Patents

Literature

78results about How to "Implement multi-touch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multiple point touch localization method

InactiveCN101105733AWide range of applicationsImplement multi-touch positioningInput/output processes for data processingComputer visionNumeric Value

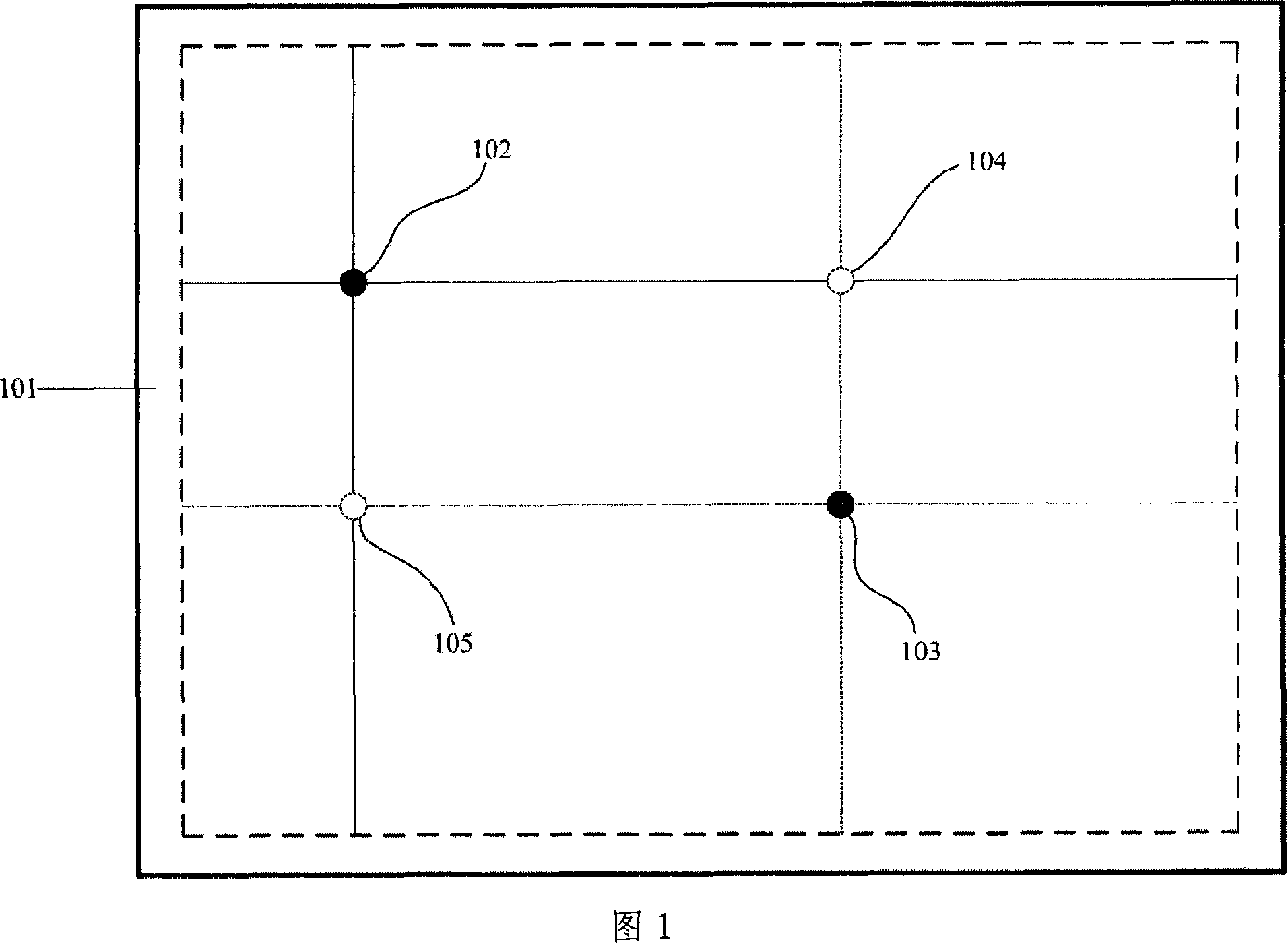

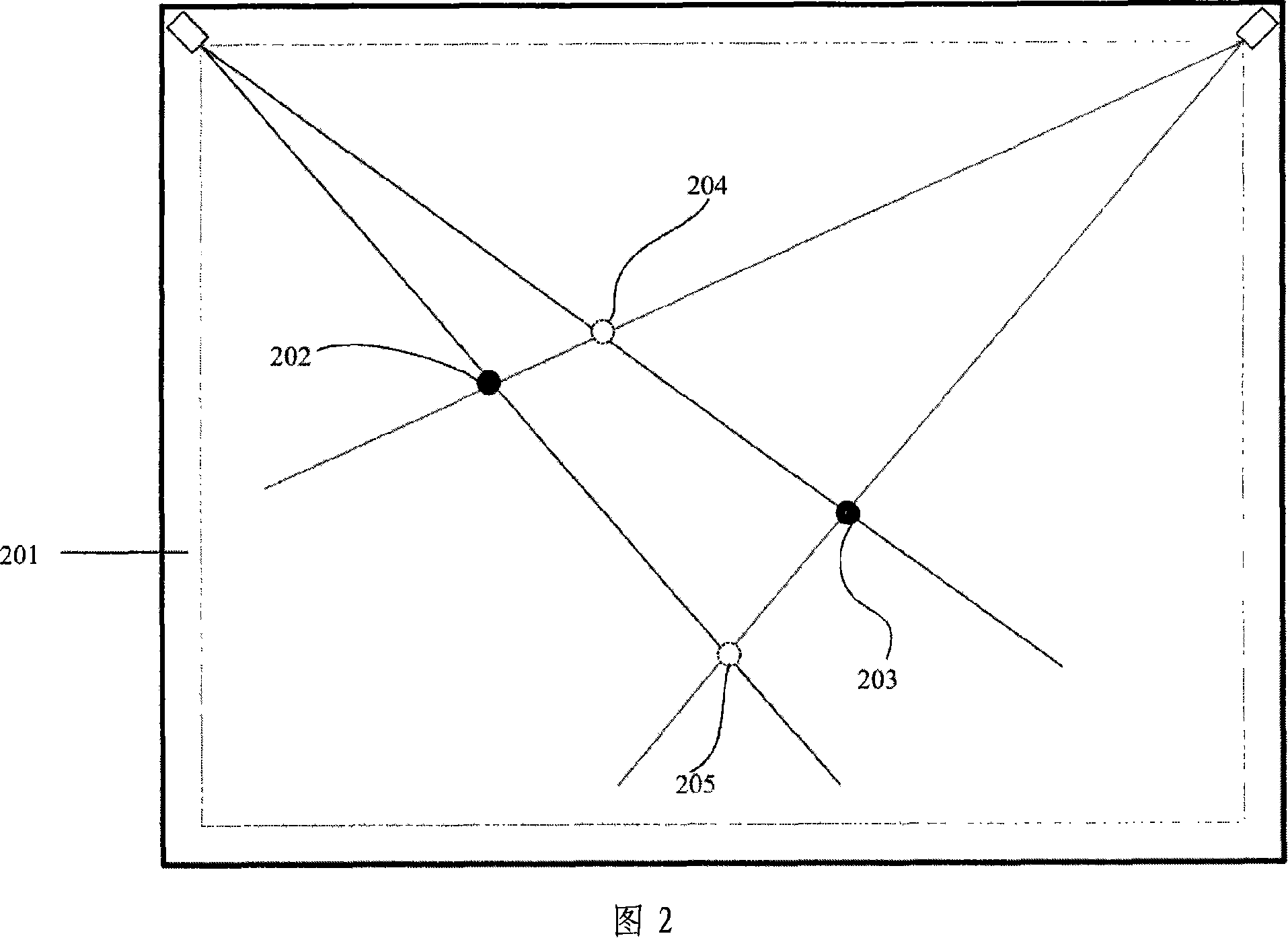

The invention provides a multi-point touch positioning method applied in touch screen systems, which contains the following steps: (a). Measure touch signals, judge signal changing situation, calculate touching location coordinates and / or shape and size of touch points; (b). judge signal-point or multi-point touch according to quantity change of location coordinates--if single-point touch, single point operations will be implemented by touch screen system, otherwise, turn to step (c); (c). determine whether there is any new touch points added or left or not by comparing quantity change of location coordinates and / or change of coordinate value. If there are new touch points added, register new touch points information and record location coordinates of new touch points. If there are touch points left, then clear those points information. The invention has wider application range but lower cost, and realizes multi-point touch positioning.

Owner:GUANGDONG VTRON TECH CO LTD

Real-time video image coordinate recognition system and method

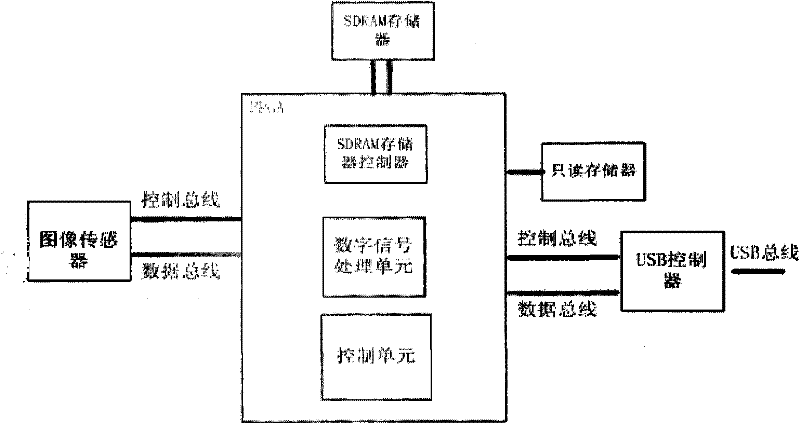

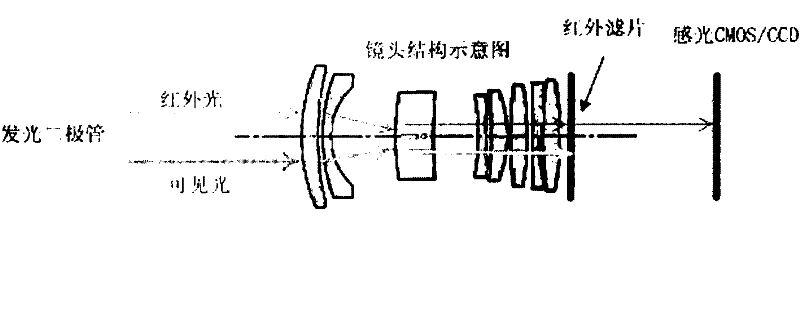

InactiveCN102221937AReal-time interactive operationImprove recognition rateCharacter and pattern recognitionInput/output processes for data processingDigital videoSynchronous dynamic random-access memory

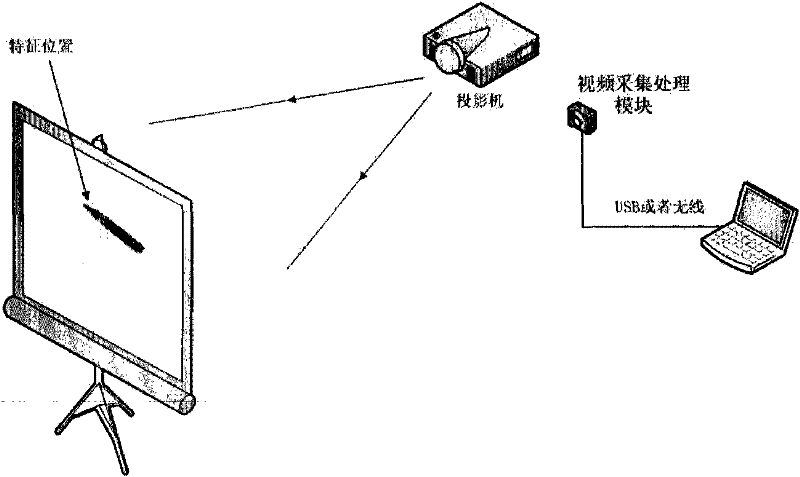

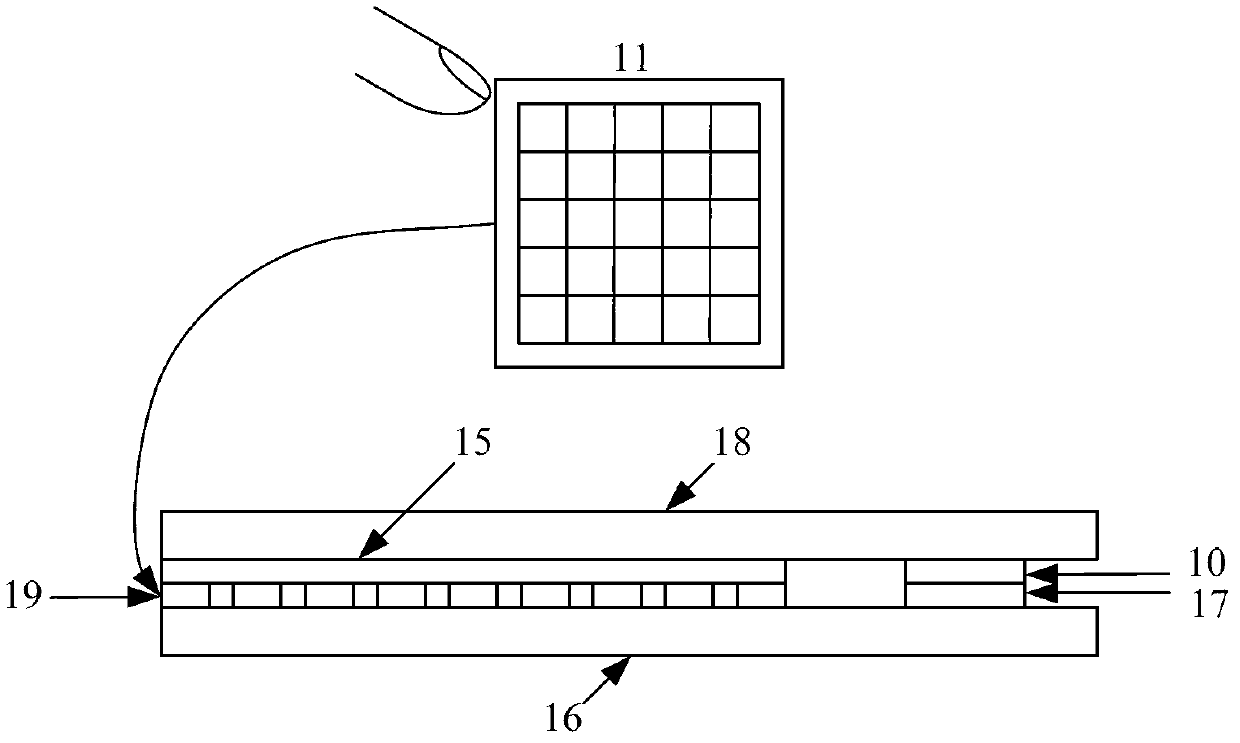

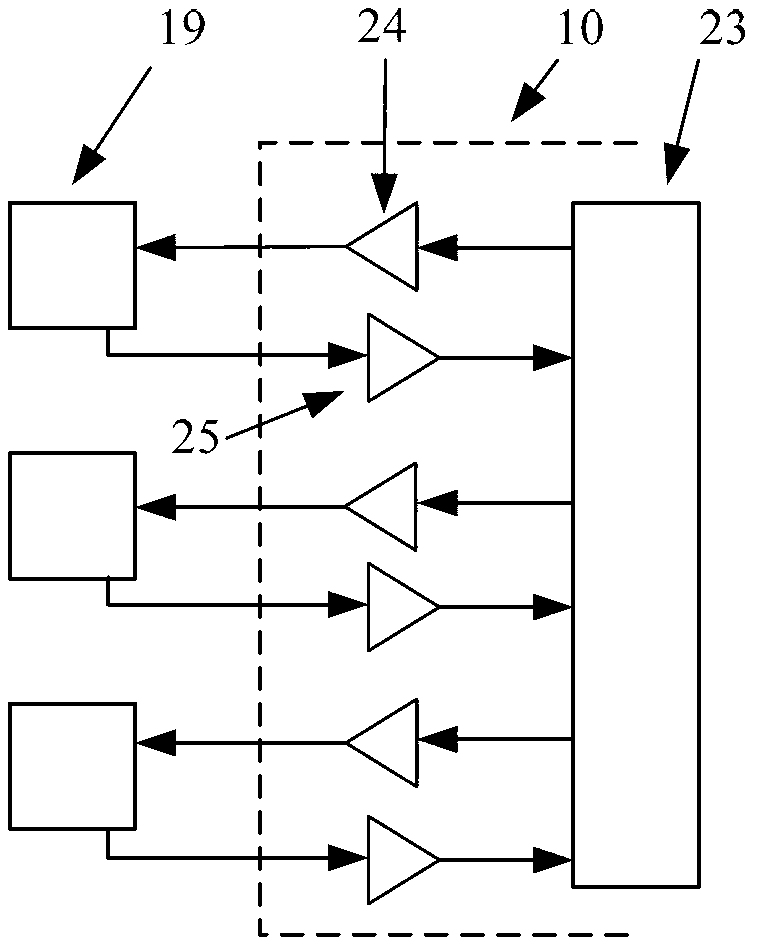

The invention relates to a real-time video image coordinate recognition system and a real-time video image coordinate recognition method. The system comprises an image sensor, a field programmable gate array (FPGA) embedded system, a synchronous dynamic random access memory (SDRAM) and a universal serial bus (USB) controller. Real-time coordinate recognition and interactive operations over digital video images are realized by a series of work comprising real-time video acquisition, video analysis, characteristic point capturing, characteristic point position coordinate transformation, computer communication and the like. The system and the method have the advantages of high positioning accuracy, low positioning error of less than 2.5mm, low power consumption, low cost, small volume, convenience of carrying and the like.

Owner:SHANGHAI TIANPAI WIRELESS TECH

Method and device for detecting touch screen

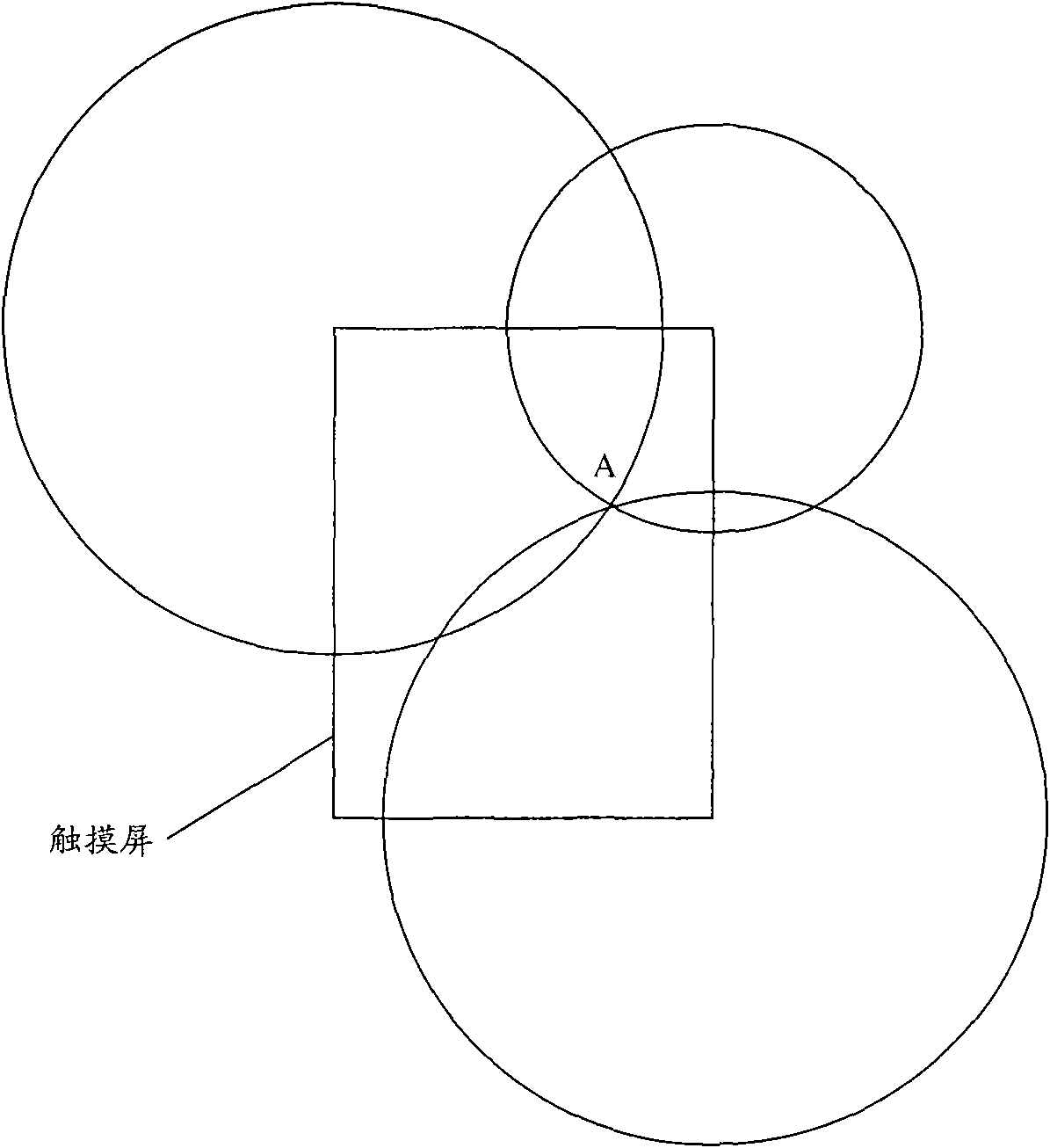

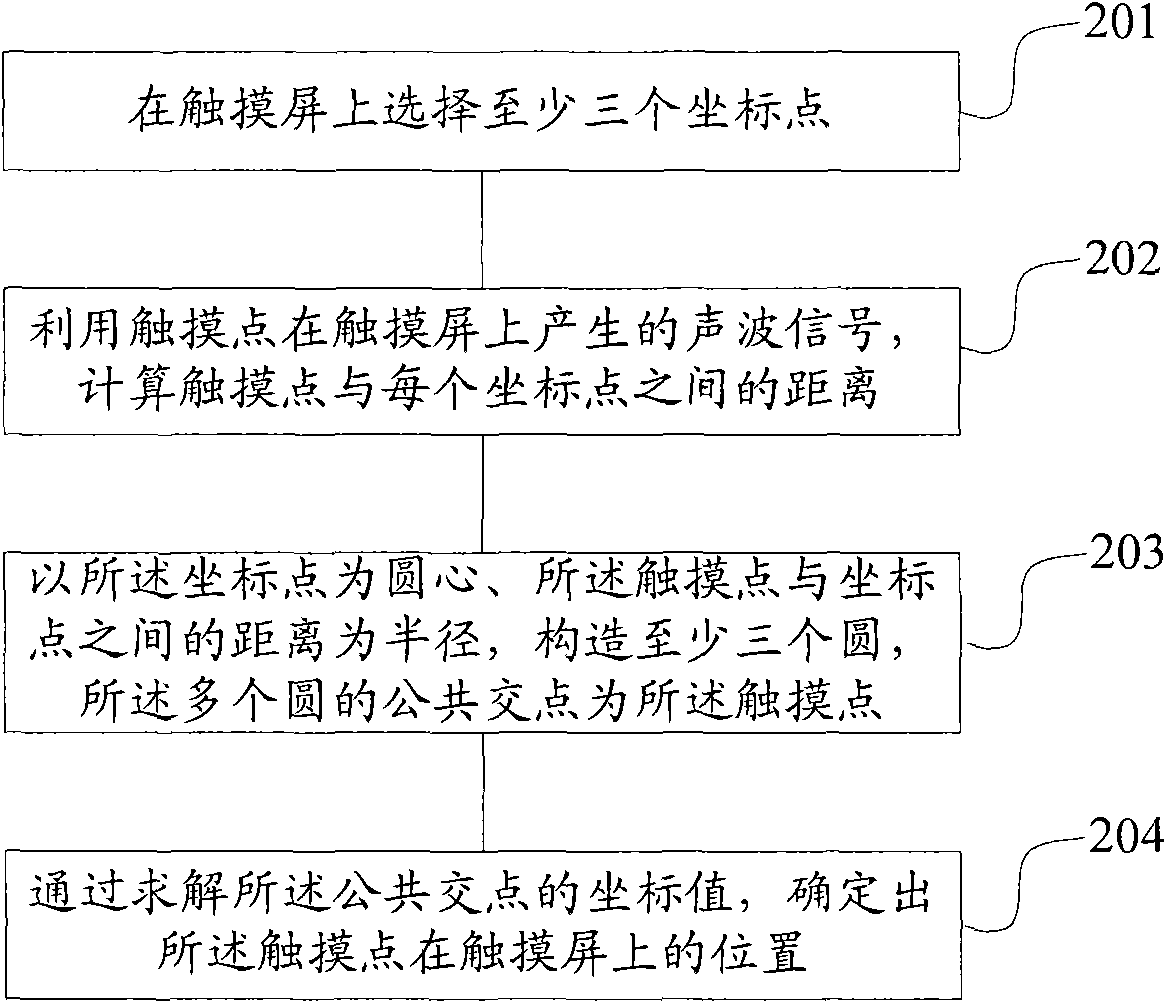

InactiveCN101644978AReduce manufacturing costReduce power consumptionInput/output processes for data processingTransmittanceAcoustic wave

