GF single-layer multi-touch frameless touch screen and preparation process thereof

A single-layer multi-point, preparation process technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the problem of reducing the visible area of the screen, and improve the conductivity and etching accuracy High, process-stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

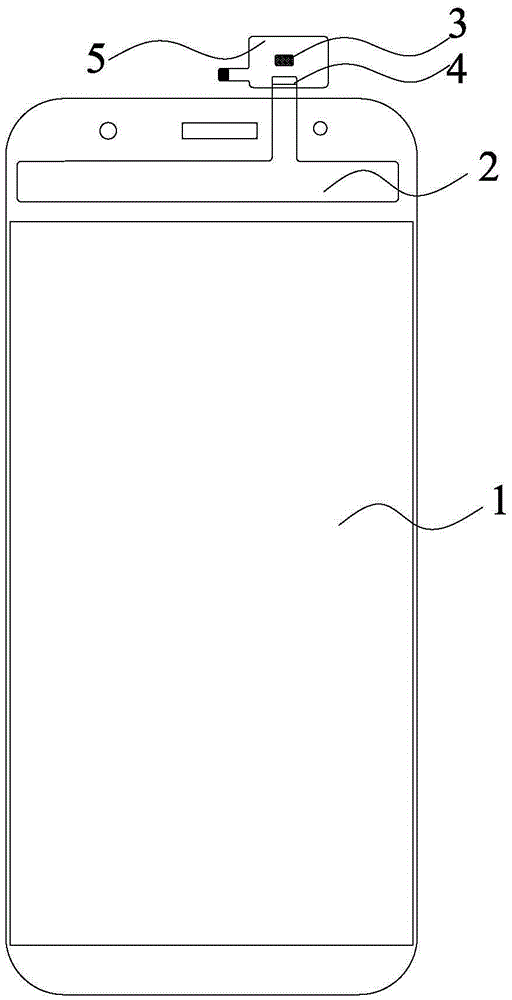

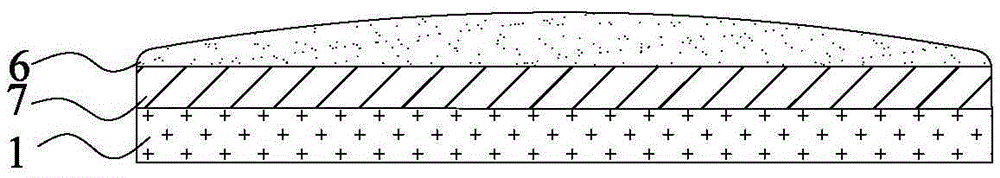

[0068] Such as figure 1 and figure 2 As shown, a GF single-layer multi-point frameless touch screen includes a tempered glass cover plate 6, a transparent optical adhesive layer 7, and an ITO conductive film 1 arranged sequentially from top to bottom. The frame of the ITO conductive film 1 is a wiring The wiring area includes a horizontal wiring area arranged at one end of the touch screen, and the ITO conductive film 1 is provided with a single-layer multi-point electrode pattern with a single-end outgoing line, and the lead-out lines of the ITO conductive film 1 are correspondingly arranged on the horizontal wiring. area, the horizontal wiring area is pressed against FPC2, and the lead wire of ITO conductive film 1 is connected to an IC chip 3 through FPC2.

[0069] In this embodiment, the horizontal wiring area is set on the upper end of the touch screen.

[0070] Further, the single-layer multi-point electrode pattern includes a sensing channel and a driving channel, an...

Embodiment 2

[0112] The difference between this embodiment and embodiment 1 is:

[0113] In this embodiment, the horizontal wiring area is set at the lower end of the touch screen.

[0114] Further, the anti-reflection layer is a nano-titanium oxide silicon layer.

[0115] Further, the FPC2 includes an FPC main body area and an FPC extension area connected to the end of the FPC main body area, the FPC main body area includes gold fingers, and the distance between the gold fingers and the edge of the FPC2 is 8mm. Further, the tempered glass cover plate 6 is divided into a black frame area and a window area, the black frame area includes a vertical black frame area and a horizontal black frame area, and the horizontal black frame area is set corresponding to the horizontal wiring area, so The ITO conductive film 1 is 0.8mm beyond the lateral boundary of the window area, which can improve the visual effect of the boundary.

[0116] In the present embodiment, silver paste is made up of the r...

Embodiment 3

[0132] The difference between this embodiment and embodiment 1 is:

[0133] In this embodiment, the FPC2 includes an FPC body area and an FPC extension area connected to the end of the FPC body area. The FPC body area includes a gold finger, and the distance between the gold finger and the edge of the FPC is 5 mm.

[0134] Further, the anti-reflection layer is a nano-titanium oxide silicon layer

[0135] Further, the tempered glass cover plate 6 is divided into a black frame area and a window area, the black frame area includes a vertical black frame area and a horizontal black frame area, and the horizontal black frame area is set corresponding to the horizontal wiring area, so The above-mentioned ITO conductive film 1 is 0.5mm beyond the lateral boundary of the window area, which can improve the visual effect of the boundary.

[0136] In the present embodiment, silver paste is made up of the raw material of following percentage by weight:

[0137] Silver powder 65%

[013...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com