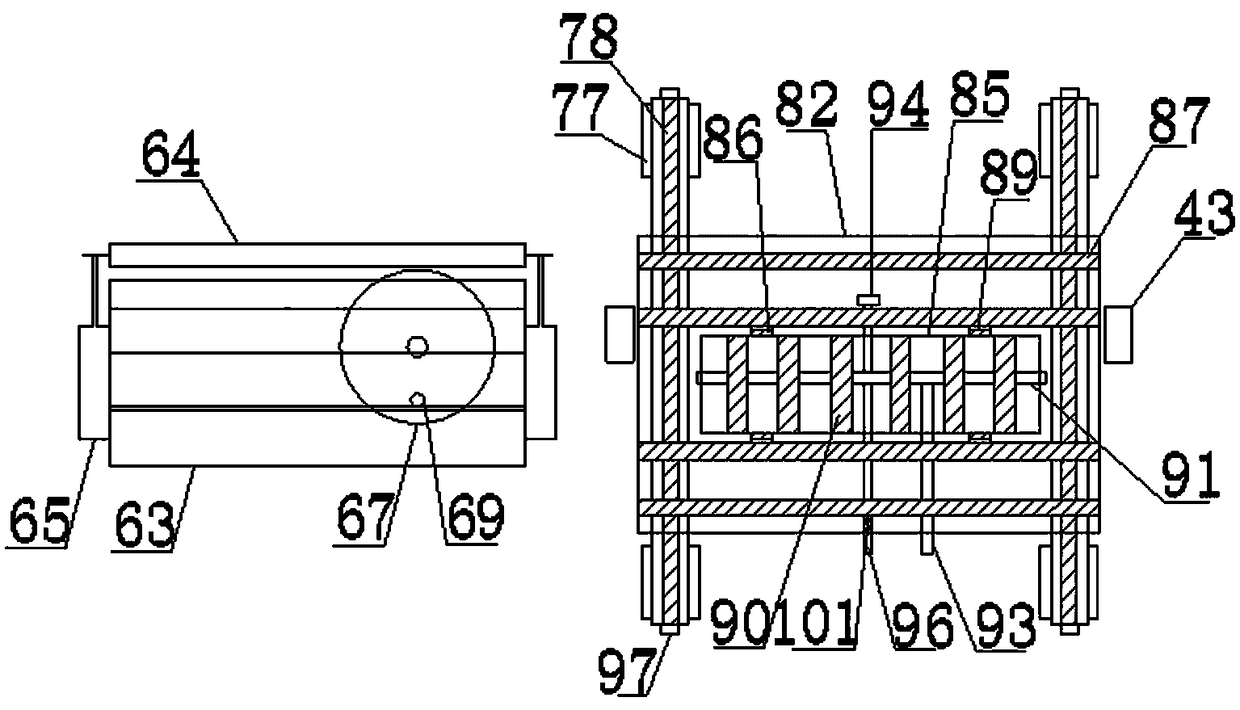

[0047] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, the present invention is a continuous production line of glass wool and rock wool composite PU rigid foam insulation board, the production line includes The lower cement board feeding device at the front end, the first conveying device is equipped with a glue spraying and curing device, a composite board bonding and rolling device, and an upper layer board feeding device from front to back; the end of the first conveying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com