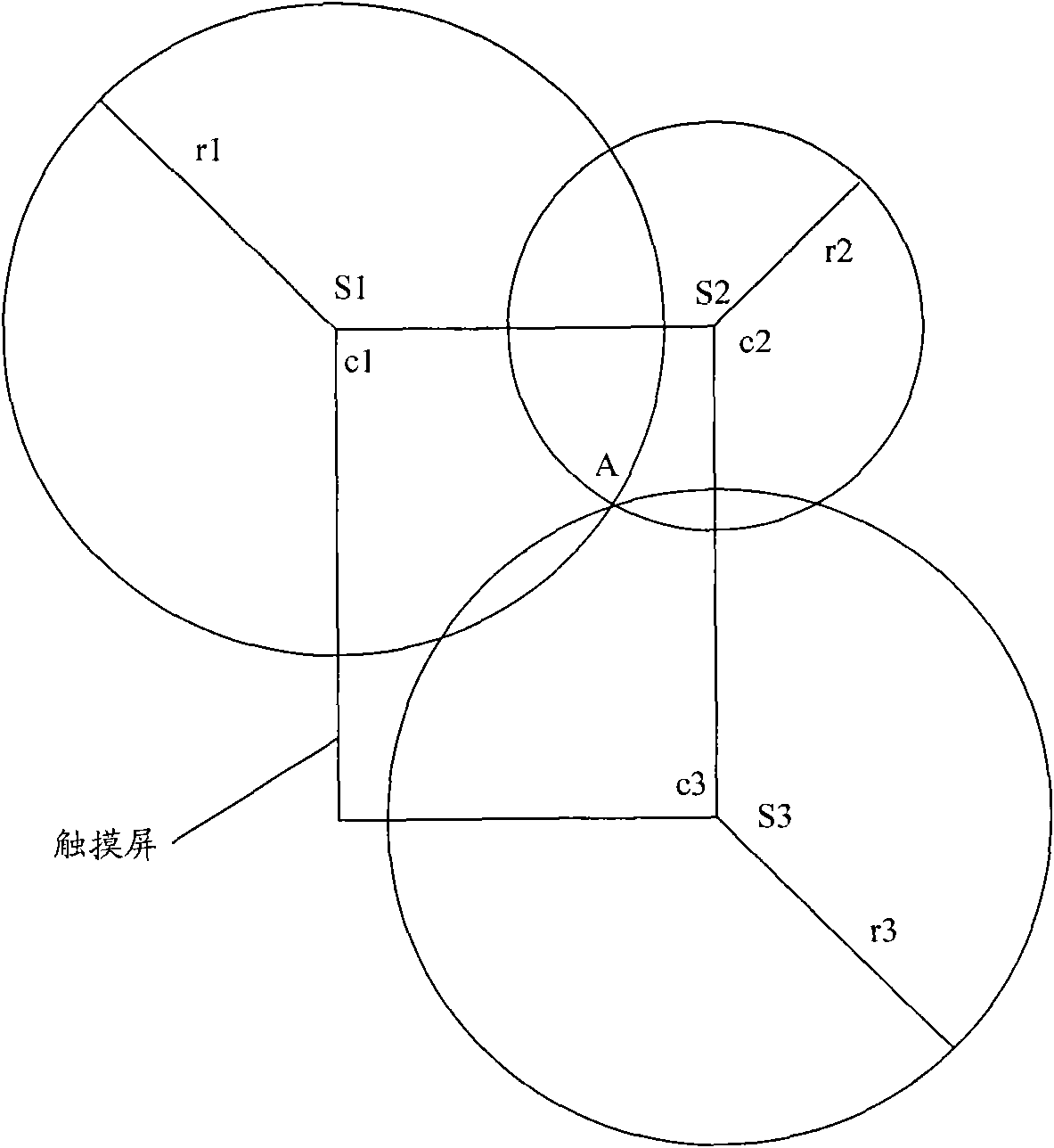

The invention provides a method and a device for detecting a touch screen to solve the problem that the current surface acoustic wave touch screens can not identify multitouch. The method comprises the following steps: selecting at least three coordinate points on the touch screen, computing the distance between a touch point and each coordinate point by utilizing the acoustic wave signal generated on the touch screen by the touch point, constructing at least three circles by taking the coordinate points as the centers of the circles and the distances between the touch point and the coordinatepoints as the radii and determining the position of the touch point on the touch screen by solving the coordinate value of a common intersection point, wherein, the common intersection point of the circles is the touch point. The invention further reduces the power consumption and cost and realizes multitouch while maintaining the advantages of the surface acoustic wave touch screens, including high light transmittance, high resolution, rapid response speed, good wear resistance and long life, etc.

Owner:VIMICRO CORP

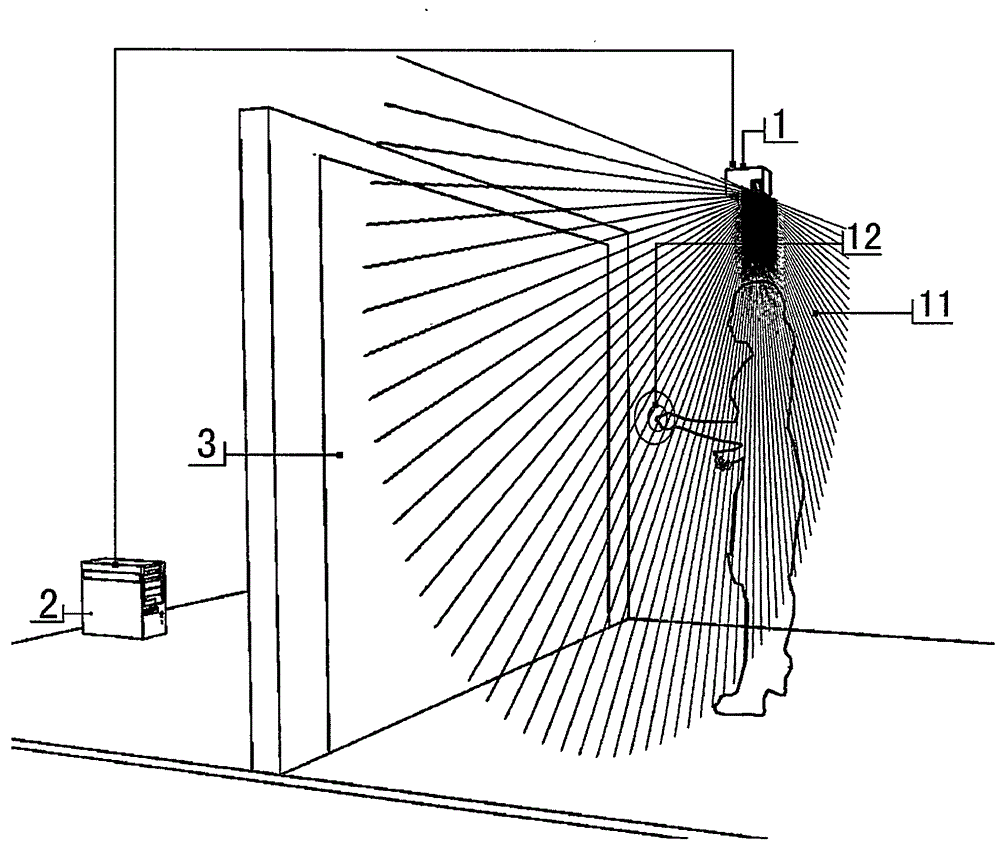

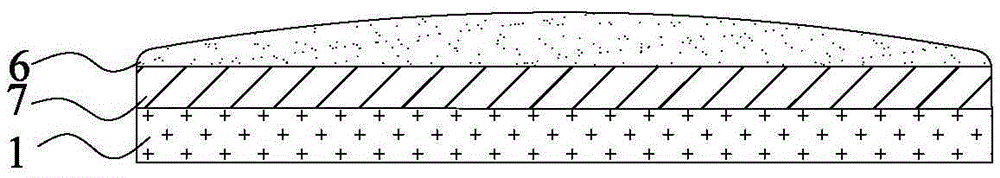

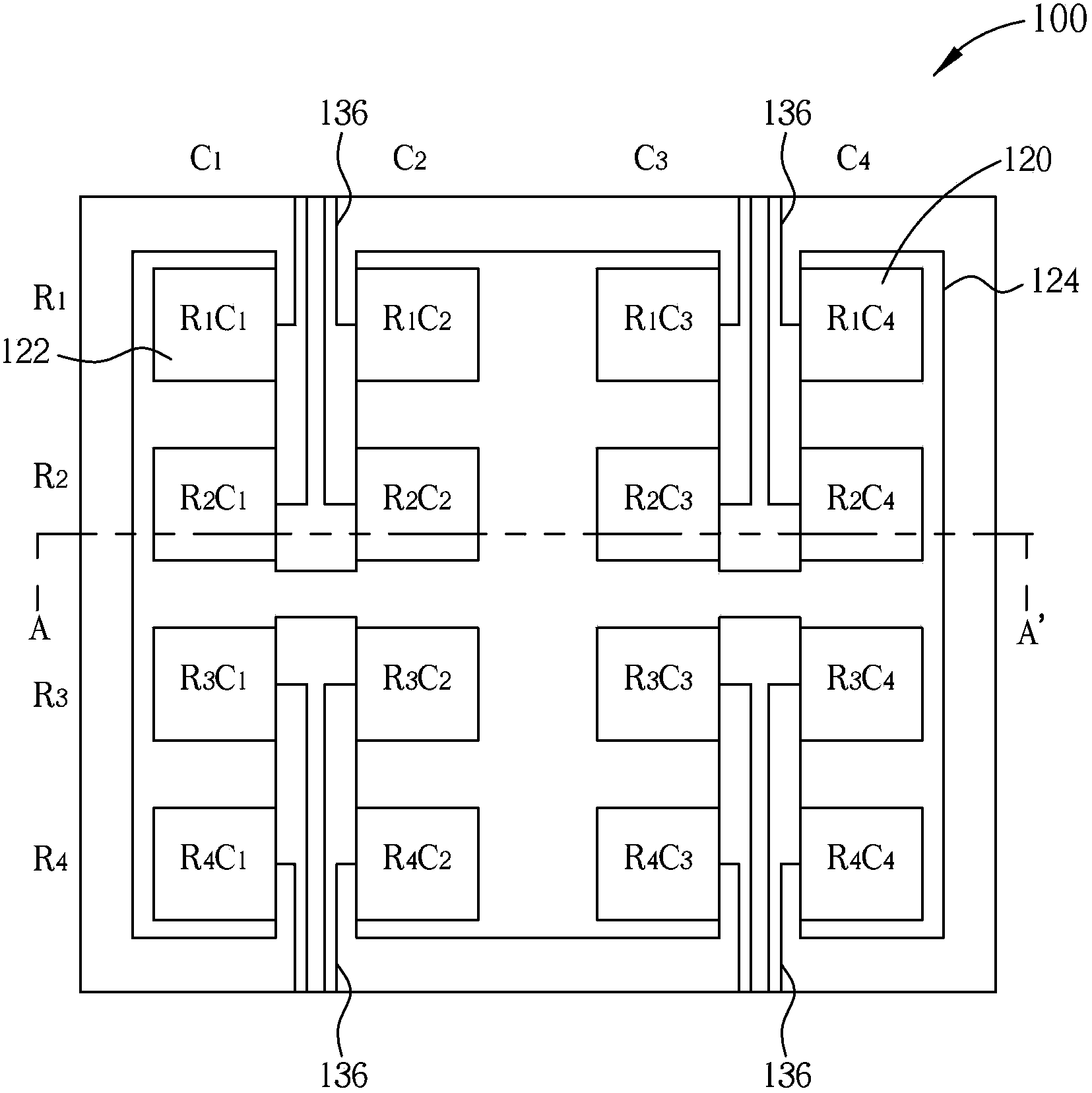

Capacitive touch screen

ActiveCN103279244AAccurate detectionImplement multi-touchInput/output processes for data processingCapacitanceEngineering

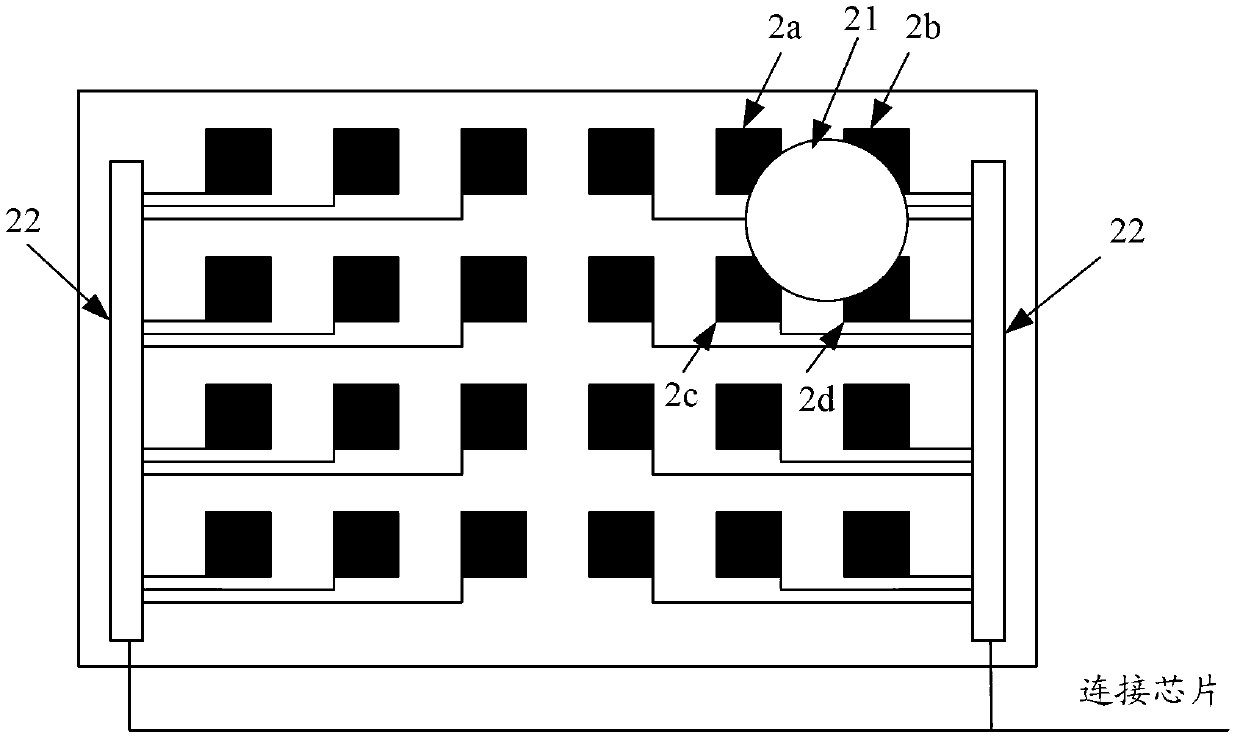

An embodiment of the invention discloses a capacitive touch screen. The capacitive touch screen comprises a substrate, a plurality of induction electrodes arranged on the substrate and a touch control chip bound to the substrate, wherein the plurality of induction electrodes are arranged to form a two-dimension array. The touch control chip is connected with every induction electrode respectively through wires. The touch control chip is arranged to utilize a detection circuit with test precision adjustable to detect self capacitance variation quantity of every induction electrode, and accordingly touch information is determined. According to the capacitive touch screen, multi-point touch can be achieved genuinely, and touch positions of different touch objects can be detected accurately.

Owner:FOCALTECH SYST LTD

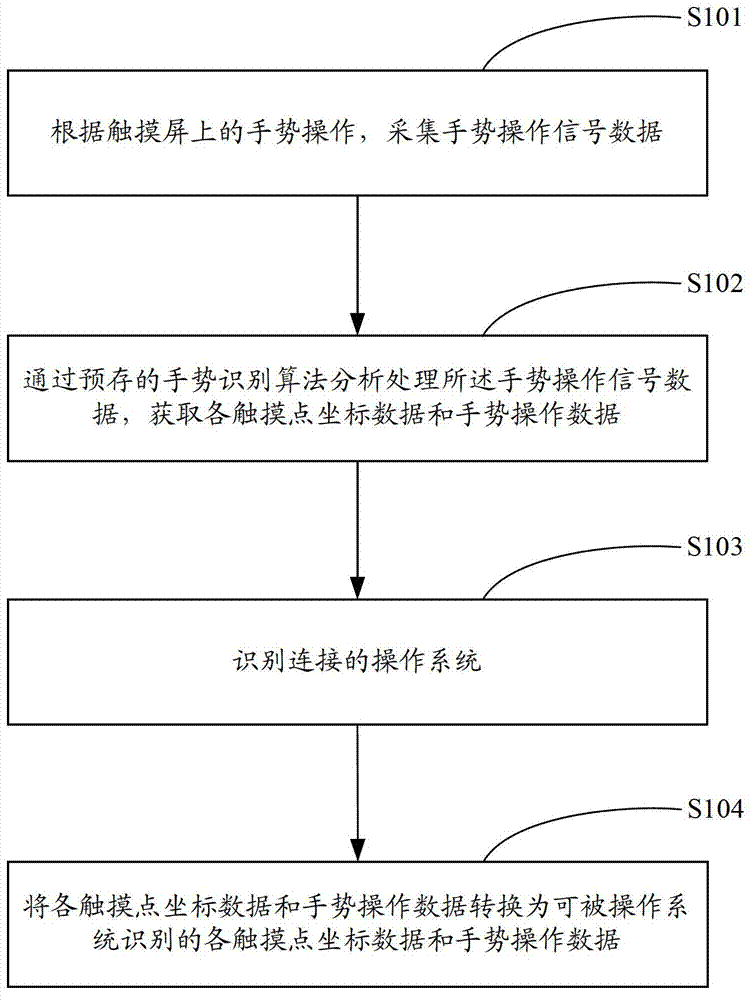

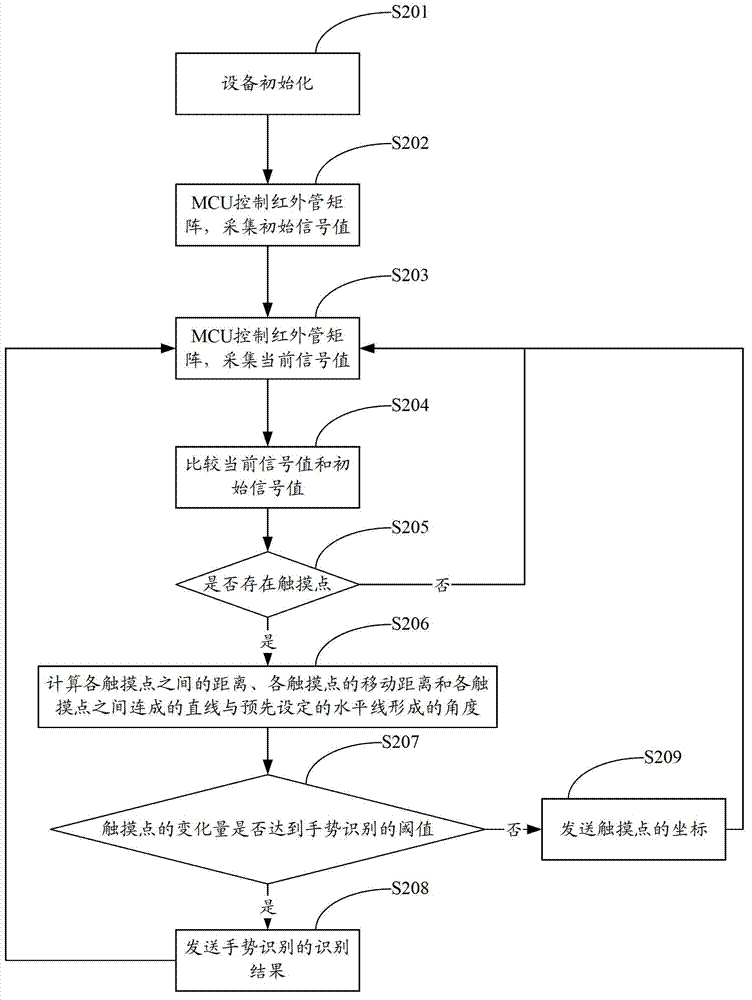

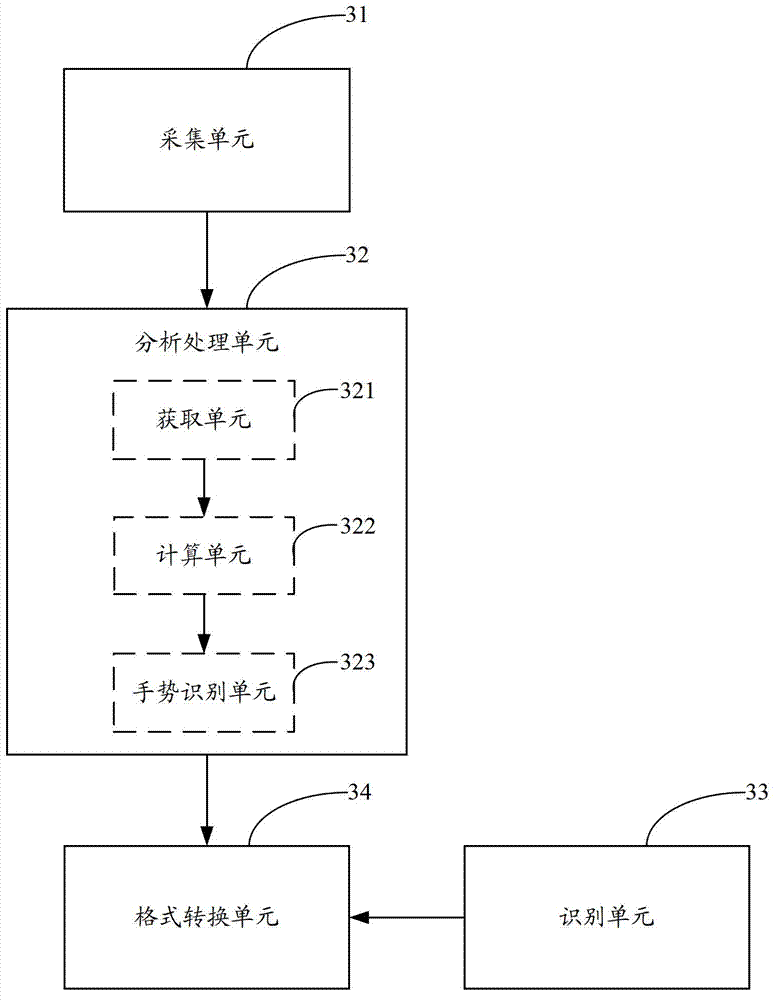

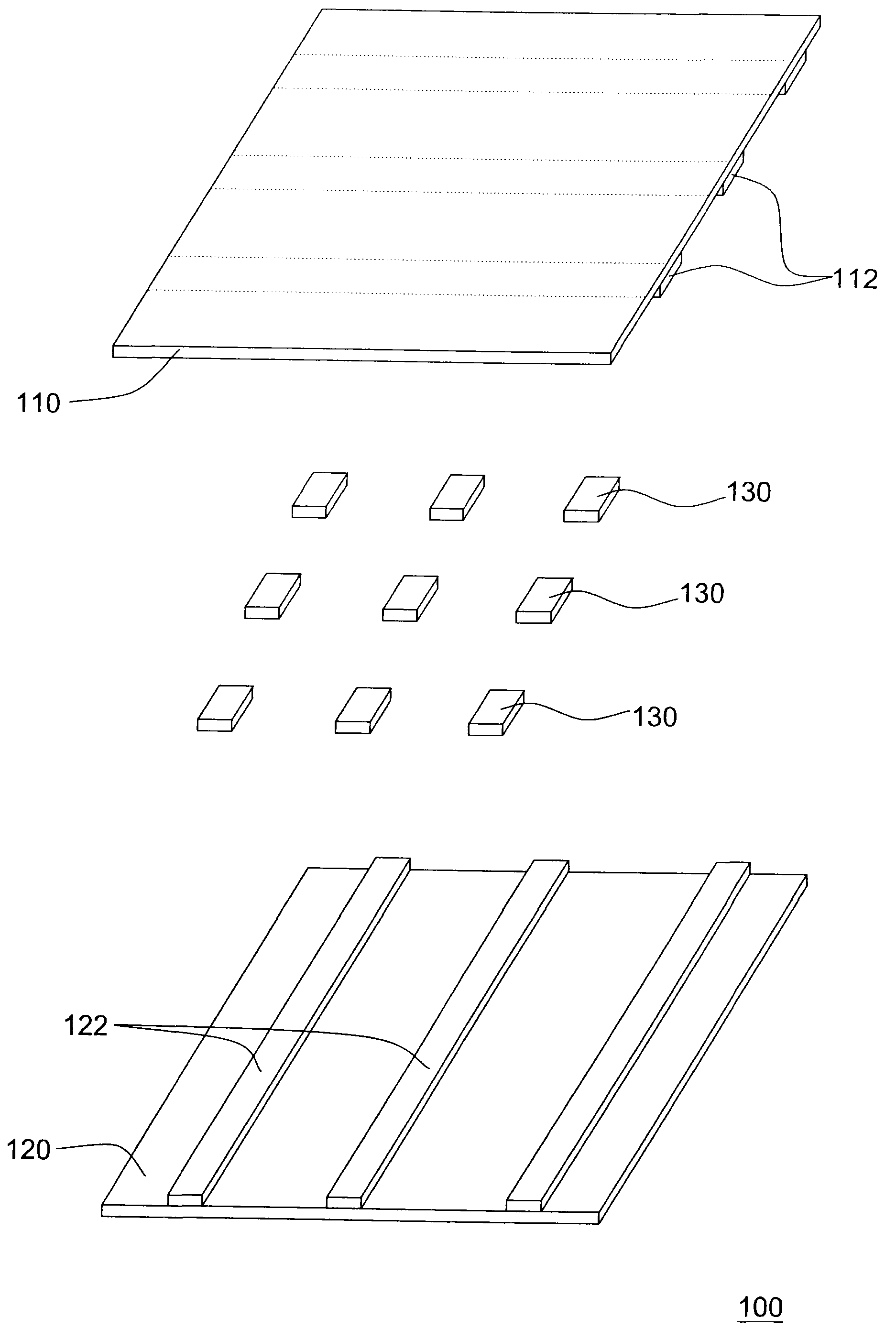

Gesture recognition method and device and touch screen terminal

ActiveCN102830858AImplement multi-touchInput/output processes for data processingTouchscreenData conversion

The invention is applicable to the field of touch screen terminals and provides gesture recognition method and device and a touch screen terminal. The method includes the steps: acquiring gesture signal data according to gestures on a touch screen; analyzing the gesture signal data by pre-stored gesture recognition algorithm, and acquiring coordinate data and gesture data of all touch points; recognizing a connected operating system; and converting the coordinate data and gesture data of all the touch points into coordinate data and gesture data of the touch points, recognizable to the operating system. Gesture recognition for at least one finger is realized, and gesture recognition results are processed into the corresponding formats according to the connected different operating systems. The recognition of multiple gestures is achieved by the gesture recognition algorithm, and compatibility of various operating systems is also realized.

