Dust explosion-proof system for medium-density fiberboard paving section

An explosion-proof system and fiberboard technology, used in blasting, wood processing appliances, household components, etc., can solve problems such as the inability to completely eliminate equipment dust explosions, and inability to completely protect the explosion-proof safety of operators, so as to avoid chain explosion reactions and reduce explosion propagation. risk and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

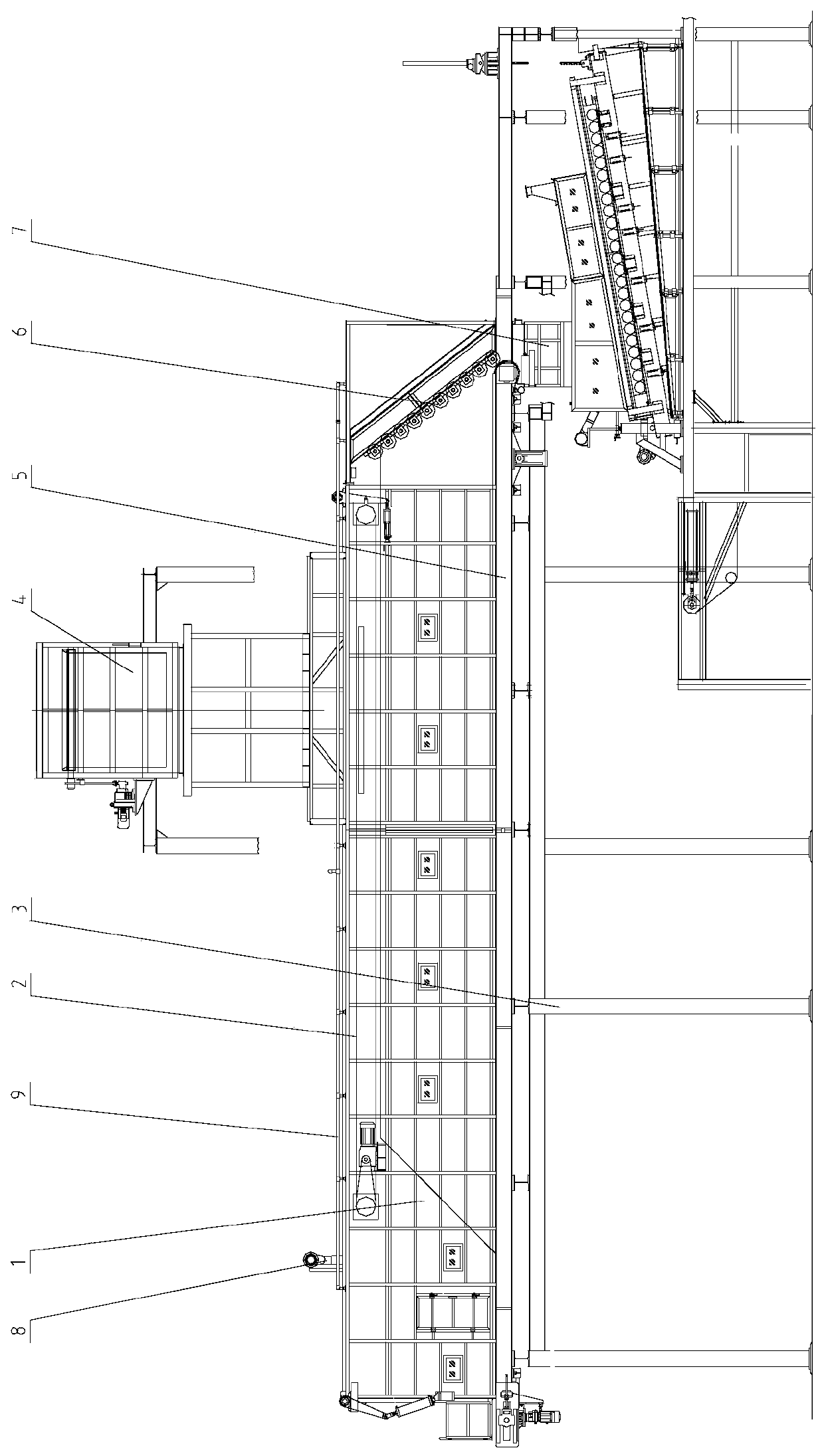

