Patents

Literature

42results about How to "Avoid secondary explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for active explosion proofing and explosion suppression through high-pressure inert gas

InactiveCN103790622AStop Gas Explosion AccidentsReduced Shockwave StrengthDust removalFire preventionGas explosionInjector

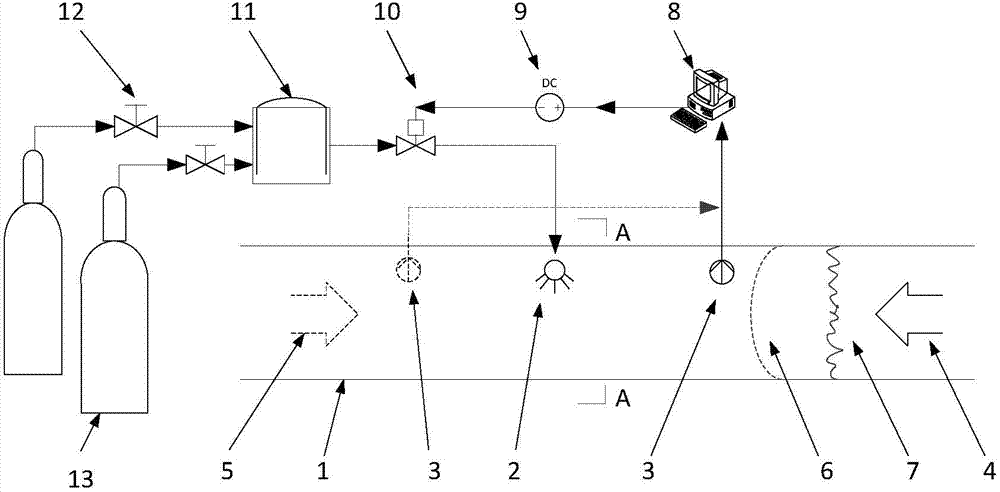

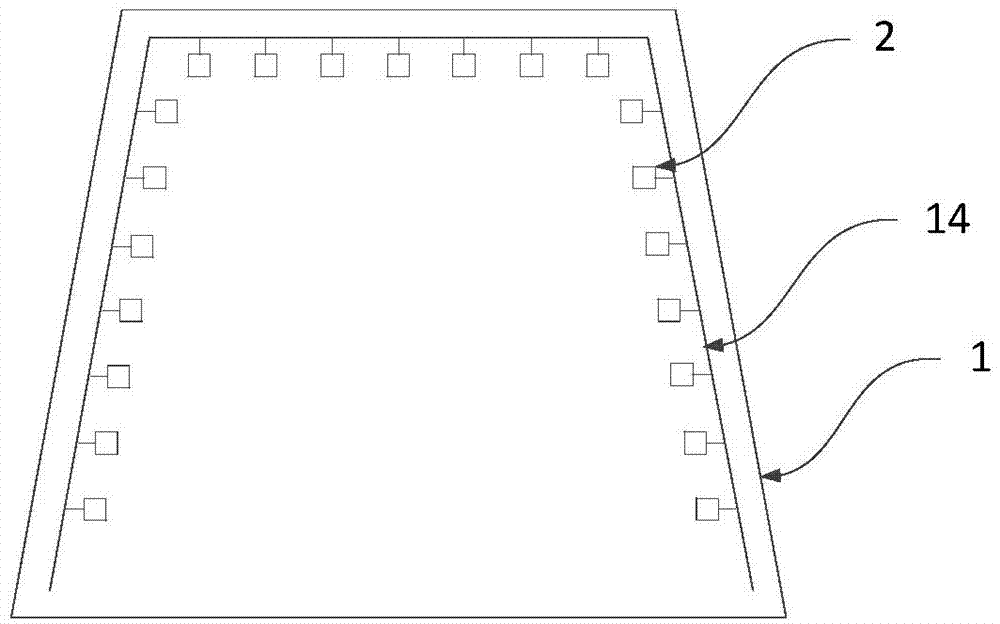

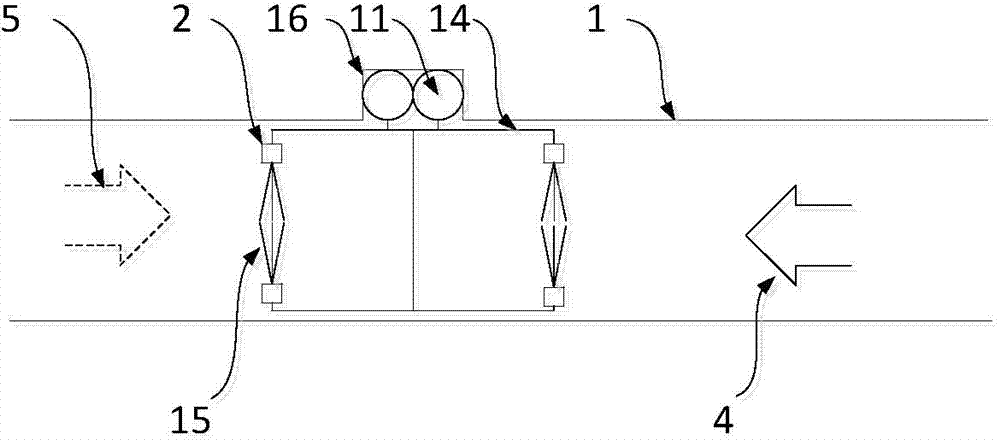

Provided is a method for active explosion proofing and explosion suppression through high-pressure inert gas. The method for active explosion proofing and explosion suppression through the high-pressure inert gas is applicable to prevention and suppression of gas explosions in a closed pipeline without external decompression space, and is particularly applicable to prevention and suppression of gas explosions in a coal mine. The method for active explosion proofing and explosion suppression through the high-pressure inert gas comprises the steps that wall grooves are constructed in a mine laneway, and a high-pressure gas source and a signal receiving and processing system are installed; a plurality of ejectors are distributed on the laneway side and a roof in an array mode at intervals, the ejectors are communicated through high-pressure rubber hoses, and pressure sensors which are connected with the signal receiving and processing system are arranged in the portions, on the two sides of each ejector, of the laneway respectively, wherein the laneway side and the roof are arranged on the same section of the mine laneway; the sensors are installed in the laneway, and receive shock wave signals, and the high-pressure inert gas source ejectors and connecting pipelines of the high-pressure inert gas source ejectors are installed; when the gas explosions happen, the sensors detect the forwards-moving shock wave signals, a solenoid valve is started, gas of the high-pressure inert gas source is ejected through the ejectors, a high-pressure inert gas curtain is formed in the laneway, and spread of explosion shock waves is obstructed.

Owner:CHINA UNIV OF MINING & TECH

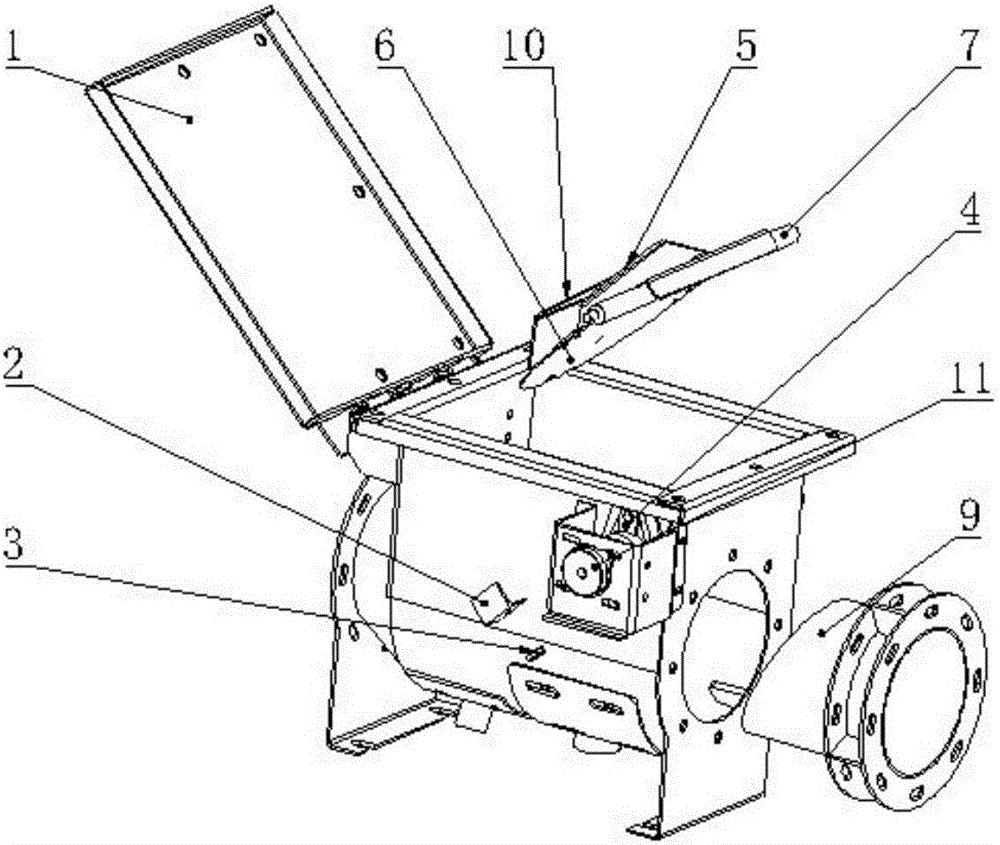

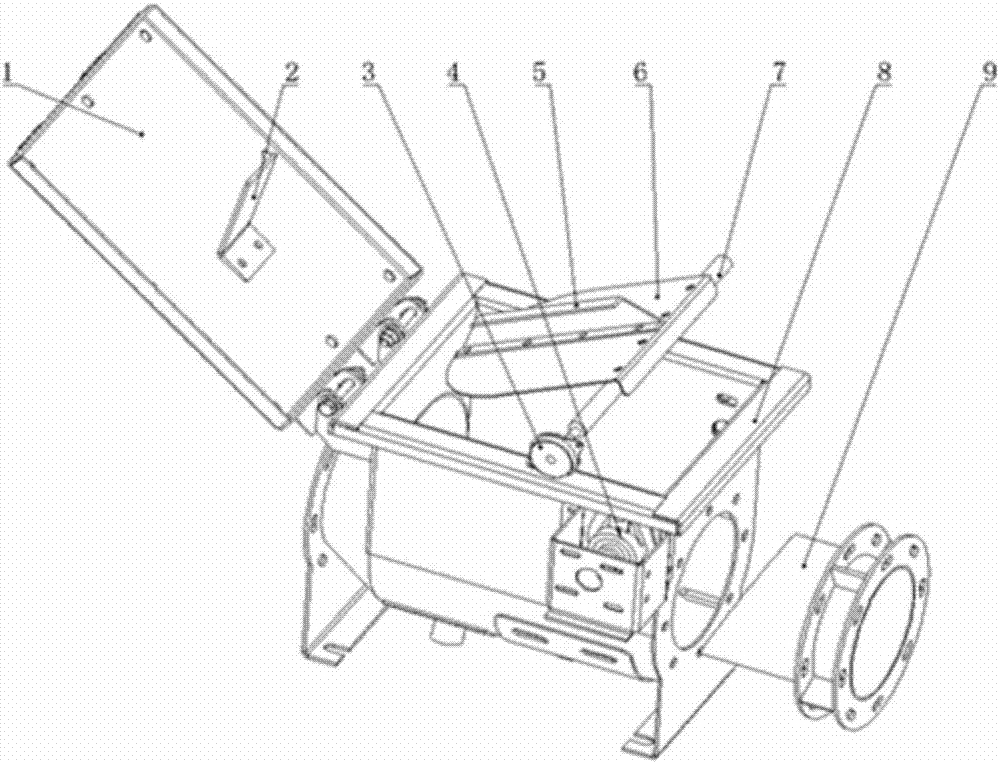

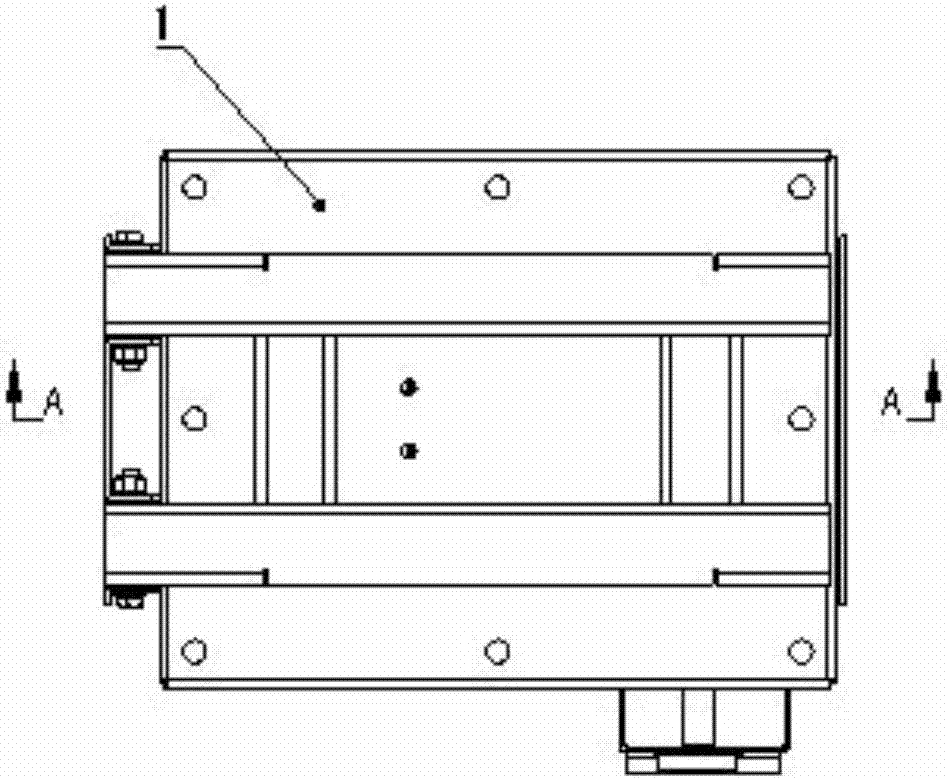

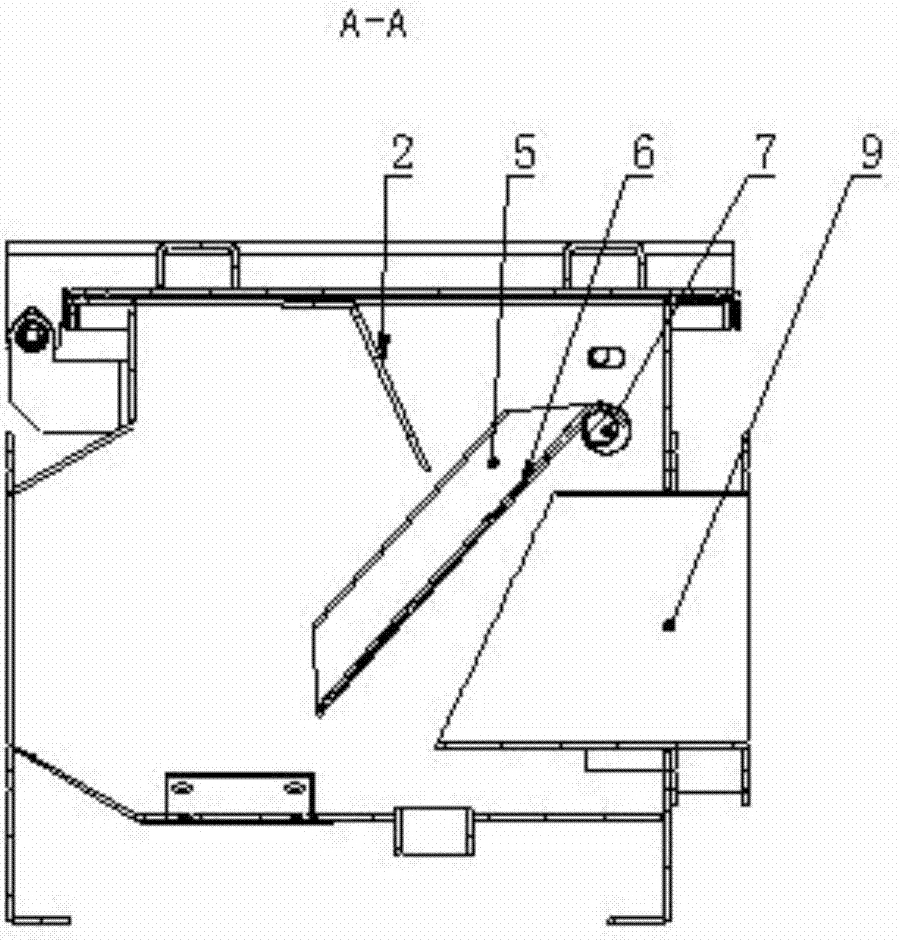

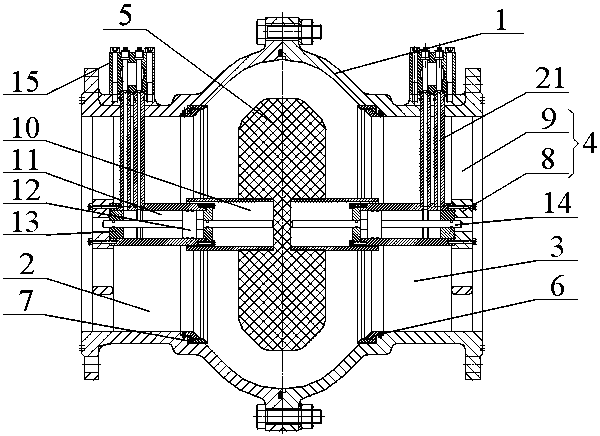

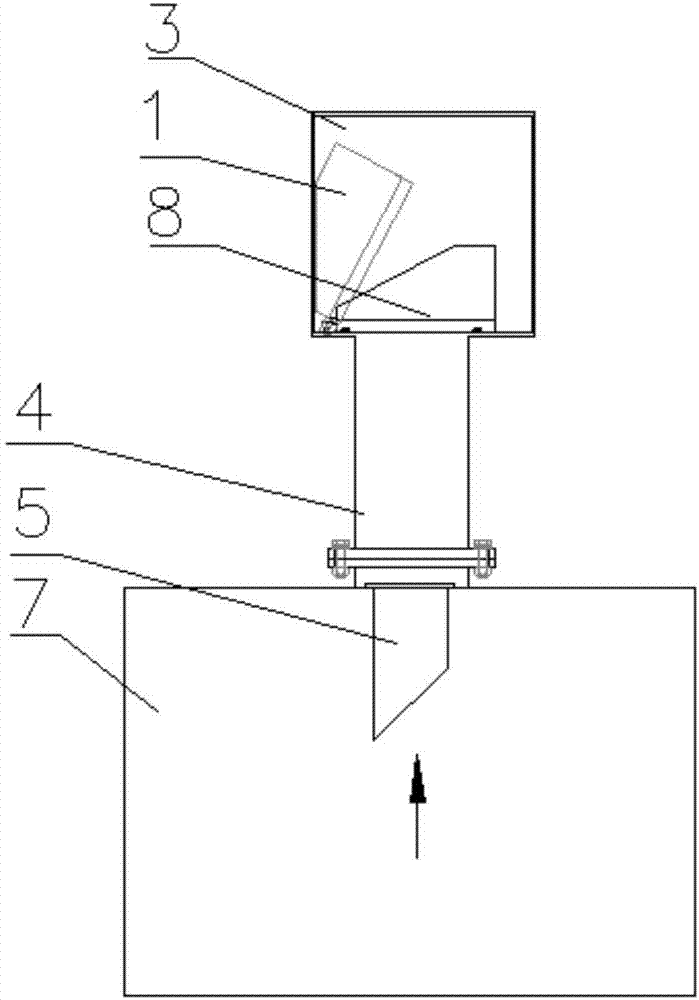

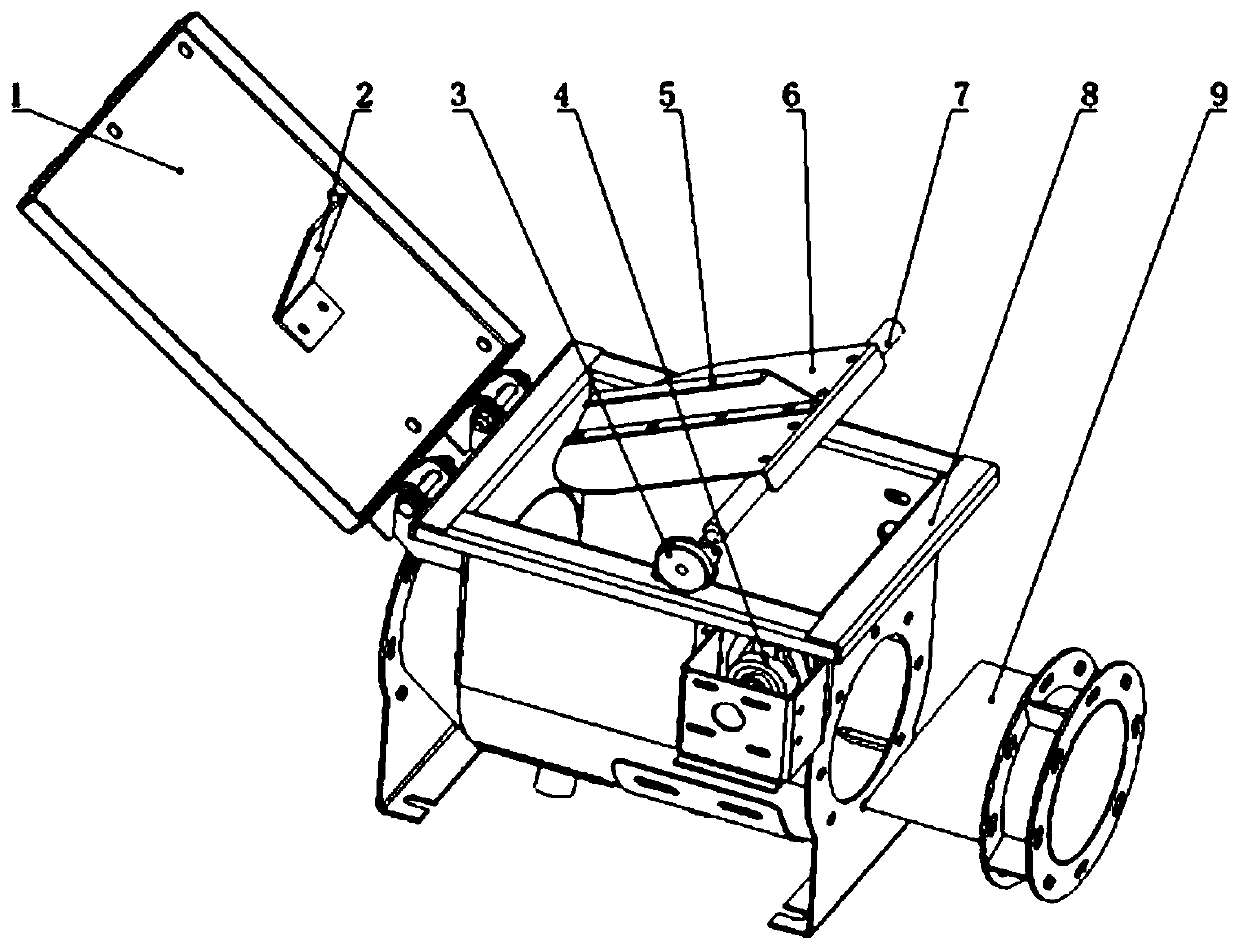

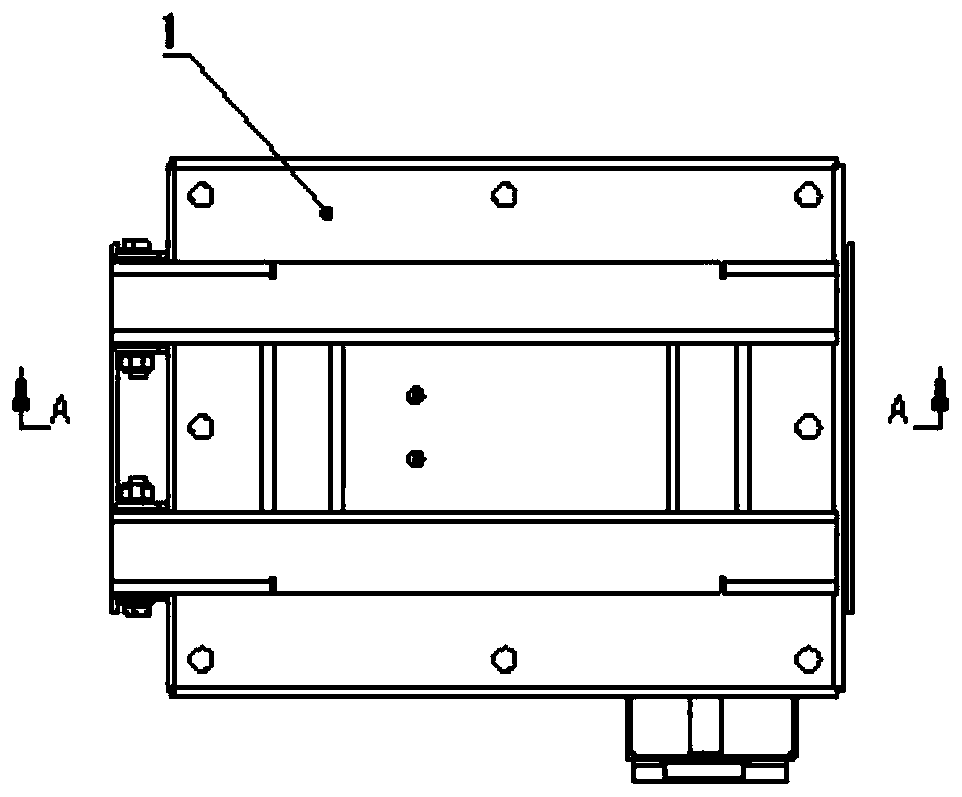

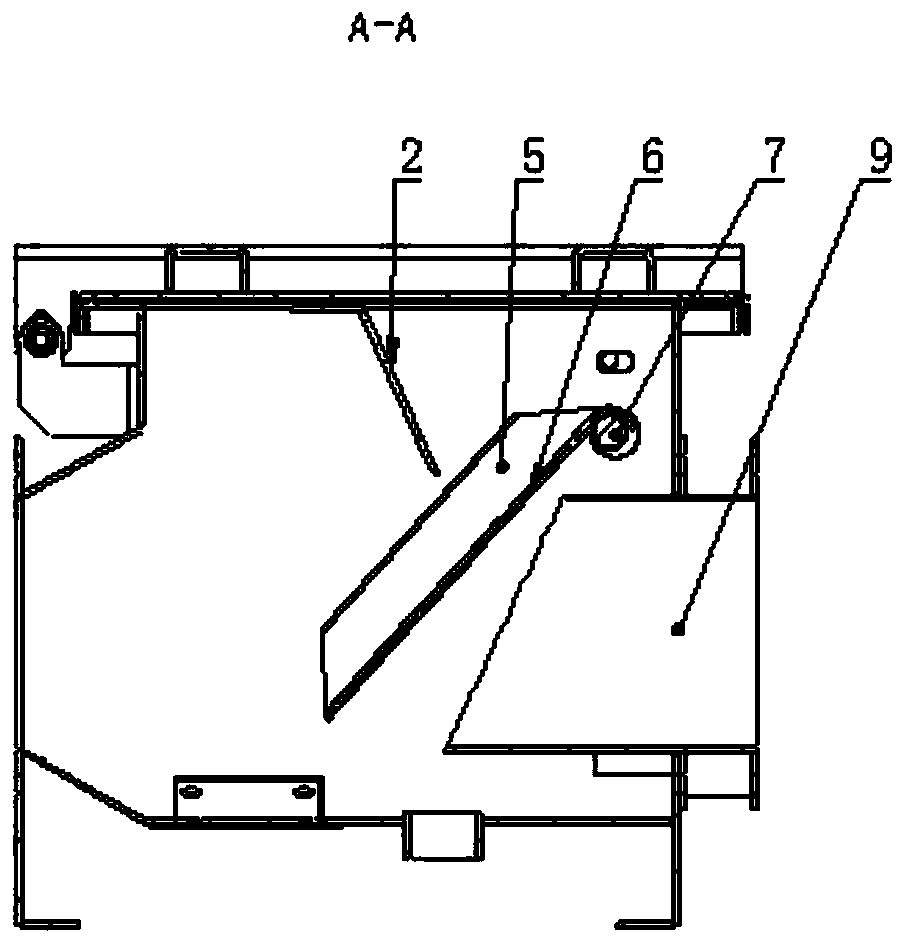

Normally-open one-way explosion-proof valve

InactiveCN106838405AProtection securityAvoid secondary explosionCheck valvesEqualizing valvesEngineeringNormal state

The invention discloses a normally-open one-way explosion-proof valve which is characterized by comprising a valve body, a valve clack, a magnet, a guide plate and a pipe flange; the valve clack is connected with the guide plate; the pipe flange comprises a pipe flange bevel; in a normal state, the valve clack is attracted to the magnet under the function of the magnet, and is away from the pipe flange bevel; and when an explosion occurs, the valve clack is subjected to impacting of explosion impact waves, the guide plate and the valve clack are pushed, the valve clack is attached to the pipe flange bevel, accordingly mechanical seal is formed, and the one-way explosion-proof valve is closed. The normally-open one-way explosion-proof valve can be used for preventing the impact waves and flames generated by the explosion from spreading, through a pipeline, towards the upper stream of dedusting equipment, a secondary explosion is avoided, and personnel and equipment safety is ensured.