Owner:SHENZHEN TMD TECH

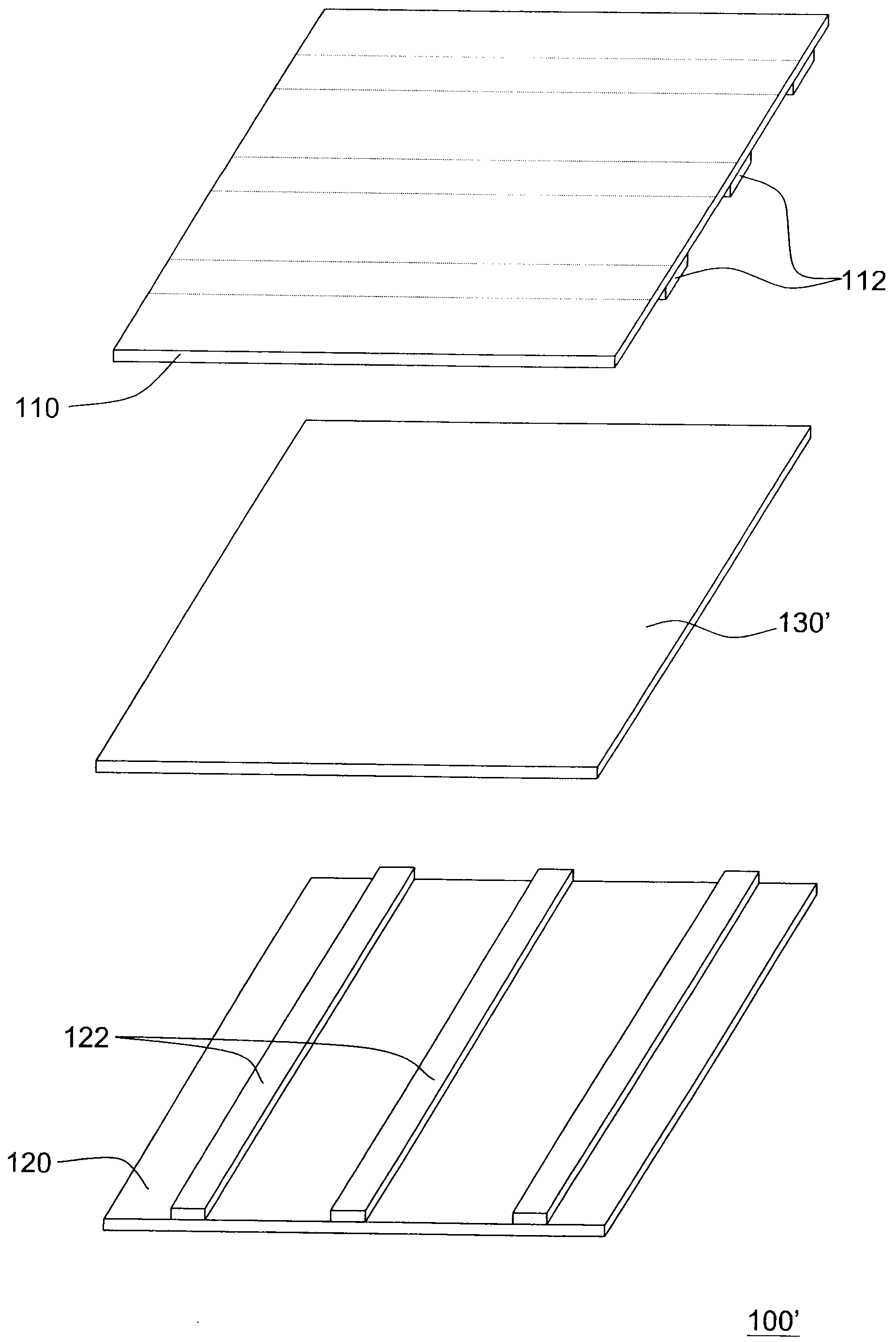

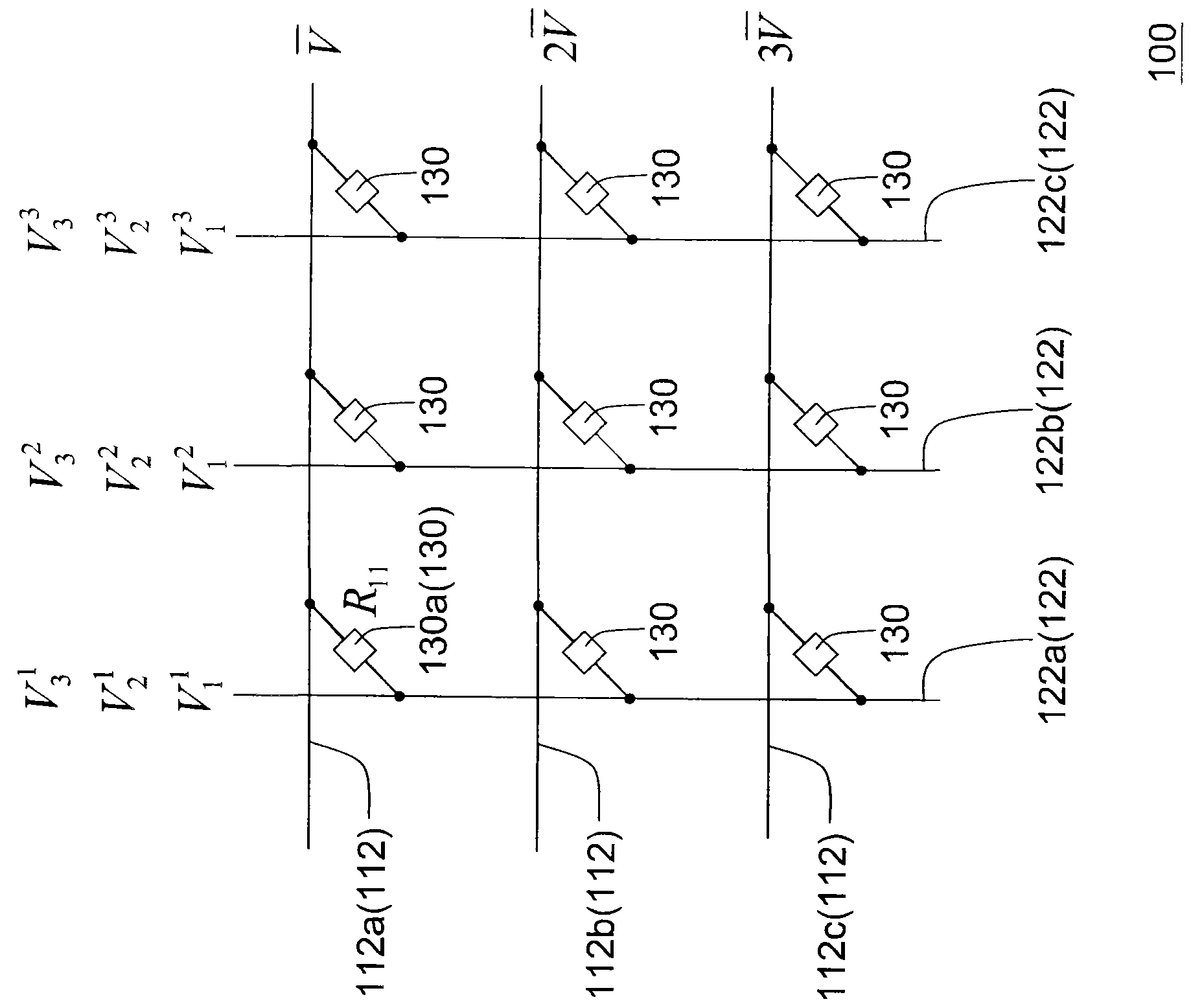

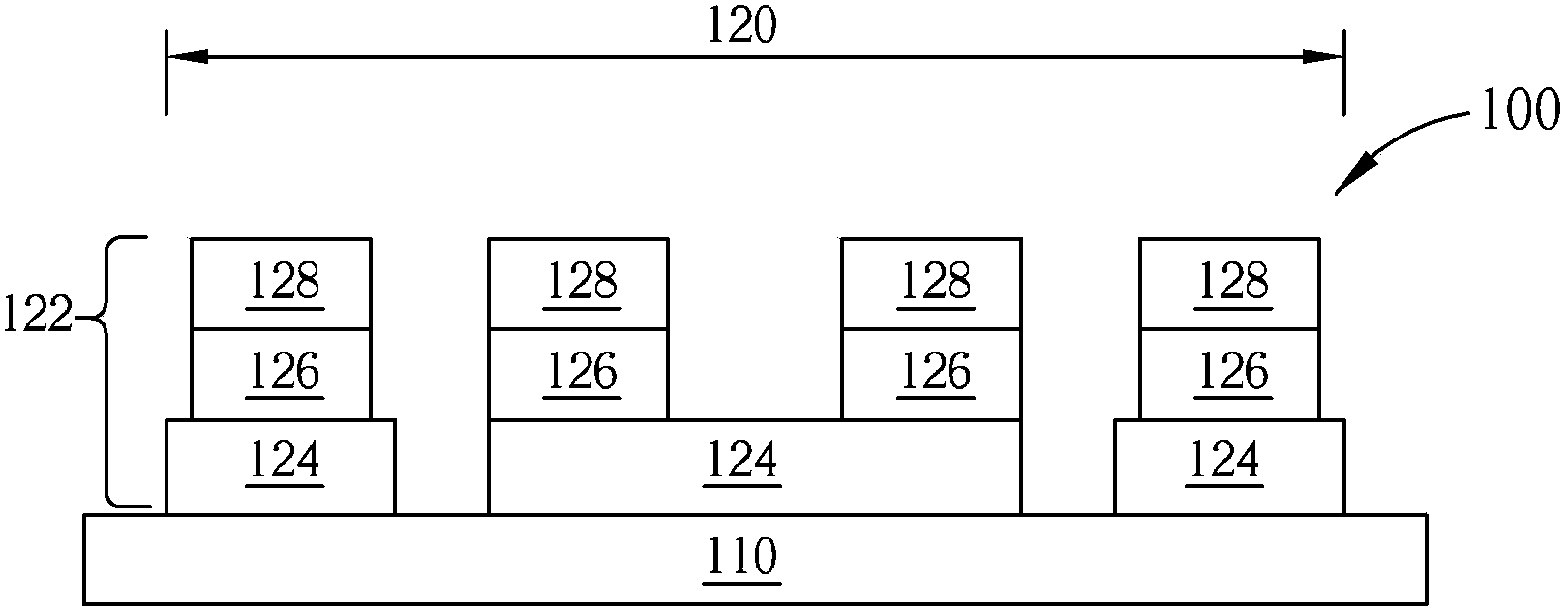

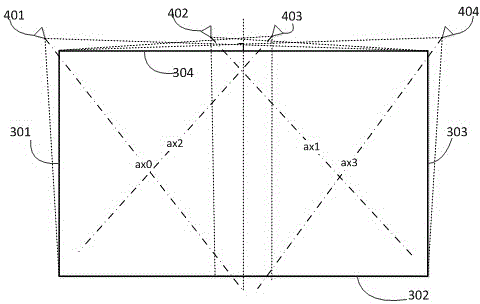

Array pressure sensing device and pressure identification method thereof

ActiveCN101655399AImplement multi-touchHigh grayscale recognition abilityForce measurementTouch SensesPressure sense

The invention provides an array pressure sensing device, which is suitable for multi-point touch sensing and pressure quantization identification. The array pressure sensing device comprises a plurality of first axes, a plurality of second axes, a plurality of piezoresistive units, a third axis, a plurality of standard resistors and a control unit, wherein the second axes are in staggered arrangement with the first axes, and one piezoresistive unit is arranged between staggered positions of each first axis and each second axis; and the third axis is in staggered arrangement with the first axes, and one standard resistor is arranged between staggered positions of each first axis and the third axis. The invention also provides a pressure identification method realized by the array pressure sensing device. The pressure identification method is realized by a scanning driving flow of the control unit, and a pressure quantization gray scale identification method for a linear piezoresistive system is provided.

Owner:IND TECH RES INST

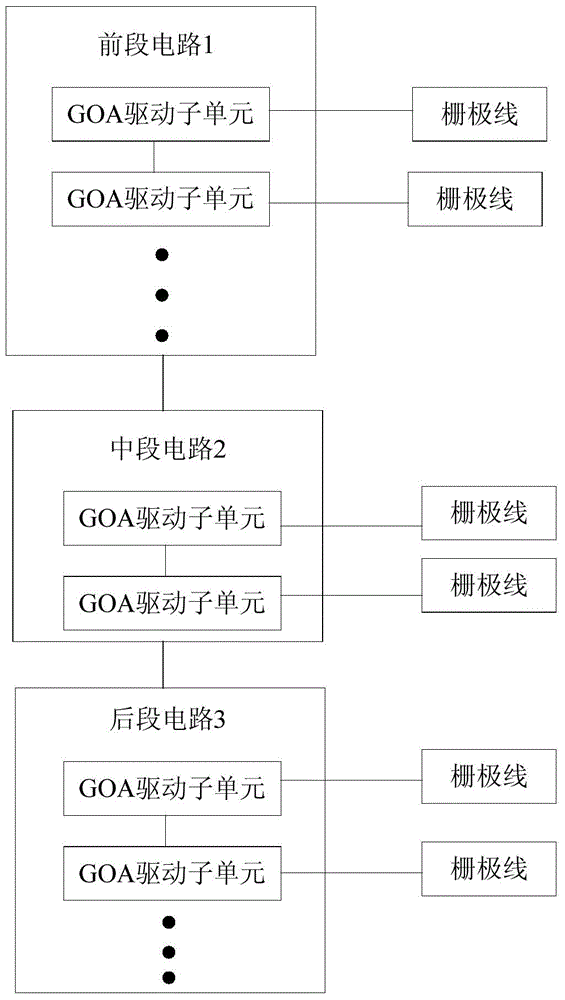

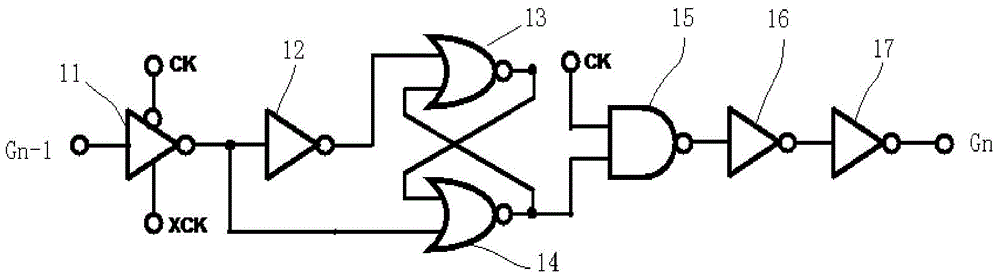

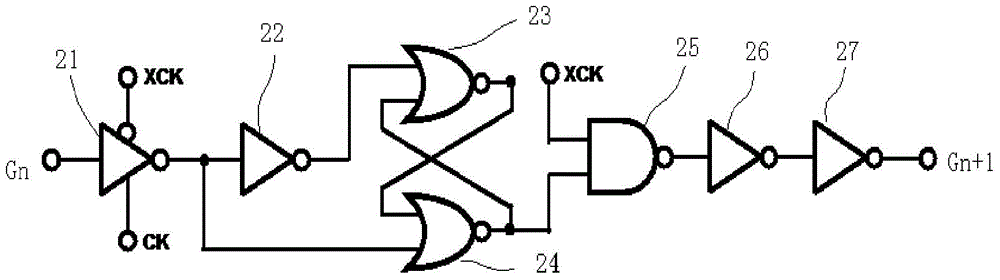

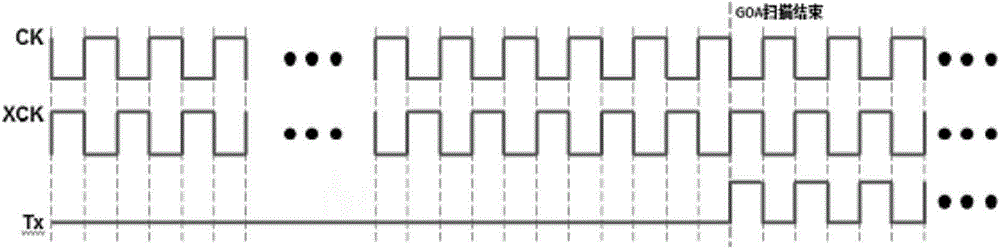

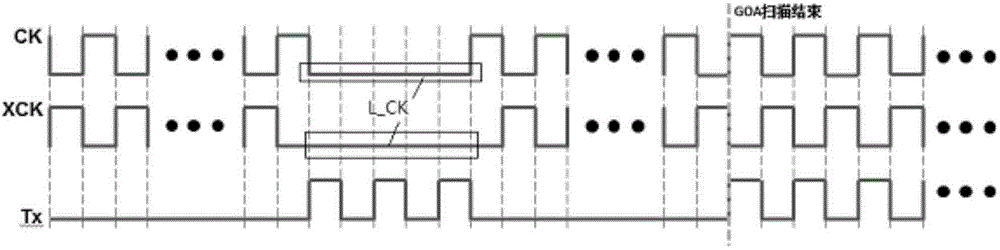

GOA drive circuit applied to flat panel display and flat panel display

ActiveCN104537994ARealization of touch detection operationImplement multi-touchStatic indicating devicesInput/output processes for data processingDisplay deviceEngineering

The invention discloses a GOA drive circuit applied to a flat panel display and the flat panel display. The GOA drive circuit comprises a front section circuit, a middle section circuit and a rear section circuit, wherein GOA drive subunits in the front section circuit, the middle section circuit and the rear section circuit respectively receive a first clock signal and a second clock signal to sequentially generate corresponding gate drive signals, interrupt cycles are set in the first clock signals and the second clock signals so that interruption can be generated between the corresponding gate drive signals which are sequentially generated, and the flat panel display executes the touch control detection operation within the interrupted intervals. By means of the mode, the scanning interruption of the GOA drive circuit can be achieved, and the touch control scanning frequency is increased.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

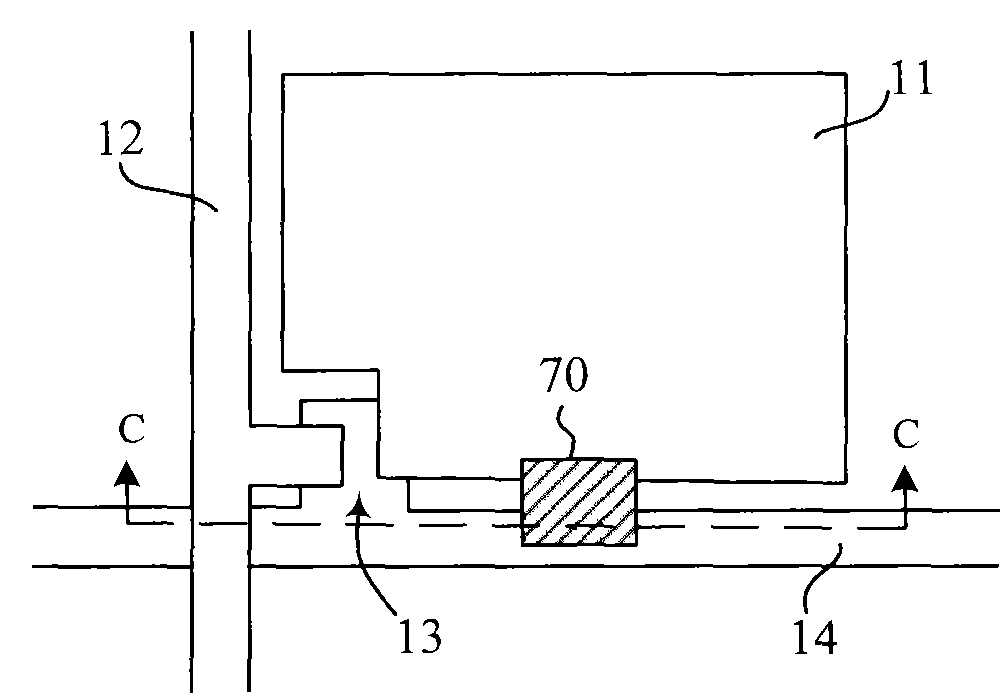

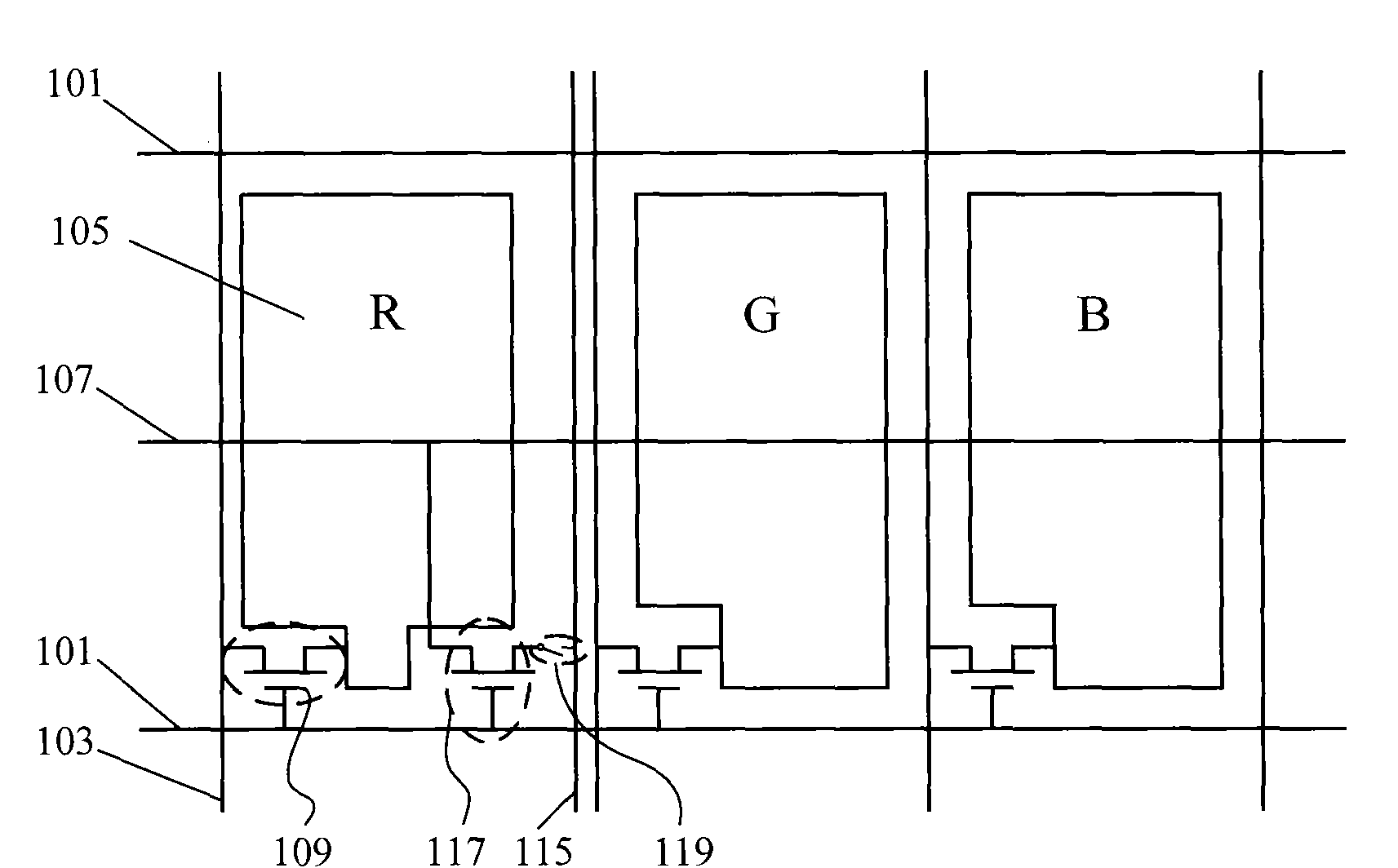

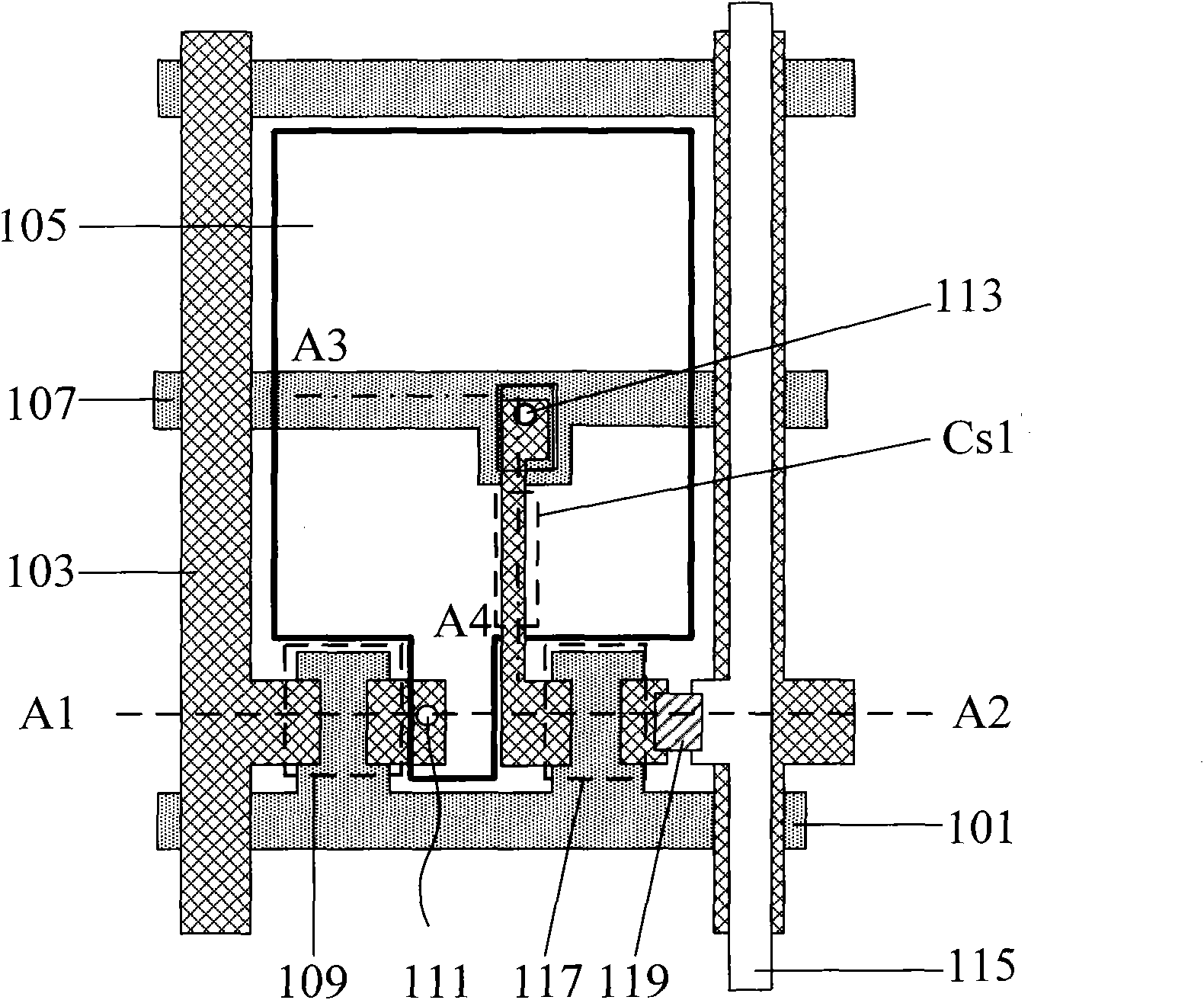

Touch-control type liquid crystal display device

ActiveCN102043270ASimple processLower control costsStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

