Normally-open one-way explosion-proof valve

A normally open, one-way technology, used in control valves, safety valves, balance valves, etc., can solve the problems of dust explosion, inability to block explosion shock wave and flame propagation, etc., to protect safety, reduce pressure loss, reduce The effect of pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

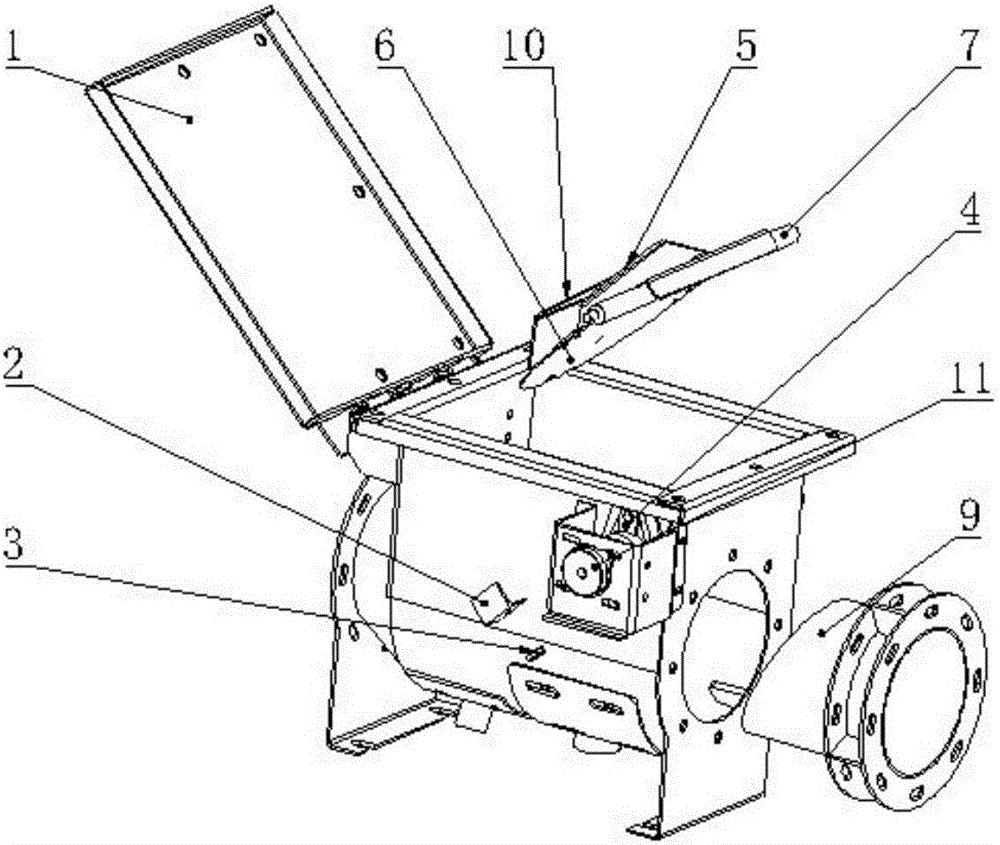

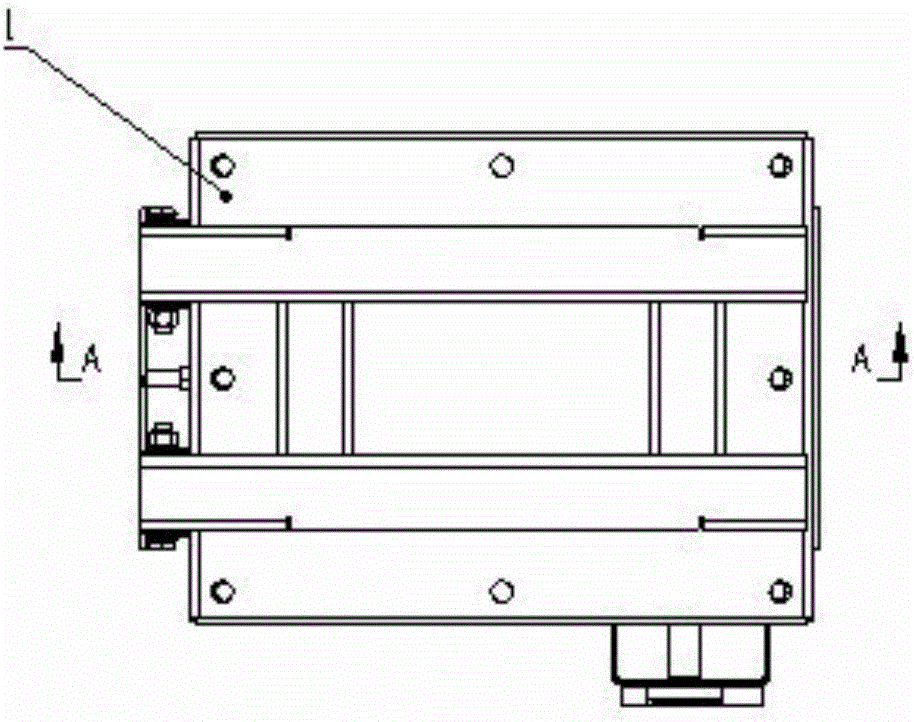

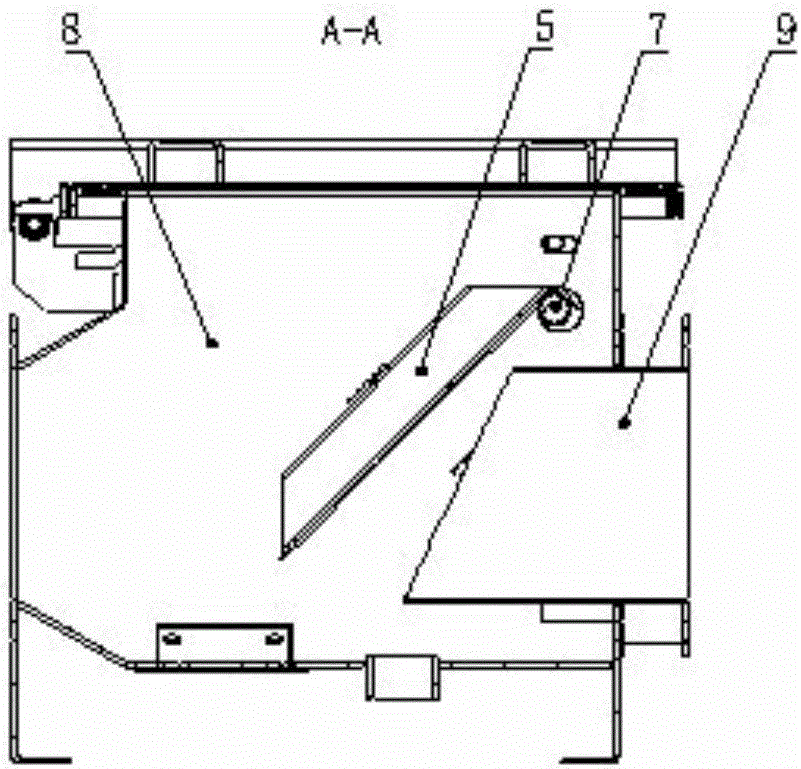

[0029] Depend on Figure 1 to Figure 7 As shown, the present invention discloses a normally open one-way explosion-proof valve, which includes a valve body 8, a valve flap 6, a magnet 3, a deflector 10, and a pipe flange 9, and the valve flap 6 is connected to the guide The flow plate 10, the pipe flange 9 includes a pipe flange slope, and the valve disc 6 is attracted by the magnet 3 under normal conditions and is kept away from the pipe flange slope. When an explosion occurs, the The valve clack 6 is impacted by the explosion shock wave, pushing the deflector 10 and the valve clack 6, so that the valve clack 6 fits with the inclined surface of the pipe flange to form a mechanical seal, and the one-way explosion-proof valve is closed. The normally open one-way explosion-proof valve of the present invention can bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com