Owner:江苏爵格工业集团有限公司

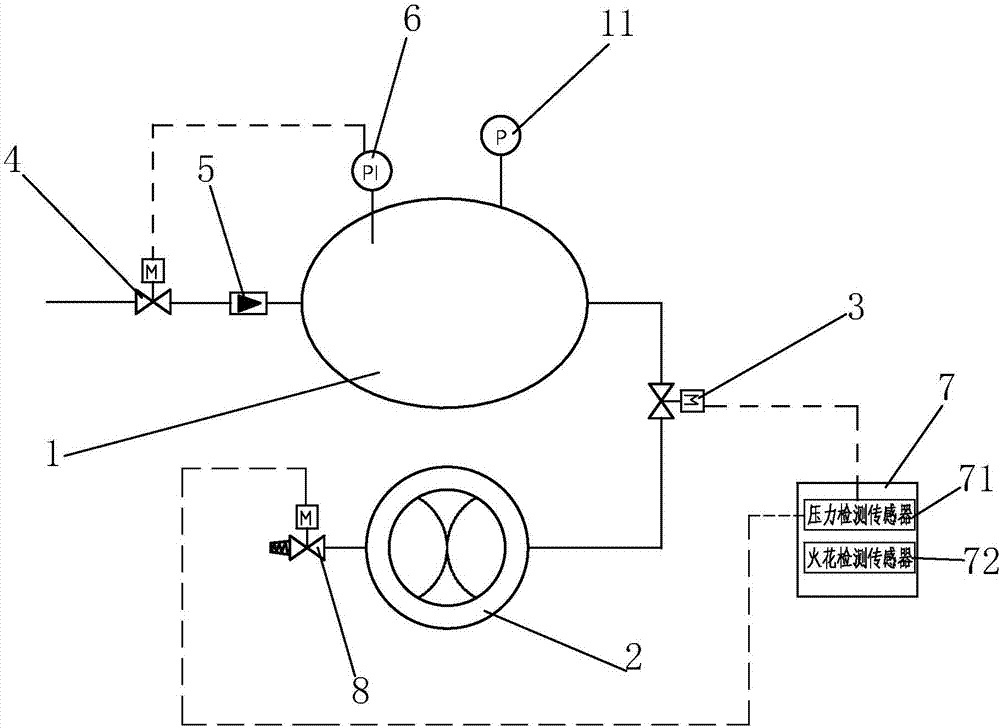

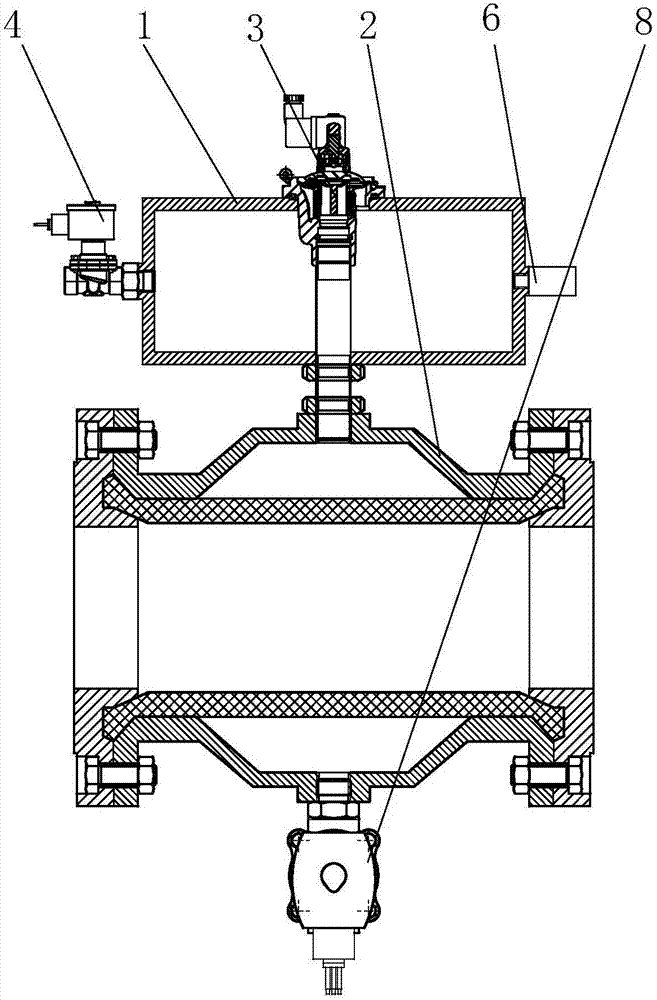

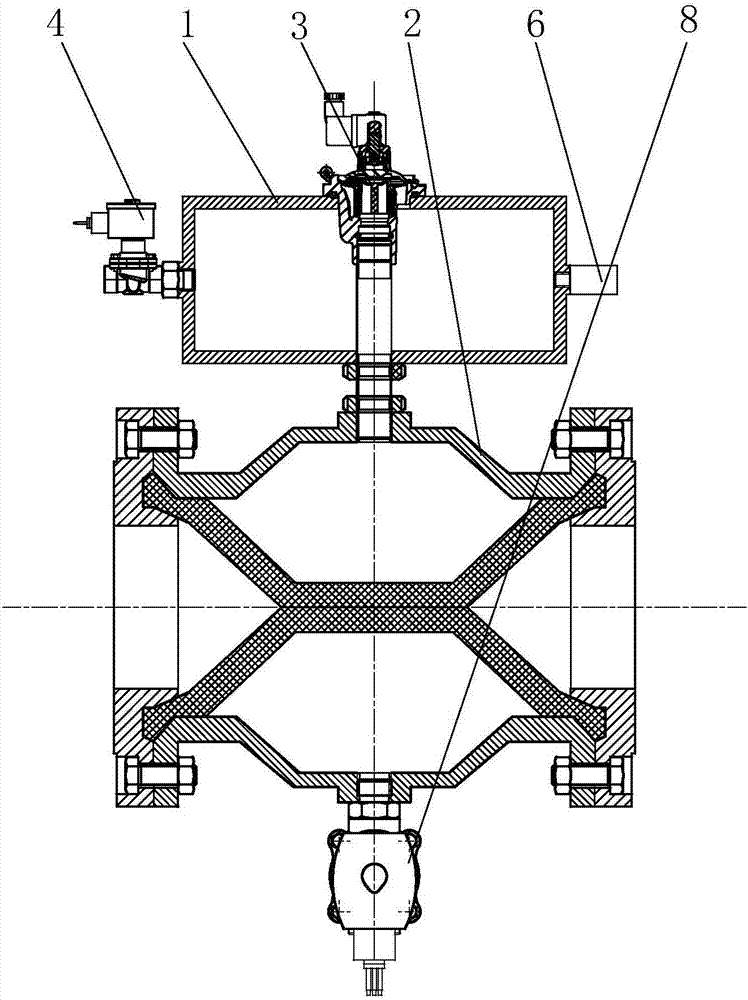

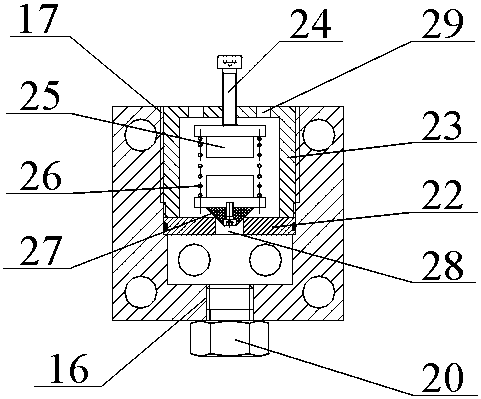

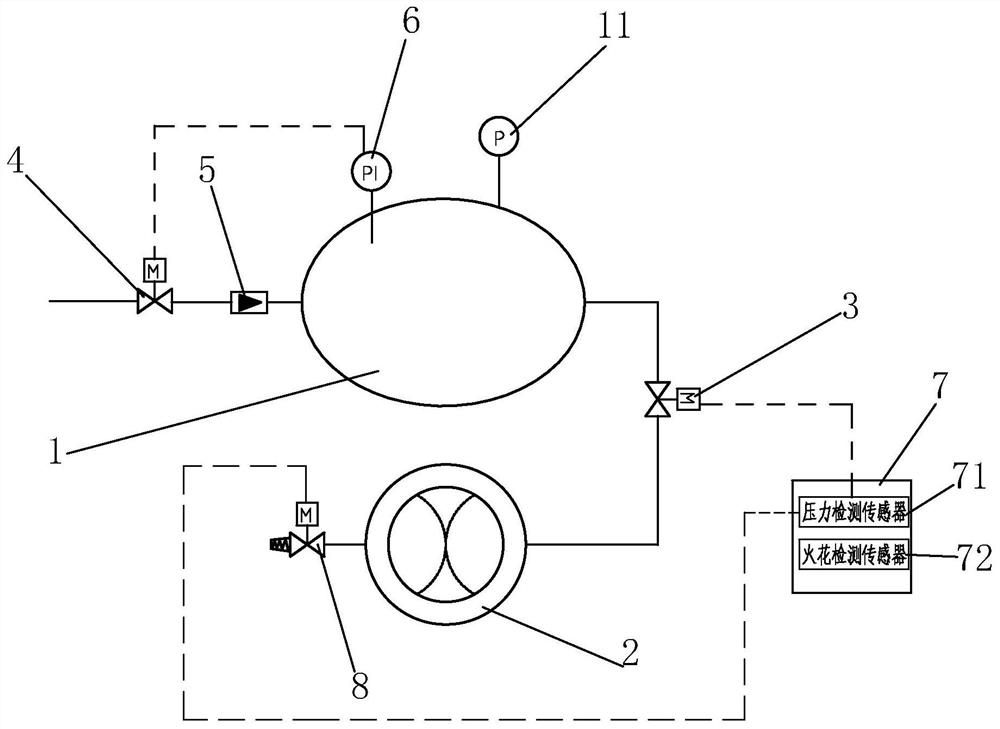

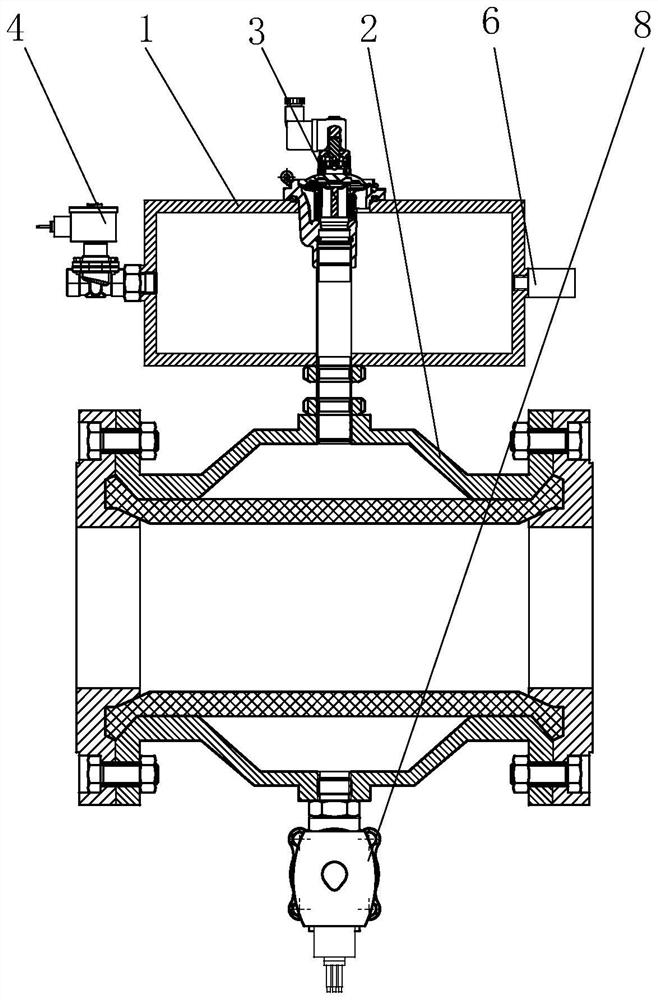

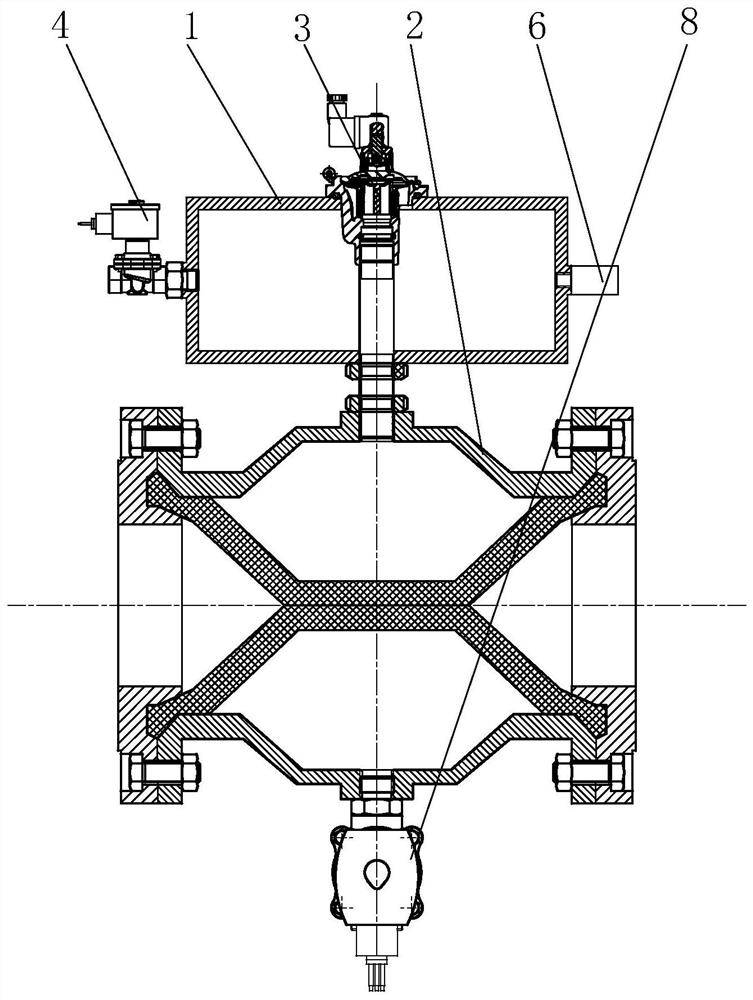

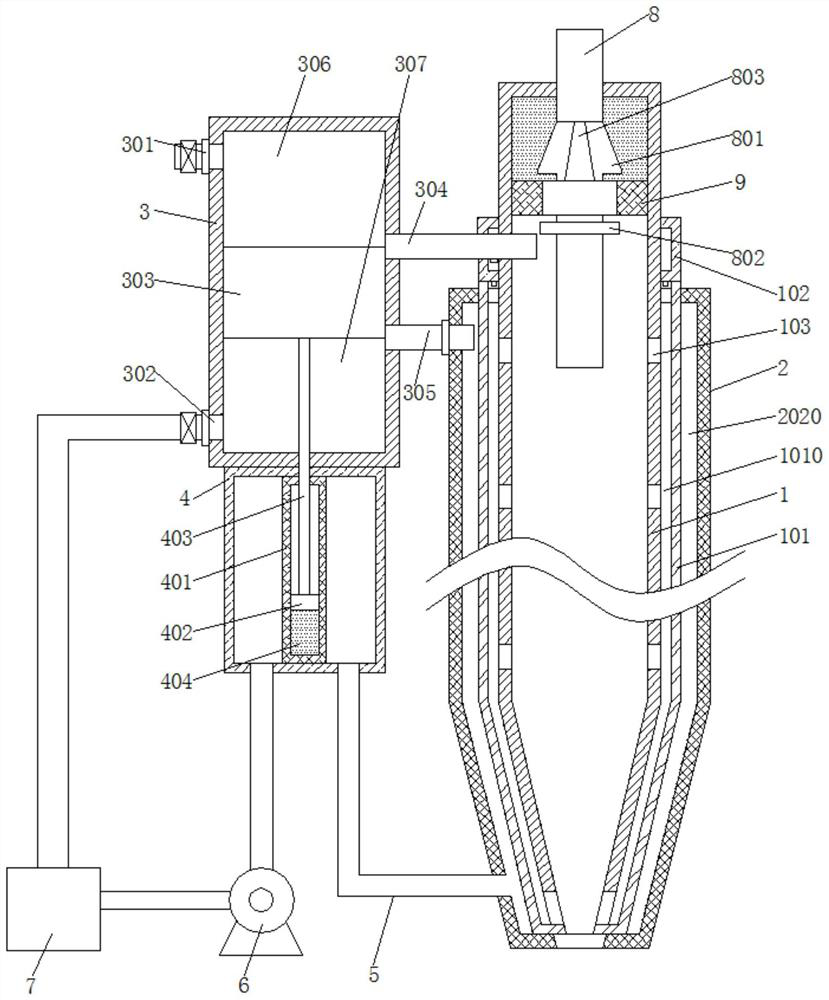

Pipe pressure type explosion suppression valve

ActiveCN106870942AAvoid secondary explosionVessel mounting detailsContainer filling methodsEngineeringAtmospheric pressure

The invention discloses a pipe pressure type explosion suppression valve which comprises a pipe pressure valve and an air storage valve. The pipe pressure valve is communicated with the air storage valve through a pipe, a pulse electromagnetic valve is arranged on the pipe for communicating the pipe pressure valve and the air storage valve, a first electromagnetic valve is arranged on an inlet pipe of an air storage tank, and a pressure sensor for detecting air pressure inside the air storage tank is arranged on the air storage tank and connected with the first electromagnetic valve; and a second electromagnetic valve is arranged on an outlet pipe of the pipe pressure valve, the pulse electromagnetic valve is connected with a front section sensor used for detecting explosion signals, and the front section sensor is connected with the second electromagnetic valve. During normal work, the pipe pressure type explosion suppression valve is in the opening state; when explosion happens, the front section sensor detects the explosion signals, and signals are sent out to control opening of the pulse electromagnetic valve, the second electromagnetic valve is closed, gas in the air storage tank is injected into the pipe pressure valve, the pipe pressure valve is closed to isolate explosion, and downstream persons and equipment are protected.

Owner:江苏爵格工业集团有限公司

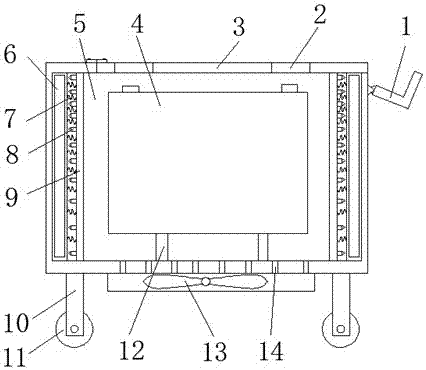

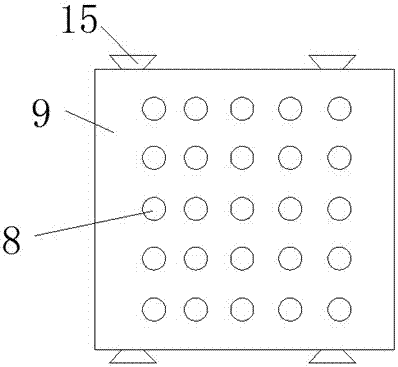

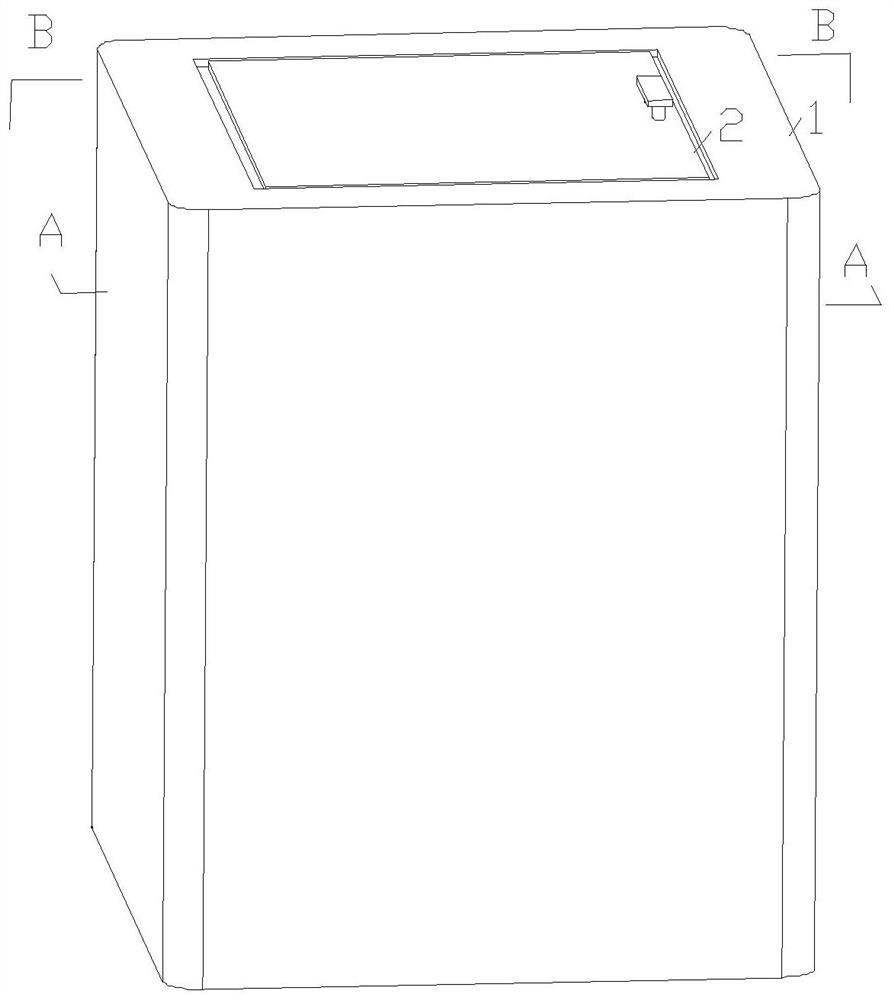

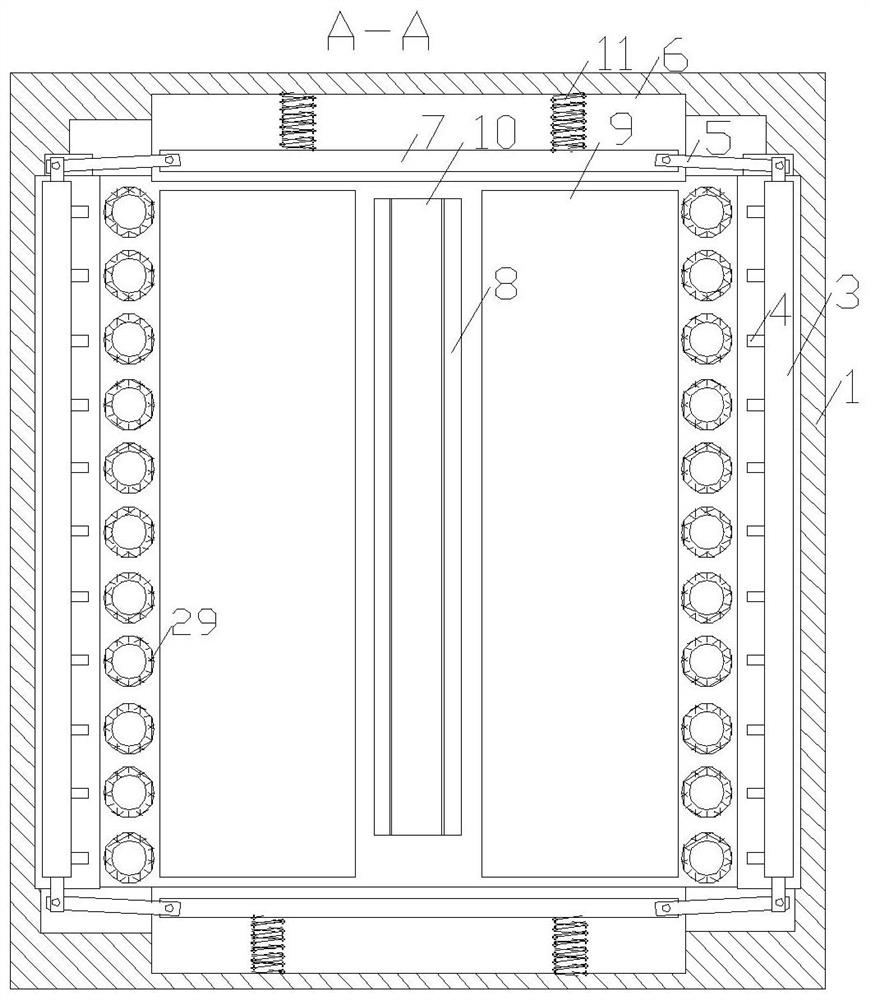

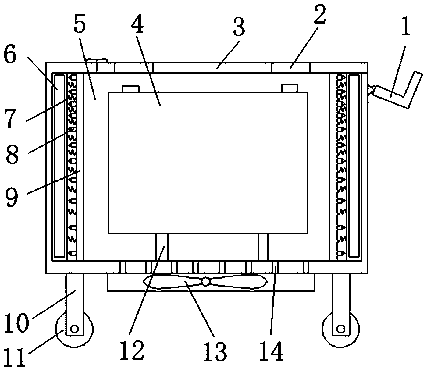

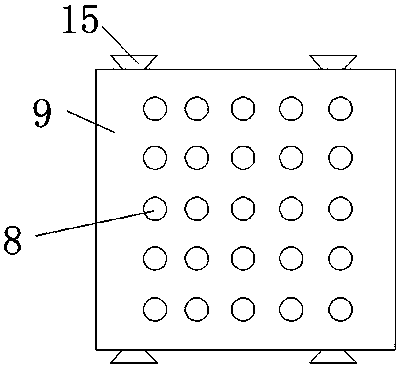

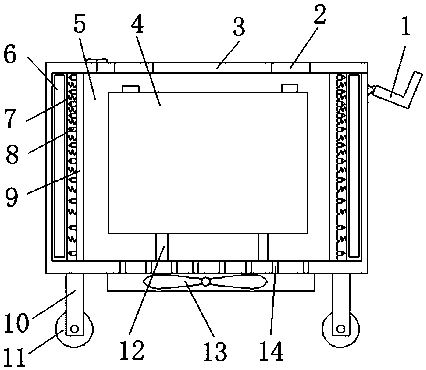

Electronic equipment anti-explosion protection device

ActiveCN107123760AAvoid secondary explosionProtect life safetySecondary cell gas removalCell component detailsExplosion protectionEngineering