The invention relates to a touch-control type liquid crystal display device comprising a first base plate, a second base plate, a liquid crystal layer, a plurality of scanning lines, a plurality of data lines and a plurality of pixel units, wherein the first base plate and the second base plate are oppositely arranged; each pixel unit comprises a plurality of sub-pixels, each sub-pixel comprises a first common electrode, a second common electrode, a pixel switch element and a pixel electrode, wherein the first common electrode is arranged on the first base plate, the second common electrode is arranged on the second base plate, the pixel switch element is arranged on the first base plate, and the pixel electrode is electrically connected to the pixel switch element. The touch-control type liquid crystal display device also comprises a touch-control structure, a touch position output line and a touch detecting device, wherein the touch position output line is connected with the touch-control structure; the touch detecting device is connected with the touch position output line; the touch-control structure comprises a touch-control switch element and a touch unit, wherein the touch-control switch element is arranged on the first base plate; and when the touch-control type liquid crystal display device is touched, the touch-control switch element is electrically connected with the touch position output line. The touch-control type liquid crystal display device can realize multi-point touch to improve the display quality.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

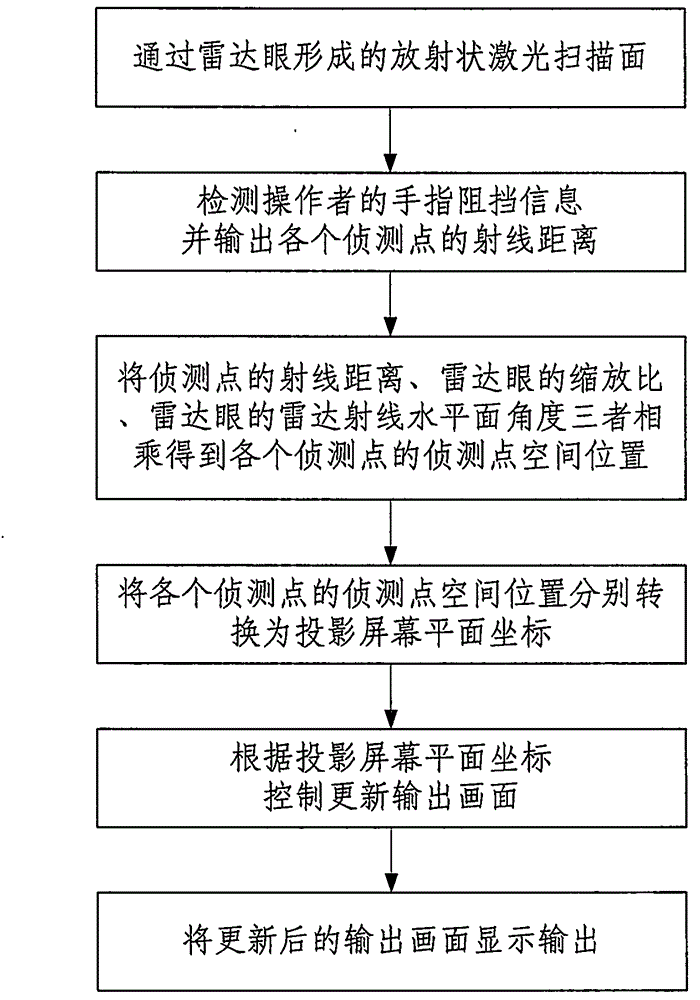

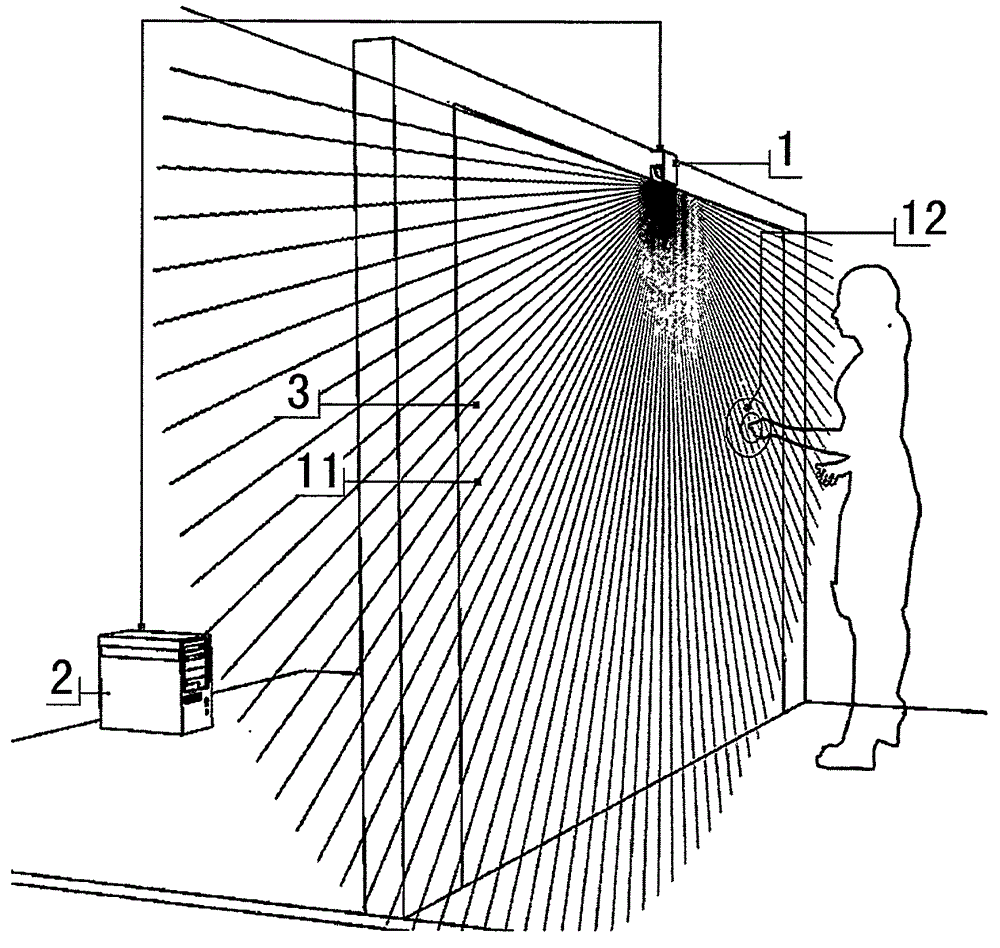

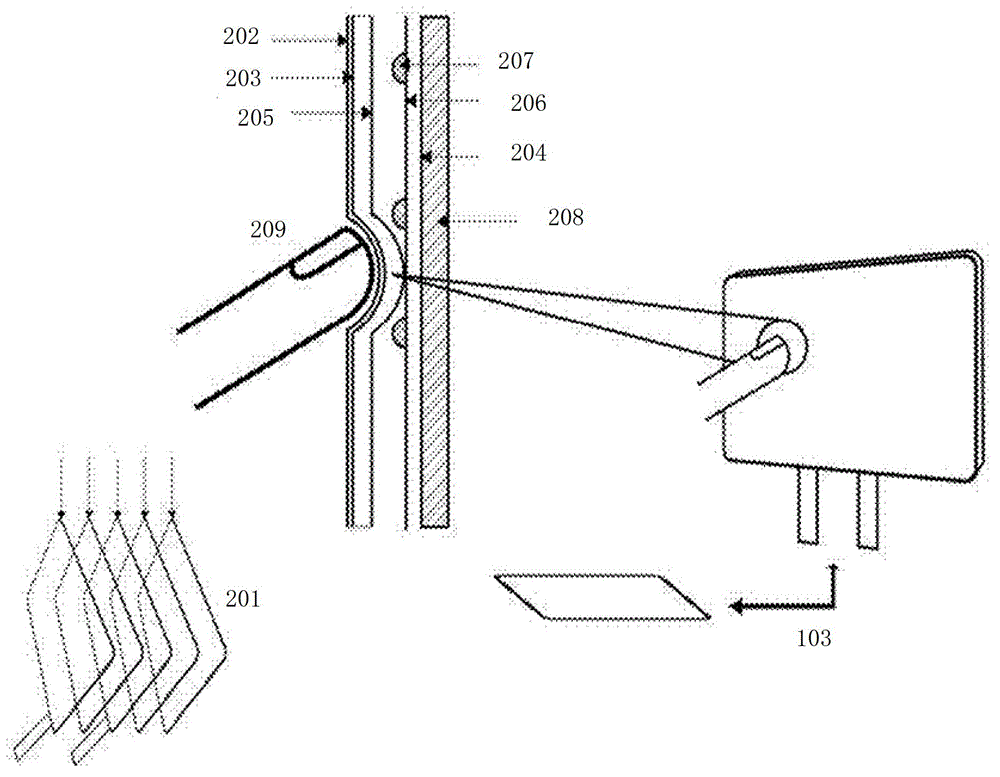

Frameless multipoint touch man-machine interaction method and system based on radar eye

InactiveCN104423721AInsensitiveLarge scanning radiusInput/output processes for data processingInterference resistanceRadar

The invention discloses a frameless multipoint touch man-machine interaction method and system based on a radar eye. The frameless multipoint touch man-machine interaction method includes steps of forming a radial laser scanning surface through the radar eye and detecting finger shading information of an operator; acquiring at least one monitoring point space position shaded by fingers through debugging software of the radar eye, converting the monitoring point space positions into projection screen plane coordinates respectively and controlling updating of output images according to the projection screen plane coordinates; displaying and outputting the updated output images. The devices include the radar eye, a host and a projection screen. The frameless multipoint touch man-machine interaction method and system based on the radar eye has the advantages of insensitivity to surrounding light, high interference resistance, reliability and accuracy in positioning, simplicity and convenience in implementing, low use cost, no frame limit, flexibility in use ways and wide use range.

Owner:苗注雨

Touch display panel and driving method thereof

InactiveCN105718129AReduce thicknessRealize thinner and lighterNon-linear opticsInput/output processes for data processingCapacitanceComputer science

Owner:BOE TECH GRP CO LTD

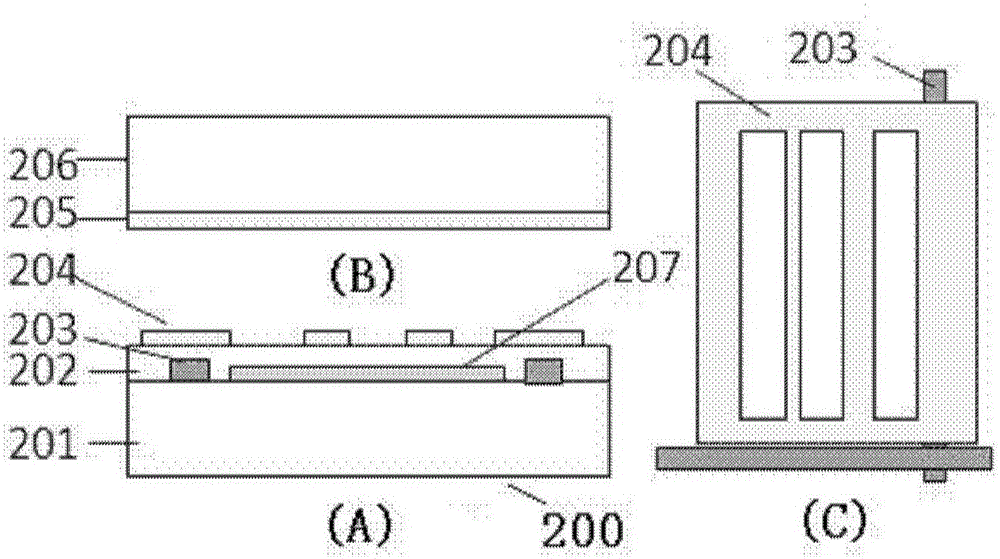

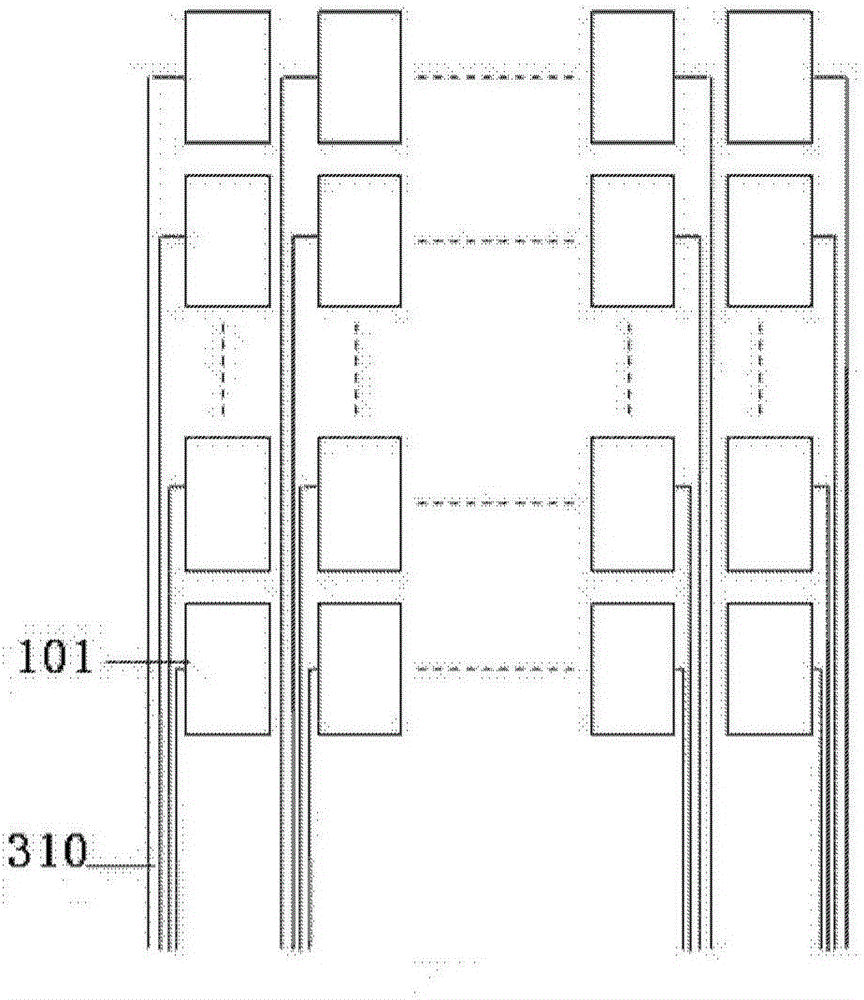

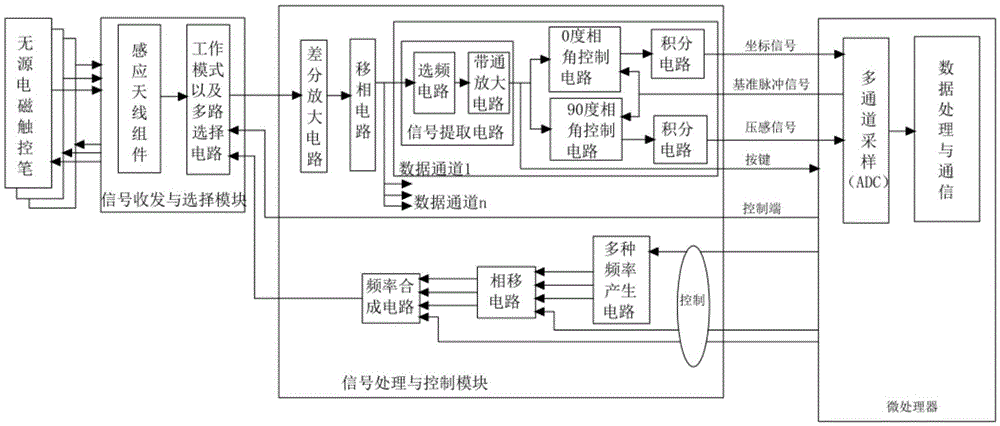

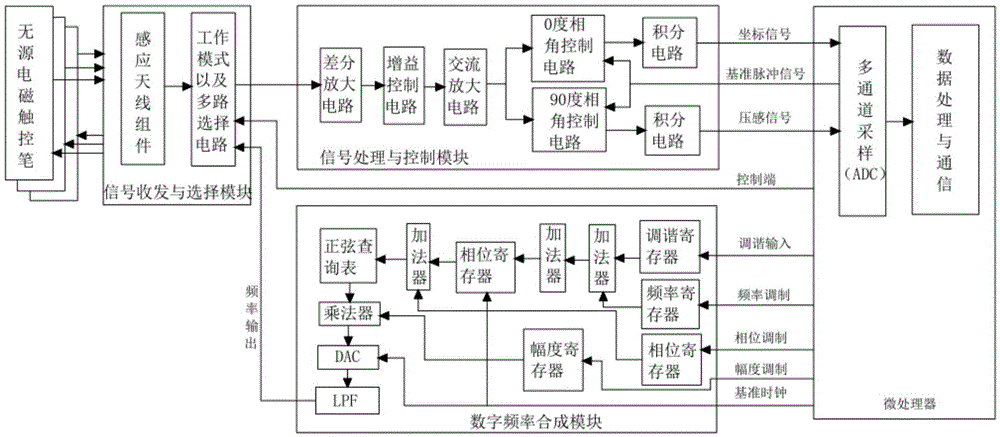

Electromagnetic induction type multi-channel handwriting input system and method

ActiveCN105607765AImplement inputImplement multi-touchInput/output processes for data processingComputer moduleEngineering

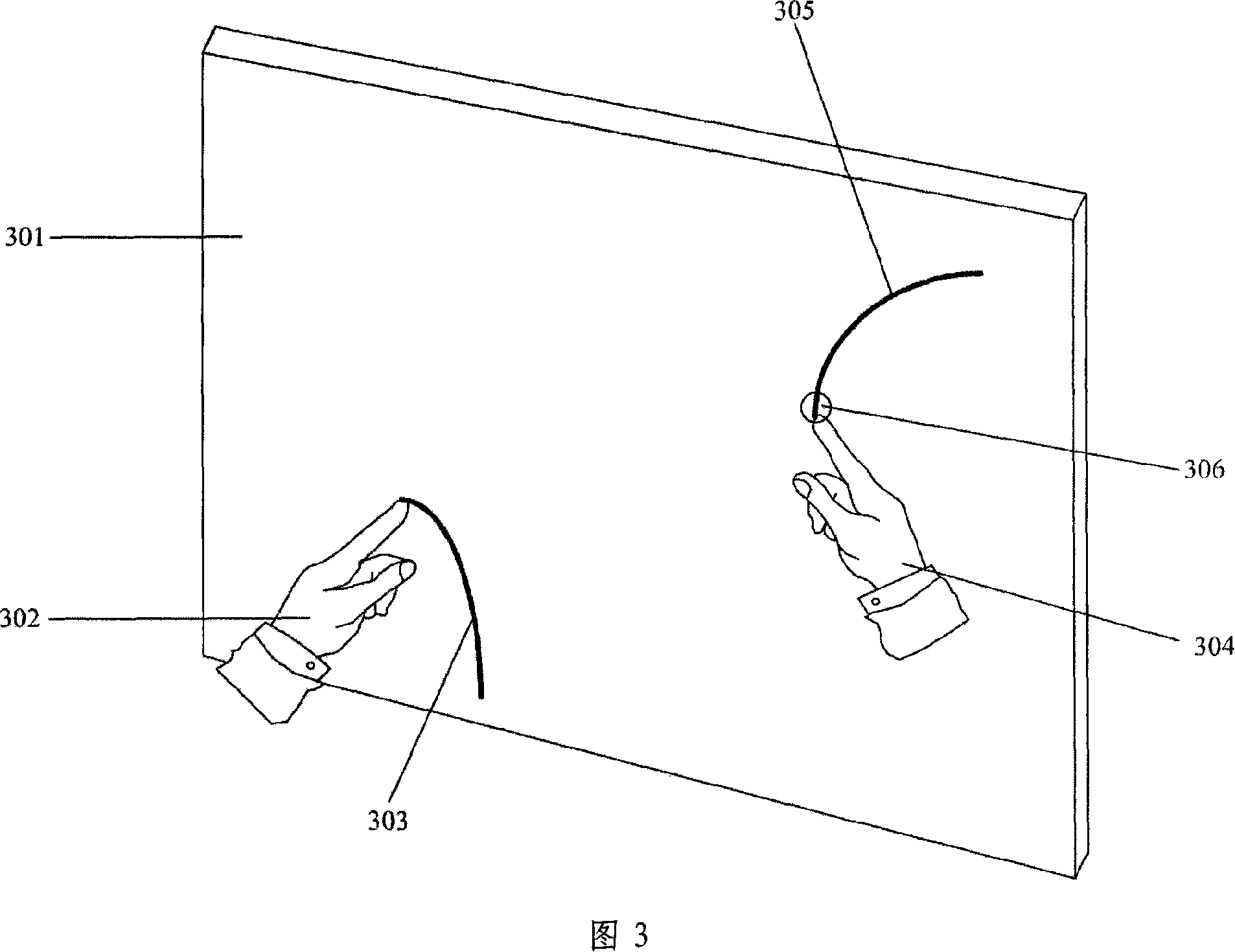

The invention discloses an electromagnetic induction type multi-channel handwriting input technical system and method. The electromagnetic induction type multi-channel handwriting input technical system comprises two or more electromagnetic pens, a signal transceiving and selecting module and a signal processing and control module, wherein the electromagnetic pens are wirelessly connected with the signal transceiving and selecting module through continuously variable electromagnetic waves; the signal transceiving and selecting module is connected with the signal processing and control module; the signal processing and control module is connected with a microprocessor. The invention provides the electromagnetic induction type multi-channel handwriting input technical system which can respond to at least more than two electromagnetic signals and a resonant electromagnetic pen input device; the device can provide support for one electromagnetic induction signal processing and control module to allow two or more wireless electromagnetic pens to operate simultaneously, so that a function of synchronous multi-channel handwriting input can be achieved.