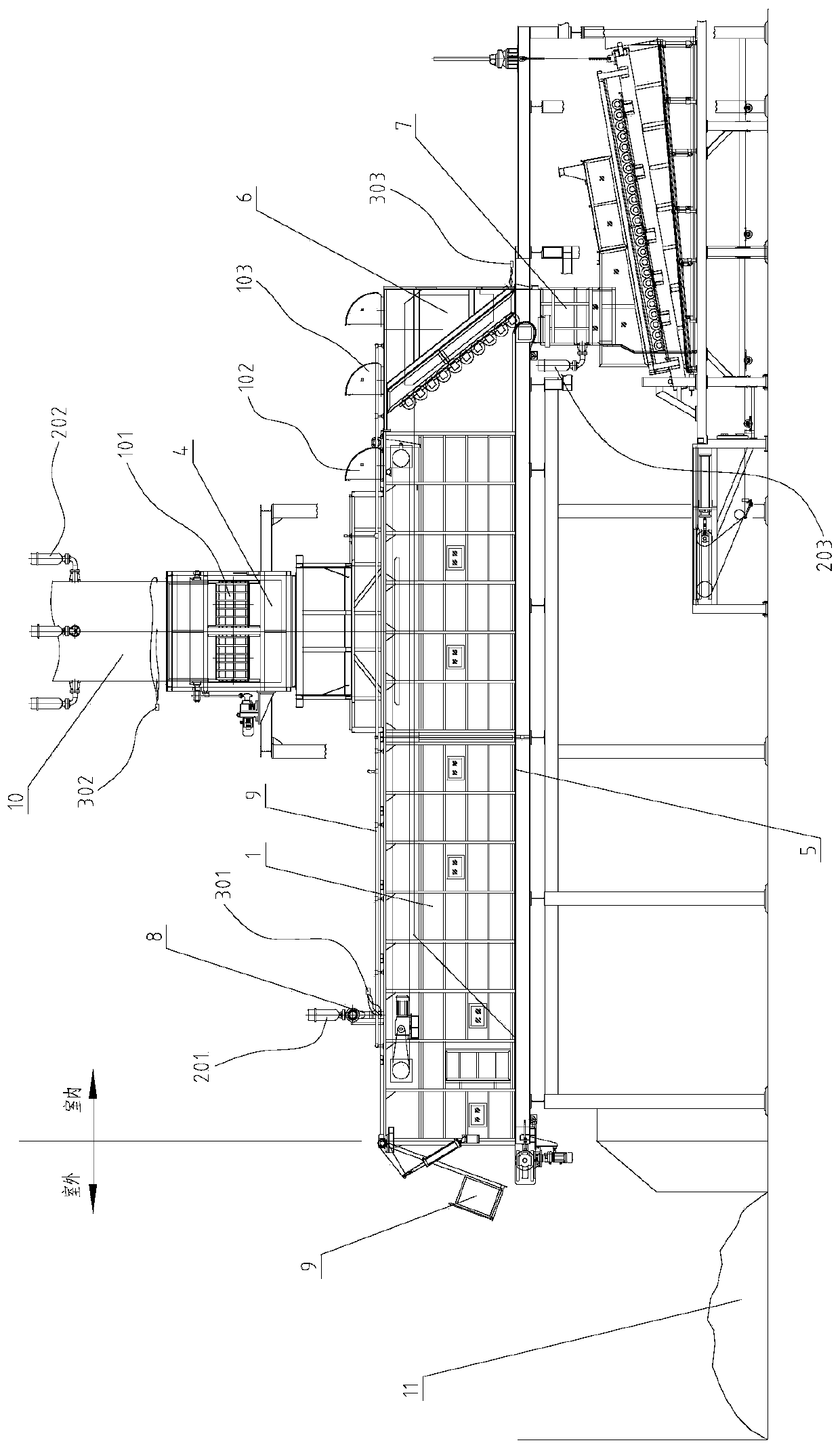

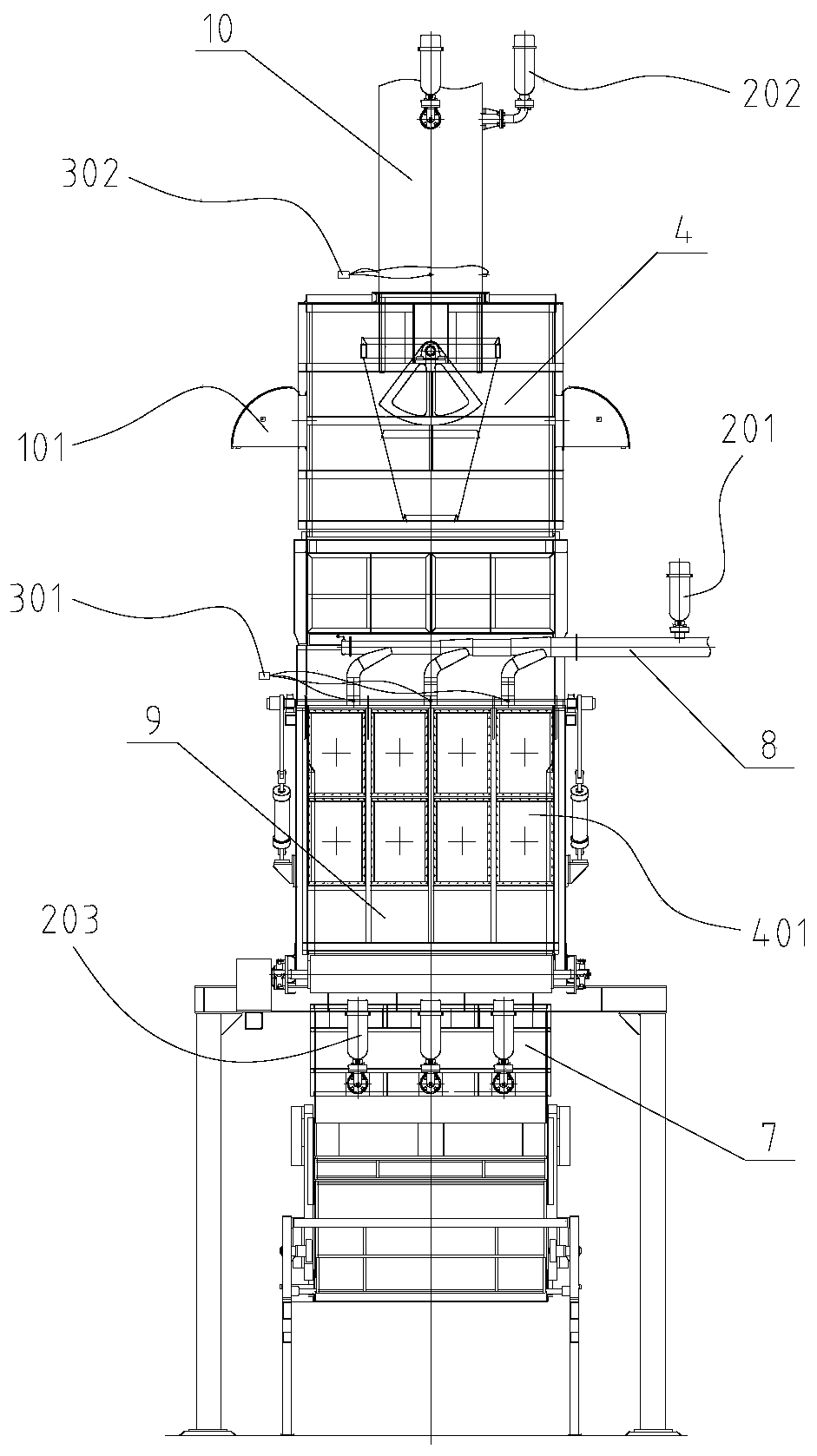

[0028] In the present invention, the equipment of the MDF pavement section is allowed to be installed indoors, but see figure 2 and image 3 , the dust explosion-proof system of the present invention requires that during the construction and installation stage, the discharge rear door 9 at the tail of the paving silo 1 must face outdoors and be close to the outdoor waste dump 11, and no one is allowed to enter this area except for maintenance time. Several bursting discs 401 need to be installed on the unloading rear door 9. It is required that there are no obstacles such as walls when the bursting discs 401 are opened.

[0029] In the present invention, the flameless explosion venting devices 101, 102, and 103 can not only quickly open the pressure relief protection equipment, but also quickly cool down the flame and extinguish it immediately, so that no flame will rush out of the equipment. Flameless explosion venting devices 101, 102, and 103 are integrated by bursting di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com