The invention relates to the technical field of electronic equipment protection devices, and particularly relates to an electronic equipment anti-explosion protection device which comprises an anti-explosion tank body, wherein first plates are arranged around inside the anti-explosion tank body respectively; the first plates are internally hollowed; the first plates are filled with an inert gas; second plates are arranged on the inner sides of the first plates; a plurality of through holes are formed in the second plate; sliding blocks are arranged at the upper ends and the lower ends of the second plate; the sliding blocks are arranged inside chutes in the anti-explosion tank body; a plurality of conical convex burrs are arranged on one sides close to the first plates, of the second plates; a plurality of springs are arranged between the second plates and the first plates; a plurality of vent holes are formed in the bottom of the anti-explosion tank body; an air sucking fan is arranged at the bottom of the anti-explosion tank body; the air sucking fan is connected with a power supply. By adopting the electronic equipment anti-explosion protection device, storage battery explosion can be effectively prevented, fire of exploded storage batteries can be extinguished in time, force generated from explosion can be decomposed in time, and the security of people can be effectively ensured.

Owner:内蒙古行上科技有限责任公司

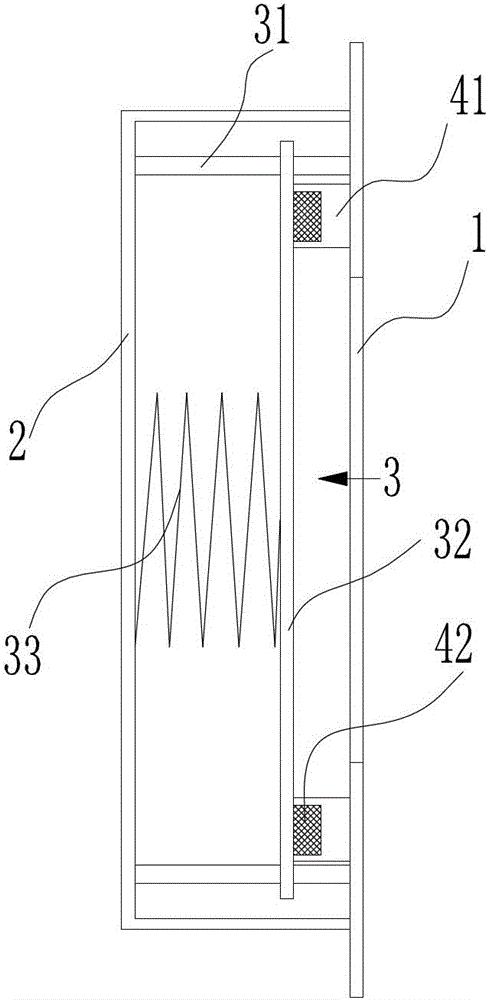

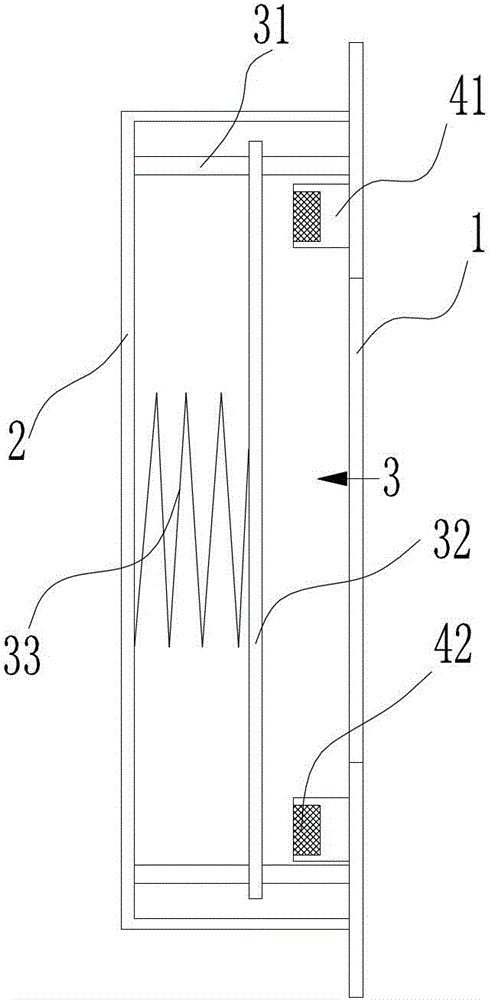

Wet dust collection device with anti-explosion function and polishing system

InactiveCN105999972AStable structureImprove securityCombination devicesGrinding/polishing safety devicesDust explosionDust collection system

The invention relates to a wet dust collection device with an anti-explosion function. The wet dust collection device comprises an air guiding spraying system and a wet dust collection system communicated with the tail end of the air guiding spraying system, wherein the air guiding spraying system comprises an air suction pipe and a first exhaust fan; the air suction pipe is used for collecting and guiding dust; the first exhaust fan is located on the air suction pipe; an air guide port, through which the dust can one-way enter, is arranged on the air suction pipe; the wet dust collection system comprises a purifying chamber communicated with the end part of the air suction pipe; a wet purifying component and a filtering component are respectively arranged above and under the purifying chamber; the top of the purifying chamber is communicated with the outside through a pipeline; an explosion vent is arranged on a side wall of the purifying chamber. The wet dust collection device provided by the invention is reliable in structure and high in safety; the possibility of dust explosion can be effectively reduced; the access is timely turned off after explosion, so that the harm to worker caused by the secondary explosion on the polishing position is avoided; the dust-containing air is purified for three times before the air is discharged; the dust purifying effect is promoted; the dust can reach the direct emitting environmental protection standard.

Owner:徐明凯

Automatic explosion-proof device for underground coal mine

InactiveCN111779530AEasy to operateReduce processing difficultyMining devicesDust removalMining engineeringCoal dust

The invention relates to the technical field of protective equipment for an underground coal mine, in particular to an automatic explosion-proof device for the underground coal mine. The automatic explosion-proof device for the underground coal mine comprises a pressure receiving mechanism, a triggering mechanism and a reaction mechanism which are connected in sequence, wherein the triggering mechanism comprises a pressure chamber; an axle center casing pipe is arranged in the pressure chamber; air leakage holes are uniformly formed in the middle position of the axle center casing pipe aroundthe circumference of the cross section of the pipe wall; a triggering piston is arranged in the axle center casing pipe, and is of a cylindrical structure with an axle center cavity; no less than twosealing grooves are formed in the outer circumference of the front end of the triggering piston; an air leakage groove is formed between the adjacent sealing grooves; and an air delivery hole is formed in the bottom of the air leakage groove and is connected to the axle center cavity of the triggering piston. When gas and coal-dust explosion occurs in the underground coal mine, the explosion flameis quickly extinguished to prevent the flame from continuing to spread and trigger more harmful secondary explosion by adopting the automatic explosion-proof device which has the mechanical structure, little processing difficulty and relatively sensitive action.

Owner:山东久泰煤安装备有限公司

One-way explosive-proof valve

PendingCN107061803AEnsure safetyIncrease the area of actionCheck valvesEqualizing valvesStructural engineeringMechanics

The invention discloses a one-way explosive-proof valve. The one-way explosive-proof valve comprises a valve shell, a valve clack, an approach switch and a bolt lock. The two ends of the valve shell are provided with an inlet flange and an outlet flange correspondingly, the valve shell is internally provided with a cavity, the valve clack is located in the cavity, and the valve clack is in rotation connection with one end of the valve shell; when the valve is in the non-work state or explosive-proof state, the inner surface of the valve clack is attached to the end face of the end, located in the cavity, of the inlet flange, the shaft is provided with a locking rod located on the valve shell, and the bottom of the valve shell is provided with the approach switch for detecting the position of the valve clack; the bolt lock is connected with the outer side wall of one end of the valve shell, the bolt lock is internally provided with a lock rod for blocking the locking rod, the approach switch is connected with the bolt lock, and the approach switch controls the lock rod to stretch out; and the approach switch gives out a signal when sensing that the valve clack reaches the designated position, the lock rod of the bolt lock is bounced out to block the locking rod. Secondary explosion is prevented, it is prevented that explosion shock waves and flames return to a pipe system again, and personnel safety and equipment safety of the upstream of the explosive-proof valve are guaranteed.

Owner:江苏爵格工业集团有限公司

Normally-closed type one-way explosive-proof valve

ActiveCN106885026ABlast damage limitProtection securityCheck valvesEqualizing valvesAir volumeEngineering

The invention discloses a normally-closed type one-way explosive-proof valve. The valve is characterized by comprising a bonnet, a valve clack, a valve body and a pipe flange; the bonnet is connected to the upper part of the valve body through a shaft; the action of the valve clack is controlled by the air volume of a downstream fan of dust removing equipment; when the fan starts working, the valve clack can be opened slowly, and the medium transfer state can be reached after running for a period; when the fan stops running, the valve clack is automatically closed under the effect of gravity and is attached to the inclined surface of the pipe flange, mechanical sealing is formed, and the medium transfer is cut off; and when an explosion occurs, the valve clack is closed under the effect of an impact wave. With the valve, when the downstream dust removing equipment explodes, the transfer pipeline can be cut off quickly, the explosion source of the dust removing equipment with front-end accessory equipment through an inlet pipeline is disconnected, and the explosion is isolated in a certain area, so that the explosion loss is limited in the controllable range.