Owner:广州磐信计算机科技有限公司

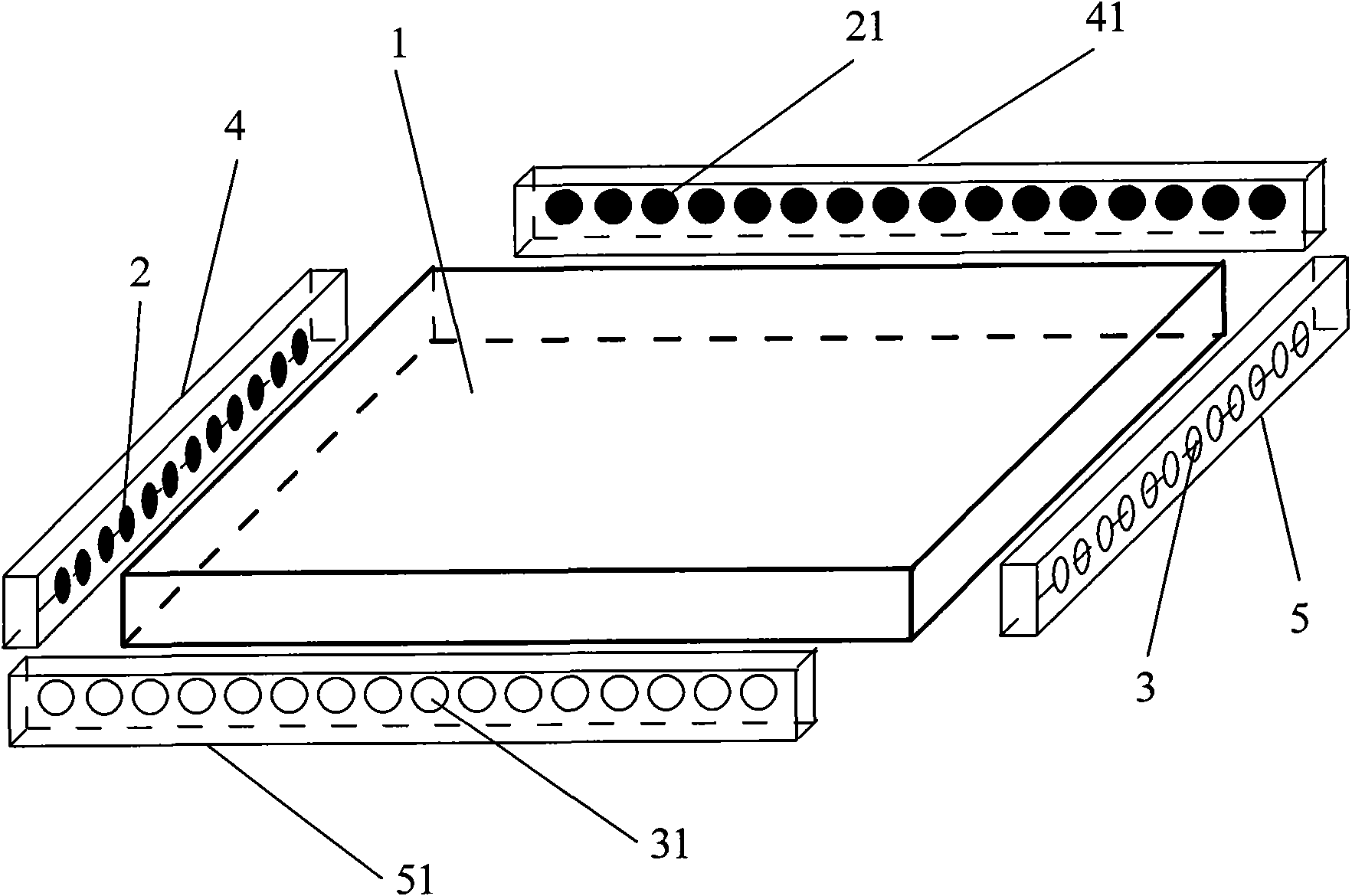

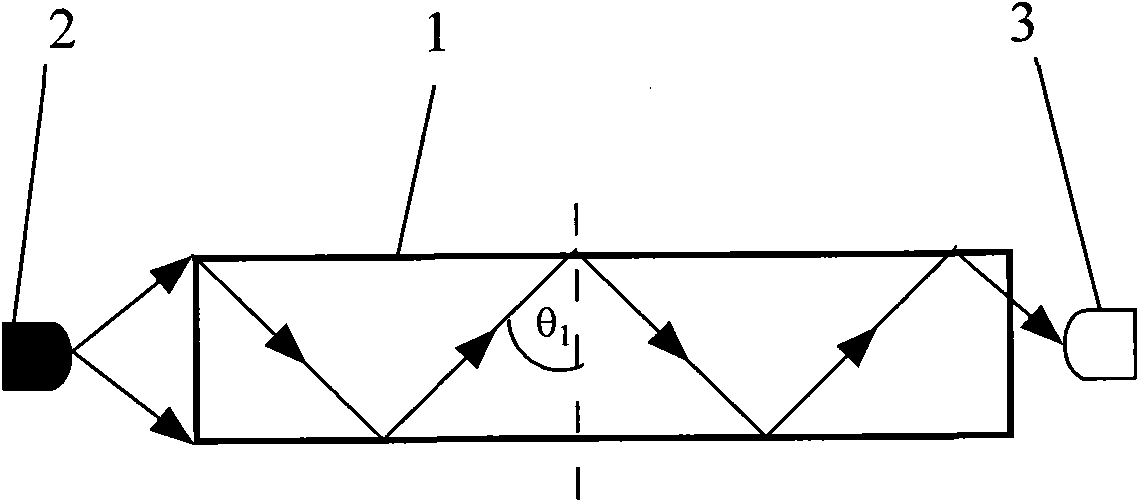

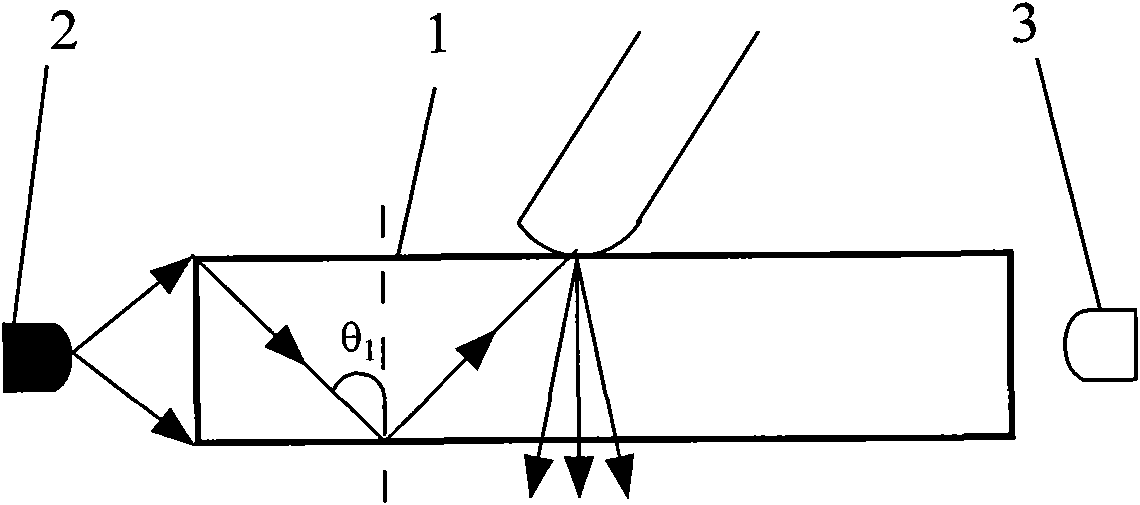

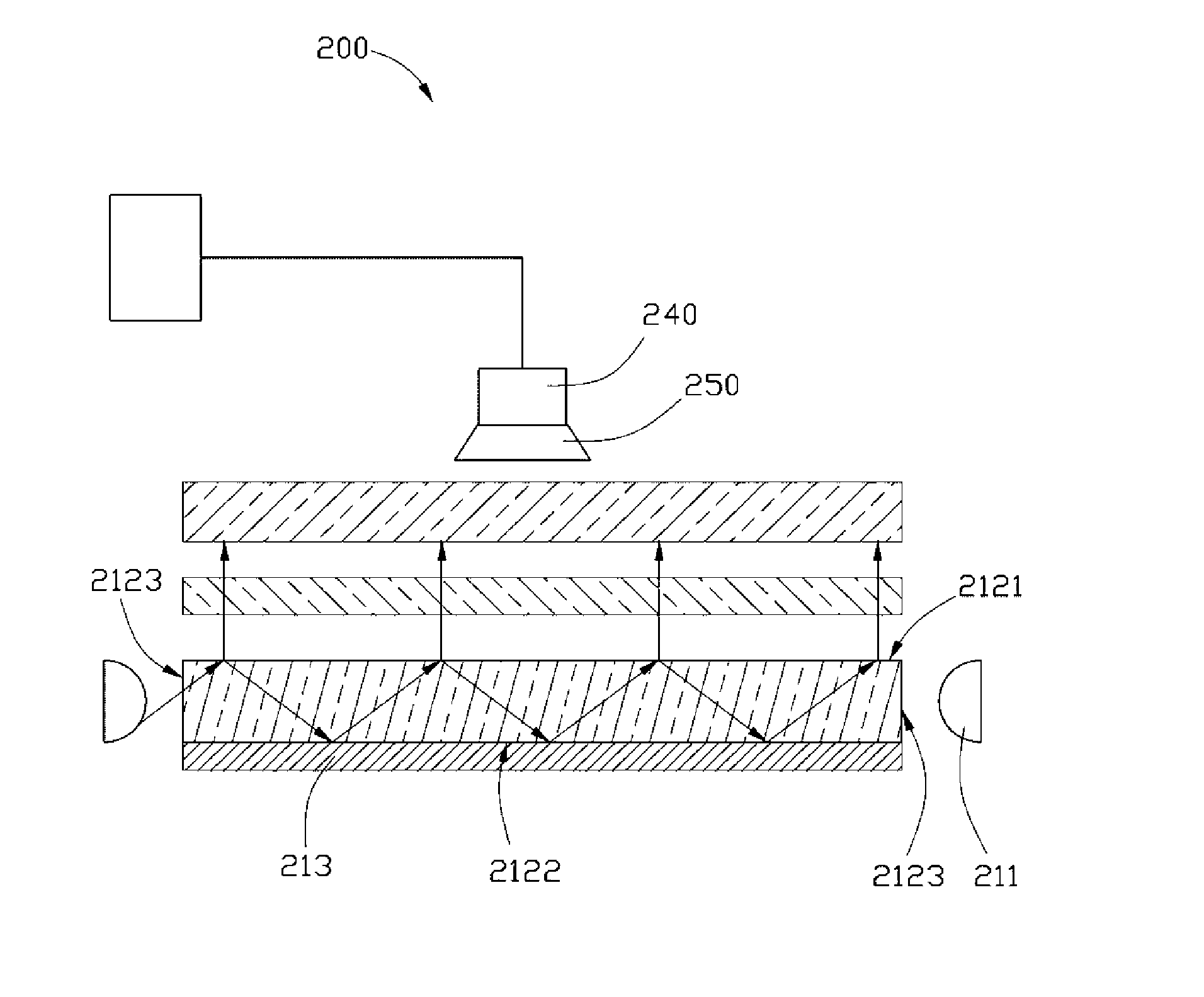

Side detection-type multipoint touch screen based on frustrated total internal reflection

InactiveCN101866247AEasy system integrationAvoid interferenceInput/output processes for data processingOpto electronicWave band

The invention relates to a side detection-type multipoint touch screen based on frustrated total internal reflection; four side surfaces of an optical panel of the multipoint touch screen are optical surfaces, LED lamps are uniformly and respectively distributed on the adjacent side surfaces of the optical panel, and the optical axis direction of the LED lamp is vertical to the side surface of the optical panel; opto-electrical receiving tubes are uniformly and respectively distributed on the other two side surfaces of the optical panel correspondingly, the optical axis direction of the opto-electrical receiving tubes is vertical to the side surface of the optical panel; in the invention, LED lamps with infrared light wave band or visible light wave band are used as light sources, and the opto-electrical receiving tubes with the corresponding wave band are used for receiving, the signal of the opto-electrical receiving tube is processed by the circuit to obtain a touch signal, so as to be convenient for system integration. By adopting a side detection mode, the LED light sources and opto-electrical receiving tubes are arranged on the four side surface of the optical panel, so as to realize multipoint touch; meanwhile, light is prevented from being leaked from the optical panel, thereby greatly reducing the thickness and volume of the system.

Owner:HEFEI UNIV OF TECH

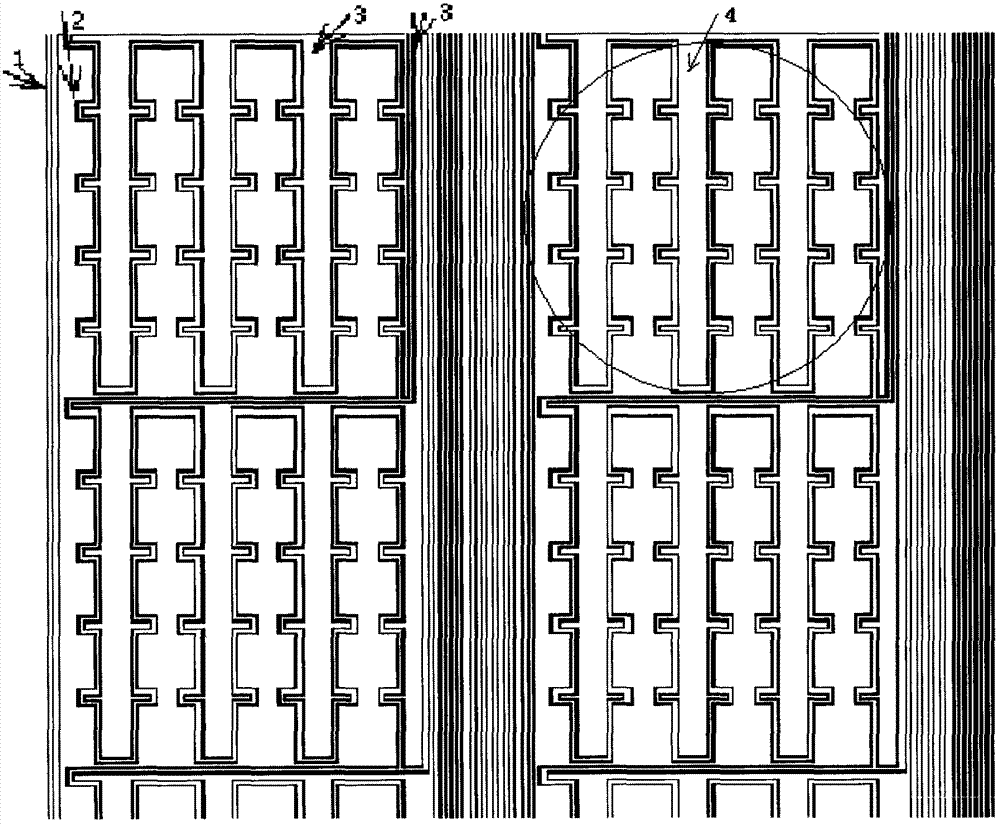

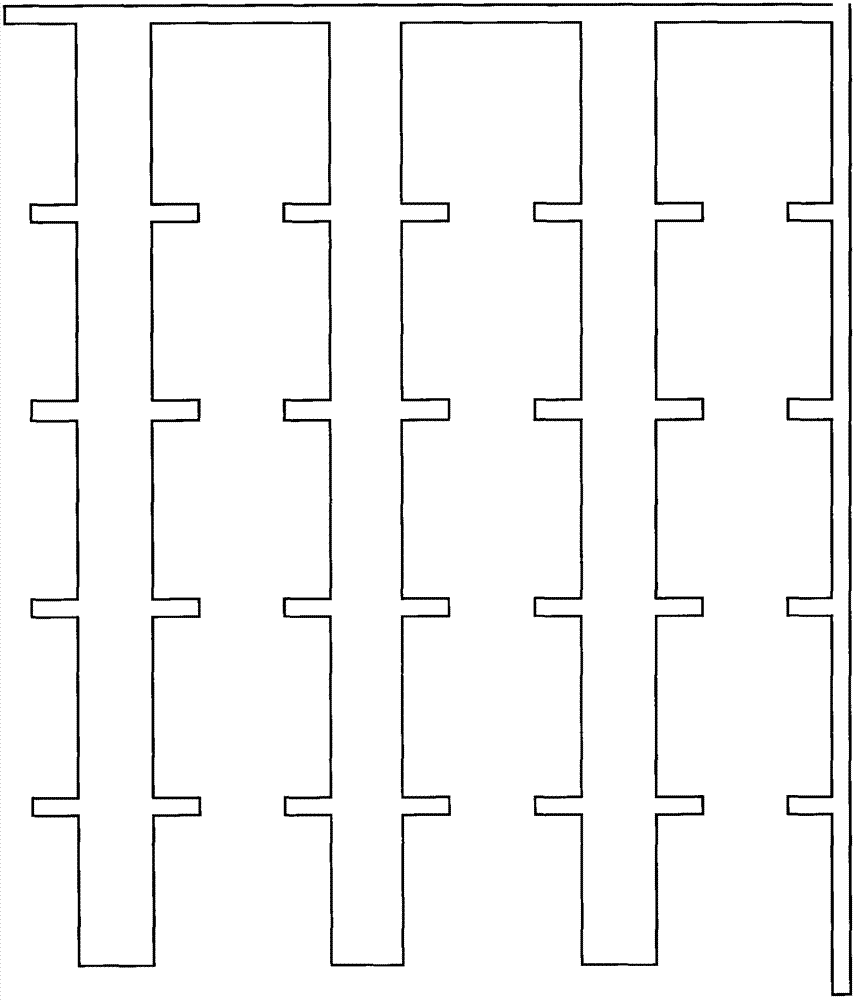

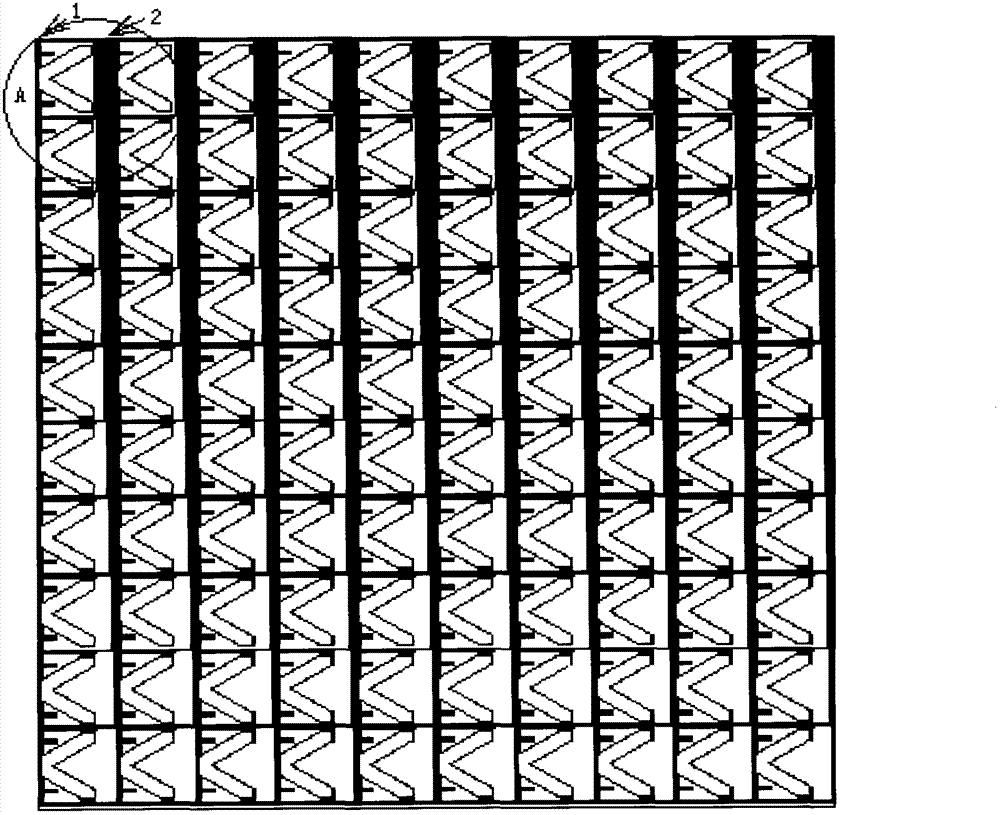

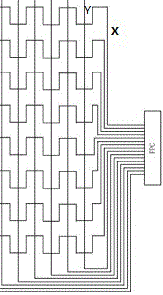

Single-layer multi-point capacitive touch screen

ActiveCN102855041AImplement multi-touchInput/output processes for data processingFlexible circuitsTouchscreen

The invention discloses a single-layer multi-point capacitive touch screen which comprises a plurality of drive electrodes formed on a same electrode layer, lead-out wires, and a plurality of induction electrodes which are complementary with the drive electrodes but are wirelessly connected and mutually isolated, wherein each drive electrode and the induction electrode complementary with the drive electrode form a repeated electrode unit; each drive electrode is composed of a plurality of first strip electrodes whose upper parts are connected, and the appearance of each first strip electrode is similar to a plurality of Chinese characters 'zhong' connected up and down; the induction electrodes in the same column of repeated electrode units are directly connected so as to form a plurality of columns of induction electrodes, and the drive electrodes in the same row of repeated electrode units are connected through the lead-out wires on a flexible circuit board or a printed circuit board, thereby forming a plurality of rows of drive electrodes. Mutual-capacitance change is formed between the lateral walls of the drive electrodes and the induction electrodes before and after the detection, so as to determine a touch position.

Owner:CHIPONE TECH BEIJINGCO LTD

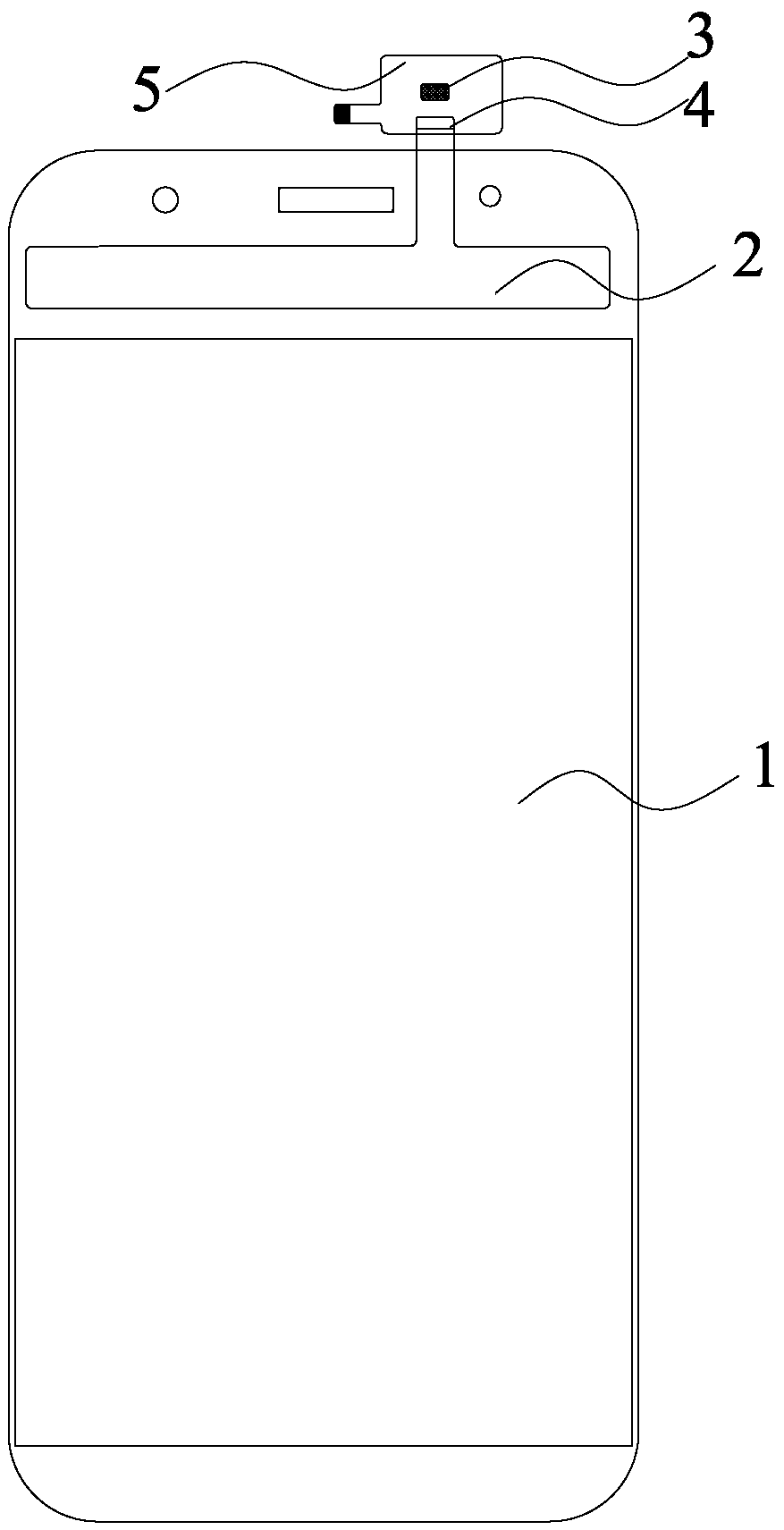

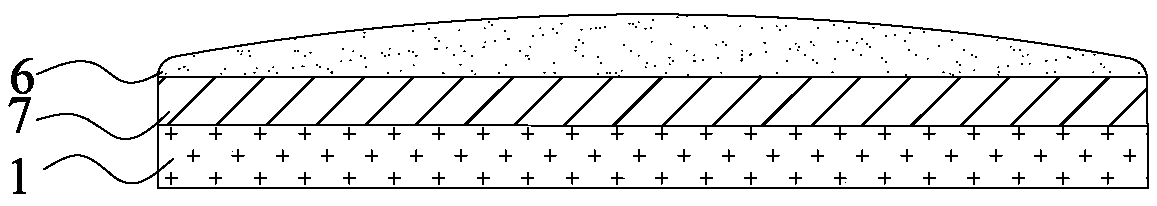

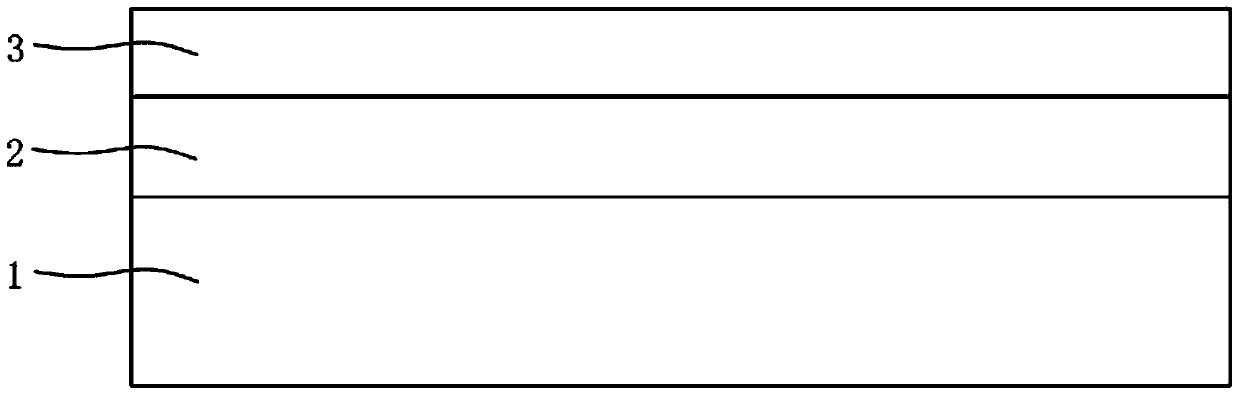

GG monolayer multipoint borderless touch screen and preparation process thereof

InactiveCN105511681AGood light transmissionImprove clarityInput/output processes for data processingSputteringGlass cover

The invention relates to the technical field of touch screens and particularly relates to a GG monolayer multipoint borderless touch screen and a preparation process thereof. The touch screen comprises a tempered glass cover plate, a transparent optical adhesive layer and ITO conductive glass, wherein a border wiring area of the ITO conductive glass comprises a transverse wiring area arranged at one end of the touch screen, the ITO conductive glass is provided with a monolayer multipoint electrode pattern of single-end outgoing line, and an FPC is mounted in the transverse wiring area in a press-fitting manner and is connected with an IC chip. According to the GG monolayer multipoint borderless touch screen and the preparation process thereof, the FPC is mounted in the transverse wiring area at one end of the touch screen in the press-fitting manner, and original left and right longitudinal wiring areas are canceled, so that longitudinal sides of the touch screen do not need wiring, and thus, a borderless visual effect is built; ultraviolet illumination is adopted during magnetron-sputtering ITO film plating, so that the photoelectric properties of the ITO conductive glass are improved, only one-time FPC press-fitting is required during preparation, the process is simple, the yield of products is high, and excellent properties and production stability for the touch screen can be guaranteed.

