Wet dust collection device with anti-explosion function and polishing system

A wet dust removal and functional technology, applied in the field of sorting, can solve problems such as hidden safety hazards, easy explosion, explosion, etc., to avoid secondary explosion, improve purification effect, and improve the effect of safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

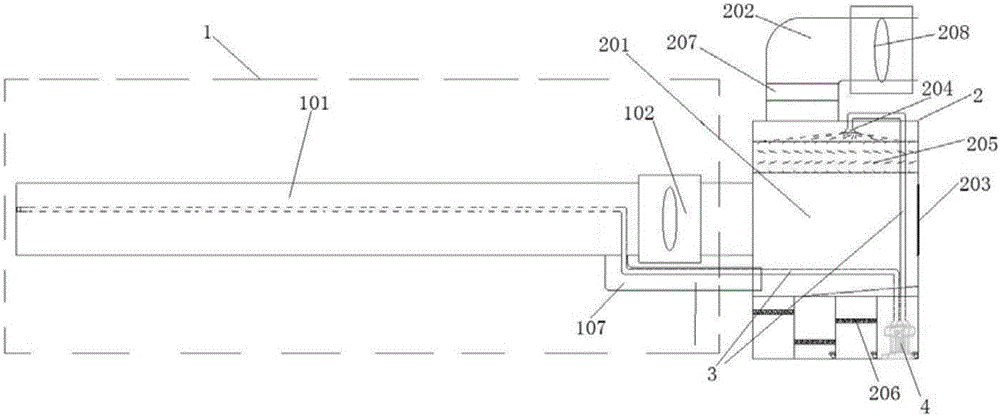

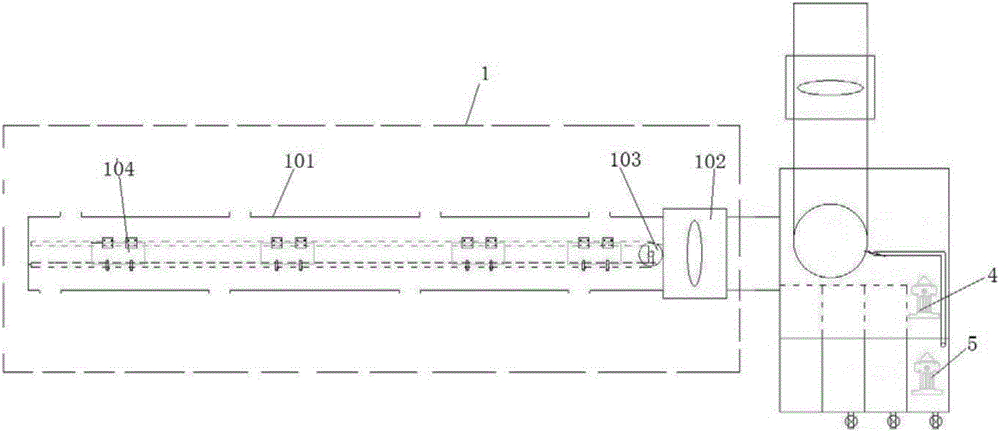

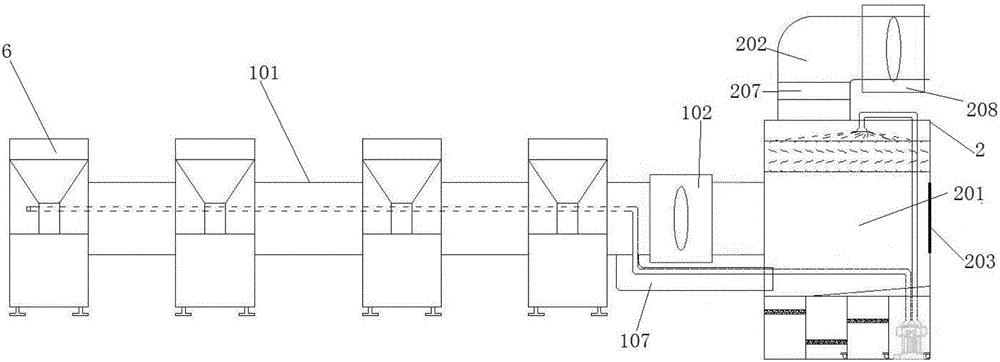

[0020] Such as figure 1 and figure 2 As shown, the present invention is realized in this way. The wet dust removal device with explosion-proof function includes an air guide spray system 1 and a wet dust removal system 2 connected at the end of the air guide spray system 1. Its structural characteristics are: The air guide sprinkler system 1 includes a suction pipe 101 for collecting and guiding dust and a first exhaust fan 102 located on the suction pipe 101, and the suction pipe 101 is provided with an air guide port 103 for one-way entry of dust The wet dedusting system 2 includes a clean room 201 communicating with the end of the suction pipe 101, the top and bottom of the clean room 201 are respectively provided with a wet clean assembly and a filter assembly, and the top of the clean room 201 passes through The pipeline 202 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com