Owner:江苏爵格工业集团有限公司

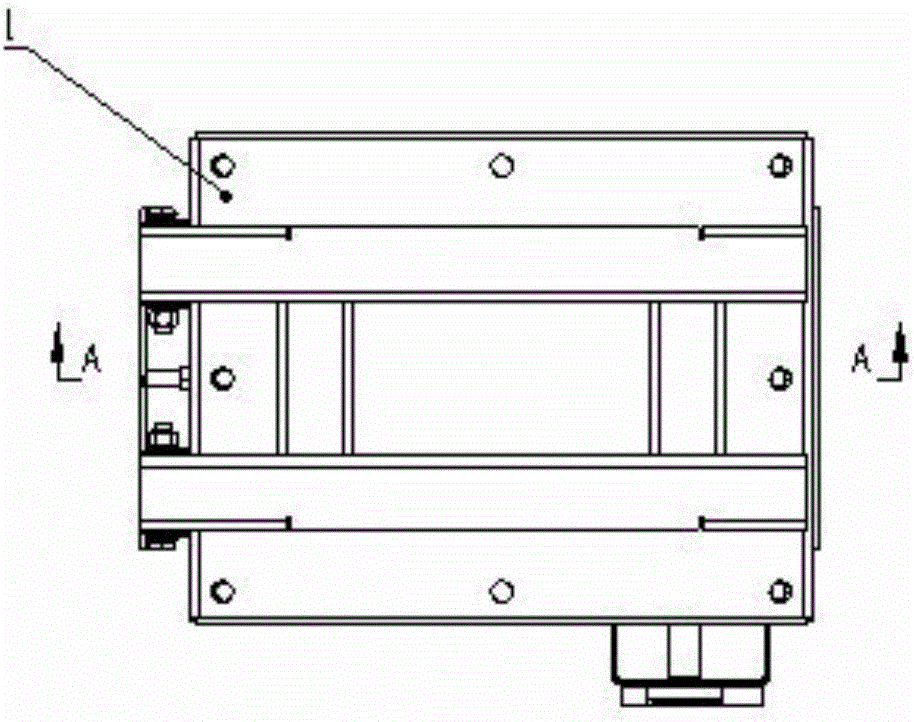

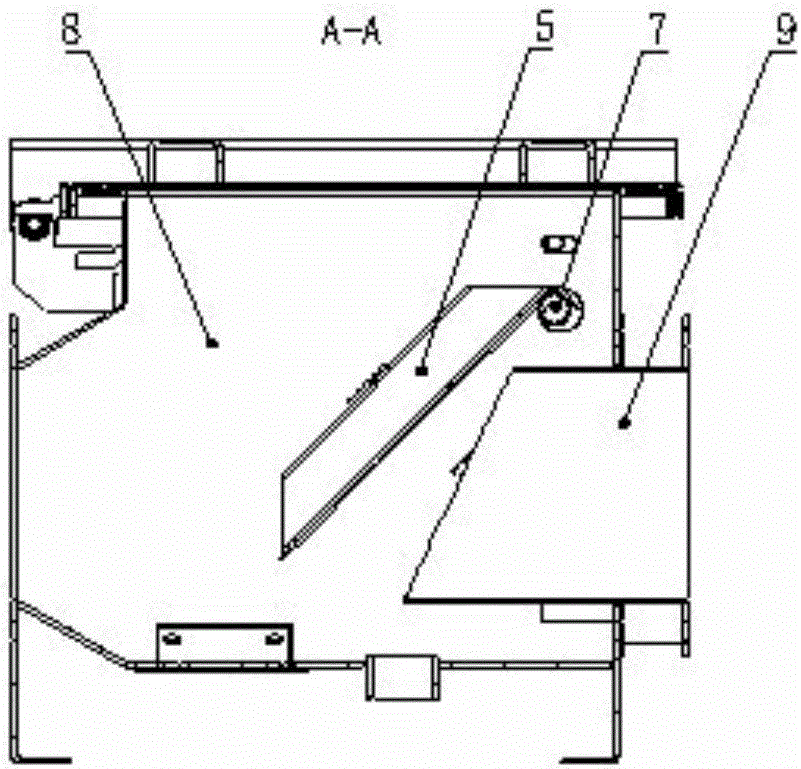

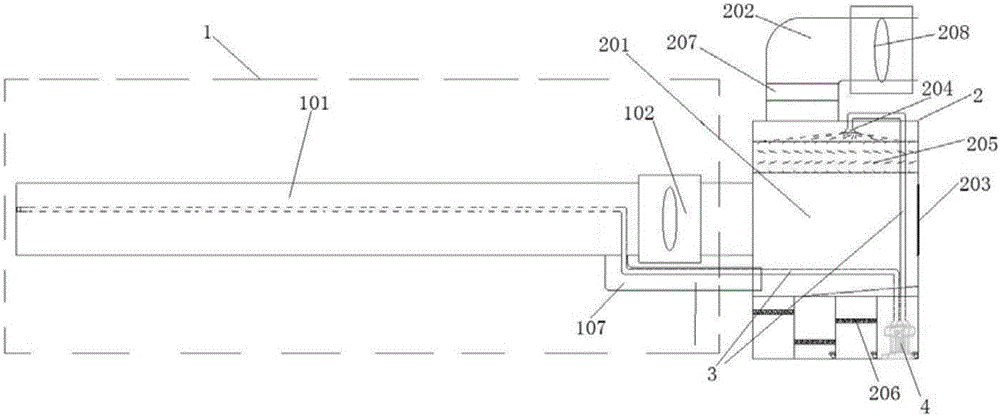

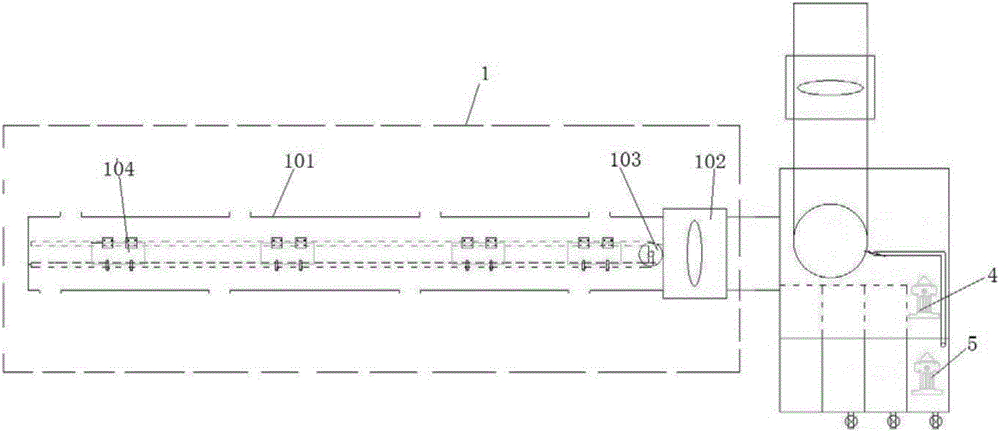

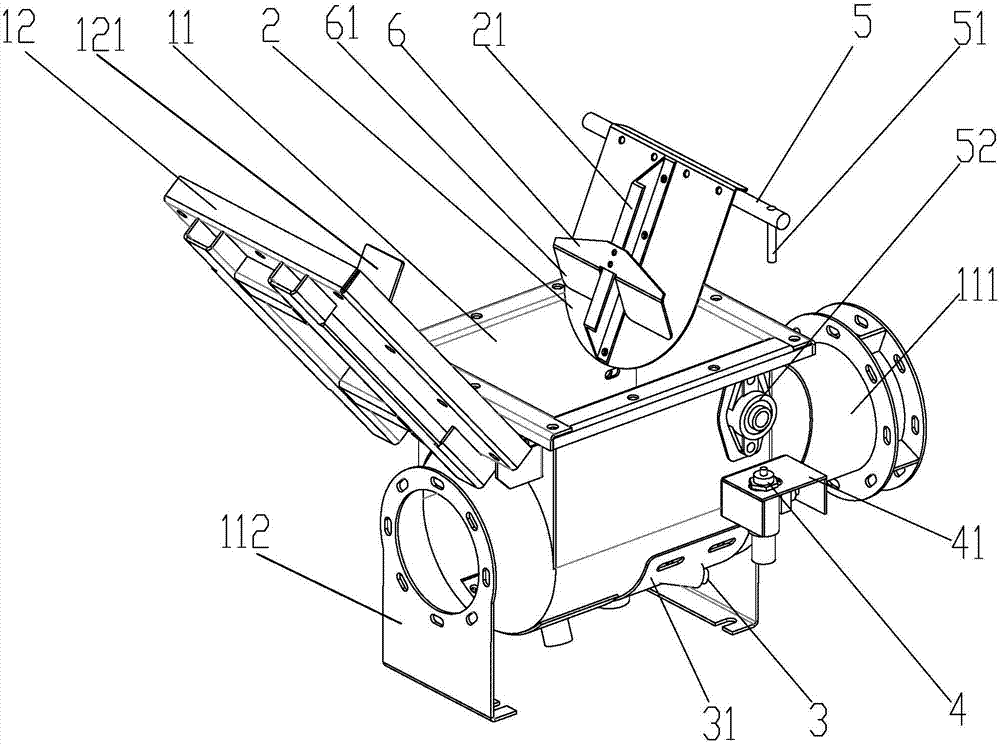

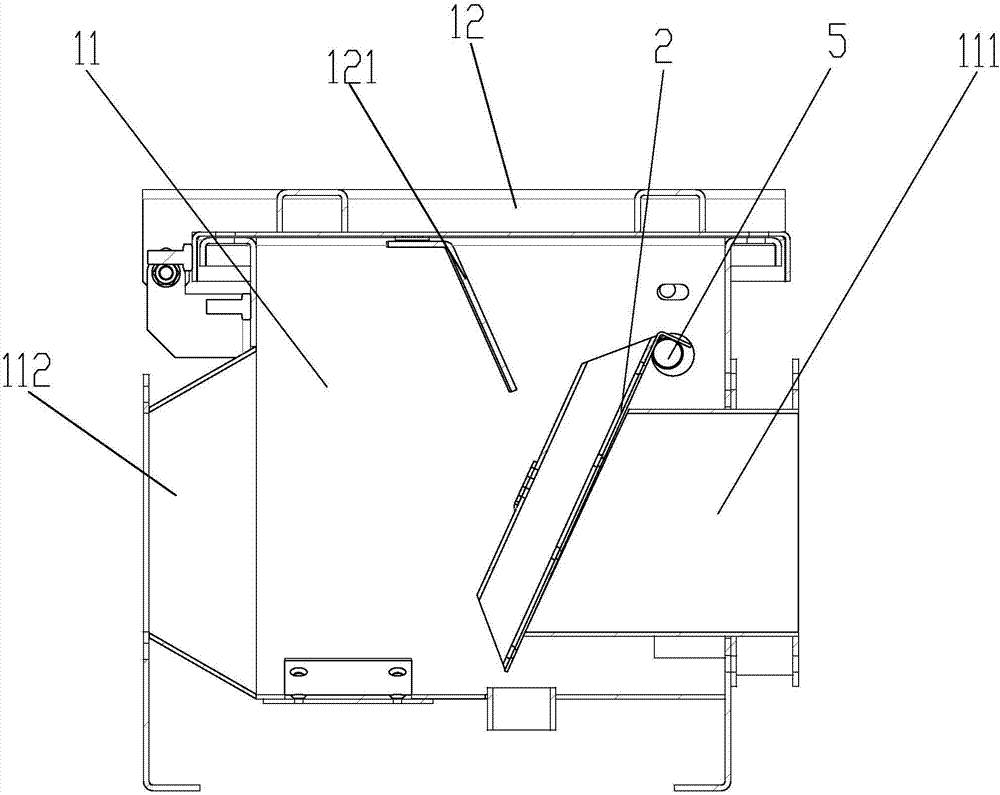

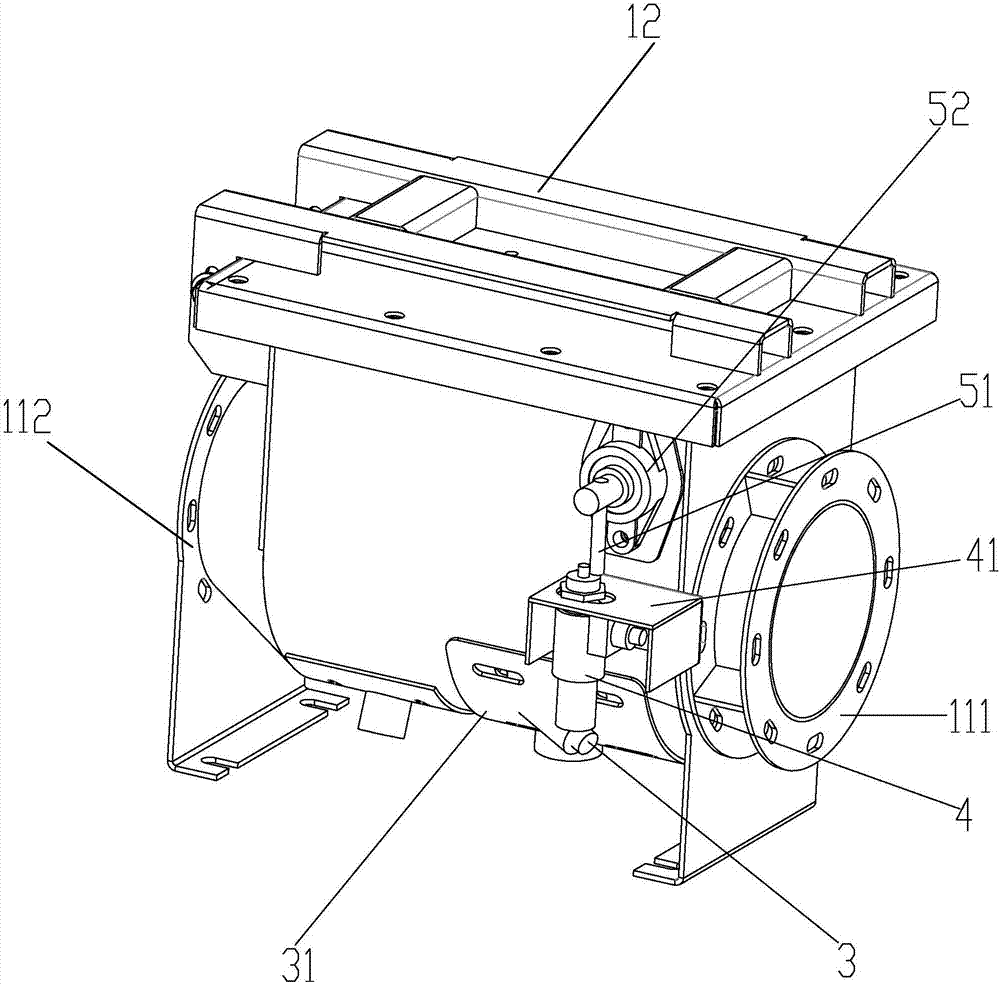

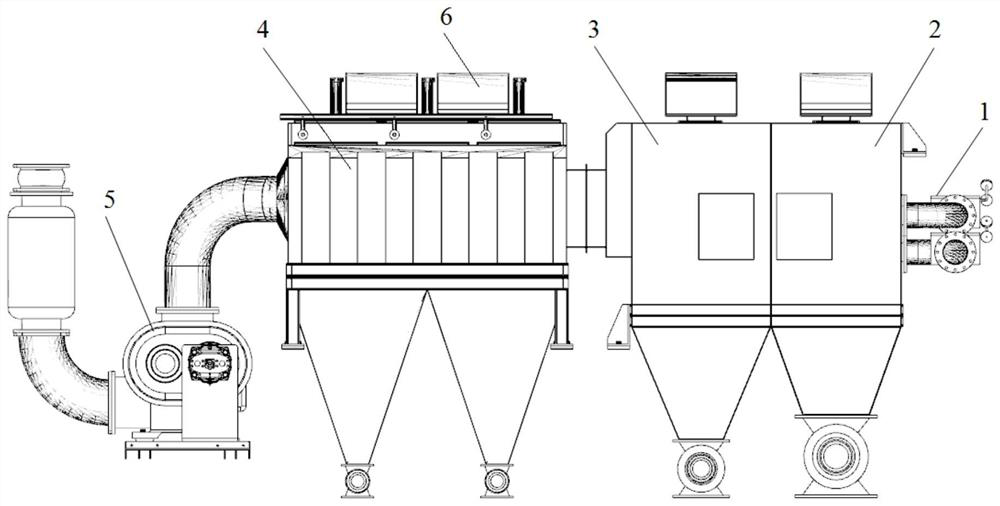

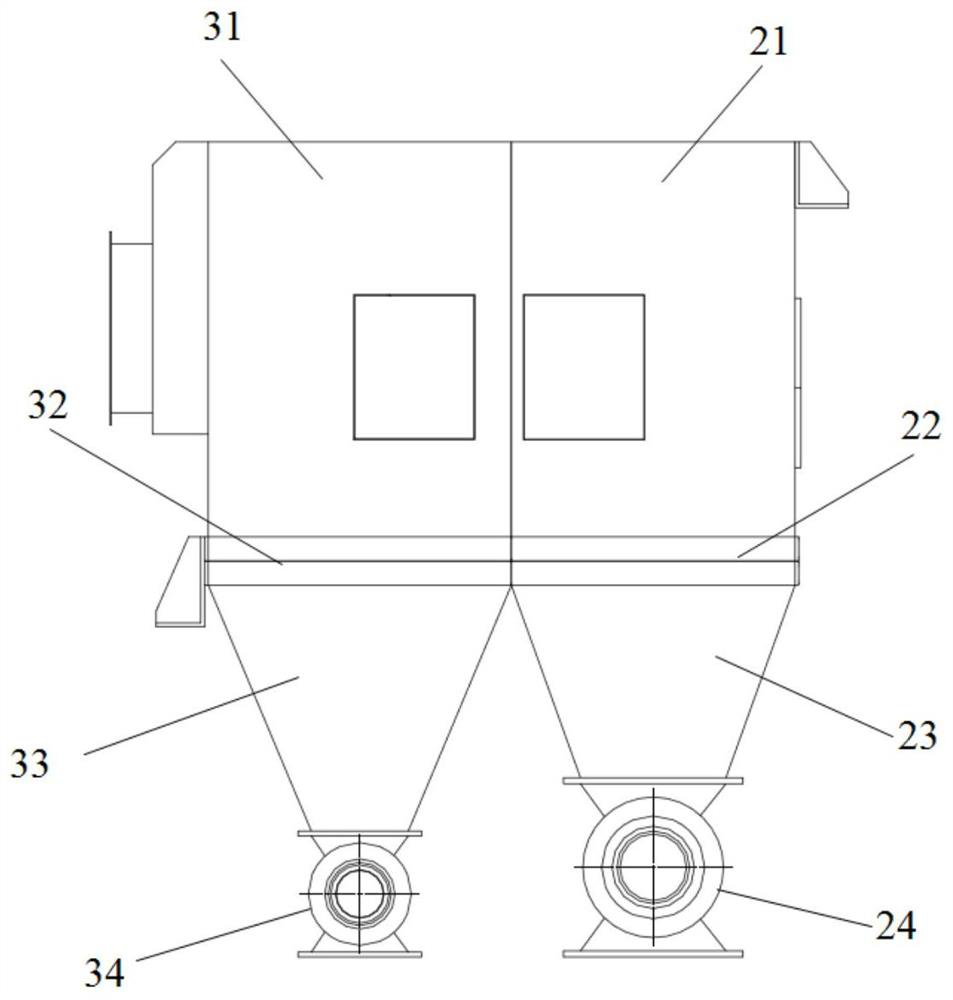

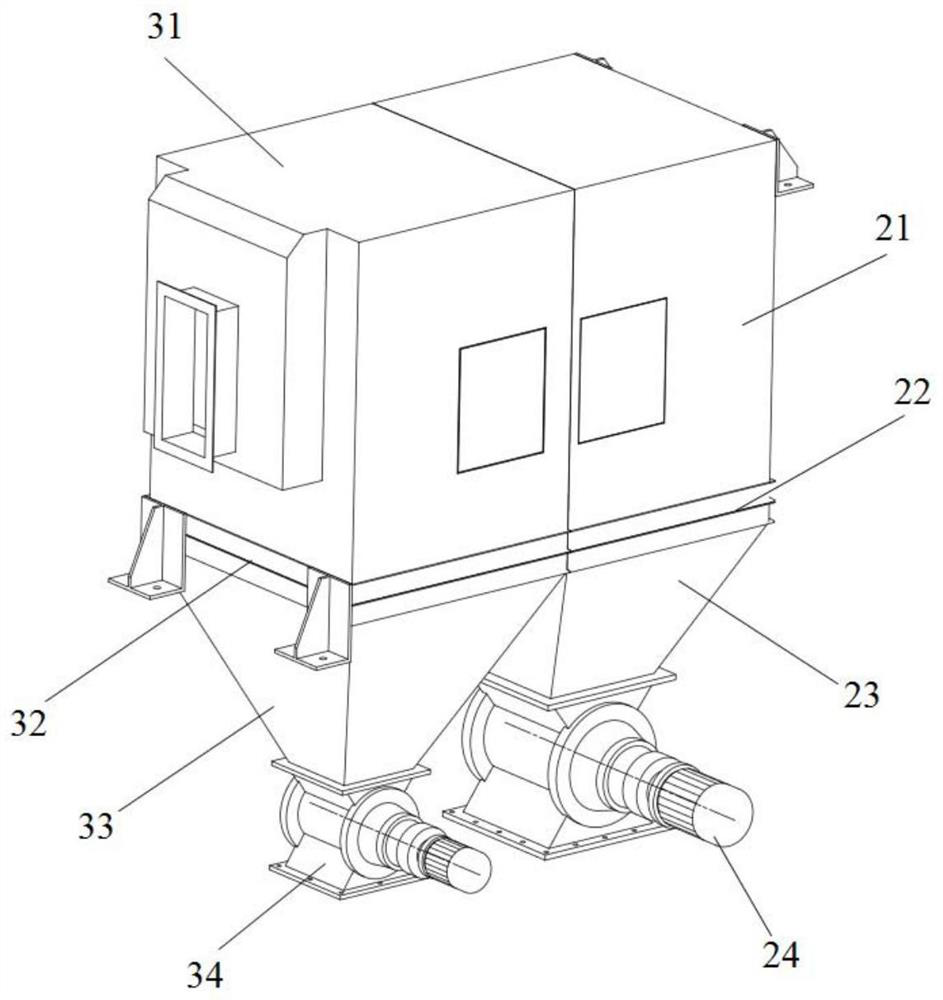

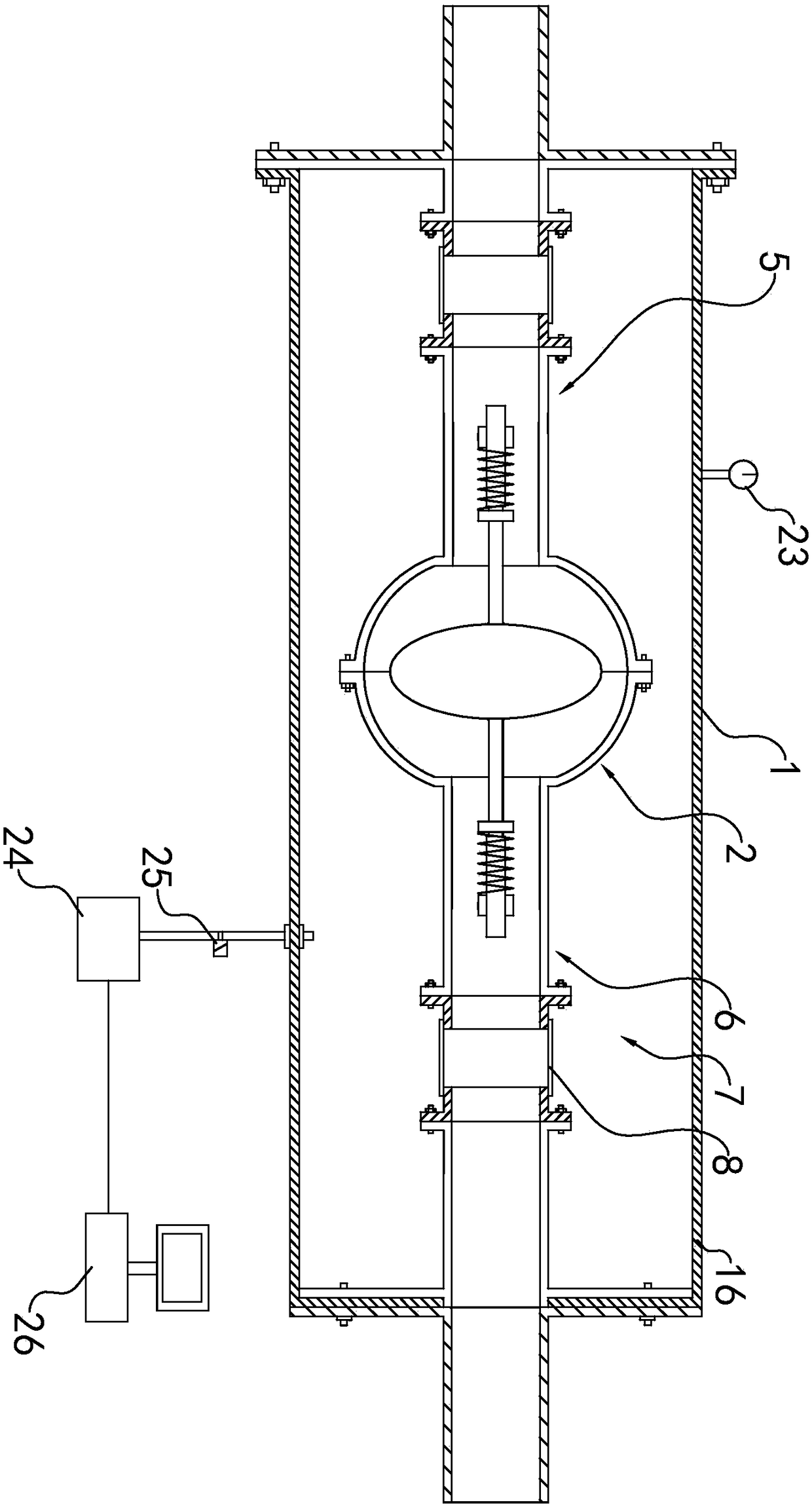

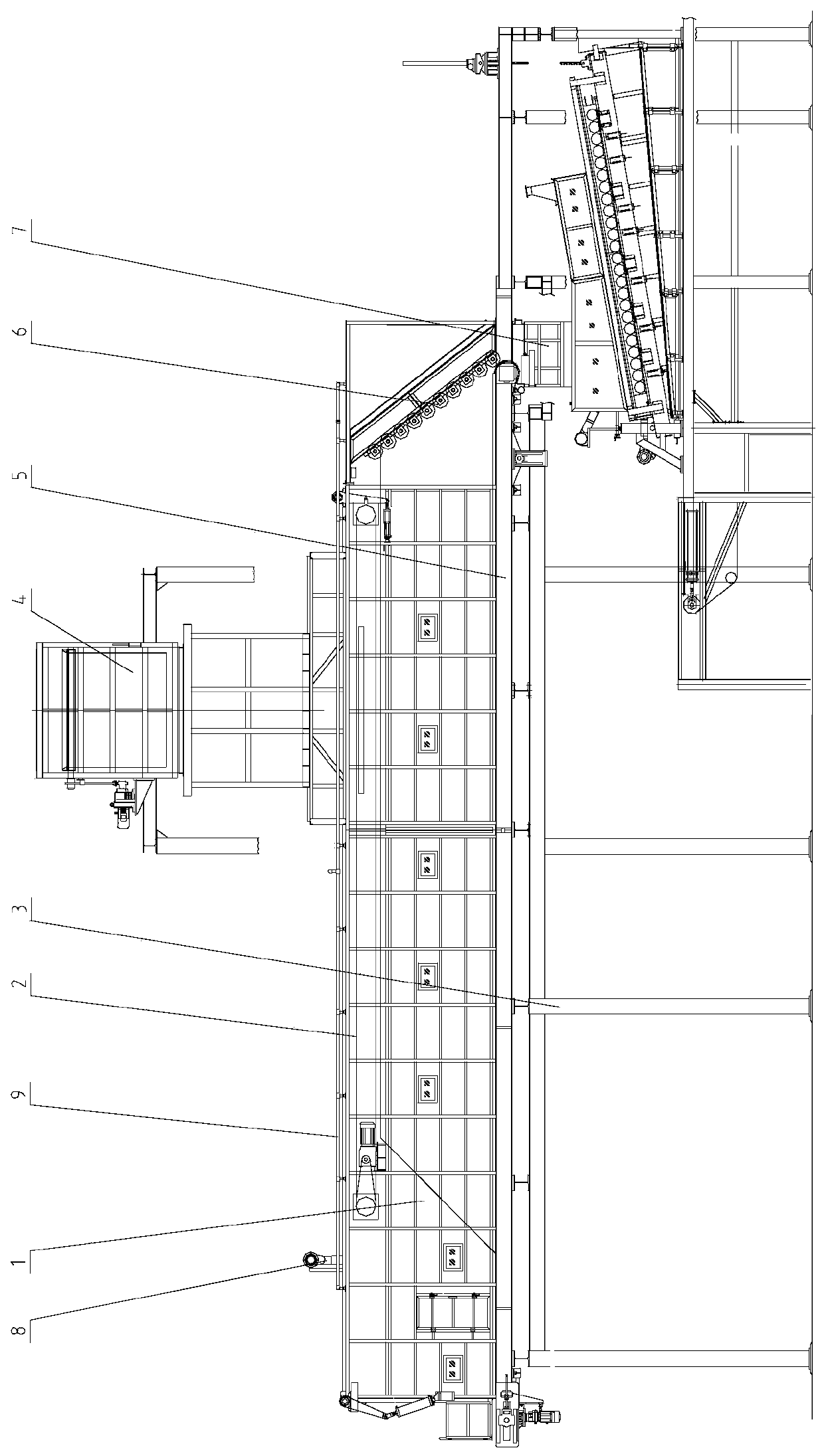

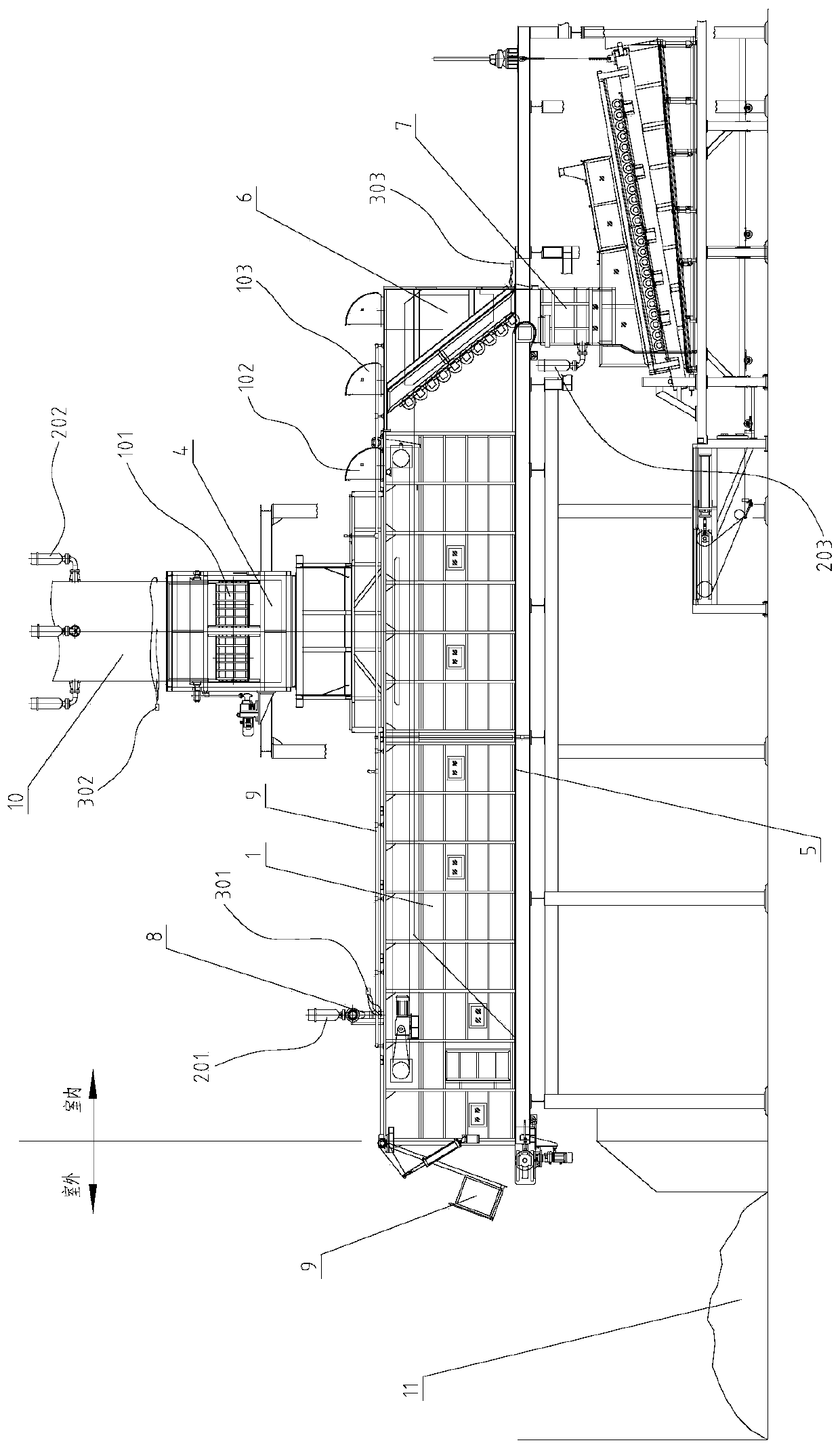

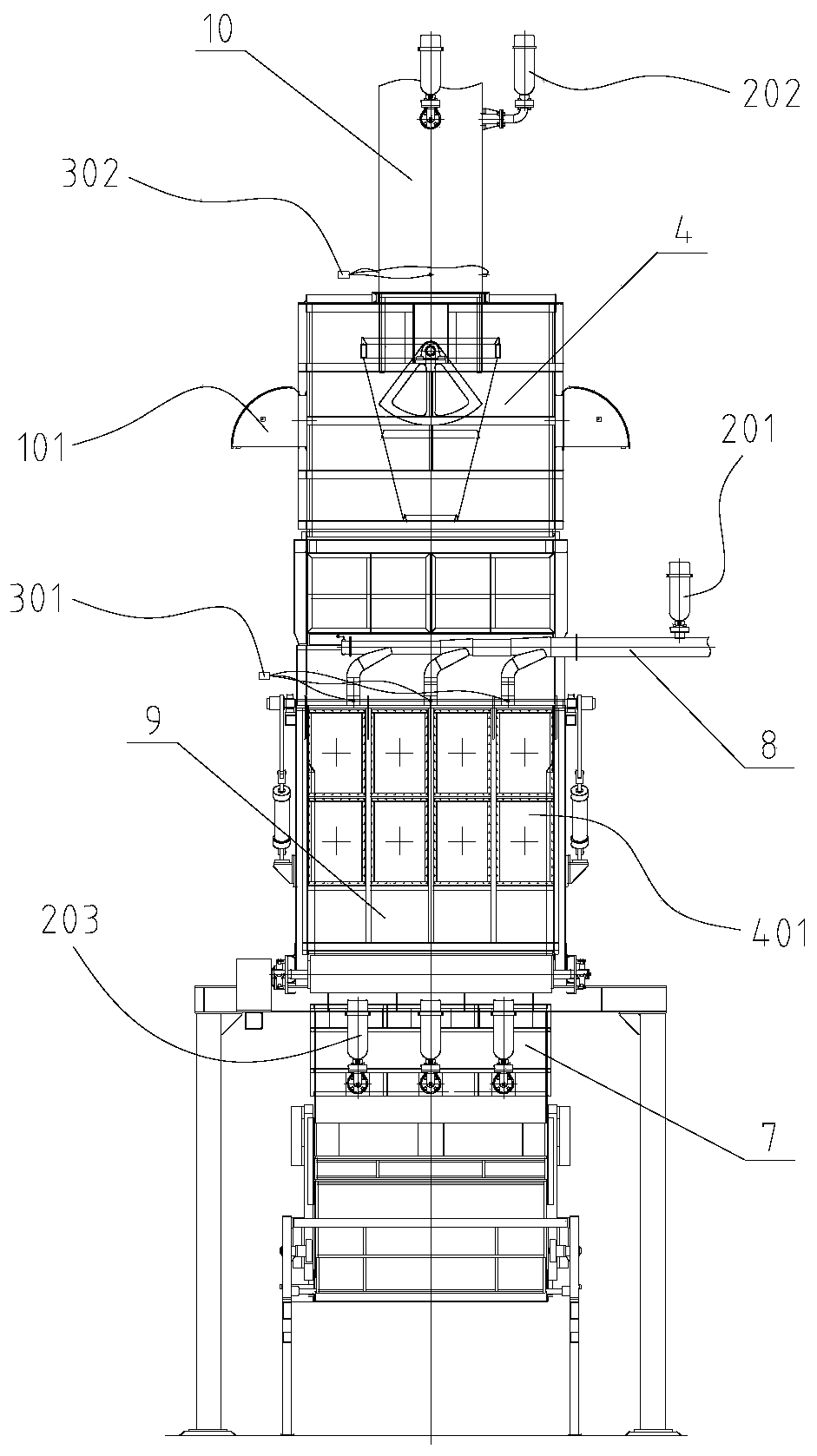

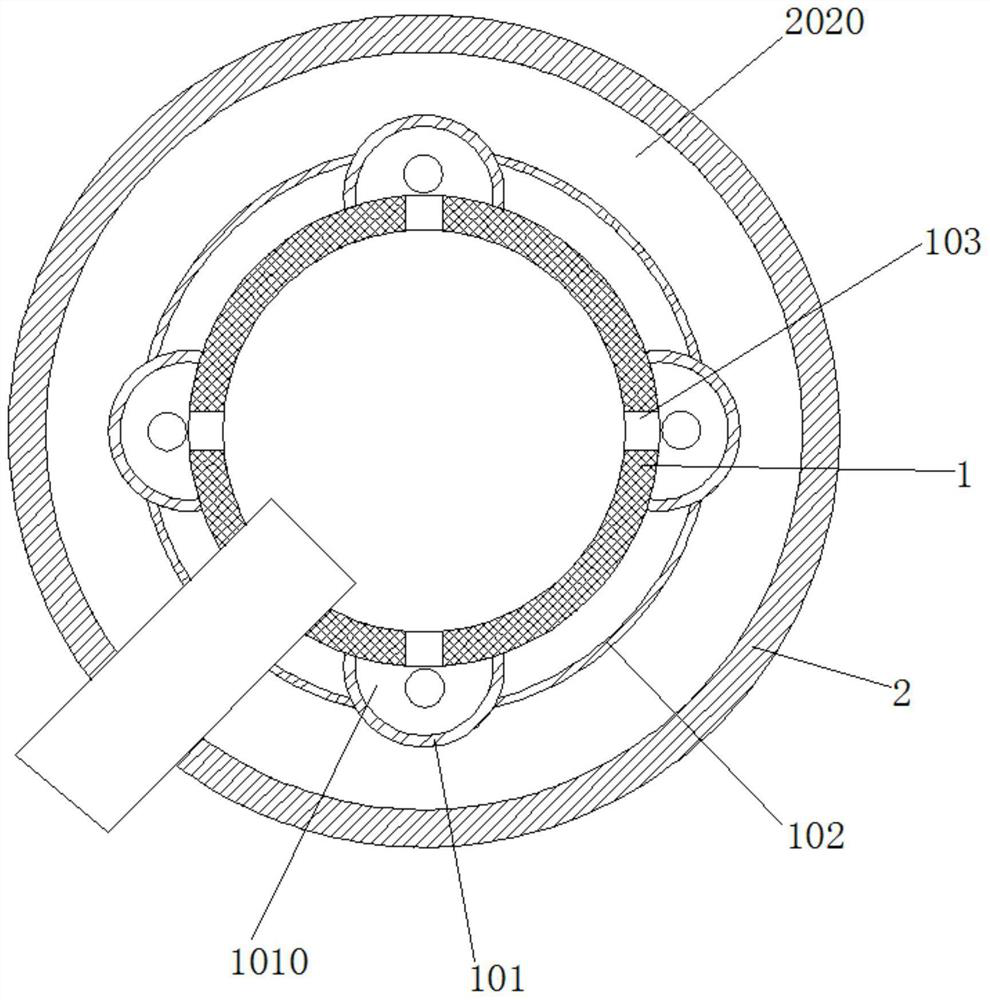

Side suction dust removal system for railway ballast bed suction-type dirt removal truck and corresponding dust removal method