Owner:深圳市欣联科技有限公司

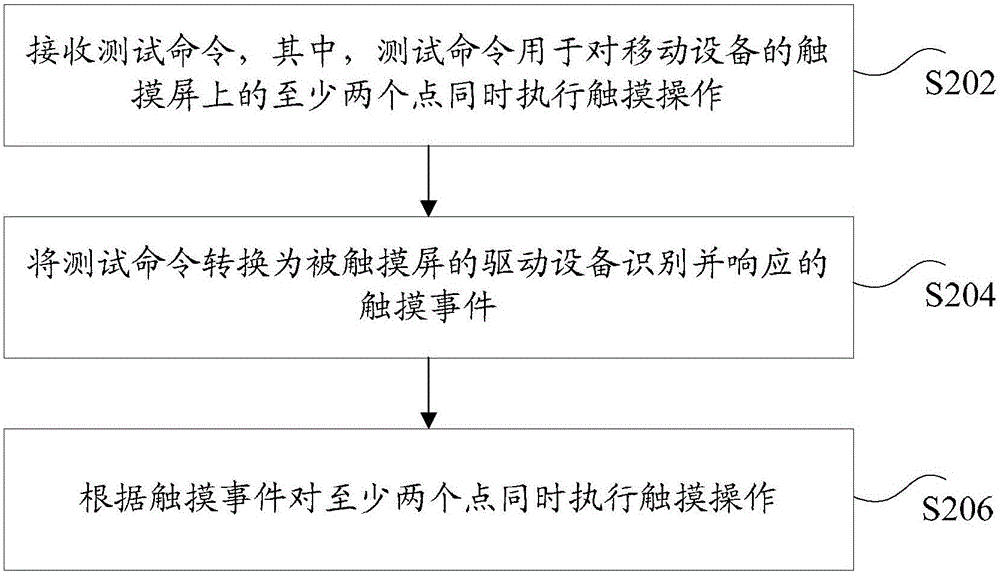

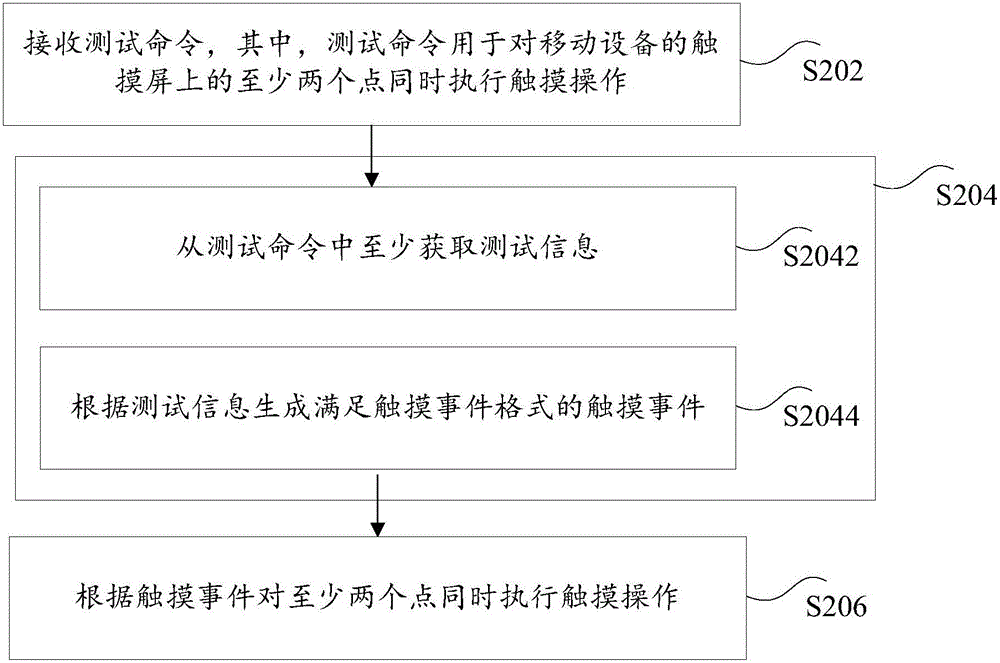

Mobile equipment test method and device

ActiveCN105975367AImprove test depthSolve the low test depthFaulty hardware testing methodsSingle pointReal-time computing

Owner:TENCENT TECH (SHENZHEN) CO LTD

Touch screen

InactiveCN102722295AReduced footprintReduce the numberInput/output processes for data processingLight guideLight beam

The invention discloses a touch screen. The touch screen comprises a touch panel, a printed circuit board, an infrared emitting element, an infrared receiving element and a light guide component, wherein the infrared emitting element and the infrared receiving element are arranged on the printed circuit board; and the light guide component is used for changing the propagation direction of a light beam emitted by the infrared emitting element so as to propagate the light beam along the touch surface of the touch panel, and changing the propagation direction of the light beam propagated along the touch surface of the touch panel so as to emit the light beam to the infrared receiving element. With the adoption of the touch screen, the coverage scope of the light beam is wide, the touch precision is high, the touch height is effectively reduced, and the high light resistance is provided.

Owner:BEIJING UNITOP NEW TECH CO LTD

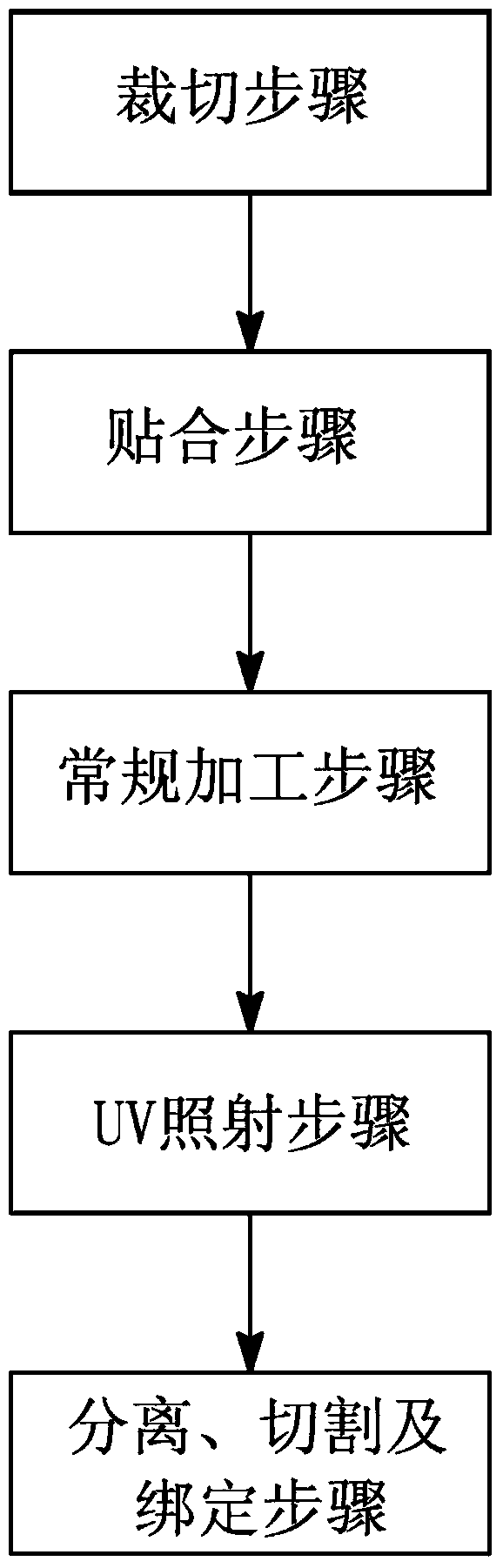

Manufacturing method of flexible film function piece

ActiveCN104199571AEasy to processImprove production efficiencyCable/conductor manufactureInput/output processes for data processingManufacturing efficiencyElectrically conductive

The invention relates to a manufacturing method of a flexible film function piece. The manufacturing method includes a cutting step, a gluing step, a conventional machining step, a UV irradiation step and a separating, cutting and binding step, wherein in the cutting step, a transparent conducting film and a UV glue are cut into the size being consistent with the size of a transparent base plate respectively; in the gluing step, the transparent conducting film is stuck to the transparent base plate by means of the UV glue to form a semi-finished product; in the conventional machining step, a predetermined circuit is formed on the transparent conducting film; in the UV irradiation step, a UV lamp is used for irradiating a machined product so as to enable adhesiveness of the UV glue to be reduced; in the separating, cutting and binding step, the transparent conducting film with the predetermined circuit is removed from the transparent base plate, and at last, cutting and binding are conducted to obtain a finished flexible film function piece. According to the manufacturing method, the sheet of the transparent conducting film is stuck to the transparent base plate, subsequent machining procedures can be conducted conveniently, the defect that processing is difficult due to the fact that the transparent conducting film is soft relatively is overcome, after machining is completed, the flexible film function piece can be removed from the transparent base plate conveniently, and the manufacturing efficiency and the product yield are high.

Owner:深圳豪威显示科技有限公司

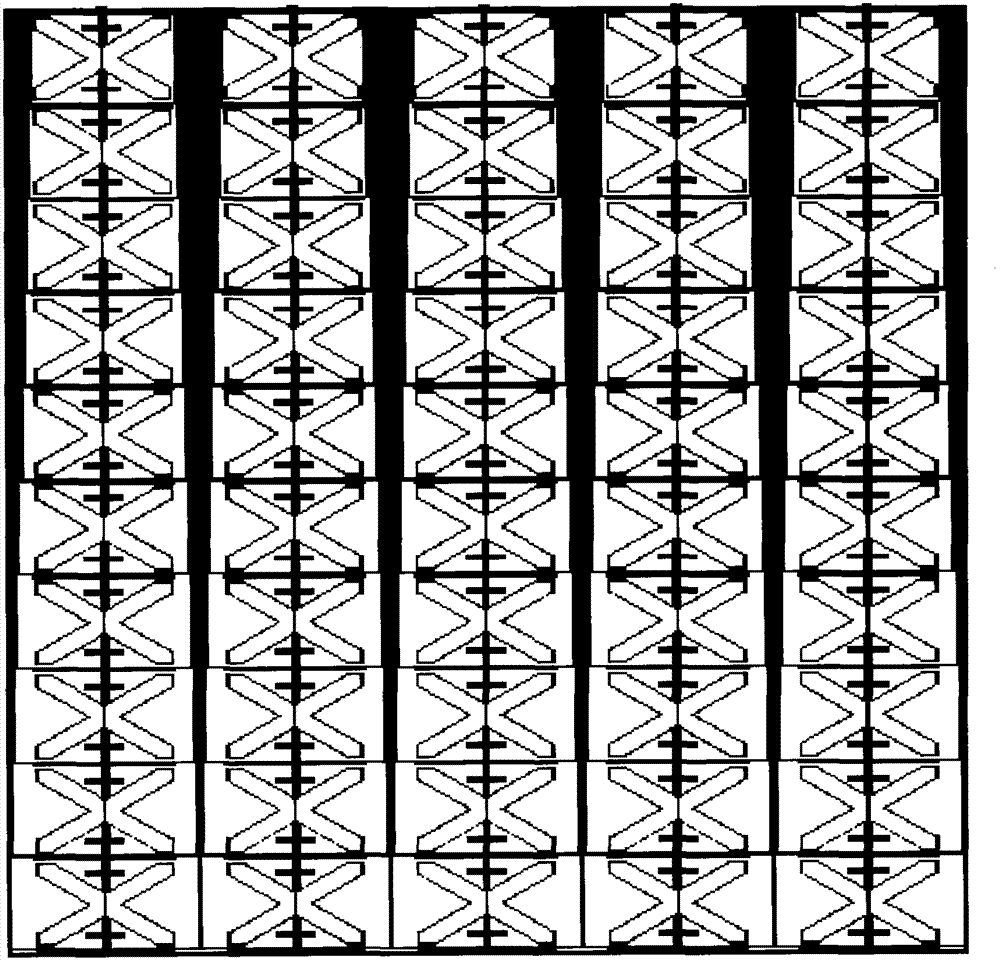

Single-layer multi-point capacitive touch screen

ActiveCN102955633AImplement multi-touchInput/output processes for data processingElectrical connectionEngineering

Owner:CHIPONE TECH BEIJINGCO LTD

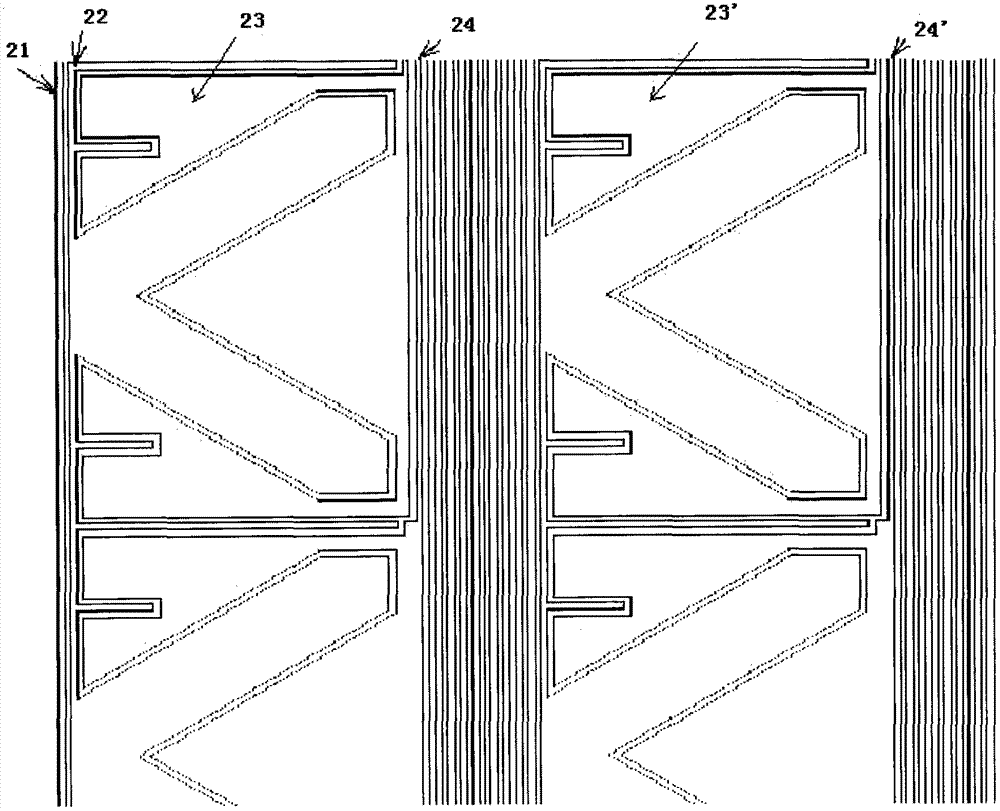

GF single-layer multi-touch frameless touch screen and preparation process thereof

ActiveCN105426014AImprove antiknock performanceReduce reflectionInput/output processes for data processingGlass coverEngineering

The invention relates to the technical field of touch screens, in particular to a GF single-layer multi-touch frameless touch screen and a preparation process thereof. The touch screen comprises a tempered glass cover plate, a transparent optical glue layer and an ITO conductive film, wherein the wiring area of an ITO conductive film frame comprises a transverse wiring area arranged at one end of the touch screen, single-layer multi-touch electrode patterns realizing single-end wiring are formed on the ITO conductive film, a FPC (flexible printed circuit) is pressed on the transverse wiring area, an outgoing line of the ITO conductive film is connected with an IC (integrated circuit) chip through the FPC, and the tempered glass cover plate is provided with an anti-explosion layer and an anti-reflective layer. According to the GF single-layer multi-touch frameless touch screen, the FPC is pressed on the transverse wiring area at one end of the touch screen, so that wires are not required to be arranged on longitudinal edges of the touch screen, and a flameless visual effect is realized; the GF single-layer multi-touch frameless touch screen has good photoelectric performance, stability and anti-explosion capacity, FPC pressing only needs to be performed once in the preparation process, the process is simple, the yield of products is high, and the good performance and the production stability of the touch screen can be guaranteed.

Owner:DONGGUAN PINGBO ELECTRONICS

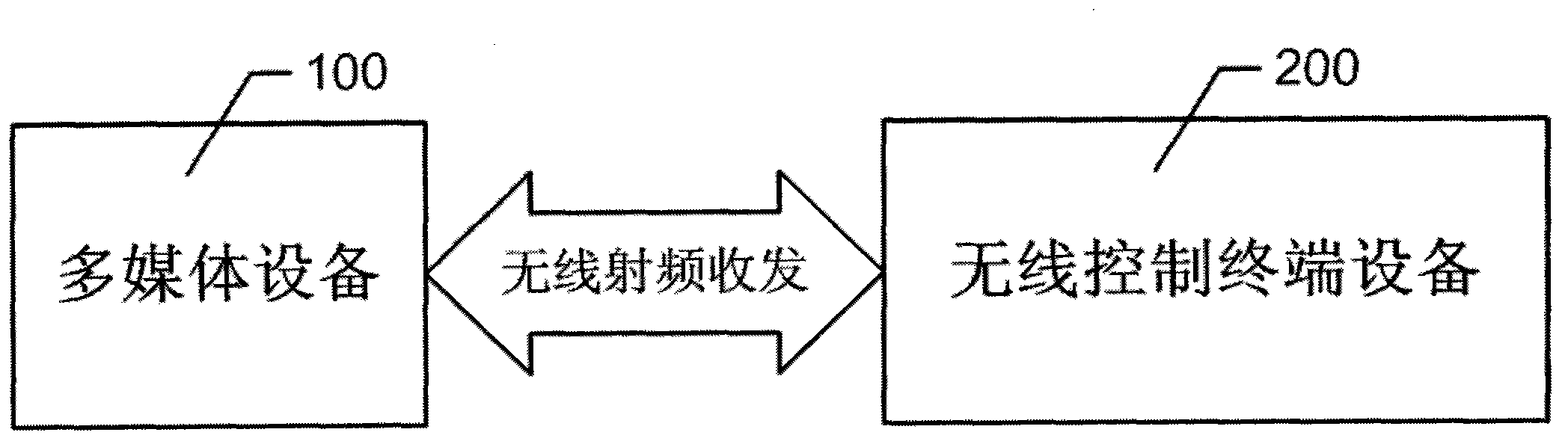

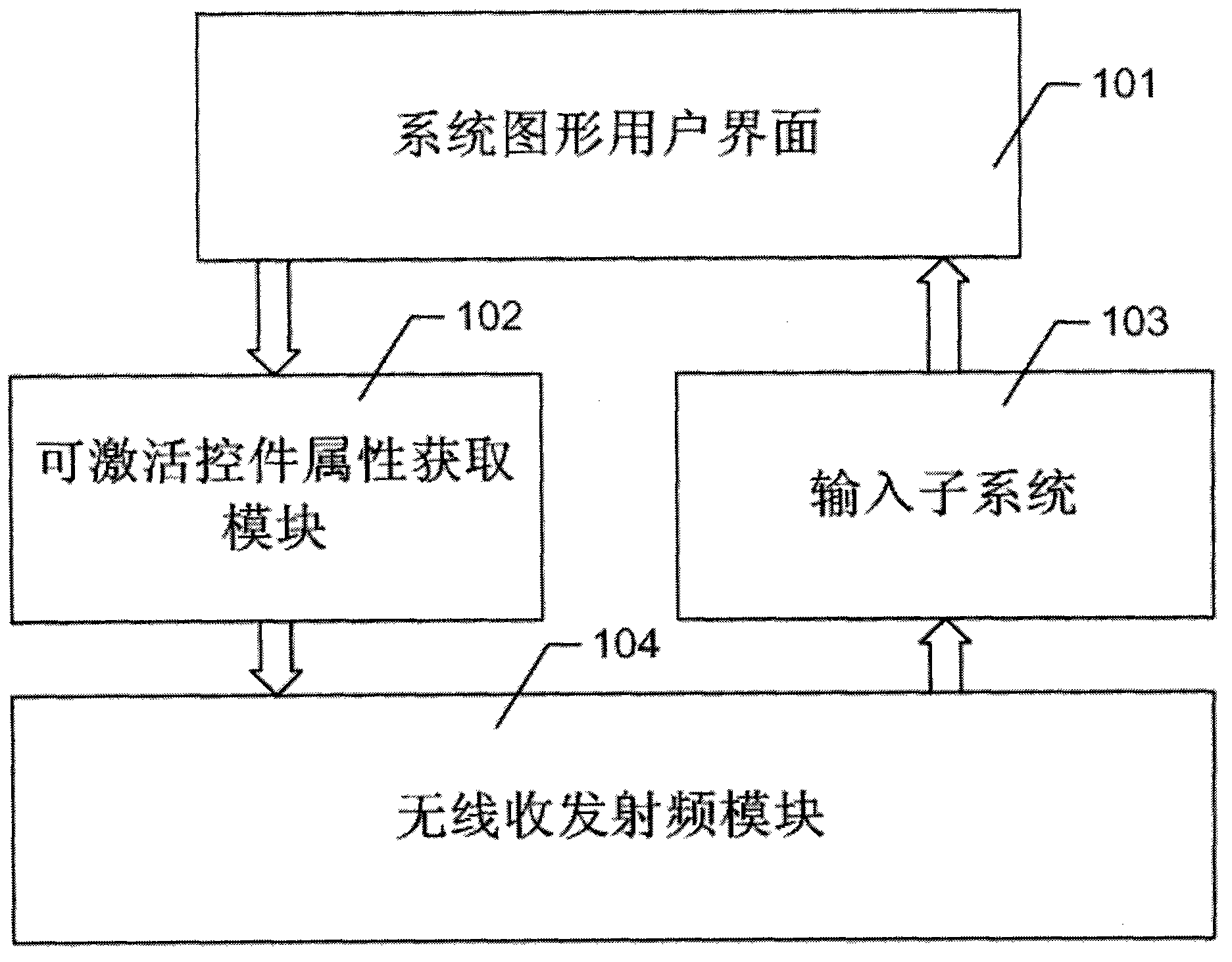

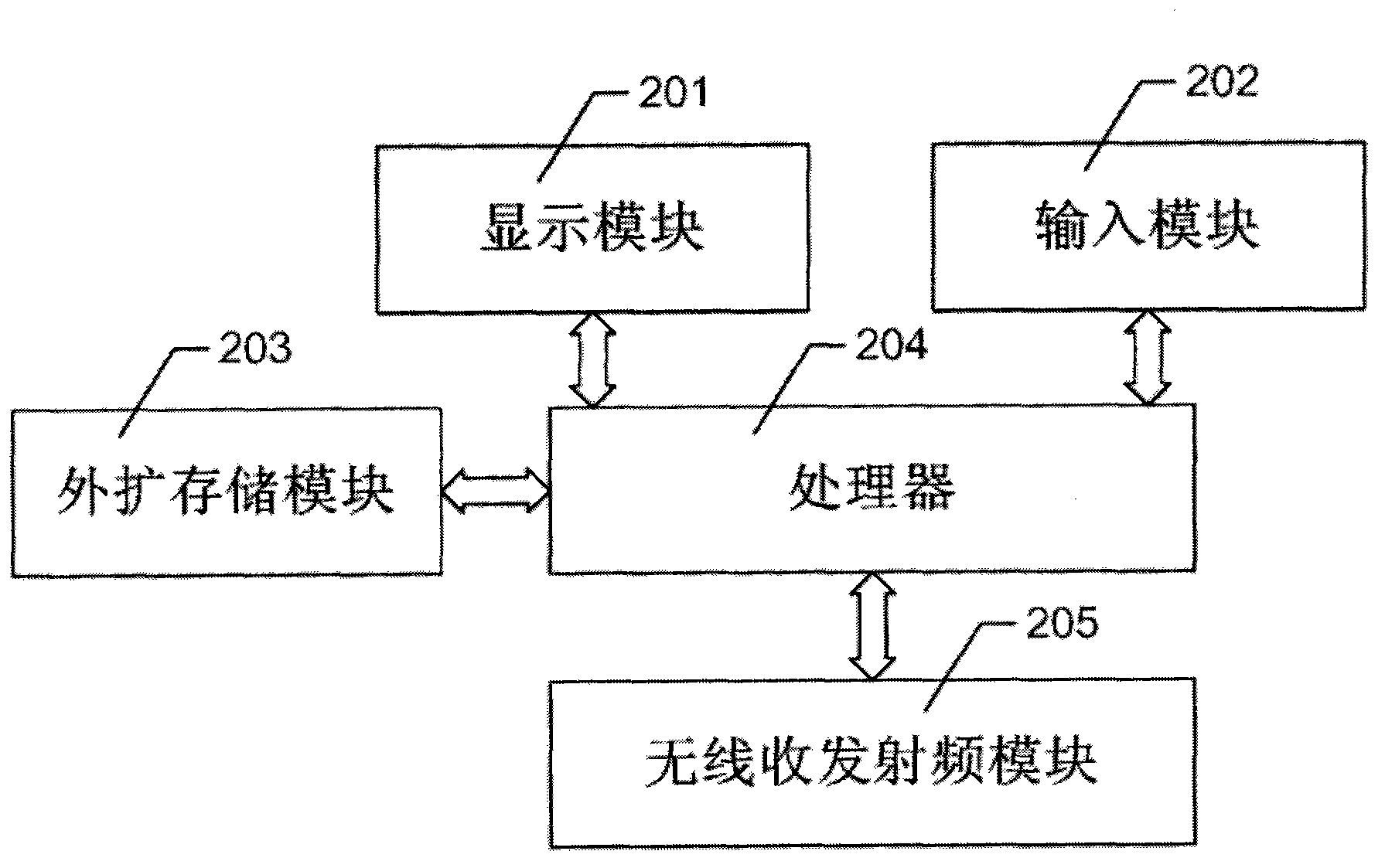

Wireless touch screen control system and menu dynamic generation method of wireless touch screen control system

InactiveCN103631406ASolve the costSolve operational problemsTransmission systemsInput/output processes for data processingWireless controlTouchscreen

The invention provides a wireless touch screen control system formed by a multimedia device and a wireless control terminal device. Wireless transmission and receiving of the wireless touch screen control system is achieved through a wireless module with low bandwidth and power consumption. The multimedia device comprises a system graphical user interface, an activated control property obtaining module, an input subsystem and a wireless transmission and receiving radio frequency module. The wireless control terminal device comprises a processor, an input module, a display module, an external expansion storage module and a wireless transmission and receiving radio frequency module, wherein the input module, the display module, the external expansion storage module and the wireless transmission and receiving radio frequency module are respectively in bothway data interaction with the processor. The invention further provides a menu dynamic generation method in the wireless touch screen control system, achieved assemblies on the system graphical user interface are simplified by the multimedia device, only the position coordinate information and the assembly names are transmitted to the wireless control terminal device, and the wireless control terminal device displays simplified graph prompting operation. The wireless touch screen control system and the menu dynamic generation method of the wireless touch screen control system are low in cost and power consumption, portable and high in transmission efficiency.

