Method for active explosion proofing and explosion suppression through high-pressure inert gas

A high-pressure inert gas, explosion-proof and explosion-suppressing technology is applied in earth drilling, safety devices, mining equipment, etc. It can solve the problems of long disaster avoidance routes, complex network systems, and difficulty in accurately judging the source of explosions, and achieve the goal of isolating external Explosion propagation, preventing gas explosion accidents, and reducing the effect of shock wave intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

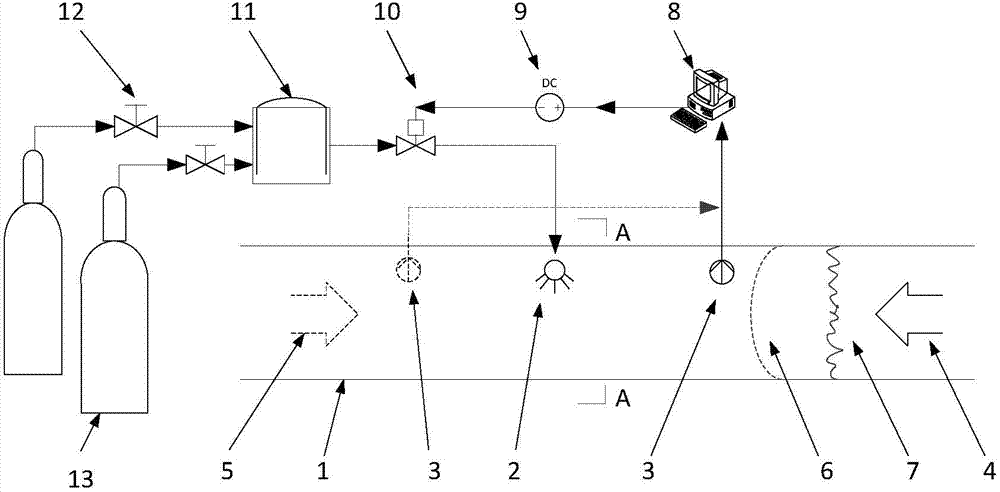

[0020] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings: the role of the pressure reducing valve 12?

[0021] The active explosion-proof and explosion-suppression method of high-pressure inert gas of the present invention, concrete steps are as follows:

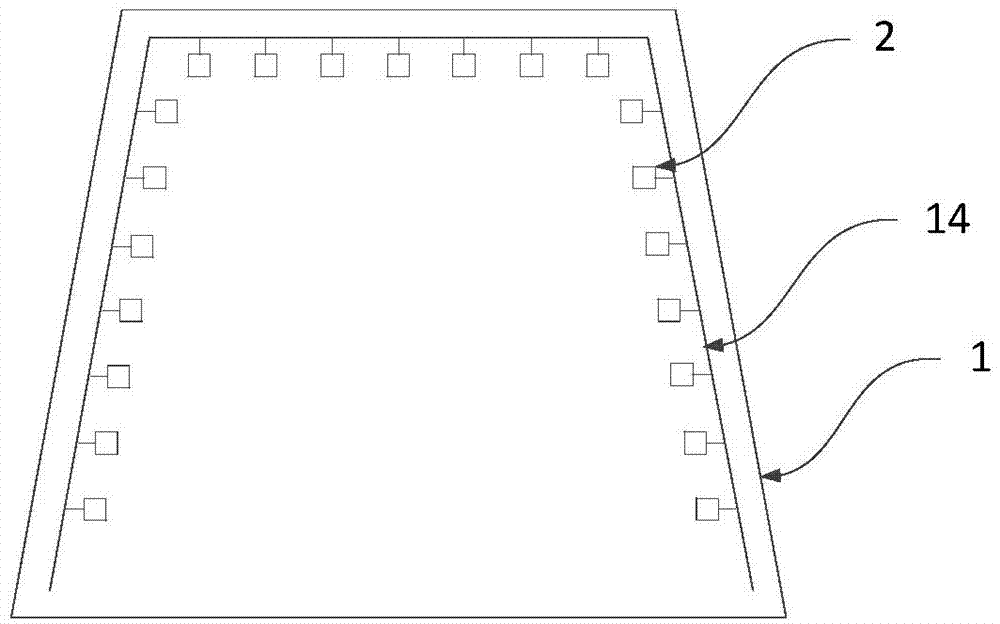

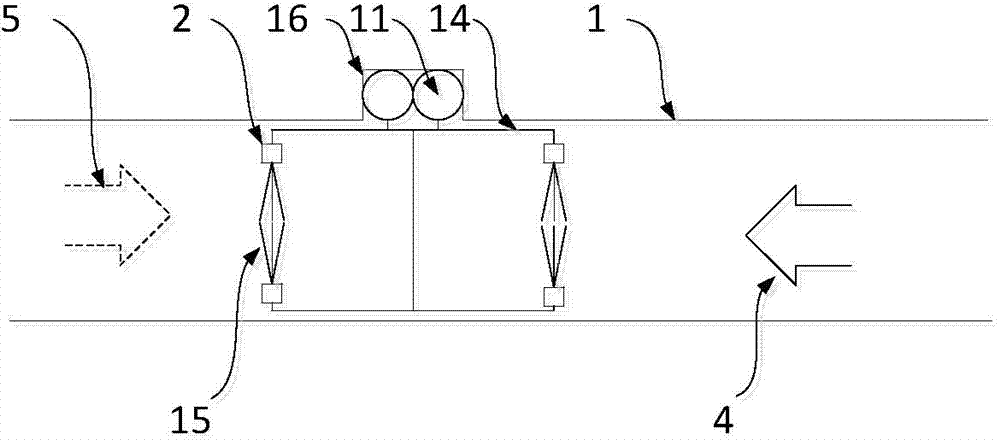

[0022] a. A plurality of injectors 2 are arranged at intervals in an array on the side of the roadway 1 and the roof. The plurality of injectors 2 are connected through the high-pressure rubber hose 14, and the signal processing system 8 is connected to the roadway on both sides of the injector 2. Pressure sensor 3; the distance between multiple injectors 2 arranged in an array on the side of the roadway 1 and the roof is <20cm; the linear distance between the injector 2 and the pressure sensor 3 is 18-22m;

[0023] b. Construct a wall groove 16 in the side lane where the injector 2 is arranged, and set a high-pressure inert gas source 13 and a gas storage ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com