PendingCN112301941AStop the explosion from spreadingStop the spreadCombination devicesRailway cleaningDust controlTruck

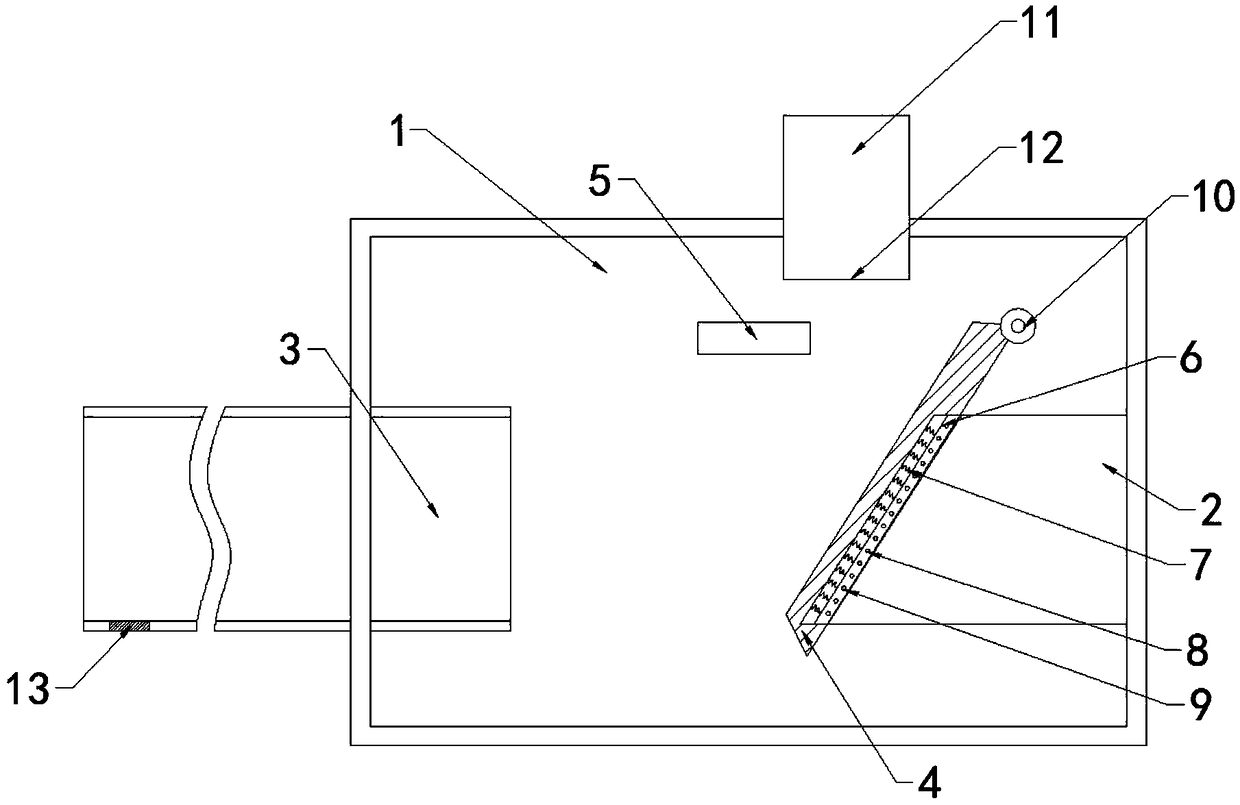

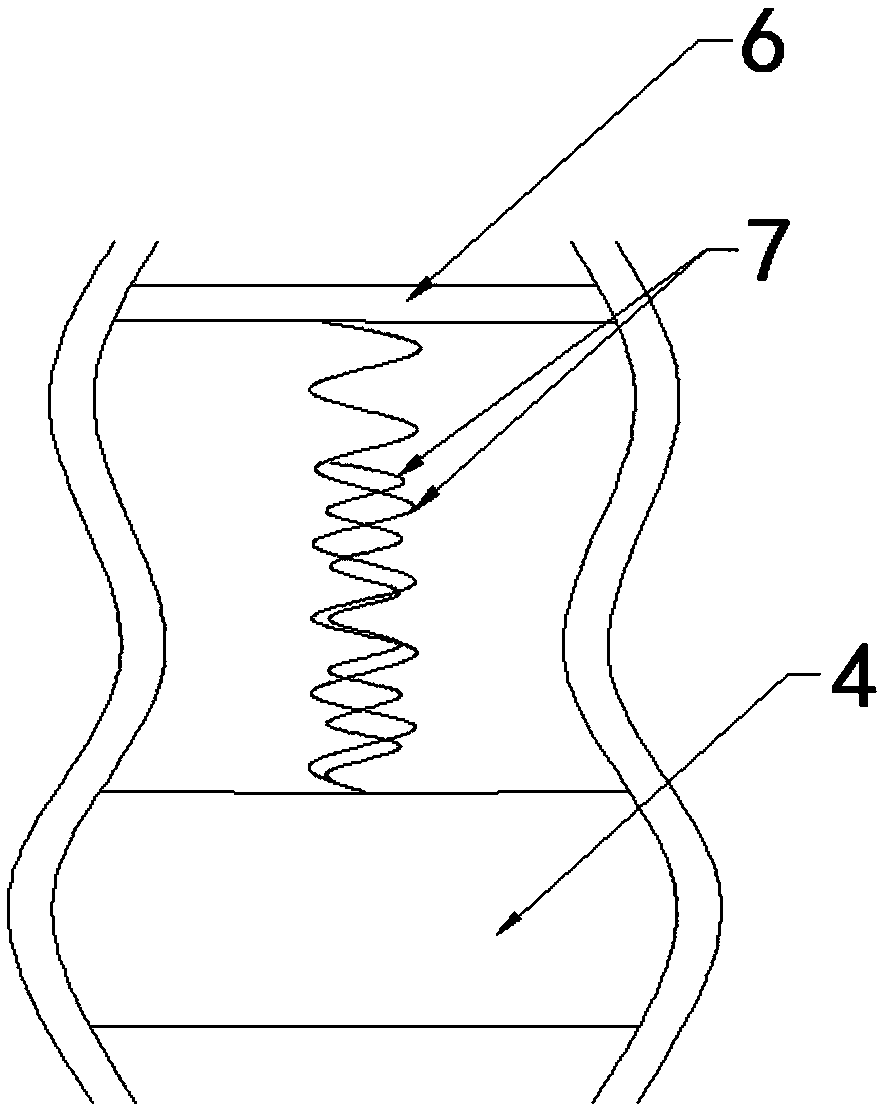

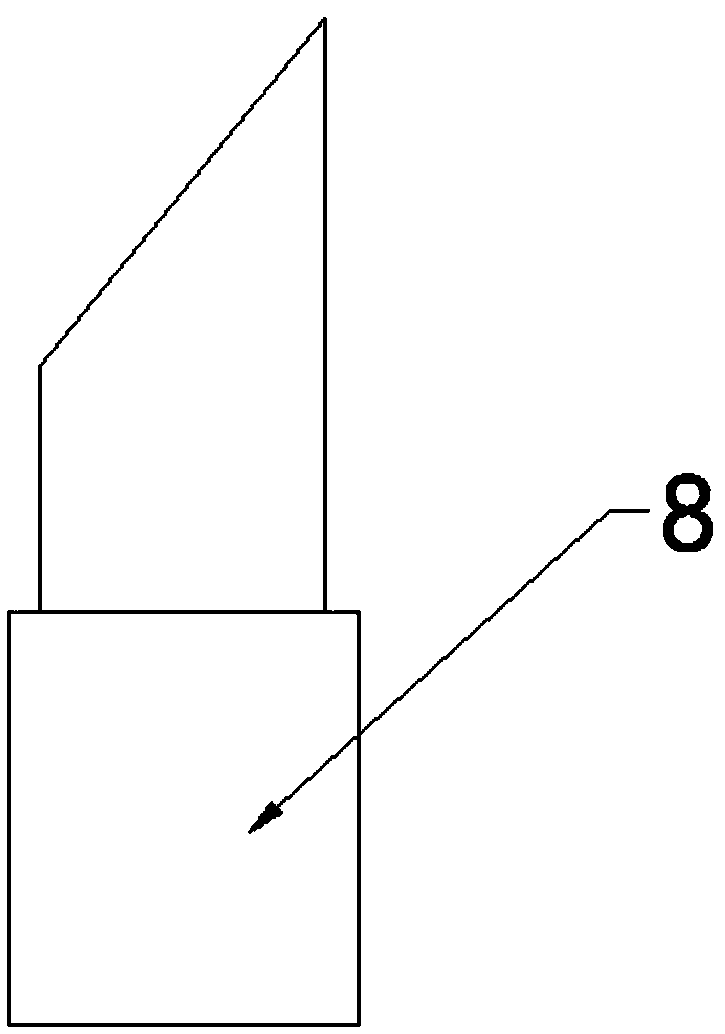

The invention discloses a side suction dust removal system for a railway ballast bed suction-type dirt removal truck and a corresponding dust removal method thereof. The dust removal system comprisesan explosion suppression device (1), a gravity dust remover (2), a multi-tube cyclone dust remover (3), a bag-type dust remover (4) and a fan (5), wherein the explosion suppression device (1) is connected with an air outlet of a dirt cleaning working device; the gravity dust remover (2) is connected with an outlet of the explosion suppression device (1); the gravity dust remover (2) is connected with the multi-tube cyclone dust remover (3); the multi-tube cyclone dust remover (3), the bag-type dust remover (4) and the fan (5) are sequentially connected, and explosion venting devices (6) are installed on tops of the gravity dust remover (2), the multi-tube cyclone dust remover (3) and the bag-type dust remover (4). With the explosion venting devices (6), when dust in the dust removers explodes, pressure relief plates are rapidly opened or explosion suppression membranes are immediately broken, so that unburned dust and explosion products escape, and the pressure in a container cannot rise to the breaking or deforming degree of the dust removers.

Owner:CRCC HIGH TECH EQUIP CORP LTD +1

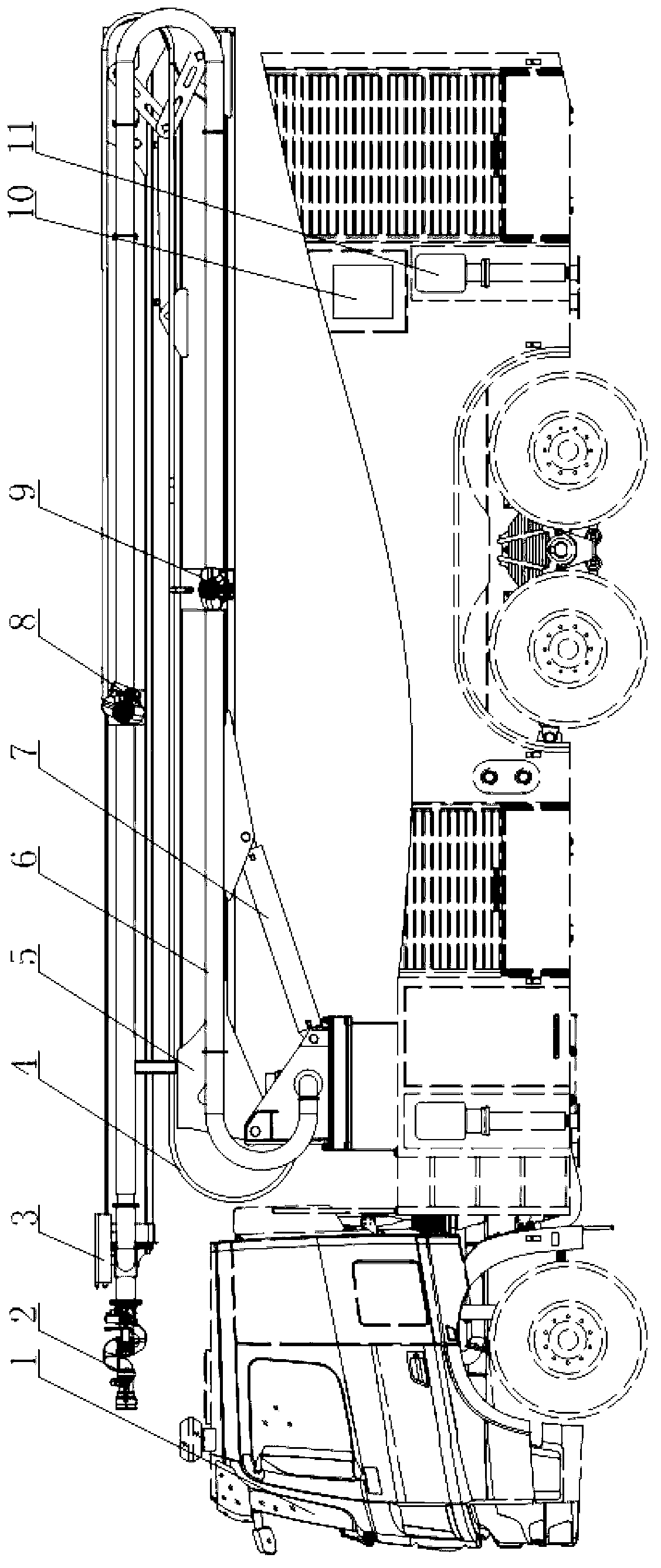

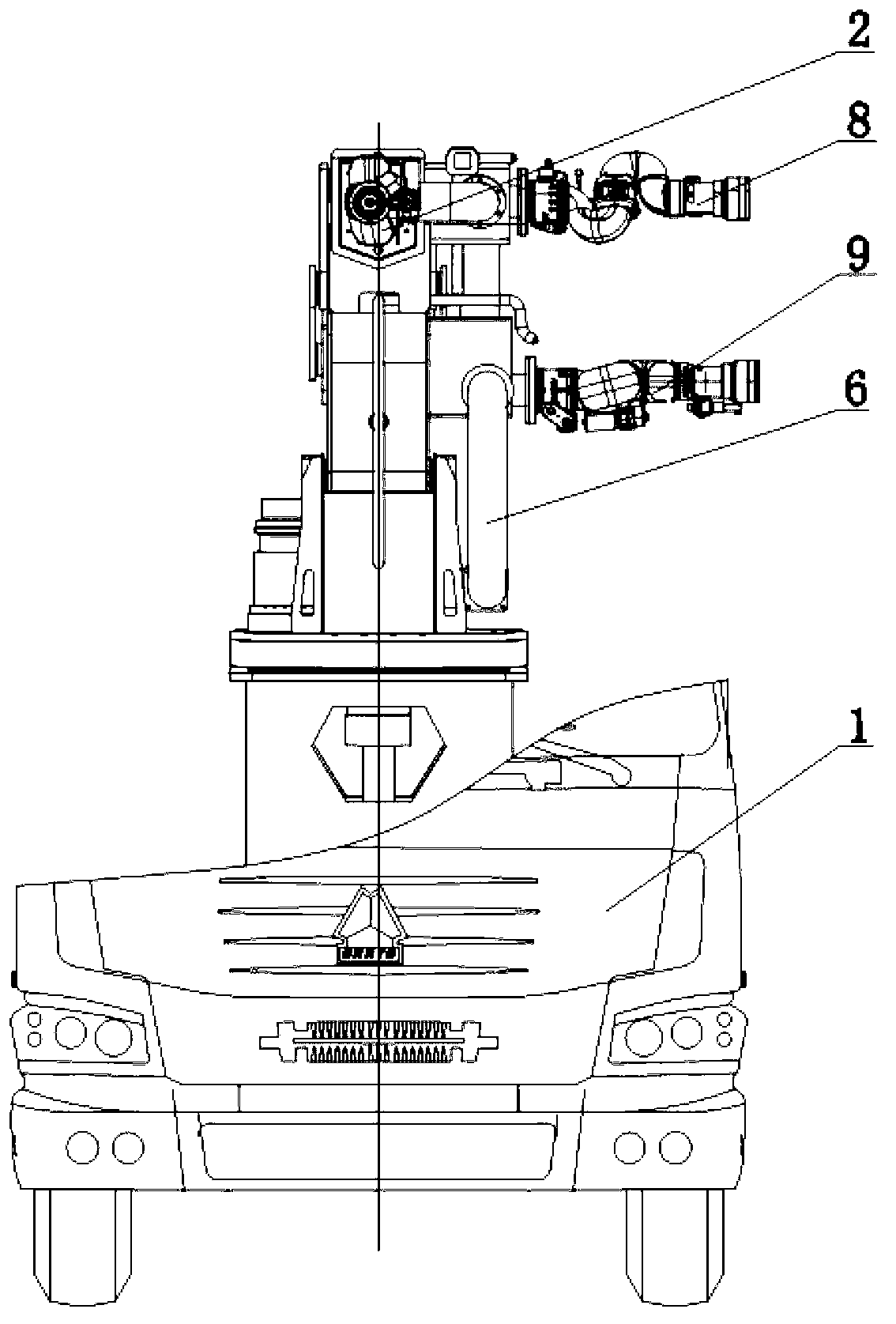

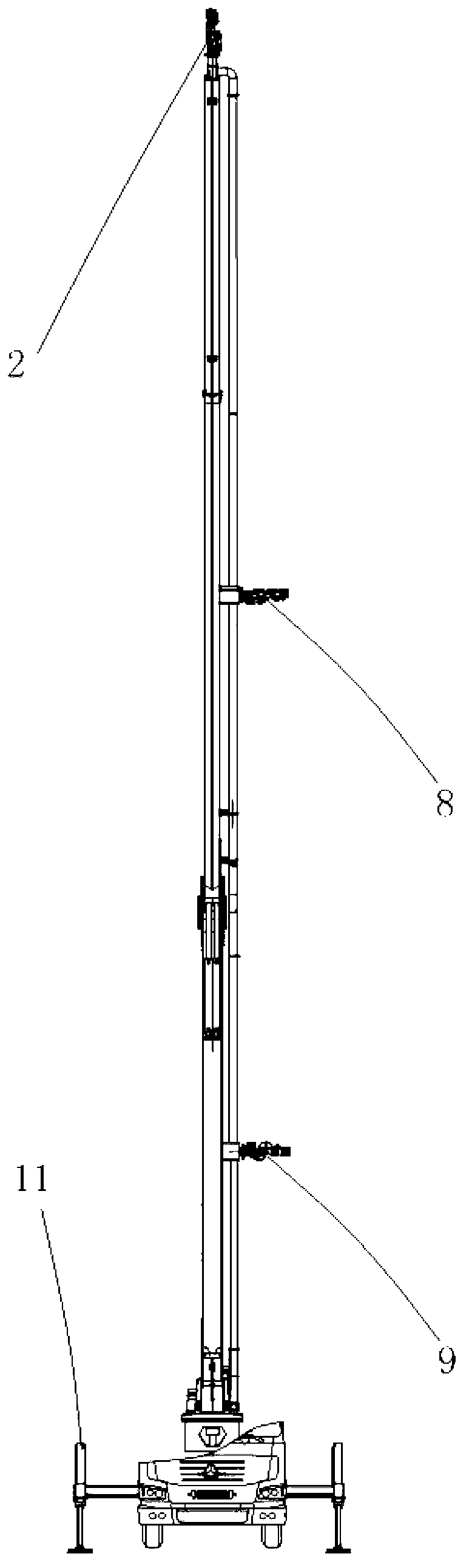

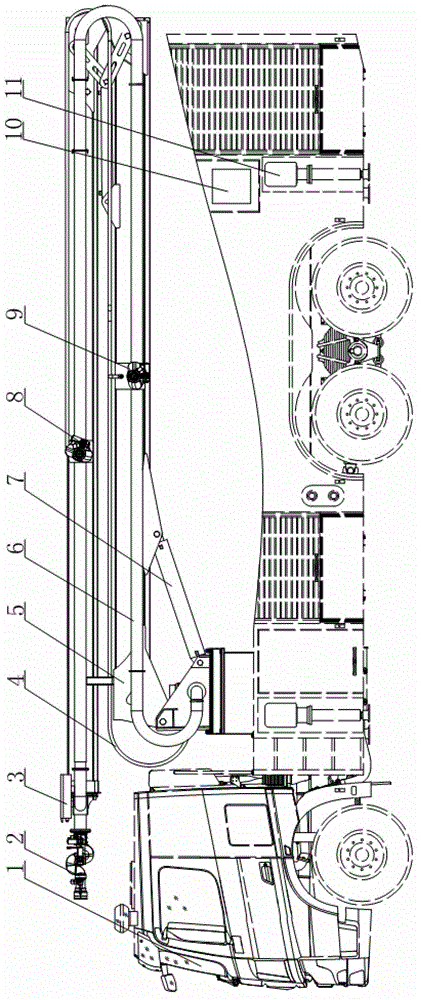

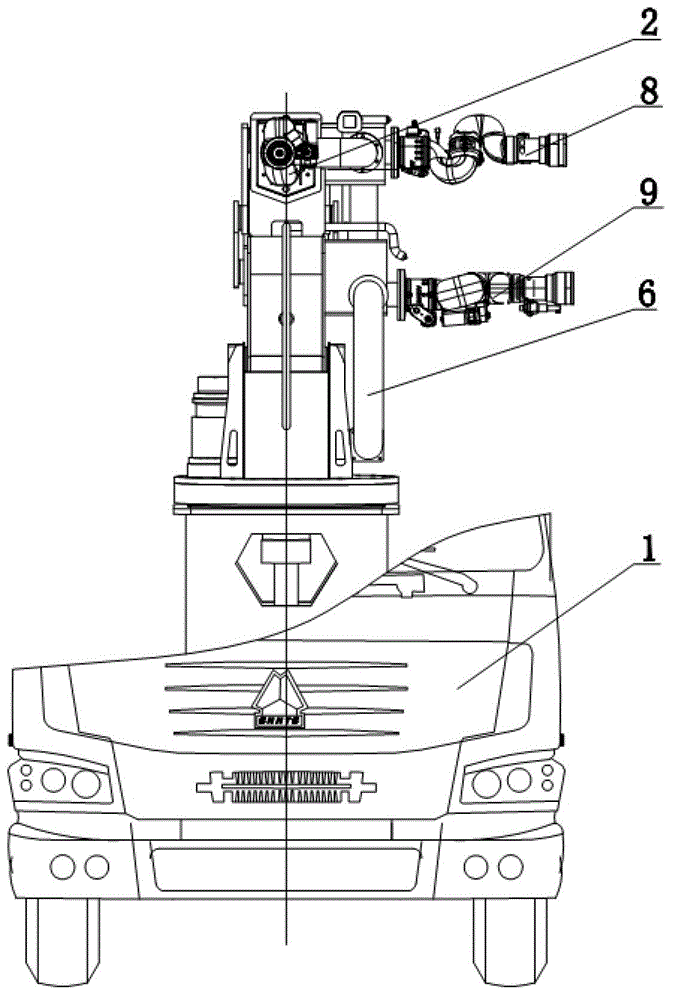

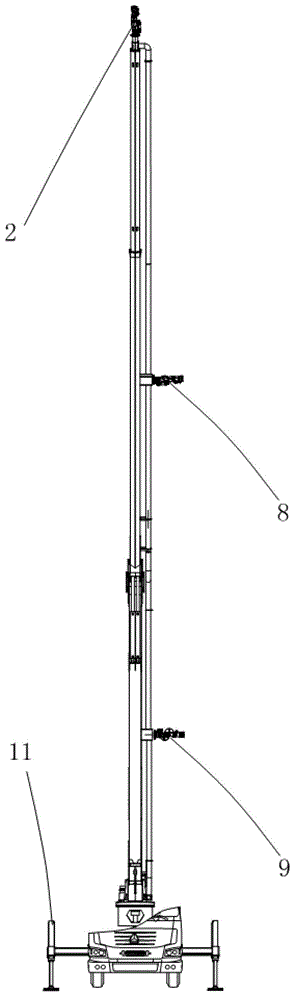

Remote-control elevating stereoscopic fire-extinguishing device

ActiveCN102698394AProtection against high temperature radiation explosionReduce the temperatureFire rescueRemote controlEngineering

The invention discloses a remote-control elevating stereoscopic fire-extinguishing device. By taking a fire truck as a carrier, a combined elevating cantilever crane and a landing leg mechanism are arranged, wherein the top end, the middle part and the bottom part of the cantilever crane are respectively provided with a first fire monitor, a second fire monitor and a third fire monitor; the cantilever crane is provided with a delivery pipe used for delivering fire-extinguishing chemicals to the three fire monitors; lift power is provided for the cantilever crane by a hydraulic system on the fire truck; and the first fire monitor, the second fire monitor and the third monitor are remotely controlled by a remote-control device on the fire truck. According to the novel, remote-control elevating stereoscopic fire-extinguishing device disclosed by the invention, remote-control and close-range stereoscopic fire fighting can be realized, and at the early period of a fire, the fire behavior can be effectively controlled, the fire-extinguishing efficiency can be increased, the fire-extinguishing chemical loss can be reduced, and the safety of fire personnel can be effectively ensured. The novel remote-control elevating stereoscopic fire-extinguishing device can be used for specially putting out large fires caused by oil tank accidents, light dydrocarbon tank accidents, well blowout and chemical unit accidents.

