Pipe pressure type explosion suppression valve

A pipe pressure and explosion-proof technology, which is applied to ship construction details, container structure installation devices, fluid treatment accessories, etc., can solve the problems of loss, inability to cut off the explosion shock wave and flame propagation, etc., to prevent secondary explosions and protect The effect of people and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

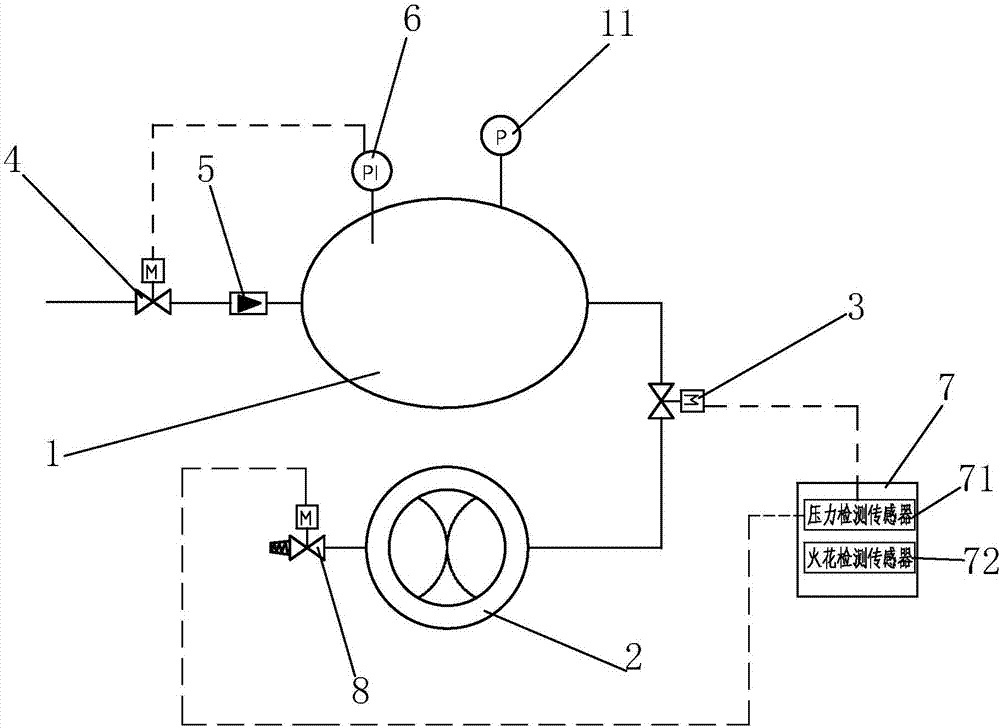

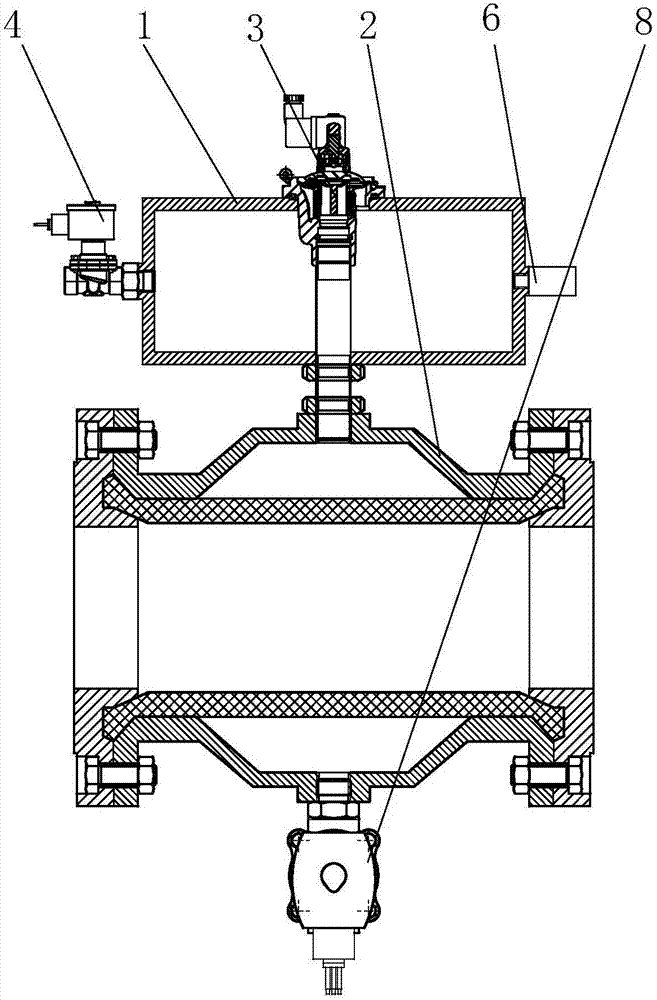

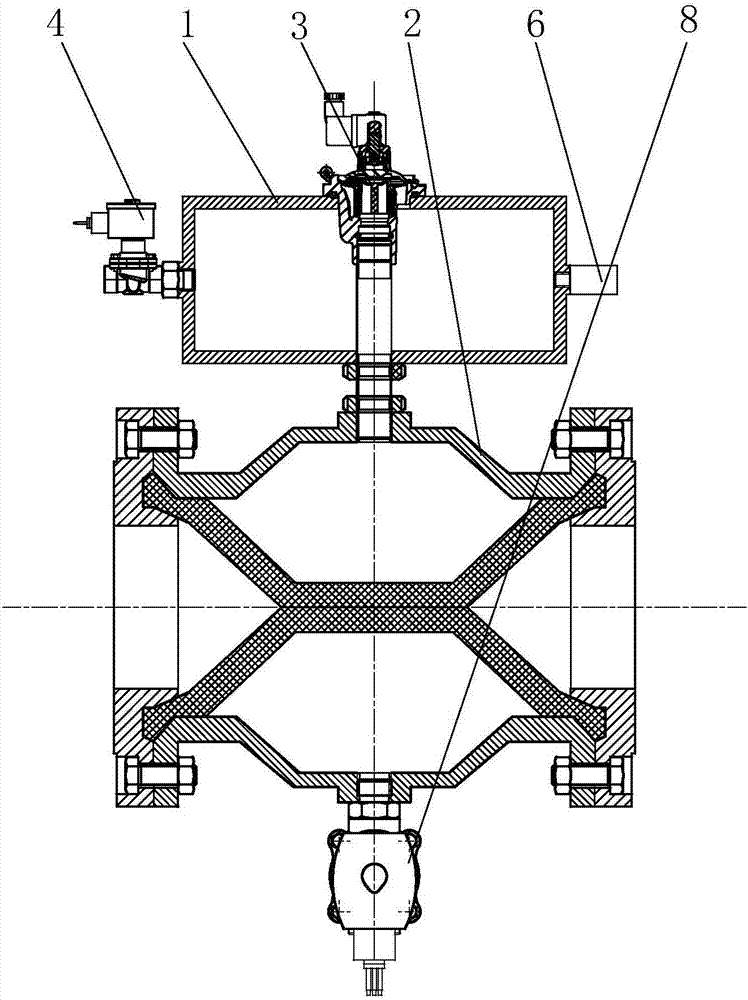

[0017] figure 1 A pipe pressure type explosion-proof valve according to an embodiment of the present invention is schematically shown. The pipe pressure type explosion-proof valve includes a pipe pressure valve 2 and a gas storage tank 1 .

[0018] The pipe pressure valve 2 communicates with the gas storage tank 1 through a pipeline, and a pulse solenoid valve 3 is arranged on the pipeline in which the pipe pressure valve 2 communicates with the gas storage tank 1 . The pulse solenoid valve 3 is used to connect or cut off the connection between the gas storage tank 1 and the pipe pressure valve 2 . The inlet pipe of the gas storage tank 1 is provided with a first solenoid valve 4 . The pipeline connecting the first electromagnetic valve 4 and the gas storage tank 1 is provided with a one-way valve 5 , the inlet of the one-way valve 5 communicates with the first electromagnetic valve 4 , and the outlet of the one-way valve 5 communicates with the gas storage tank 1 . A one-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com