Owner:清远市智博网络资讯有限公司

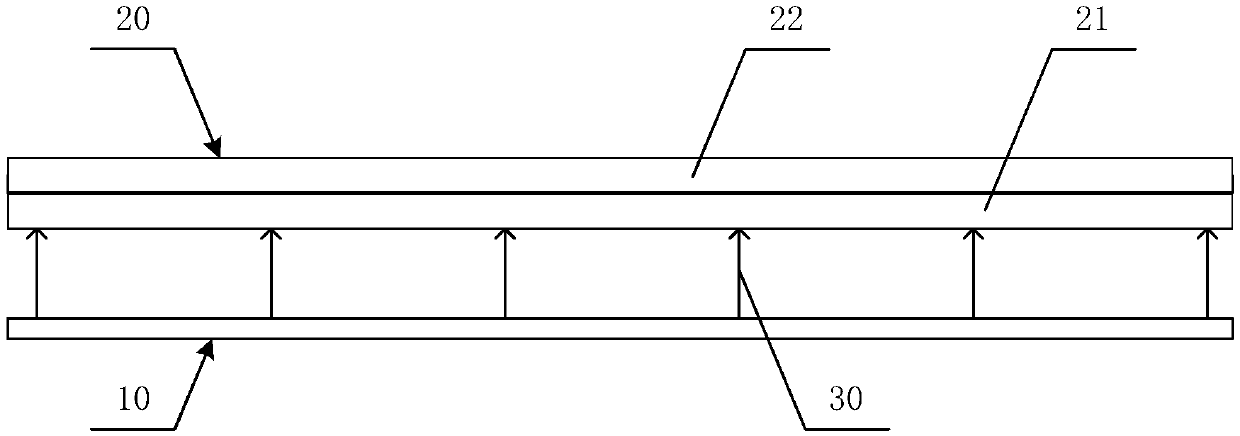

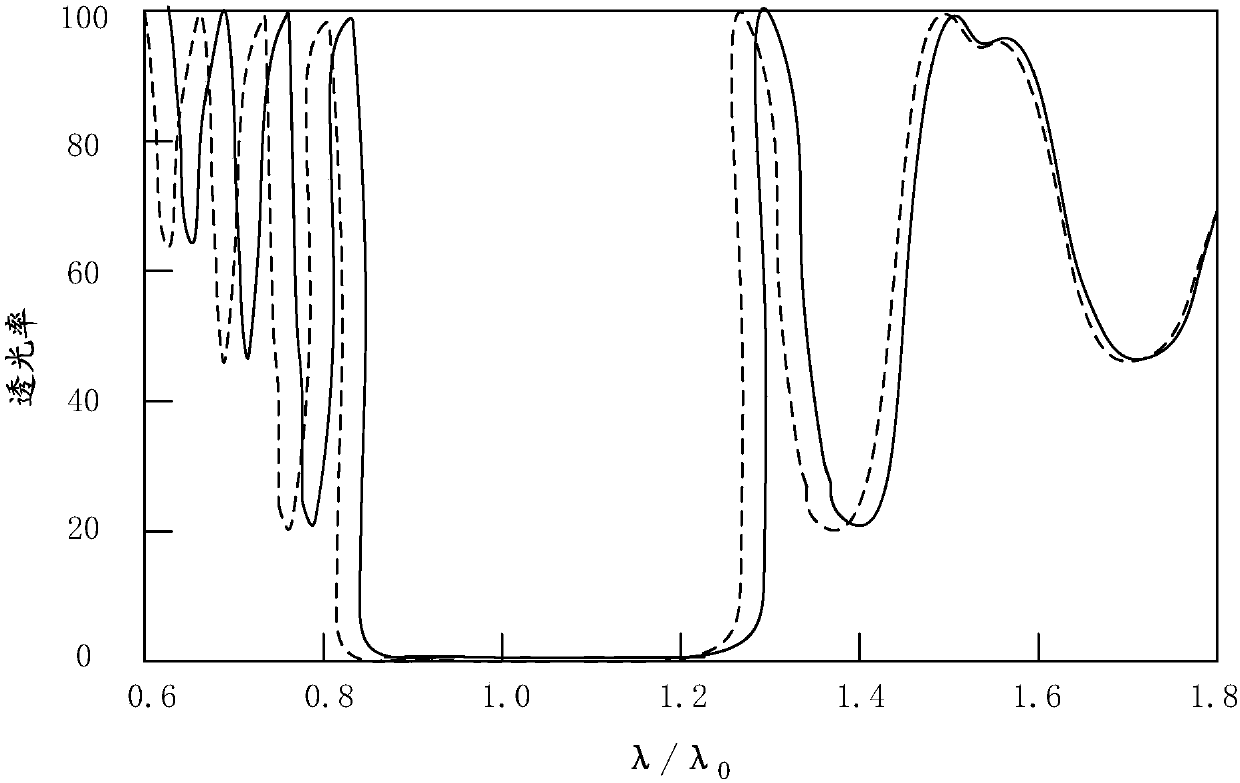

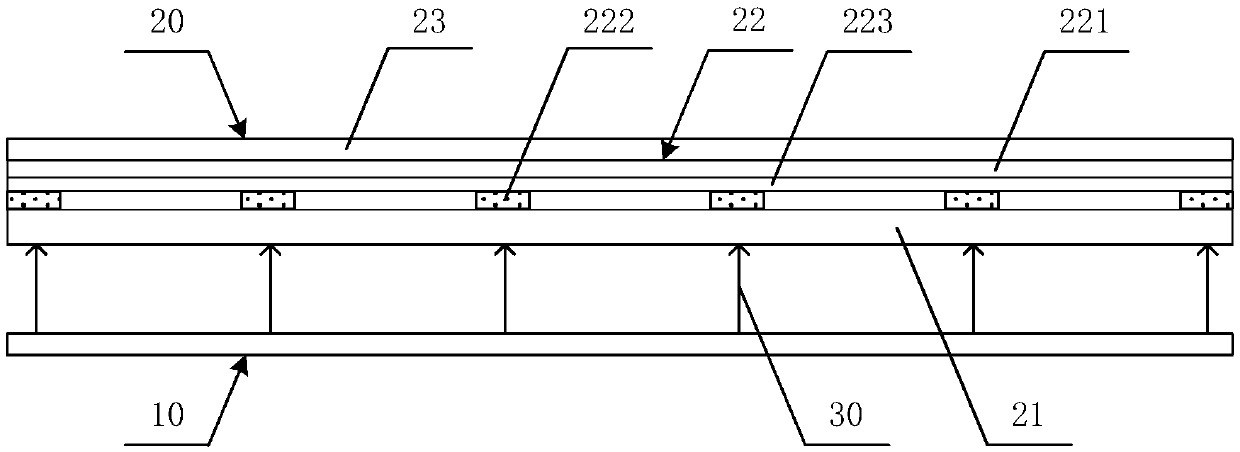

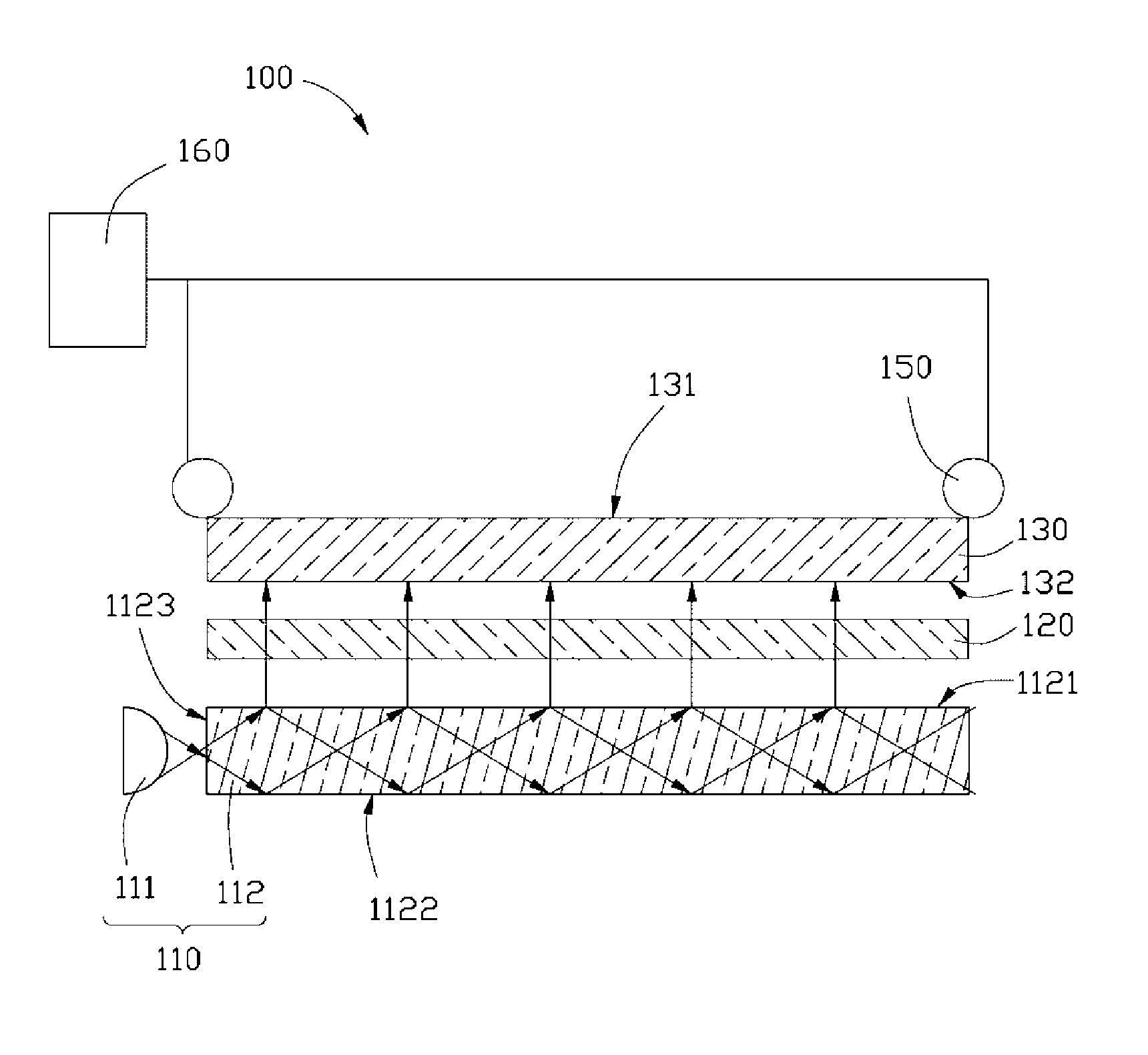

Infrared touch module and touch display device

InactiveCN107678602AReduce thicknessImprove anti-interference abilityNon-linear opticsInput/output processes for data processingInfraredDisplay device

The embodiment of the invention provides an infrared touch module and a touch display device. The infrared touch module comprises an infrared emitting unit and a touch structure unit of a layered structure, wherein the infrared emitting unit and the touch structure unit are arranged oppositely, the infrared emitting unit is used for emitting infrared rays, and the touch structure unit is used fordetermining a touch position by changing the transmittance of the infrared rays in case of touch. By the adoption of the layered structure, the thickness of the infrared touch module is effectively lowered, thinning is realized, and the infrared touch module and a display panel can form an ON-Cell or IN-Cell structure. Due to the fact that the infrared touch module determines the touch position bychanging the transmittance of the infrared rays at the touch position, multipoint touch can be realized. The embodiment effectively overcomes the defects that an existing infrared touch screen has large thickness and cannot realize multipoint touch.

Owner:BOE TECH GRP CO LTD +1

Touch device and detection method thereof

ActiveCN103513801AImplement multi-touchElectronic switchingInput/output processes for data processingSignal onControl area

The invention discloses a touch device and a detection method of the touch device. The touch device comprises a plurality of piezoelectric induction units and a plurality of signal wires, wherein the piezoelectric induction units are arrayed in a touch control area of a substrate, and the signal wires are located on the substrate and electrically connected with the piezoelectric induction units. According to the touch device, mechanical deformation can be transformed to electrical signals, signals on the touch device can be detected without additional driving voltage, and therefore the touch device is low in energy consumption and capable of saving energy.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

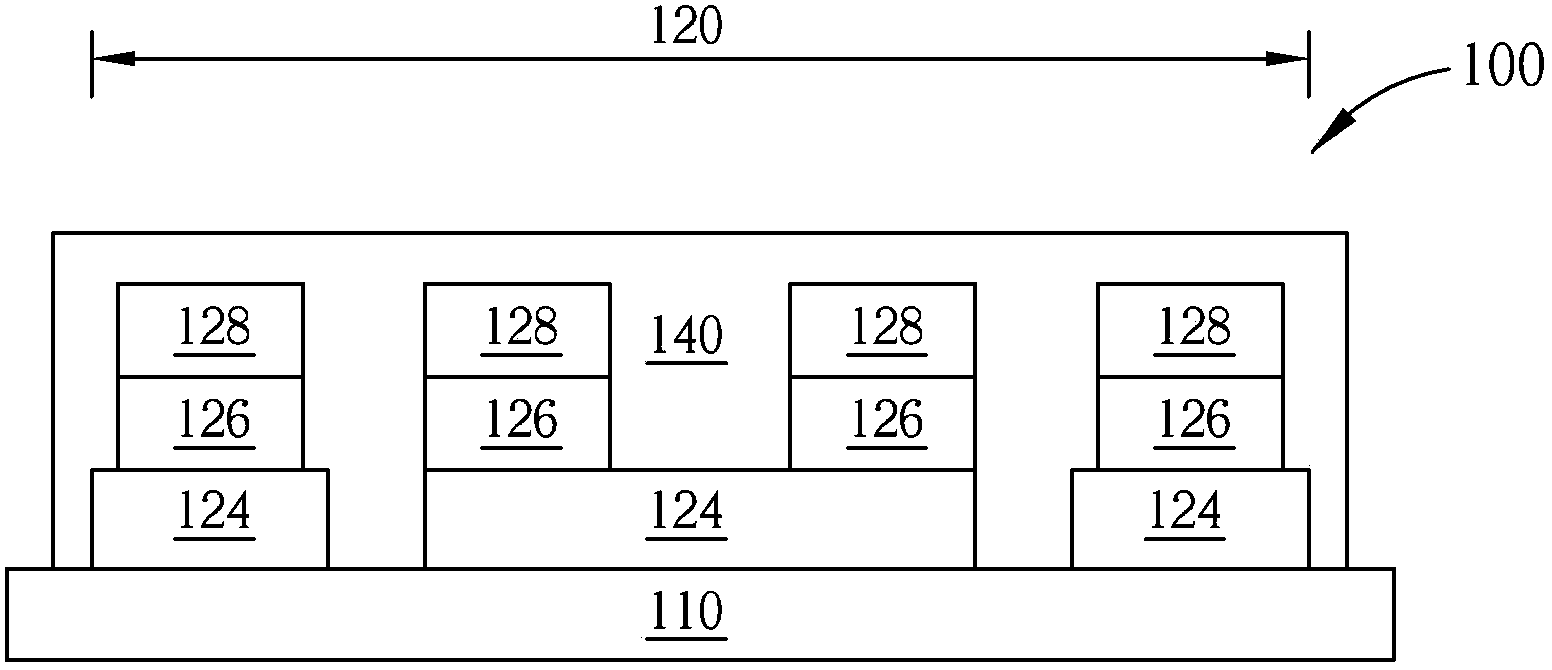

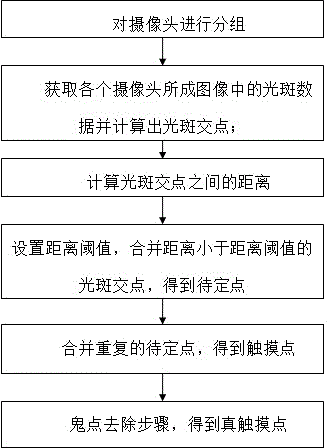

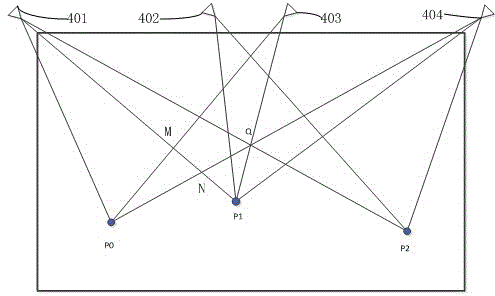

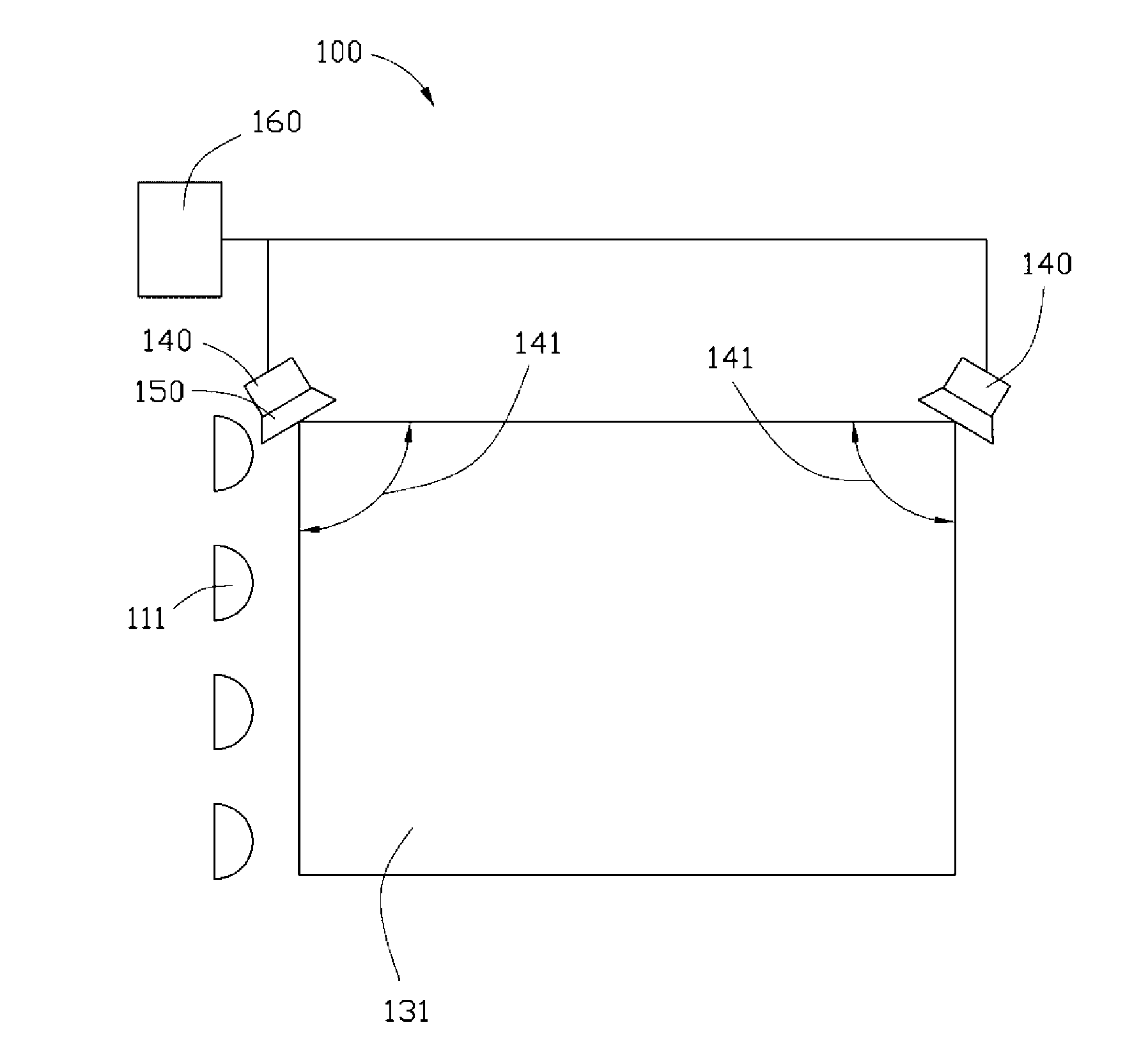

Touch screen multi-point touch control method and device for front positioning of cameras

InactiveCN102622137AImprove recognitionImplement multi-touchInput/output processes for data processingLight sourceComputer graphics (images)

The invention relates to the technical field of optic touch control, particularly to a touch screen multi-point touch control method and a device for front positioning of cameras. Cameras are respectively mounted at the left and the right corners of the upper edge frame of the positioning frame of a touch screen, two cameras shooting in the opposite directions are mounted in the middle of the upper edge frame, infrared light sources are respectively mounted on the left edge frame, the right edge frame and the lower edge frame of the positioning frame respectively, and the method comprises the following steps: acquiring light spot data in images of the cameras and calculating the light spot intersections; calculating the distance between the light spot intersections; arranging a distance threshold value and merging light spot intersections with distances smaller than the threshold value to obtain points to be located; and merging repeated points to be located to obtain touch points. According to the invention, real touch points and false touch points can be judged accurately, the resolution of the touch points is improved greatly, and the multi-point touch control in the technical field of front positioning of the cameras is achieved.