Owner:MINGGUANG HAOMIAO SECURITY PROTECTION TECH

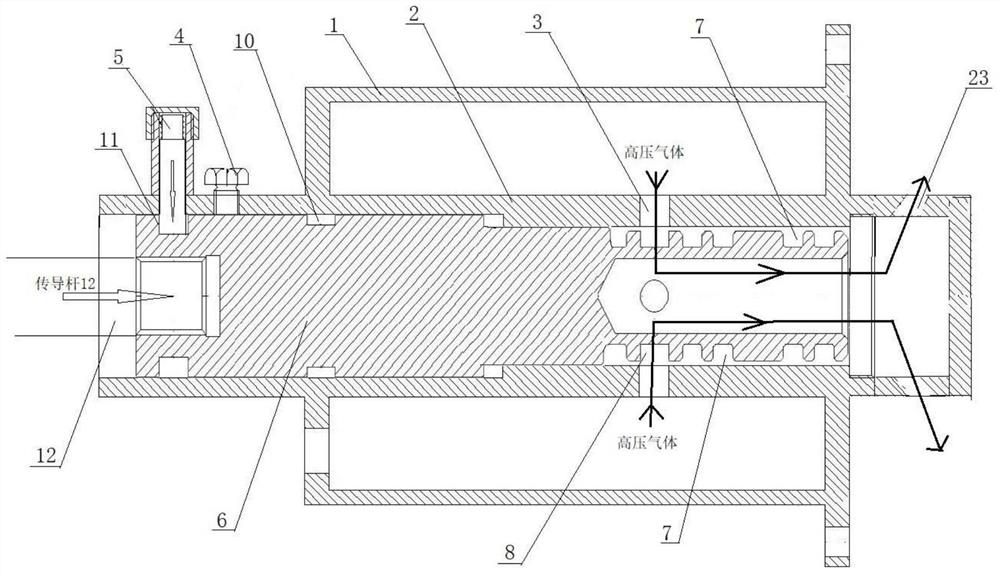

Double-trigger umbrella type oil and gas pipeline explosion-proof valve

ActiveCN112963591AImprove device reliabilityReduce pipe space occupancyEqualizing valvesSafety valvesEngineeringStructural engineering

The invention relates to a double-trigger umbrella type oil and gas pipeline explosion-proof valve which comprises a valve body, a support, a valve rod guide rail, a valve rod set, an explosion-proof cover, a left mechanical response mechanism, a right mechanical response mechanism, a locking mechanism and a temperature sensing action mechanism. Valve diameter parts are arranged at the two ends of the valve body, and the valve rod guide rail is arranged between the left mechanical response mechanism and the right mechanical response mechanism. The valve rod guide rail is located in the valve body, the valve rod set surrounds the valve rod guide rail, and the valve rod set is externally wrapped by a layer of anti-explosion cover. The left mechanical response mechanism and the right mechanical response mechanism are centrally installed in the valve diameter parts at the two ends of the valve body through the supports respectively. When a pipeline is burnt or exploded, a limiting disc at one end of the device is unfixed and rapidly moves in the guide rail, the valve rod set is rapidly shrunk, and therefore a valve clack is in an opened posture. When the limiting disc moves to the limit distance, the limiting disc and another limiting disc are locked through a locking block and a locking cavity and cannot move continuously, at the moment, the valve clack is tightly attached to the inner wall of the valve body, flames or shock waves can be blocked, and the explosion-proof effect is achieved.

Owner:NORTHEAST GASOLINEEUM UNIV

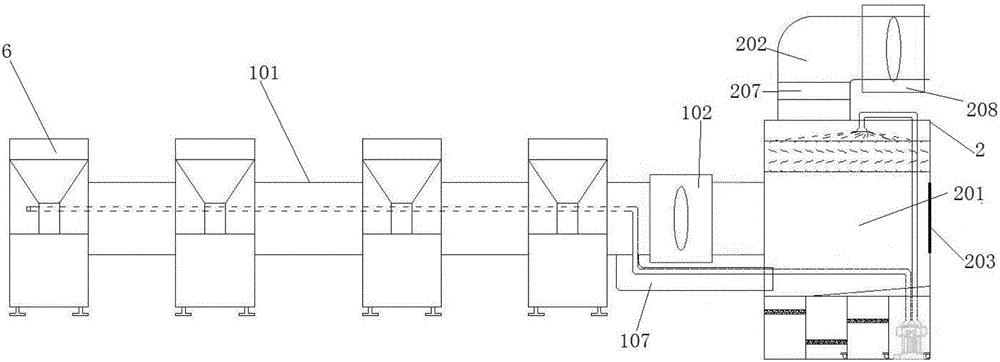

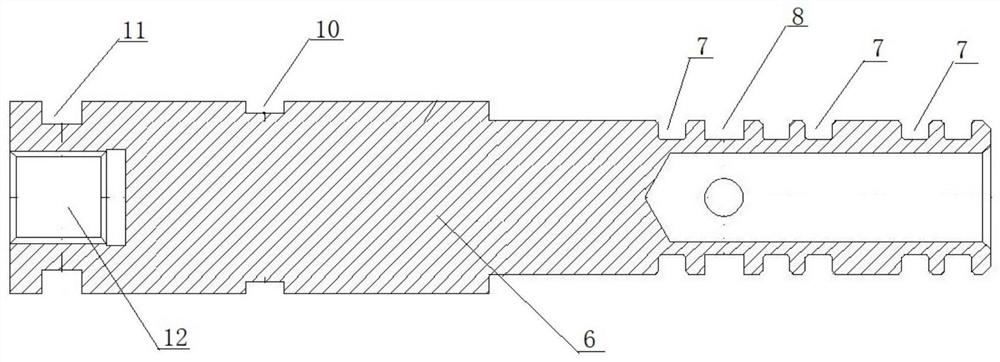

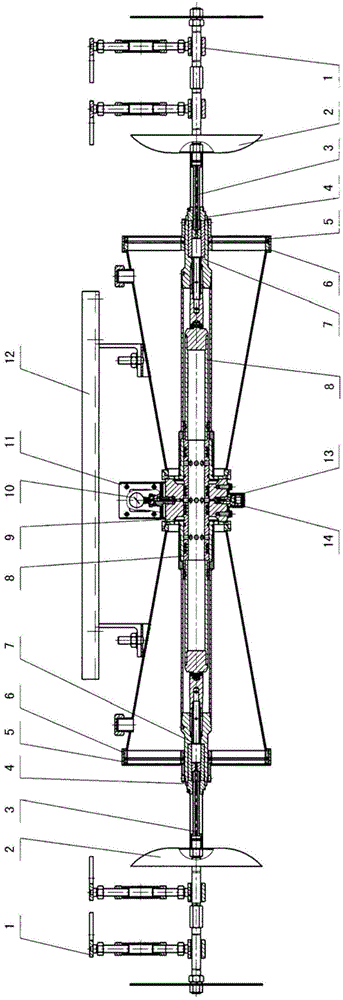

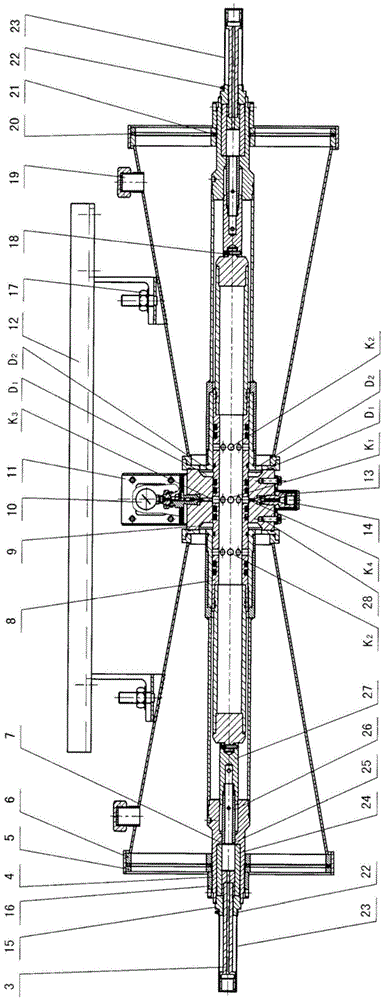

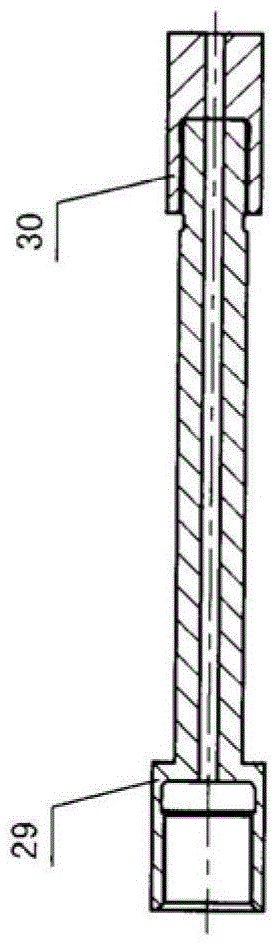

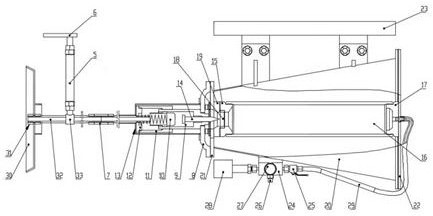

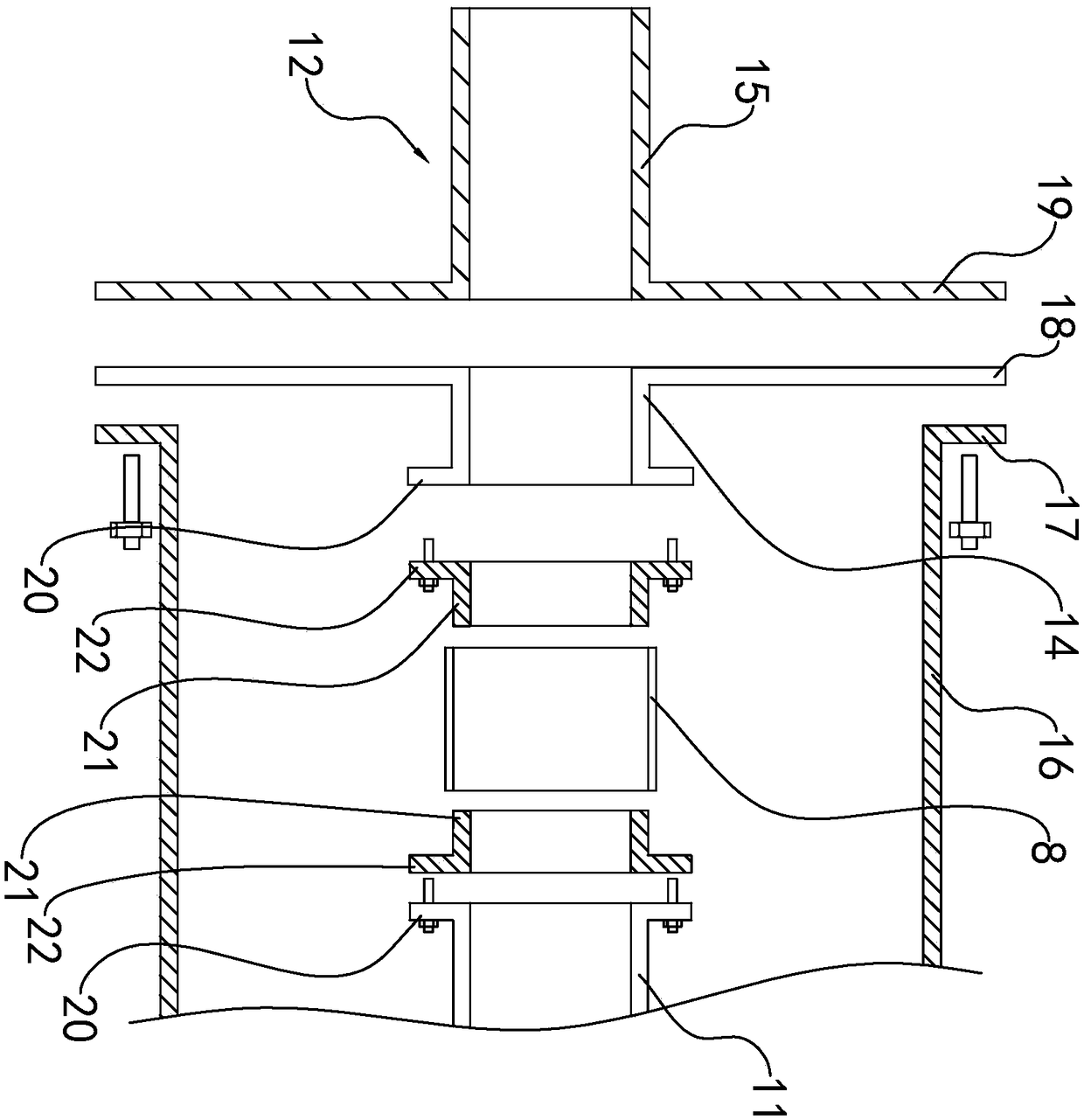

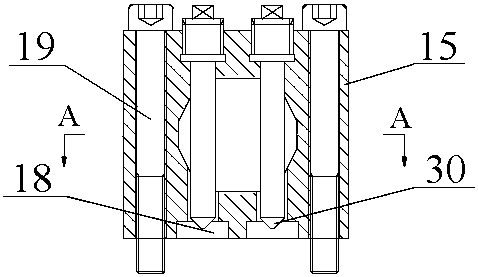

Coal mine automatic explosion-proof device with two-way triggering

InactiveCN103291349BNo manual operationAvoid secondary explosionDust removalFire preventionBilateral symmetryCoal

A mine under-shaft automatic explosive-suspension device triggered in two directions comprises receiving rod hanging devices, impact wave receiving devices, motion triggering components, transferring rod assemblies, outer-layer sleeve assemblies, air spraying pipe assemblies, middle sleeve assemblies, an outer cover assembly, a pressing sieve assembly, a pressure gauge component and pressure gauge protective cover, a valve needle and inflation cover assembly and a main body hanging device, the rest of the parts except the first two parts form the main body part, the number of each of the first seven parts is two, and the first seven parts are in bilateral symmetry regarding the axial vertical central line of the main body part as the center. The air spraying pipe assemblies are assembled inside axial center holes of the middle sleeve assemblies, are in sliding fit, are located in the center of the main body part, and are in bilateral symmetry regarding the axial vertical central line of the main body part as the center. The motion triggering components adopt safety gaskets. The mine under-shaft automatic explosive-suspension device triggered in the two directions is installed in an mine under-shaft tunnel with gas and coal duct explosion dangers, automatically suppressing an explosion in a bi-direction-triggered and spraying mode when the explosion occurs, and prevents the explosion from expanding and causing a secondary explosion, one set of the automatic explosive-suspension device replaces an original front set and an original reverse set, the cost of equipment is reduced, and installation and coal dust filling are convenient.

Owner:SHANDONG LIYE MINE EXPLOSION PROOF EQUIP

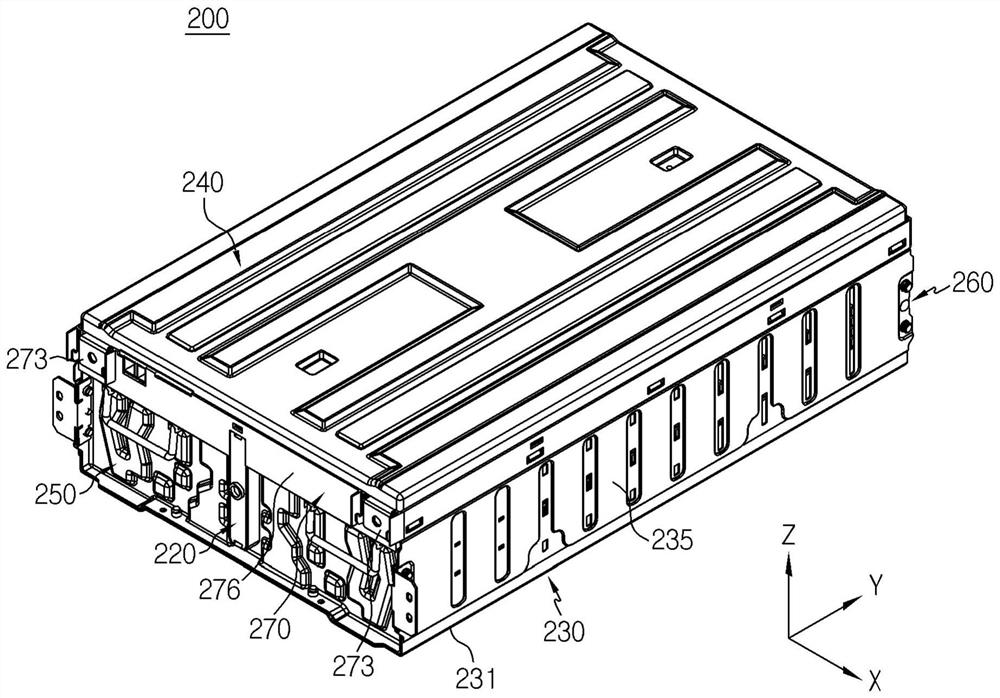

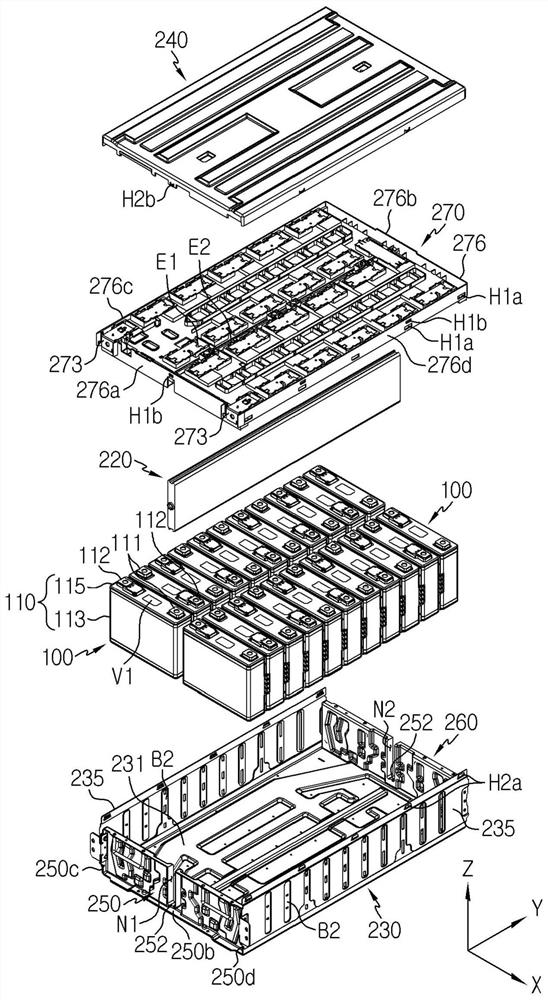

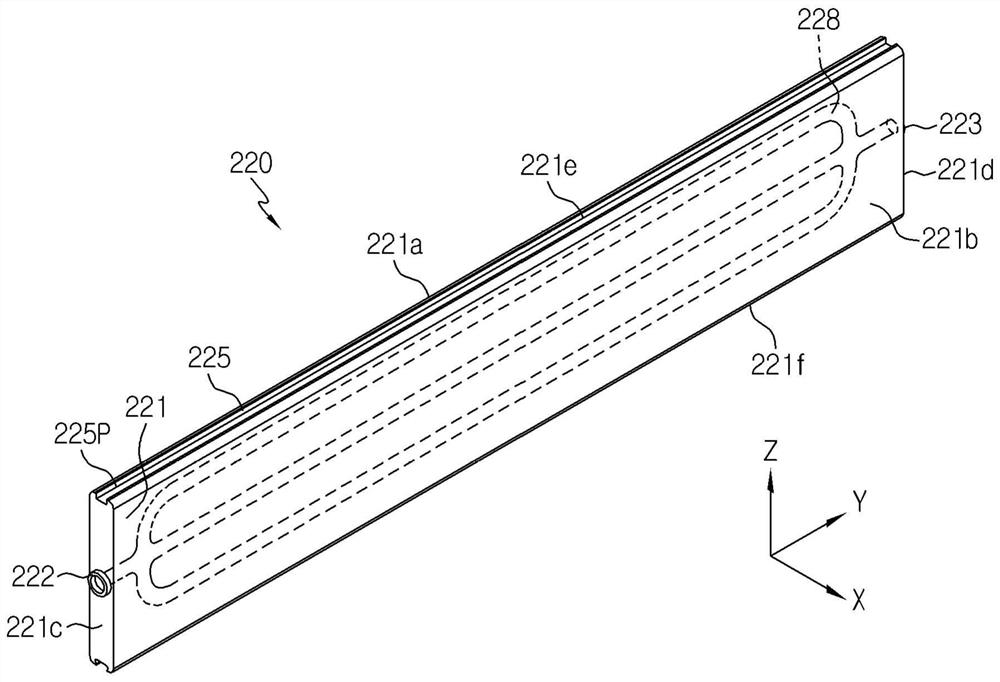

Battery module, battery pack including the same, and energy storage system including the battery pack

ActiveCN112103447AImprove securityAvoid secondary explosionSecondary cellsCell lids/coversElectrical batteryProcess engineering

The present invention relates to a battery module, a battery pack including the same, and an energy storage system including the battery pack to reduce the risk of secondary combustion or explosion and enhance durability against external impact. The battery module comprises: a plurality of secondary batteries arranged in two rows in the front and rear directions, each of the plurality of secondarybatteries comprising a gas venting unit for discharging a gas generated inside to the outside at a predetermined pressure; and a cooling member comprising a main body part provided between the two rows of the plurality of secondary batteries and having a size corresponding to the side parts in the left and right directions of the plurality of secondary batteries, and a gas discharge unit providedat at least one of the upper portion and the lower portion of the main body part and having a gas discharge path elongated from the front end to the rear end of the main body part.

Owner:LG ENERGY SOLUTION LTD

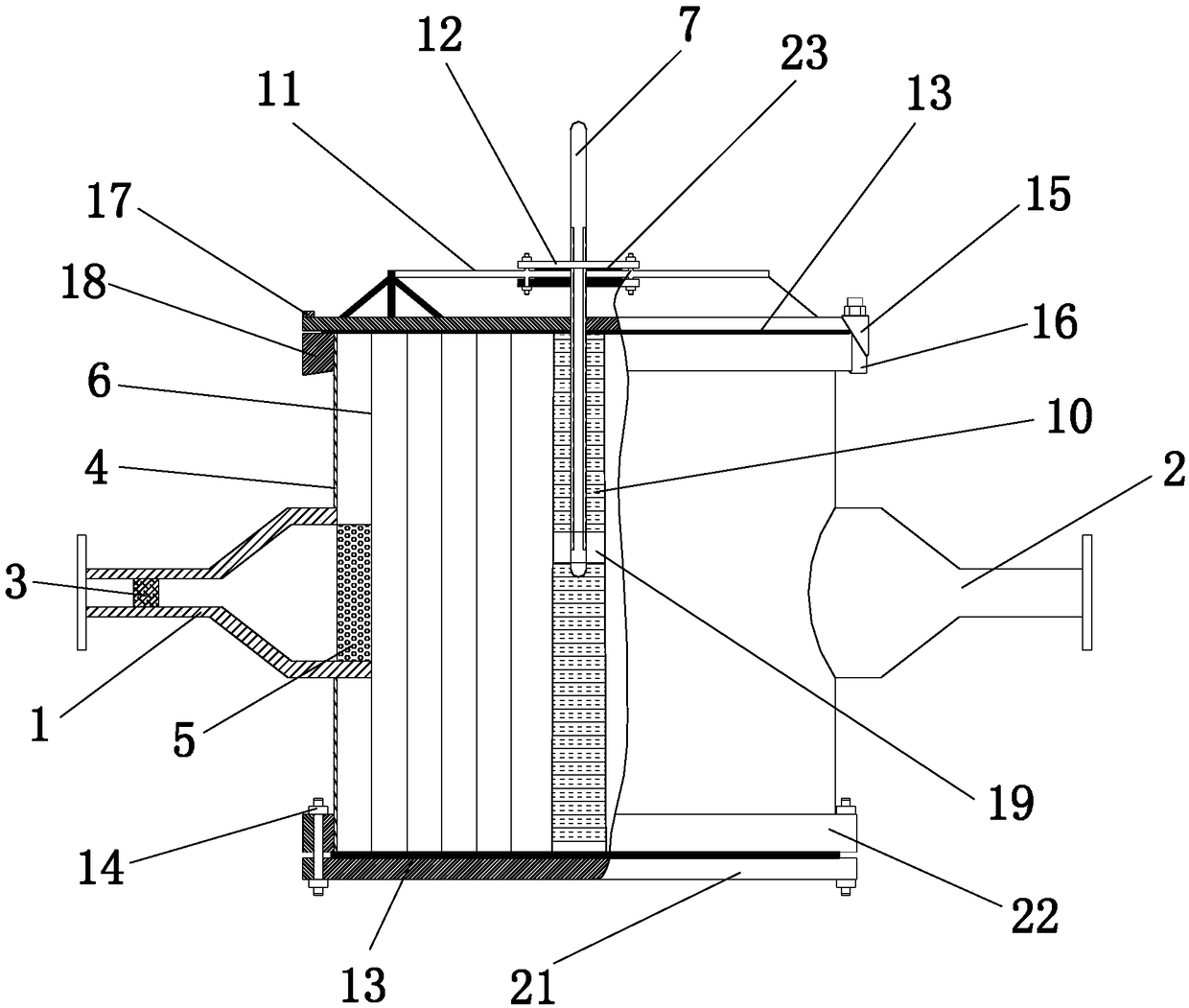

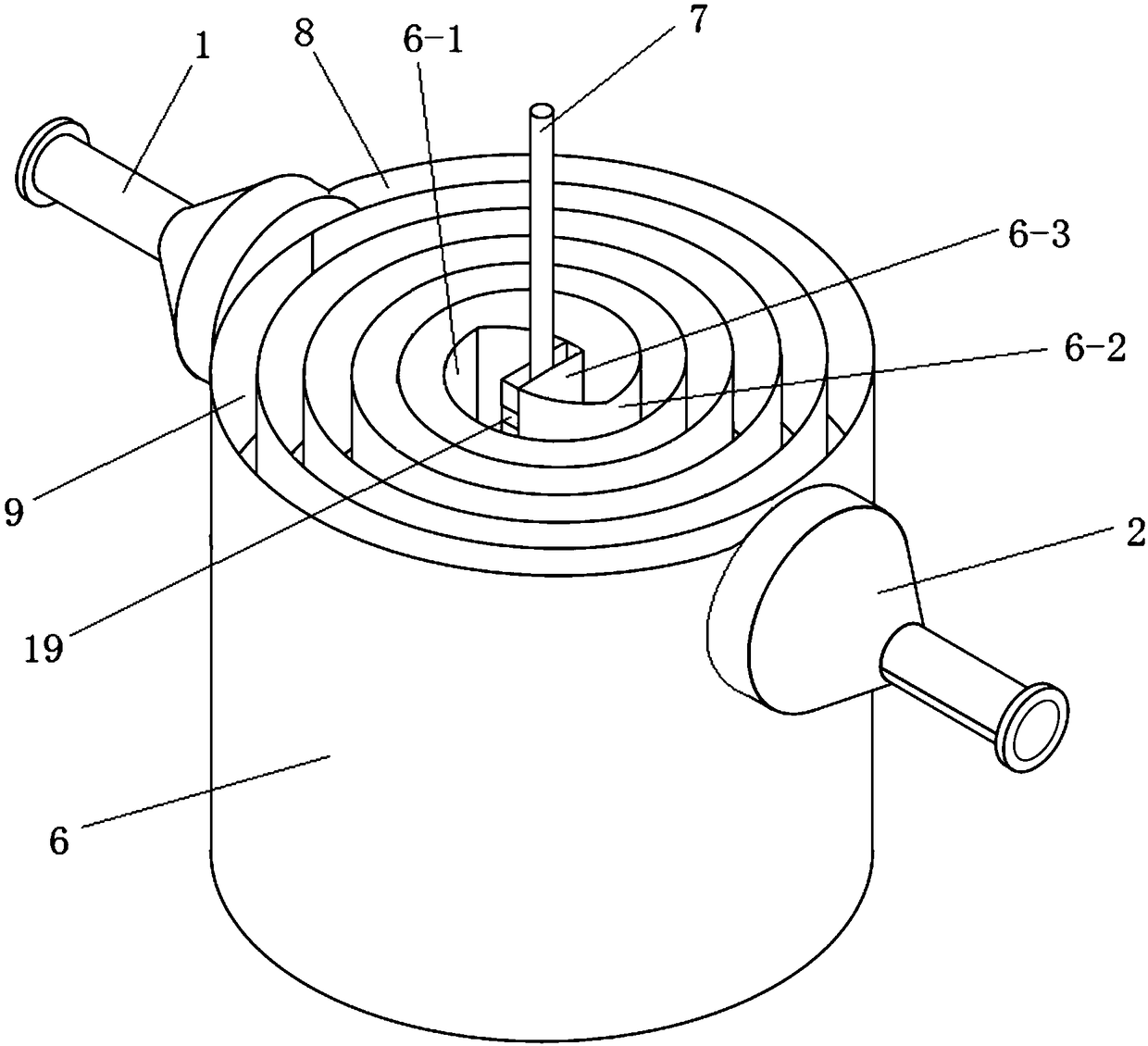

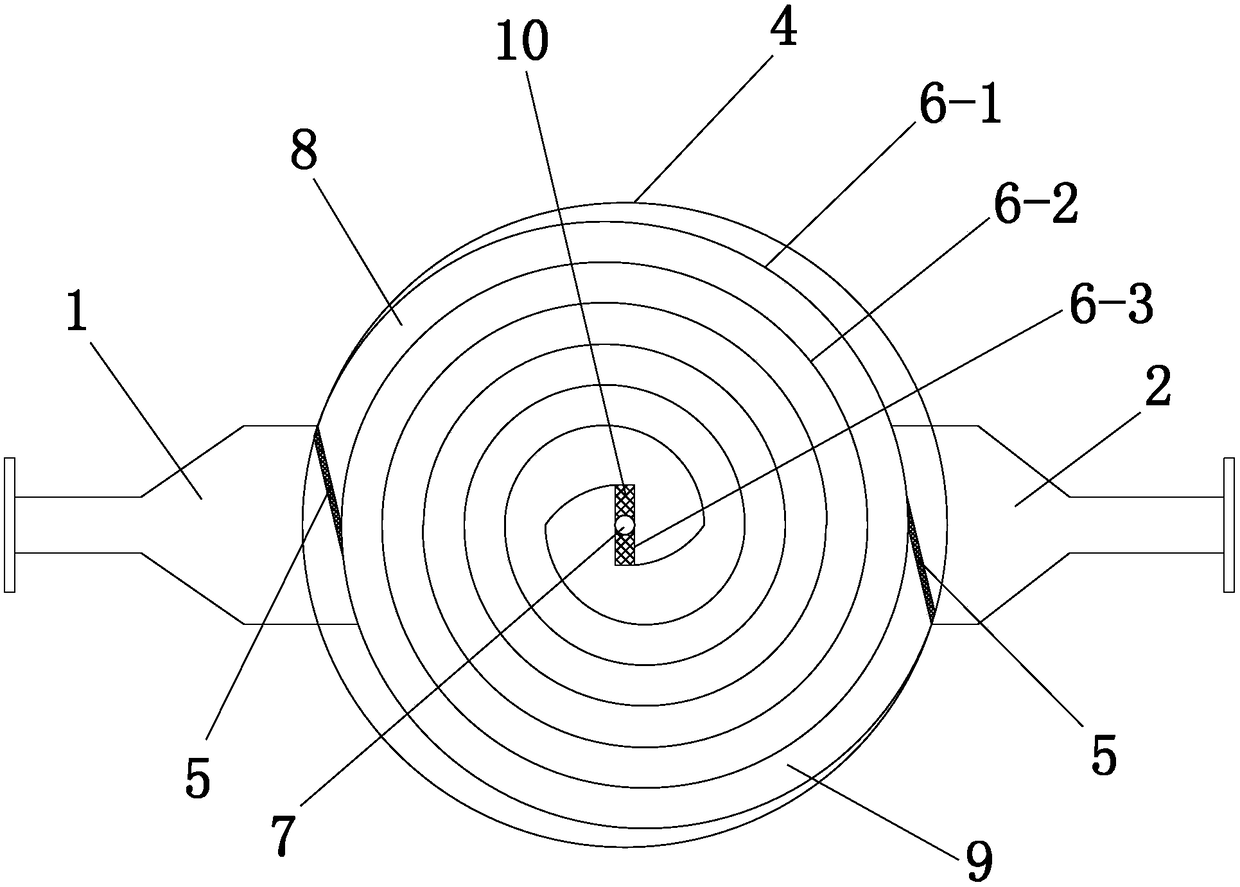

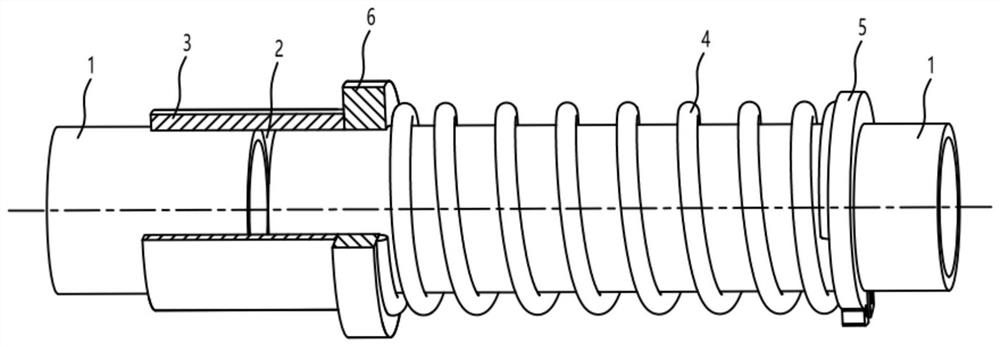

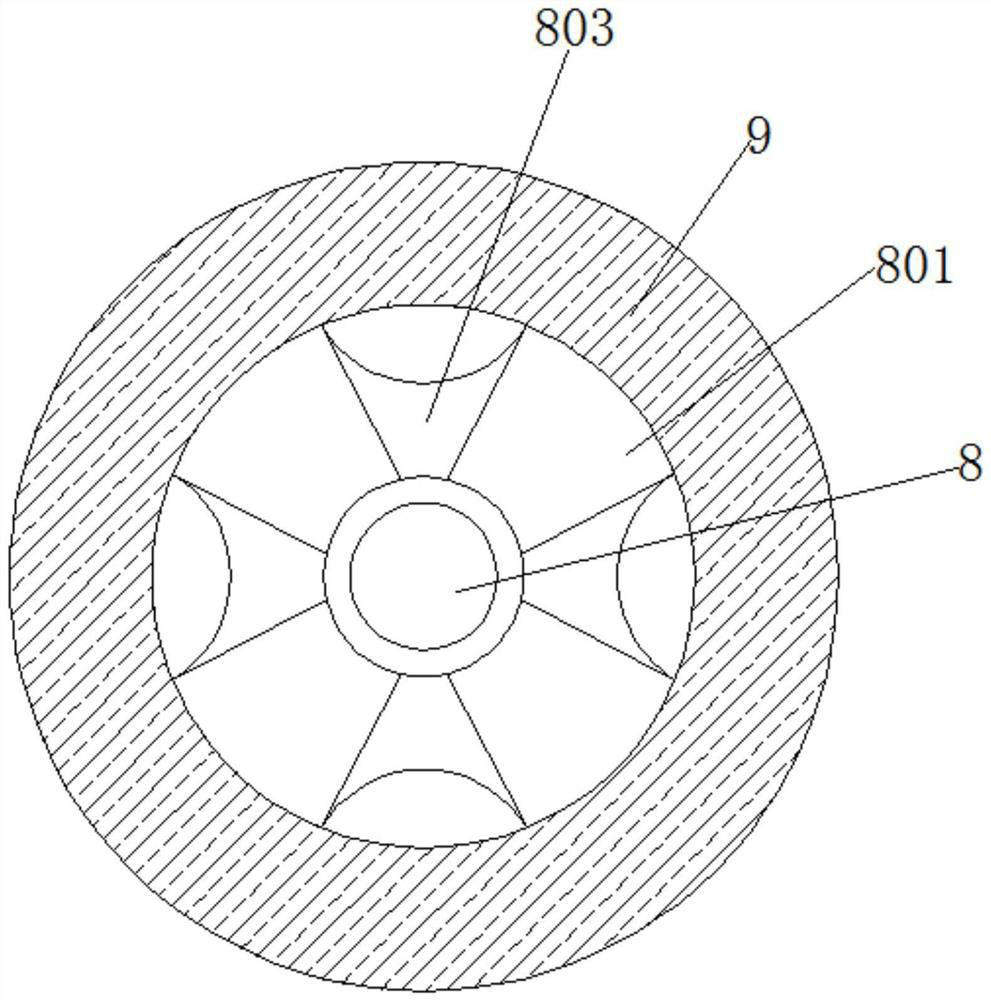

Spiral plate-type heat tube flame arrester

ActiveCN108498979AImprove temperature resistanceSolve the problem of cohesionFire rescueFlame arresterCombustion

The invention discloses a spiral plate-type heat tube flame arrester. The spiral plate-type heat tube flame arrester comprises a fireproof shell and a heat tube, wherein the fireproof shell is in a cylindrical shape, the bottom of the fireproof shell is provided with a base, and the top of the fireproof shell is provided with a cover body; and a spiral plate is arranged in the fireproof shell, thespiral plate is formed by connecting and winding a first metal plate and a second metal plate, a metal box body is formed on a welded part of the first metal plate and the second metal plate, the wound part of the first metal plate is wound outwardly surrounding the metal box body, the wound part of the second metal plate is encircled around the first metal plate by adopting the metal box body asthe center, and a first spiral runner and a second spiral runner are formed between the wound part of the first metal plate and the wound part of the second metal plate. The spiral plate is arrangedin the fireproof shell to form the spiral runner, so that the fireproof space is increased, the wall effect produced by the structural change of a multilayer channel is sufficiently used for sharply reducing the free radicals of the combustion, and the explosion is effectively prevented.

Owner:XIAN UNIV OF SCI & TECH

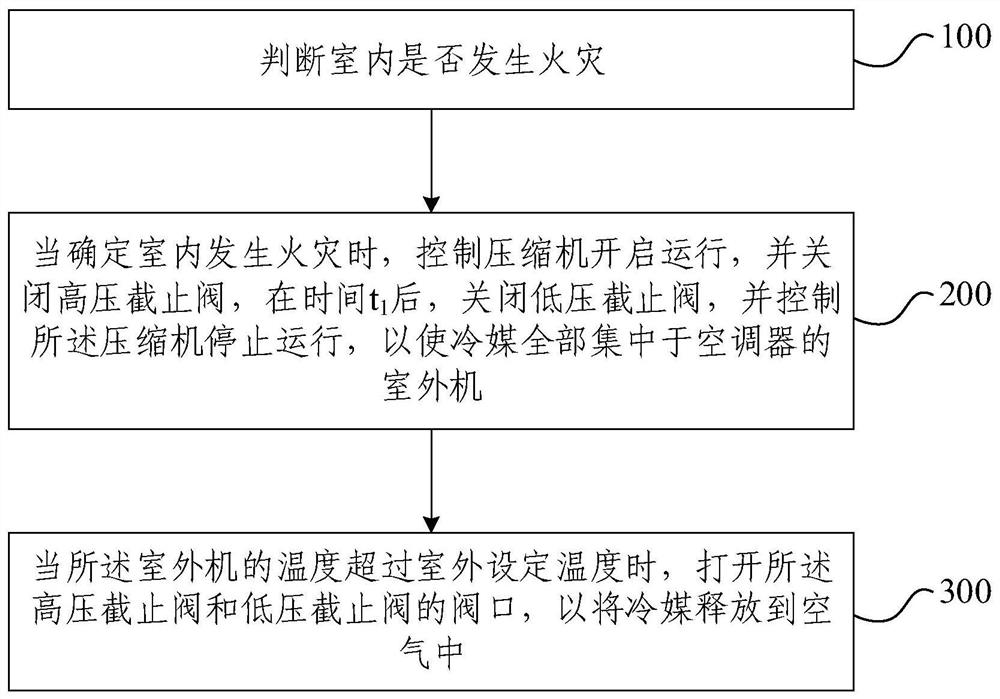

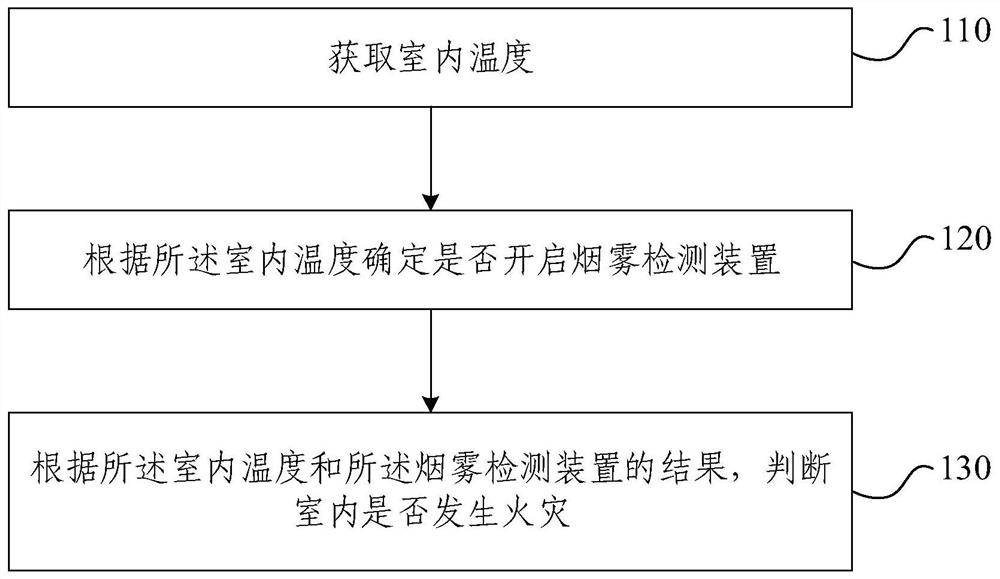

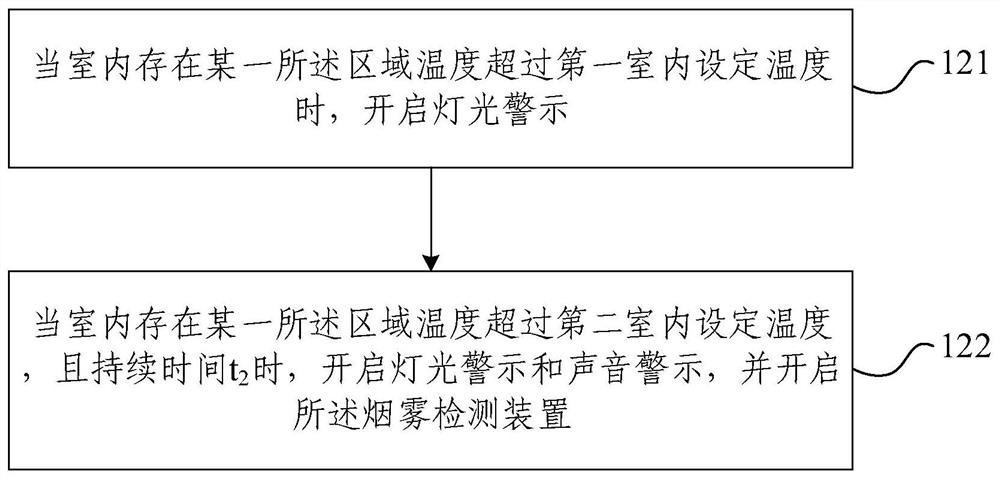

Safety control method of air conditioner, electronic equipment and storage medium

PendingCN113375286AImprove the safety of useAvoid secondary explosionMechanical apparatusSpace heating and ventilation safety systemsEngineeringRefrigerant

The invention provides a safety control method of an air conditioner, electronic equipment and a storage medium. The safety control method of the air conditioner comprises the steps that whether a fire occurs indoors or not is judged; when it is determined that a fire occurs indoors, a compressor is controlled to start running, a high-pressure stop valve is closed, after time t<1>, a low-pressure stop valve is closed, and the compressor is controlled to stop running, so that all refrigerants are concentrated in an outdoor unit of the air conditioner; and when the temperature of the outdoor unit exceeds the outdoor set temperature, valve ports of the high-pressure stop valve and the low-pressure stop valve are opened, so that the refrigerant is released into the air. According to the safety control method of the air conditioner, secondary explosion can be avoided, and the use safety of a user is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

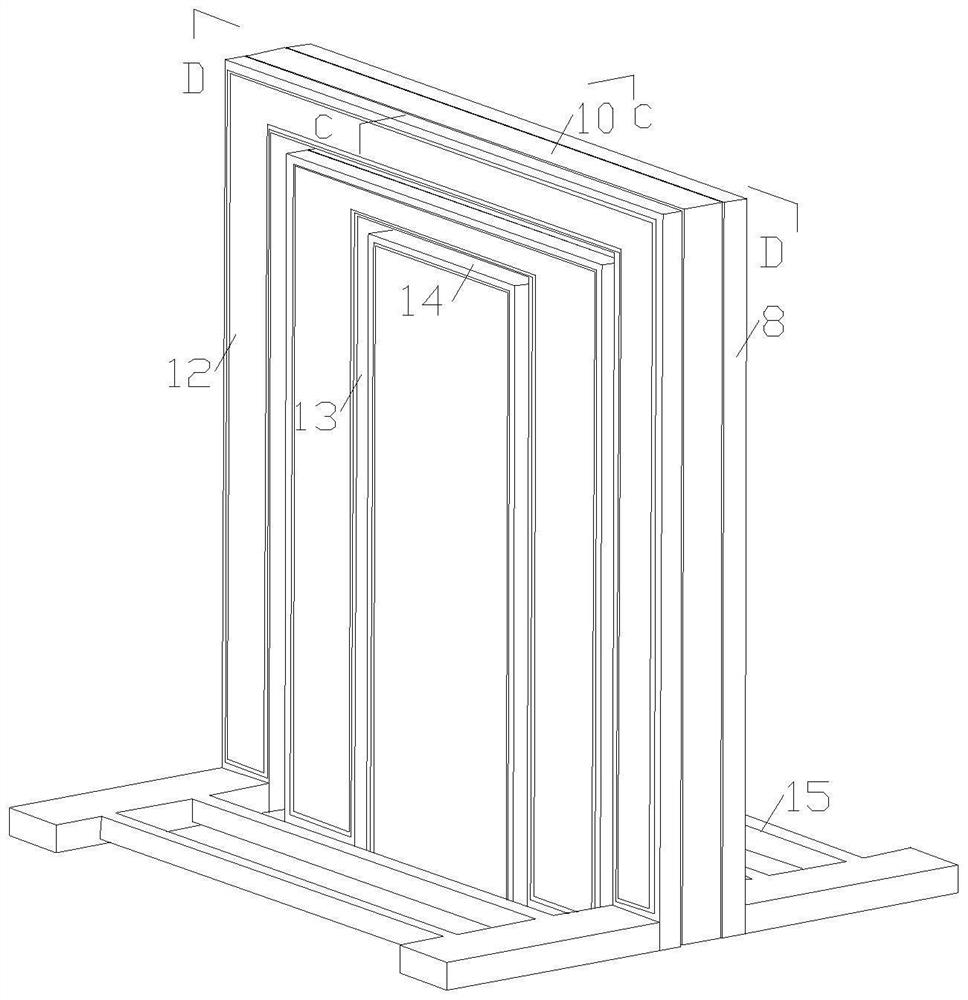

Automatic explosion-proof device for underground coal mine

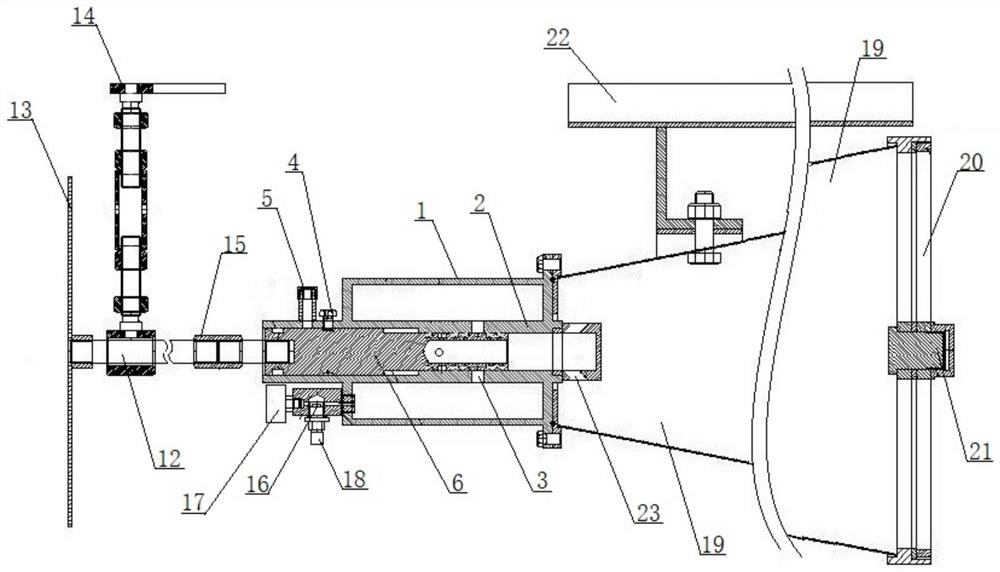

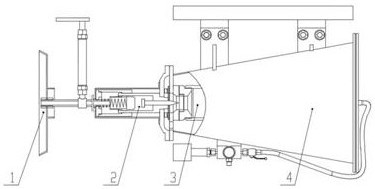

PendingCN112832843AThe transmission is fast and efficientEasy to installDust removalFire preventionThermodynamicsFlame propagation

The invention discloses an automatic explosion-proof device for an underground coal mine. The automatic explosion-proof device comprises a transmission mechanism, a trigger mechanism is fixedly mounted on the outer surface of one end of the transmission mechanism, a gas storage cylinder group is fixedly mounted on the outer surface of one end of the trigger mechanism, and a horn group is fixedly mounted on the outer surface of one side of the gas storage cylinder group. According to the automatic explosion-proof device for the underground coal mine, when explosion occurs due to dangerous gas or coal dust in an underground, the shock wave transmission mechanism receives an explosion shock wave signal, a transmission rod is rapidly pushed to do horizontal movement, the trigger mechanism in the explosion-proof device is started to pierce a blocking piece in the gas storage cylinder group, and high-pressure gas stored in the gas storage cylinder group is instantaneously sprayed out, so that a dry powder extinguishing agent stored in the horn group is quickly sprayed out under the action of the thrust of the high-pressure gas, and therefore a flame propagation path is covered in a large area, an explosion-proof dry powder barrier is formed, the effects of extinguishing flames and inhibiting explosion are achieved, and a better use prospect is brought.

Owner:JIANGSU JUXI MINING EQUIP SCI & TECH

Negative pressure bidirectional detonation flame-proof device

PendingCN108533810AReduced blast strength requirementsReduce manufacturing costEqualizing valvesMultiple way valvesDetonationEngineering

The invention discloses a negative pressure bidirectional detonation flame-proof device and relates to the field of anti-detonation equipment. The negative pressure bidirectional detonation flame-proof device comprises a negative pressure cavity pipe and a bidirectional flame-proof valve arranged inside a negative pressure cavity; the bidirectional flame-proof valve comprises a valve body internally provided with a valve element containing cavity and a valve element arranged inside the valve element containing cavity; the two ends of the valve body are provided with a first pipeline and a second pipeline which penetrate out of the negative pressure cavity pipe and communicate with the outside; the negative pressure cavity pipe is in sealed connection with the outer walls of the first pipeline and the second pipeline to form the negative pressure cavity; the walls of the first pipeline and the second pipeline are provided with brittle annular rupture disks; and the annular rupture disksare arranged inside the negative pressure cavity. The negative pressure bidirectional detonation flame-proof device has the beneficial effects that the negative pressure cavity can extinguish all ormost of flame, the requirements for anti-detonation intensity of the valve element, the valve body and the pipelines are reduced, the production cost of enterprises is reduced, and the efficacy and safety of the flame-proof device are improved. A computer can detect the pressure inside the negative pressure cavity in real time, so that the negative pressure cavity always keeps the needed negativepressure intensity.

Owner:GUANGZHOU SPECIAL MECHANICAL & ELECTRICAL EQUIP INSPECTION & RES INST

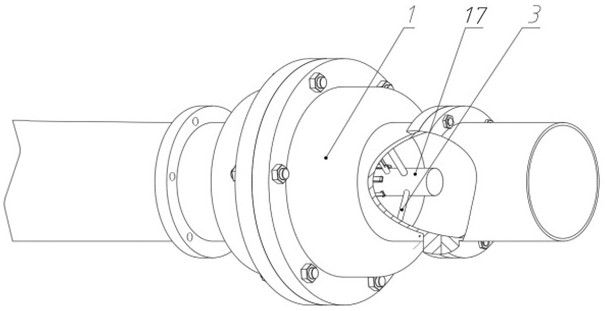

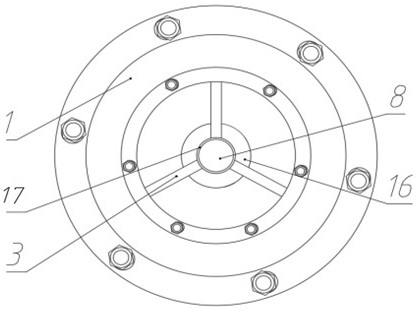

A double-trigger umbrella type oil and gas pipeline explosion-proof valve

The invention relates to a double-trigger umbrella type oil and gas pipeline explosion-proof valve, which includes a valve body, a bracket, a valve stem guide rail, a valve stem group, an explosion-proof cover, a left mechanical response mechanism, a right mechanical response mechanism, a locking mechanism, a sensor Warm action mechanism, the two ends of the valve body are the valve diameter, the valve stem guide rail is set between the left mechanical response mechanism and the right mechanical response mechanism, the valve stem guide rail is located in the valve body, the valve stem group is surrounded by the valve stem guide rail, and the valve stem group is outsourced A layer of explosion-proof cover; the left mechanical response mechanism and the right mechanical response mechanism are installed in the center of the valve diameter at both ends of the valve body through brackets. When the pipeline burns or explodes, the limiting plate at one end of the present invention is released and moves quickly in the guide rail, so that the valve stem group shrinks rapidly, so that the valve disc presents an open posture; when the limiting plate moves to the limit distance, It is locked with another limit plate through the lock block and the lock cavity, and cannot continue to move. At this time, the valve disc is close to the inner wall of the valve body, blocking flame or shock wave, and achieving the effect of flameproofing.

Owner:NORTHEAST GASOLINEEUM UNIV

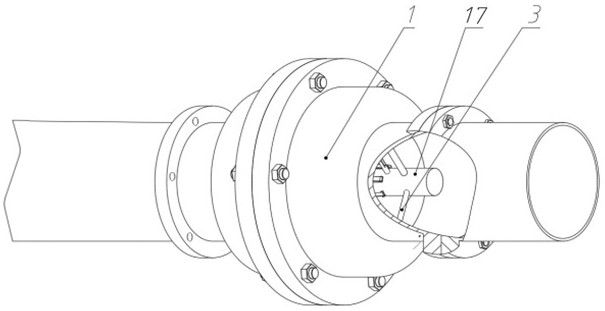

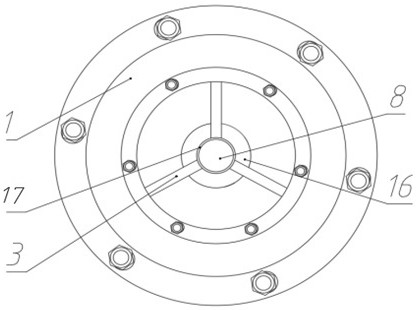

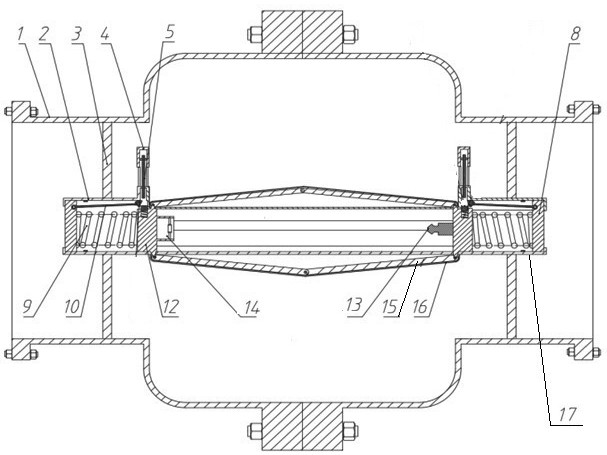

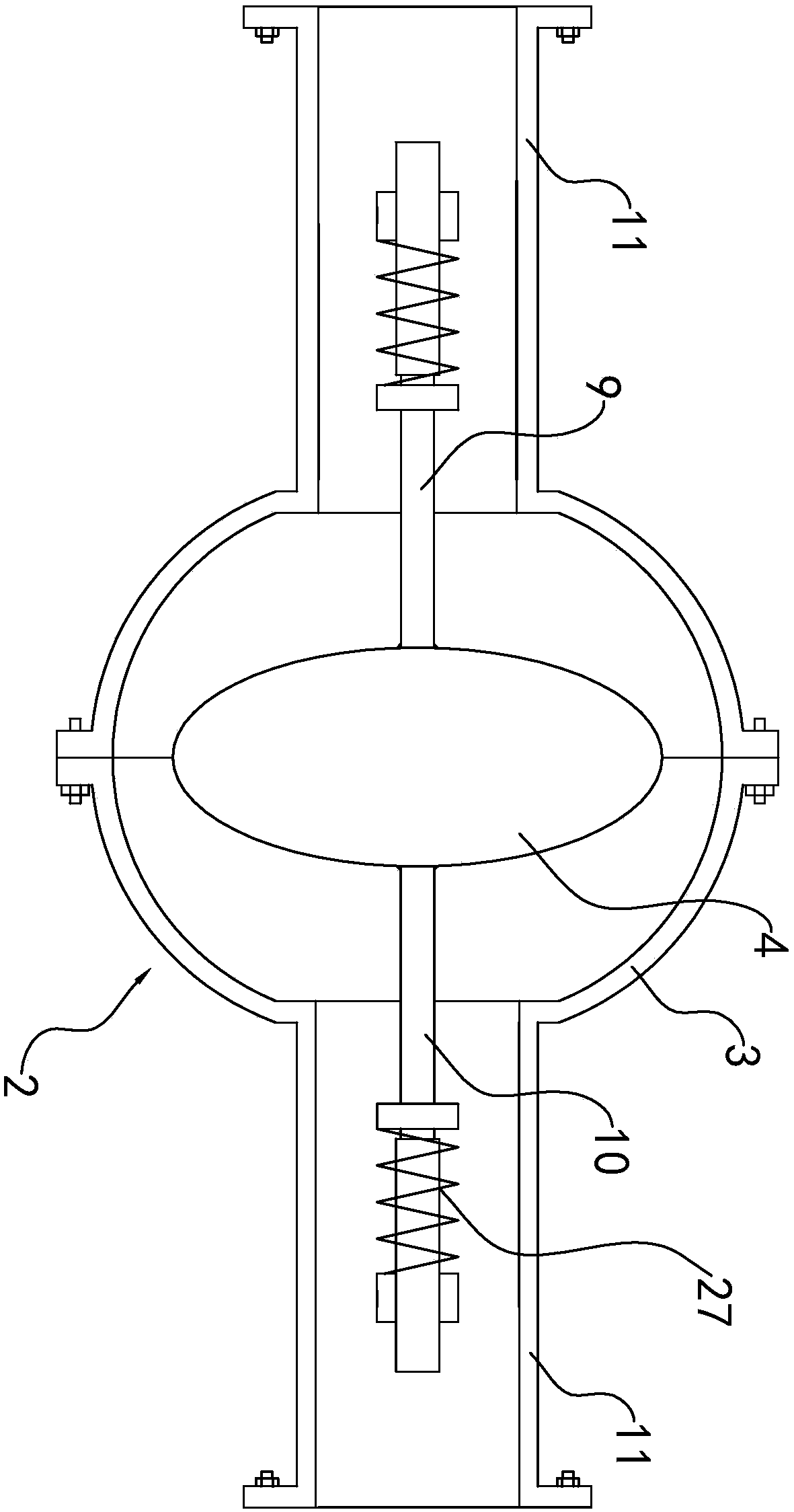

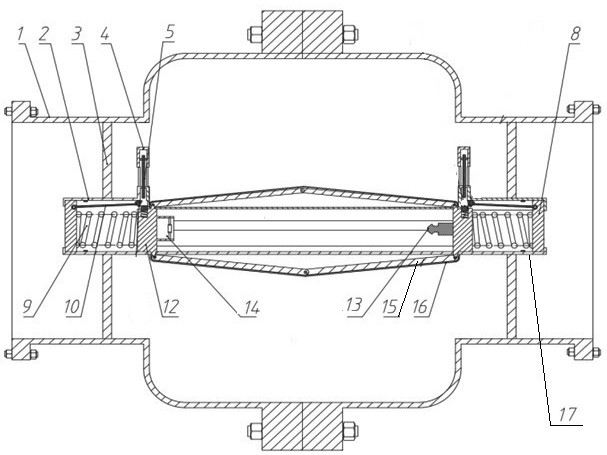

Pressure relief explosion-proof valve

ActiveCN103244722BAvoid enteringAvoid secondary explosionEqualizing valvesSafety valvesEngineeringFlange

The invention relates to a pressure-relief anti-explosion valve comprising a flange, a sealing cap and an explosion door. The flange sealed with a device having explosion hazards is fixedly connected with the same, the sealing cap is sealed with the flange, and the explosion door is installed inside the sealing cap and sealed to the periphery of a center hole of the flange. The explosion door comprises at least one guide rail, an explosion door body and a spring. The guide rails vertical to the flange are connected between the sealing cap and the flange, the explosion door body is used for relieving pressure when the device is popped open due to large pressure inside, the spring is used for connecting the explosion door body and the periphery of the center hole of the flange in a sealed manner, and the explosion door body is slidably connected with the guide rails and sealed with the periphery of the center hole of the flange. Since the explosion door body and the flange are connected in a sealed manner by the spring, when the pressure inside the device is large, the explosion door body is restored rapidly after being popped open to prevent air from entering, and a secondary explosion is avoided; and the pressure-relief anti-explosion valve is pressed against the flange relying on elastic force of the spring, so can be used repeatedly on the device in any manner of installation, and is wide in application.

Owner:XIECHANG ENVIRONMENTAL PROTECTION TECH CO LTD

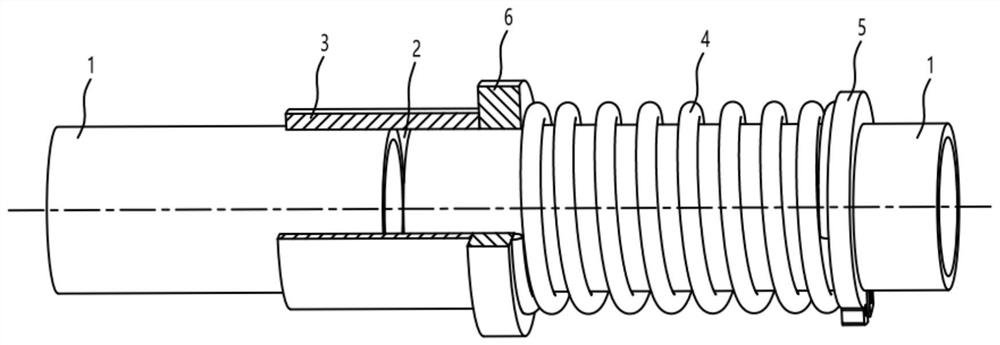

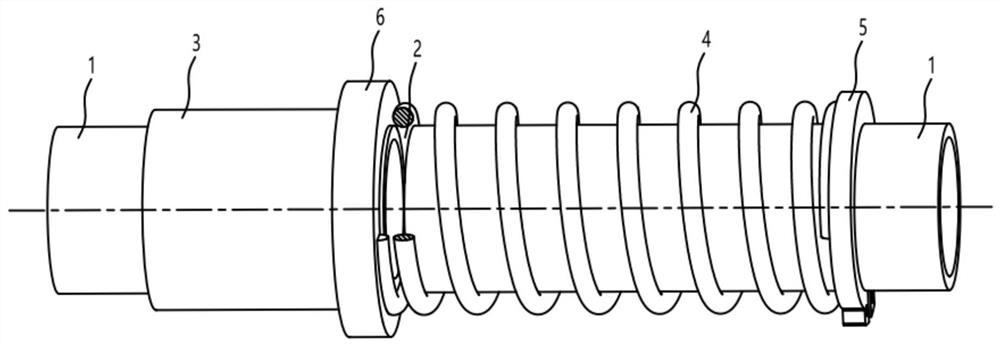

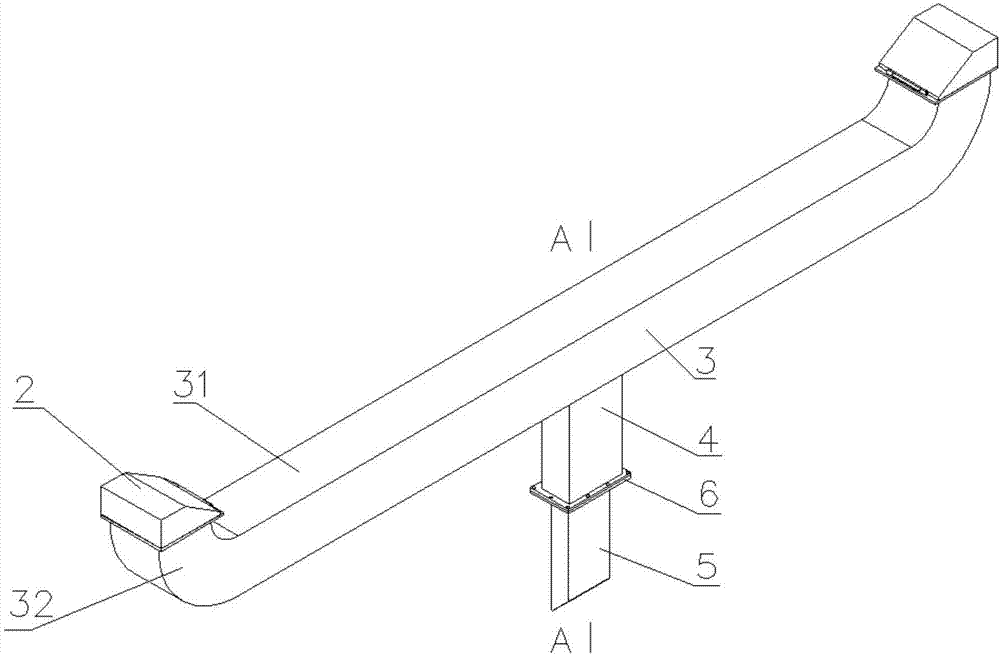

Pipeline sealing structure capable of achieving high-temperature air leakage safety protection, pipeline sealing method and high-temperature air leakage method

ActiveCN113124247AGuarantees the proper functioning of the sealAvoid secondary explosionEqualizing valvesPipe elementsWorking temperatureMechanical engineering

The invention belongs to the technical field of pipeline high-temperature air leakage safety protection, particularly discloses a pipeline sealing structure capable of achieving high-temperature air leakage safety protection, a pipeline sealing method and a high-temperature air leakage method. The scheme aims at achieving normal work of pipeline sealing under the working temperature working condition and achieving air leakage for safety protection under the abnormal high-temperature state. According to the specific scheme, the memory inner diameter of a memory pipe joint is smaller than the pipeline outer diameter, so that an air leakage channel can be sealed after heating, and normal pipeline sealing work at the working temperature is guaranteed; and when abnormal high temperature occurs, as the memory length of a memory spring is larger than the distance between a spring check ring and the air leakage channel, enough recovery stroke is achieved, and the memory recovery force is larger than the friction force between the memory pipe joint and the pipeline, the memory spring recovers the memory shape and can drive the memory pipe joint to move, and therefore, the air leakage channel is opened to avoid explosion and other dangers.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

Tube explosion closing valve

PendingCN107859766AHigh sensitivityImprove reliabilityEqualizing valvesSafety valvesEngineeringControl valves

The invention provides a tube explosion closing valve. The tube explosion closing valve comprises valve bodies, a water inlet channel, a water outlet channel, valve clacks arranged in the valve bodiesand drive mechanisms arranged at the two ends of the valve clacks. Each drive mechanism comprises a cylinder body connected with the corresponding valve clack, a piston mounted in the cylinder body and a control guide valve communicating with the cylinder body. Each control guide valve comprises a guide valve body mounted on the corresponding valve body, a water inlet formed in the guide valve body, a water outlet, multiple communicating openings communicating with the corresponding cylinder body, an adjusting valve mounted on the water outlet and used for controlling on-off of the water outlet, needle valves each mounted on the corresponding communicating opening and a plug movably mounted on the water inlet, wherein the water inlet communicates with the communicating openings. The valveclacks are in contact with the pistons. According to the tube explosion closing valve, the whole valve clacks are used as a medium for inducting flowing speed changes, after being amplified, the change feature of the flowing speed of the medium is converted into a pressure signal, the tube explosion feature is inducted through the pressure changes generated after conversion, the induction manneris high in sensitivity and reliability, and the response condition of tube explosion closing is sufficient and reliable.

Owner:ANHUI REDSTAR VALVE

Gas firefighting explosive-proof valve

InactiveCN108843799AAvoid secondary explosionImprove sealingOperating means/releasing devices for valvesValve members for absorbing fluid energyFirefightingMagnet

The invention relates to the technical field of gas firefighting, and discloses a gas firefighting explosive-proof valve. The gas firefighting explosive-proof valve comprises a shell; a feeding pipe,a discharging pipe and a valve clack are arranged at the two ends of the shell correspondingly; the valve clack is made of a metal magnetic material; a magnet capable of attracting the valve clack isarranged on the inner wall of the shell; a gas firefighting mechanism is arranged on the position, above the valve clack, of the shell, and a gas outlet is formed in the lower portion of the gas firefighting mechanism and located above the valve clack; a temperature sensor is arranged at the end, opposite to the valve clack, of the discharging pipe; and the temperature sensor and the gas firefighting mechanism are connected with a control system. Firefighting gas can extinguish a fire, during an explosion, the temperature sensor detects that the temperature is increased, then the control system controls the firefighting mechanism to release the firefighting gas into the shell, the firefighting gas impacts the valve clack, thus the valve clack rotates to be closed with the feeding pipe, therefore, the valve clack can be horizontally placed during normal working, and dust transporting is prevented from being affected.

Owner:HENAN YUNLE TECH CO LTD

Remote control lifting three-dimensional fire extinguishing device

ActiveCN102698394BProtection against high temperature radiation explosionReduce the temperatureFire rescueRemote controlEngineering

The invention discloses a remote-control elevating stereoscopic fire-extinguishing device. By taking a fire truck as a carrier, a combined elevating cantilever crane and a landing leg mechanism are arranged, wherein the top end, the middle part and the bottom part of the cantilever crane are respectively provided with a first fire monitor, a second fire monitor and a third fire monitor; the cantilever crane is provided with a delivery pipe used for delivering fire-extinguishing chemicals to the three fire monitors; lift power is provided for the cantilever crane by a hydraulic system on the fire truck; and the first fire monitor, the second fire monitor and the third monitor are remotely controlled by a remote-control device on the fire truck. According to the novel, remote-control elevating stereoscopic fire-extinguishing device disclosed by the invention, remote-control and close-range stereoscopic fire fighting can be realized, and at the early period of a fire, the fire behavior can be effectively controlled, the fire-extinguishing efficiency can be increased, the fire-extinguishing chemical loss can be reduced, and the safety of fire personnel can be effectively ensured. The novel remote-control elevating stereoscopic fire-extinguishing device can be used for specially putting out large fires caused by oil tank accidents, light dydrocarbon tank accidents, well blowout and chemical unit accidents.

Owner:MINGGUANG HAOMIAO SECURITY PROTECTION TECH

New energy anti-overheating lithium battery pack

PendingCN114079078AReduce pressureAvoid secondary explosionLi-accumulatorsCell component detailsNew energyCooling pipe

The invention relates to the field of lithium battery anti-overheating, in particular to a new energy anti-overheating lithium battery pack. The battery pack comprises a protection box, a closing plate is installed on the upper side of the protection box, a lithium battery pack body is installed in the protection box, cooling pipes are evenly arranged on the left side and the right side of the lithium battery pack body, and a refrigeration block is fixedly installed at the bottom of the protection box. The cooling pipe is fixedly mounted on the refrigeration block, and a crushing wall is arranged on the cooling pipe; moving cavities are formed in the protection box outside the lithium battery pack, first moving rods are movably mounted in the moving cavities on the left and right sides of the cooling pipe, first springs are fixedly connected to the front and rear sides of the moving cavities, and the other ends of the first springs are fixedly connected with moving blocks; a pushing rod is movably installed at the upper end of the side, away from the lithium battery pack, of the moving block, the upper end of the pushing rod is rotationally connected with a first rotating rod, cooling and fire extinguishing are conducted on the lithium battery pack through a cooling agent in the cooling pipe, an oxygen-poor sealing environment is provided for the protection box, high-pressure gas in the protection box is released, and secondary explosion is avoided.

Owner:徐正跃

An explosion-proof protection device for electrical equipment

ActiveCN107123760BAvoid explosionProtect life safetySecondary cell gas removalCell component detailsExplosion protectionStructural engineering

The invention relates to the technical field of electronic equipment protection devices, and particularly relates to an electronic equipment anti-explosion protection device which comprises an anti-explosion tank body, wherein first plates are arranged around inside the anti-explosion tank body respectively; the first plates are internally hollowed; the first plates are filled with an inert gas; second plates are arranged on the inner sides of the first plates; a plurality of through holes are formed in the second plate; sliding blocks are arranged at the upper ends and the lower ends of the second plate; the sliding blocks are arranged inside chutes in the anti-explosion tank body; a plurality of conical convex burrs are arranged on one sides close to the first plates, of the second plates; a plurality of springs are arranged between the second plates and the first plates; a plurality of vent holes are formed in the bottom of the anti-explosion tank body; an air sucking fan is arranged at the bottom of the anti-explosion tank body; the air sucking fan is connected with a power supply. By adopting the electronic equipment anti-explosion protection device, storage battery explosion can be effectively prevented, fire of exploded storage batteries can be extinguished in time, force generated from explosion can be decomposed in time, and the security of people can be effectively ensured.

Owner:内蒙古行上科技有限责任公司

Dust explosion-proof system for medium-density fiberboard paving section

PendingCN111037702AImprove antiknock performanceAvoid structural damageWood working apparatusBlastingProduction lineDust explosion

The invention discloses a dust explosion-proof system for a medium-density fiberboard paving section. The dust explosion-proof system comprises an unloading rear door on a paving bin, rupture disks, aflameless explosion venting device and an explosion isolation device, the unloading rear door is close to an outdoor waste stacking field, and a plurality of rupture disks are mounted on the unloading rear door; the flameless explosion venting device is integrated by two parts, namely the rupture disk and a flame filter, the explosion isolation device is composed of an explosion suppression device and a spark detection probe, and the explosion suppression device is filled with powdery inhibitors. The invention provides a novel system which can be configured in the current paving section, cantimely release explosion when explosion occurs and can prevent explosion from spreading to the whole production line.

Owner:SHANGHAI WOOD-BASED PANEL MASCH CO LTD

Safe explosion venting device

PendingCN108006286AAvoid destructionAvoid secondary explosionEqualizing valvesSafety valvesNuclear engineeringCombustible gas

The invention discloses a safe explosion venting device. The explosion venting device comprises a primary explosion venting door and a secondary explosion venting door, wherein an isolation cavity isformed between the primary explosion venting door and the secondary explosion venting door, and non-flammable and combustible gas is filled in the isolation cavity. According to the explosion ventingdevice, the gas subjected to primary explosion venting is prevented from being in contact with air, so that secondary explosion is avoided, damage to the surrounding environment is avoided, and the safety is greatly improved.

Owner:张跃

A pipe pressure type explosion-proof valve

ActiveCN106870942BAvoid secondary explosionVessel mounting detailsContainer filling methodsSolenoid valveEngineering

The invention discloses a pipe pressure type explosion-proof valve, which comprises a pipe pressure valve and a gas storage tank. The pipe pressure valve and the gas storage tank are connected through a pipeline. The inlet pipe of the gas tank is provided with a first solenoid valve, and the gas storage tank is provided with a pressure sensor for detecting the internal pressure of the gas storage tank. The pressure sensor is connected with the first solenoid valve, and the outlet pipe of the pipe pressure valve is provided with a second valve. The electromagnetic valve, the pulse electromagnetic valve is connected with the front sensor for detecting the explosion signal, and the front sensor is connected with the second electromagnetic valve. When working normally, the pipe pressure type explosion-proof valve is in the open state; when the explosion occurs, the front sensor detects the explosion signal, then sends out a signal to control the pulse solenoid valve to open, the second solenoid valve closes, and the gas in the gas storage tank is poured into the pipe. In the pressure valve, the pipe pressure valve is closed to isolate the explosion and protect people and equipment downstream.

Owner:江苏爵格工业集团有限公司

A normally closed one-way explosion-proof valve

ActiveCN106885026BBlast damage limitProtection securityCheck valvesEqualizing valvesAir volumeDust control

Owner:江苏爵格工业集团有限公司

Safety protection device for dust removal system

ActiveCN112619303AGuaranteed temperatureReduce the likelihood of an explosionDispersed particle filtrationThermodynamicsDust control

The invention relates to the technical field of dust removal, and discloses a safety protection device for a dust removal system. The safety protection device comprises an inner cylinder, wherein the side surface of the upper part of the inner cylinder is provided with an air inlet, the periphery of the inner cylinder is provided with an outer cylinder, and the inner cylinder and the outer cylinder are coaxially assembled. According to the invention, inert cooling gas is used for cooling the inner cavity of the inner cylinder, heat in the inert cooling gas is absorbed by heat absorption liquid under fixed duration, and the temperature of the inner cylinder is measured according to the expansion size of the volume of the heat absorption liquid; and the pushing effect of a push rod on a gas distribution plug and the shielding effect of the gas distribution plug on a dusty gas outlet and a inert cooling gas outlet are matched, so the gas inlet amount of dusty gas and the gas inlet amount of inert cooling gas are kept balanced, the purpose of ensuring that the temperature of the inner cavity of the inner cylinder is within a safe range is achieved, the possibility of explosion is reduced, and safety protection effect in a dust removal process is improved.

Owner:张翔

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com