Owner:GUANGDONG VTRON TECH CO LTD

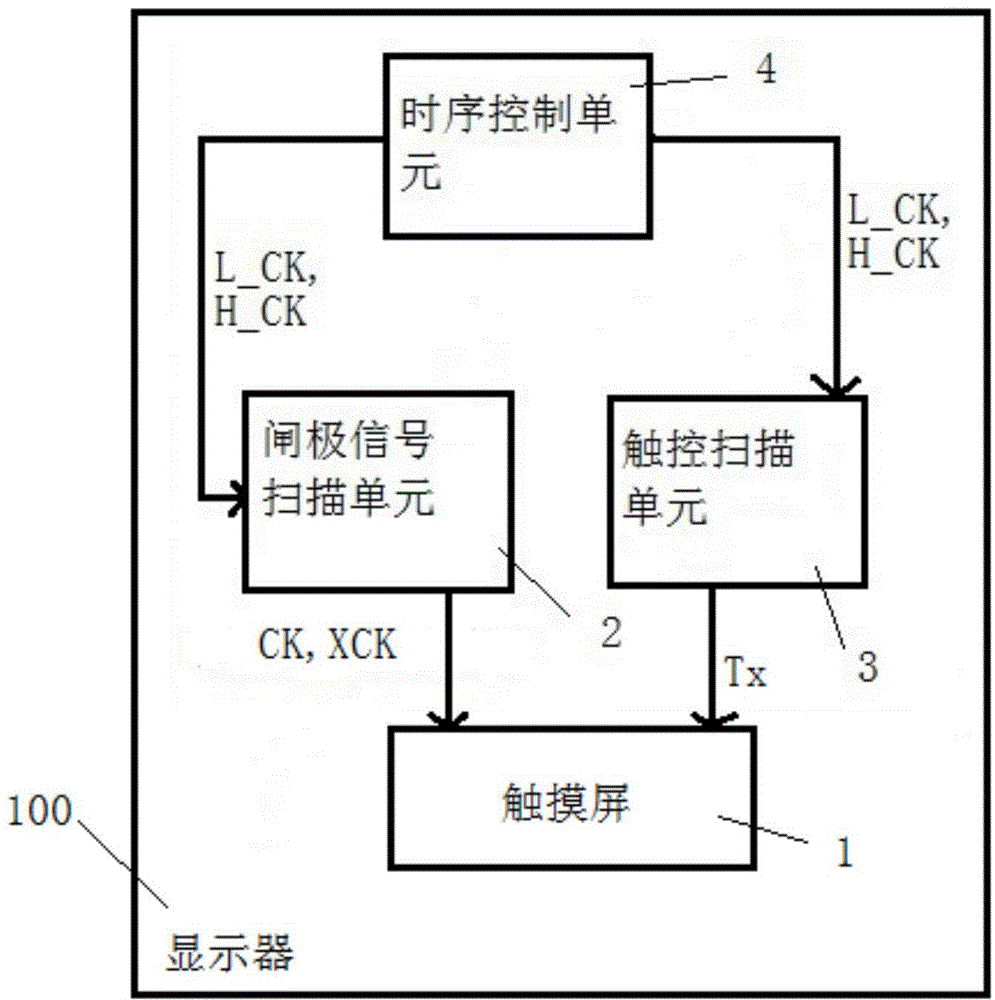

Display used for controlling gate drive timing sequence and corresponding control method

InactiveCN104992684AInconsistent scan frequencyIncrease scan frequencyStatic indicating devicesSequence controlDisplay device

The invention provides a display used for controlling the gate drive timing sequence, comprising a touch screen, a gate drive signal sending unit, a touch scanning unit, and a timing sequence control unit. The gate drive signal sending unit is used to send more than one gate drive signal. The touch scanning unit is used to send a touch scanning signal. The timing sequence control unit is connected with the gate drive signal sending unit and the touch scanning unit, and is used to control a timing sequence of the gate drive signals and adjust the timing sequence of the touch scanning signal according to the timing sequence of the gate drive signals.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

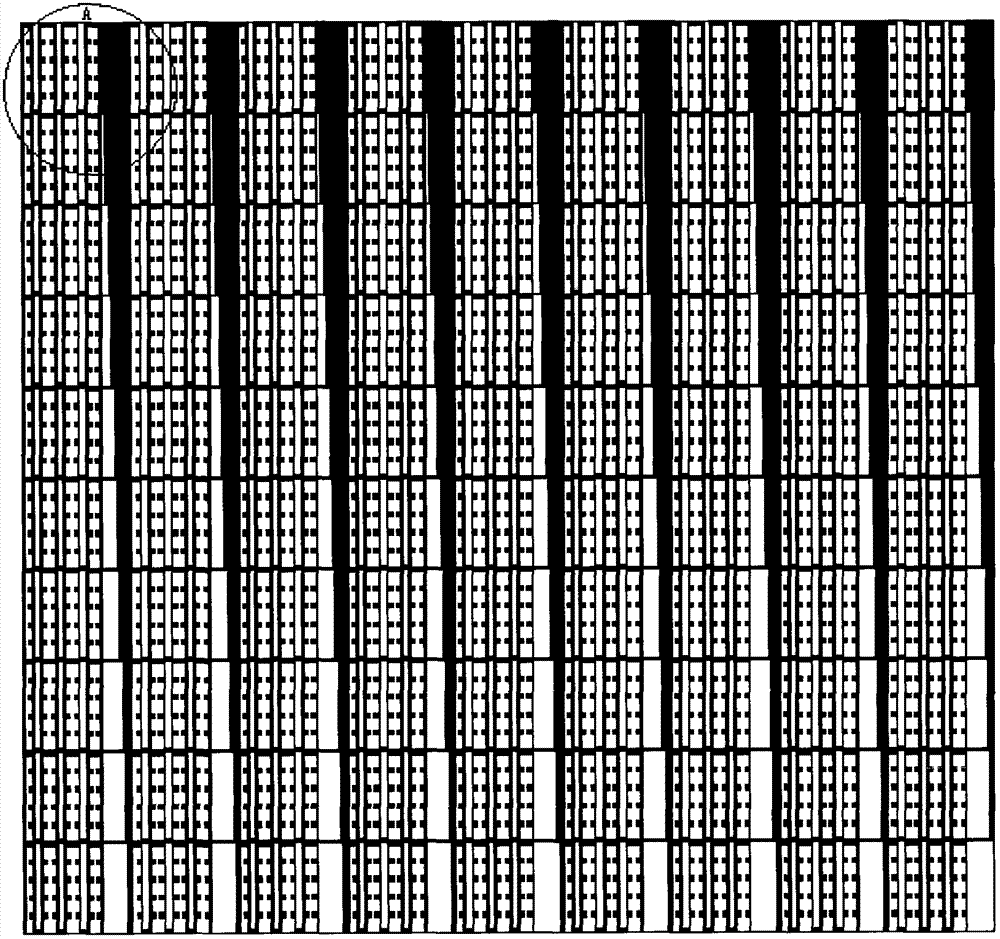

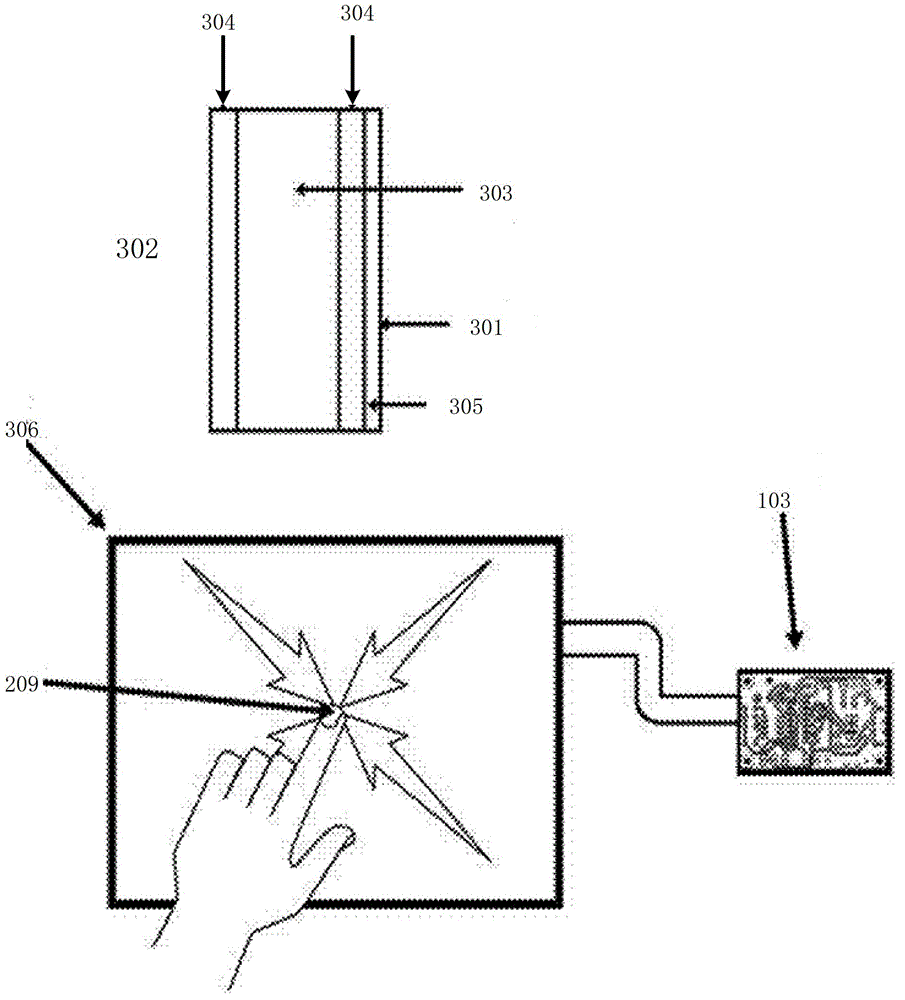

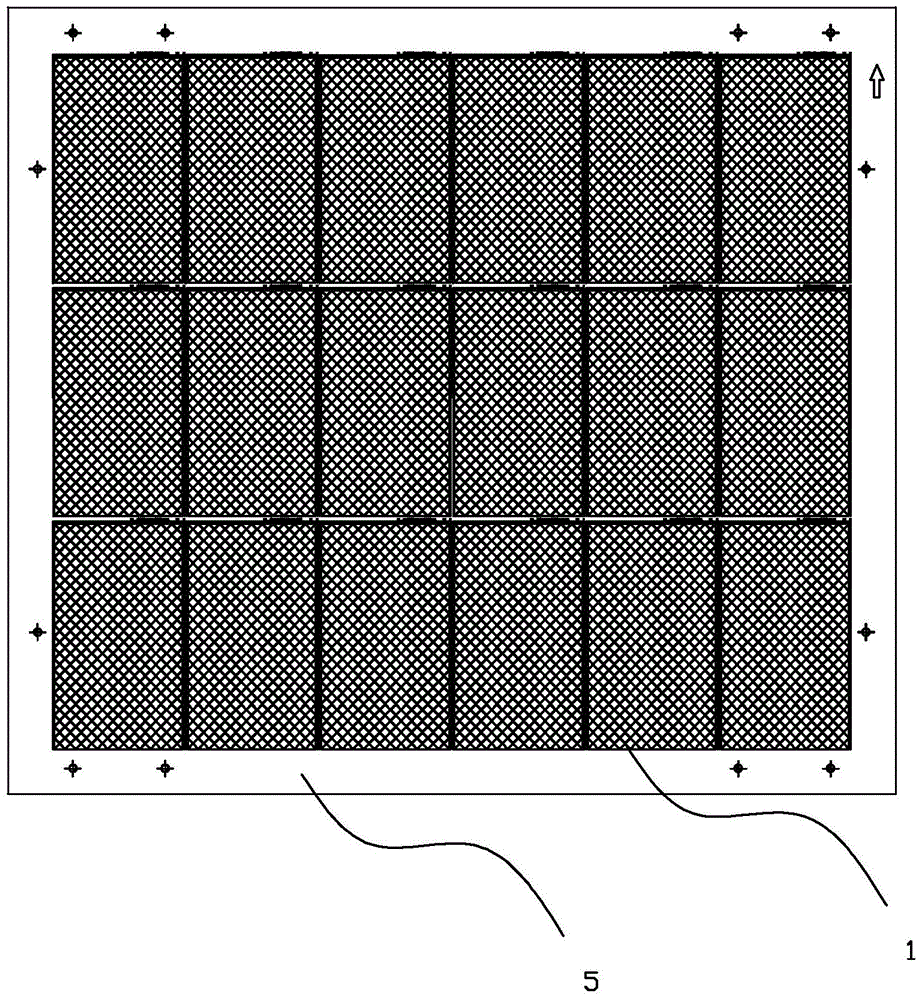

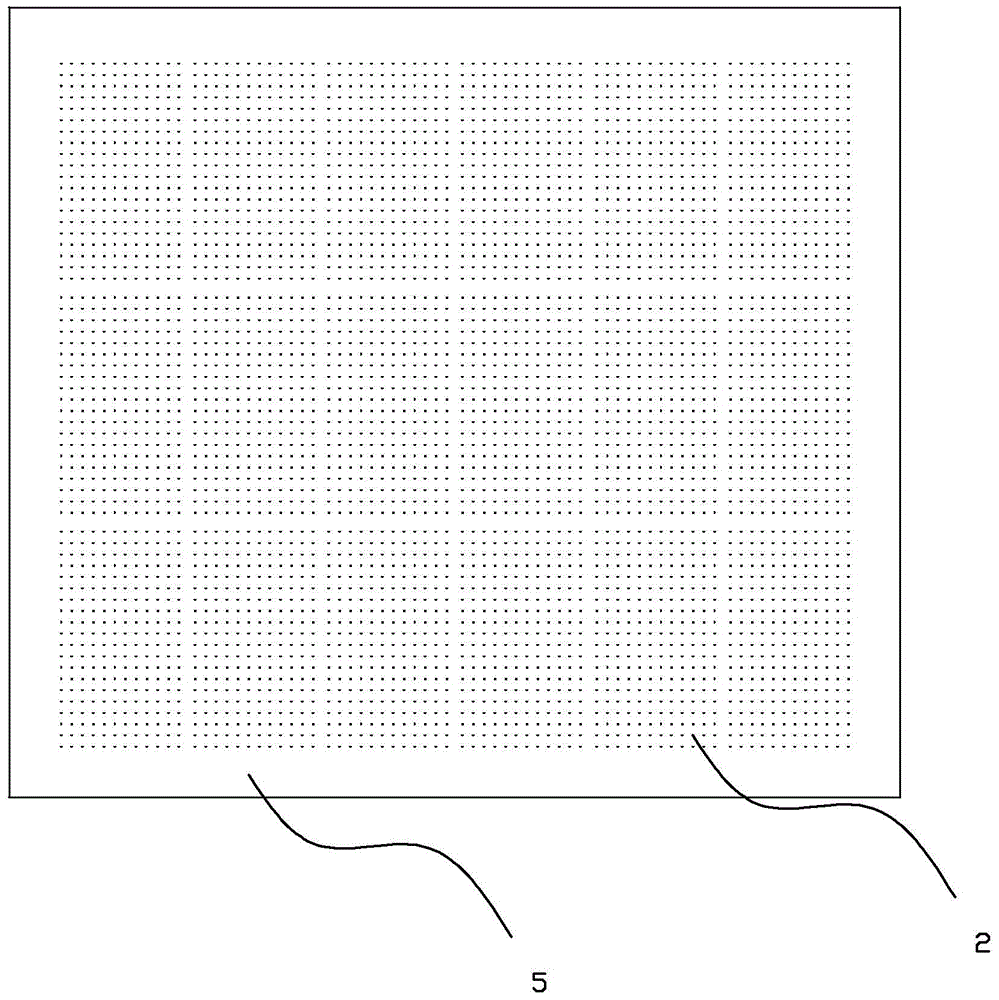

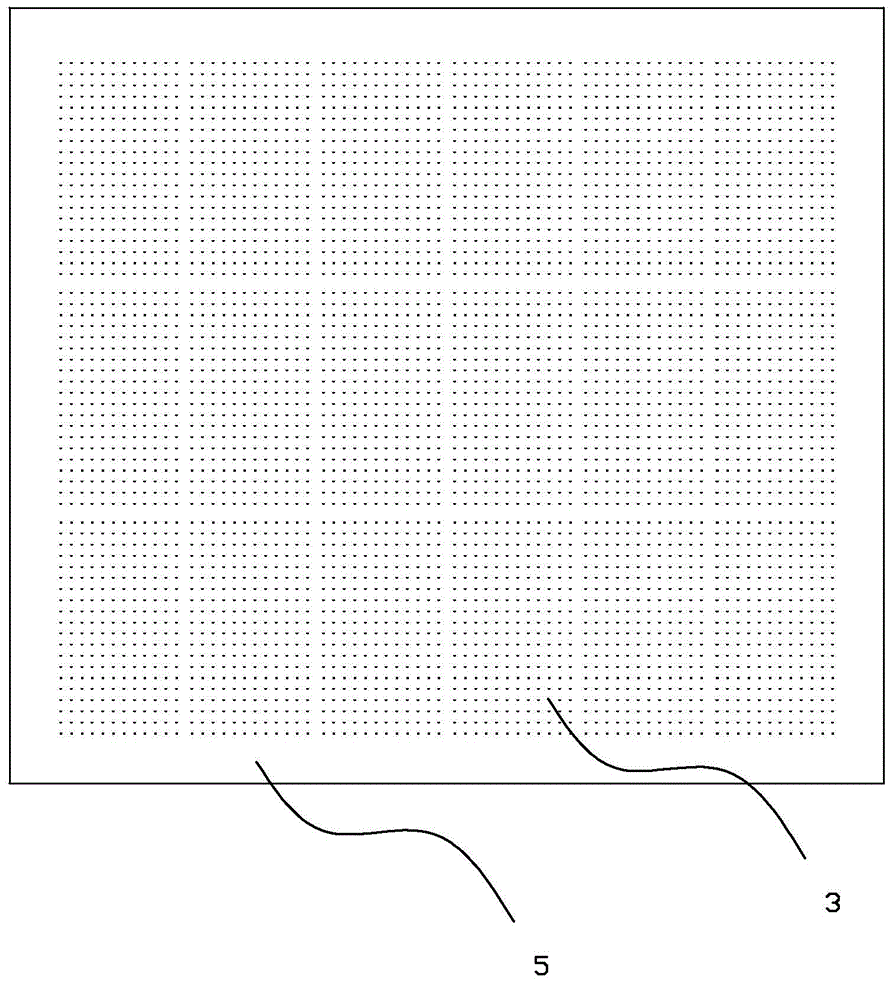

Manufacturing process of multi-point touch single-layer film touch sensor

InactiveCN103914199AReduce configurationSave configuration spaceInput/output processes for data processingChemical solutionAdhesive

The invention relates to a manufacturing process of a multi-point touch single-layer film touch sensor. The process is based on a three-dimensional (3D) printing process to perform layering printing on functional images of the sensor by starting from the bottom layer and overlaying the images layer by layer; after the functional images are formed, the functional images are glued to optical adhesive to be subjected to de-foaming, cutting and forming, and the manufacturing process of the multi-point touch single-layer film touch sensor can be achieved. The manufacturing process of the multi-point touch single-layer film touch sensor has the advantages that the process is single, configuration space of a factory is small, a single 3D printer device is merely required, personnel allocation is small, and producing costs are sharply reduced; the utilization ratio of raw materials is high, and consumables are used for solid printing of functional zone patterns by nearly 100%; proofing can be rapidly achieved, and the production cycle is shortened; the production line is quite short, deficient manufacturing procedure factors are few, and the product yield of the manufacturing process is higher than that of traditional processes; chemical solution treatment is absent, and producing costs are further lowered compared with those of the traditional processes; different dots per inch (dpi), each layer film thickness and the number of layers are set on a 3D printer to manufacture electrode patterns with different impedances.

Owner:FUJIAN BAOFA PHOTOELECTRIC TECH

Touch type input device

InactiveCN101923417ATouch input implementationImplement multi-touchInput/output processes for data processingPolarizerStress sensing

The invention provides a touch type input device comprising an infrared light supply module, a first polaroid, a stress sensing chip, at least one second polaroid, at least one infrared camera and an image processor, wherein the infrared light supply module, the first polaroid and the stress sensing chip are sequentially arranged close to each other; the stress sensing chip is arranged between the first polaroid and the second polaroid and is used for internally generating stress when touched, therefore first polarized light generates double refraction when passing through the stress sensing chip and then is emitted; the polarization direction of the second polaroid is perpendicular to the polarization direction of the first polaroid; the infrared camera is used for acquiring an interference fringe image generated by the stress sensing chip due to stress through the second polaroid, and the image processor is connected with the infrared camera and used for receiving and processing theinterference fringe image acquired by the infrared camera to judge the touched position and touch loci of the stress sensing chip.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

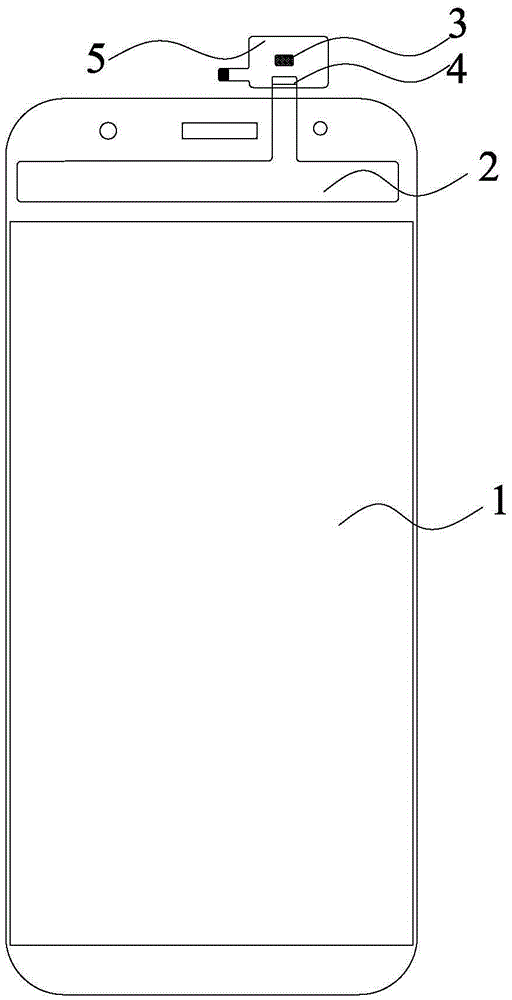

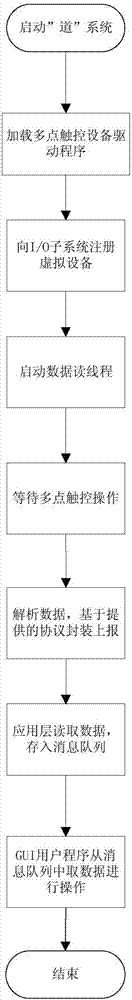

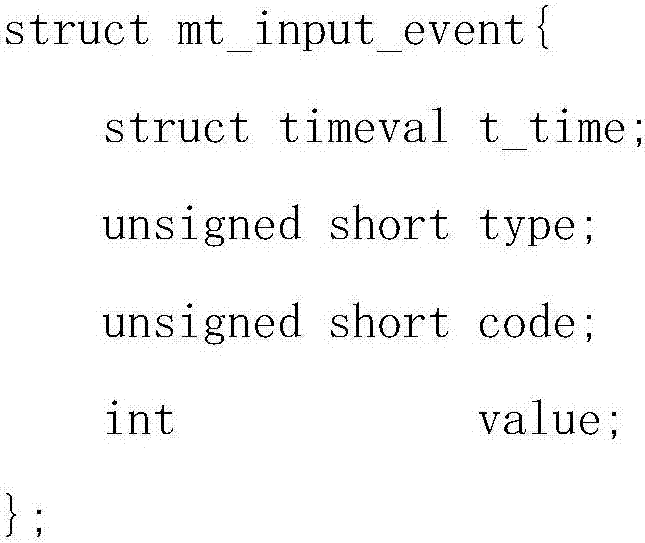

Implementation method for multipoint touch under "channel" system

ActiveCN106896956AImplement multi-touchProgram loading/initiatingExecution for user interfacesCommunications protocolHuman–computer interaction

The invention discloses an implementation method for multipoint touch under a "channel" system. A data processing interlayer is provided on a multipoint touch screen driving program of the "channel" system. The method is used for completing the tasks that (1) a virtual device is registered to an I / O subsystem of an operating system, and switch-on operation, data reading operation and switch-off operation of the virtual device are all linked to an actual multipoint touch screen; (2) a data receiving thread is created, multipoint touch operation is waited for, and data generated by the received multipoint touch operation is analyzed; and (3) the analyzed data is repackaged and reported to an application layer according to a communication protocol provided by the data processing interlayer for a GUI layer user program to read, analyze and process. Through the method, multipoint touch of the touch screen of any data interface under the "channel" system can be realized, and any GUI user program (such as QT) can make a response to the multipoint touch operation just by observing the agreed protocol.

Owner:CHANGSHA XIANGJI HAIDUN TECH CO LTD

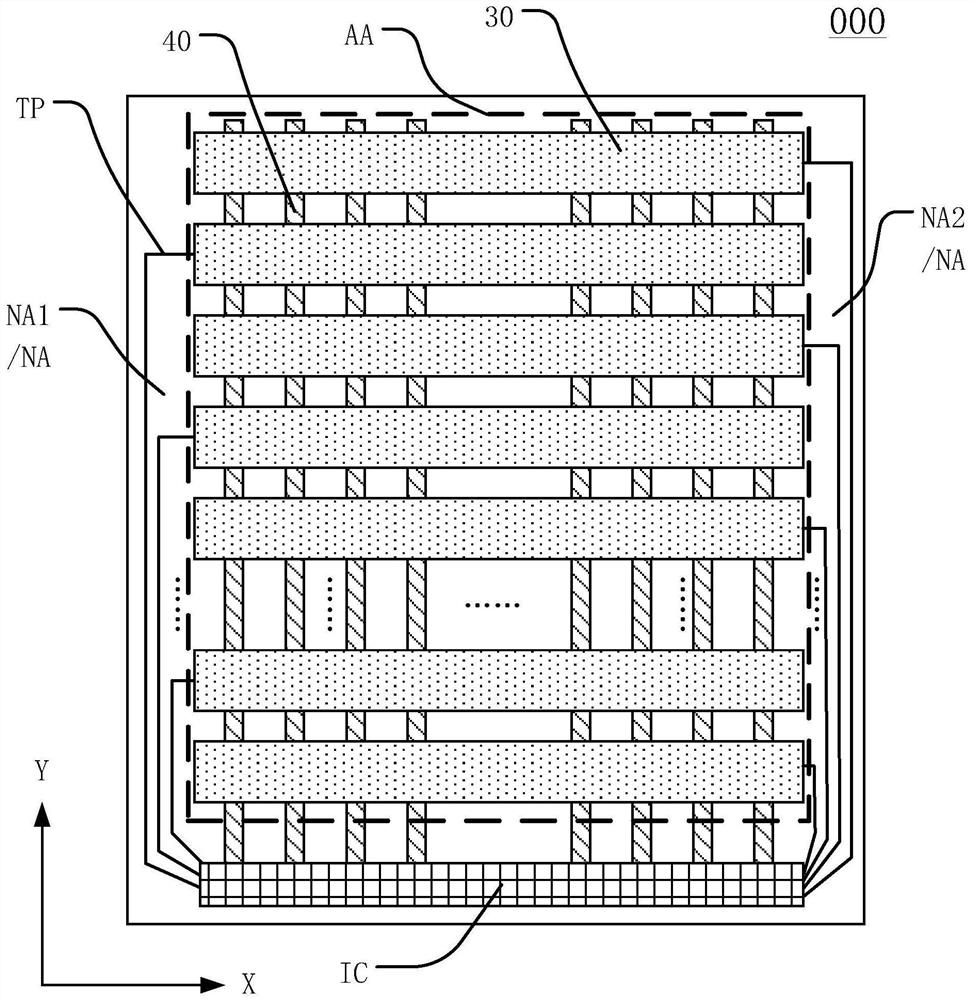

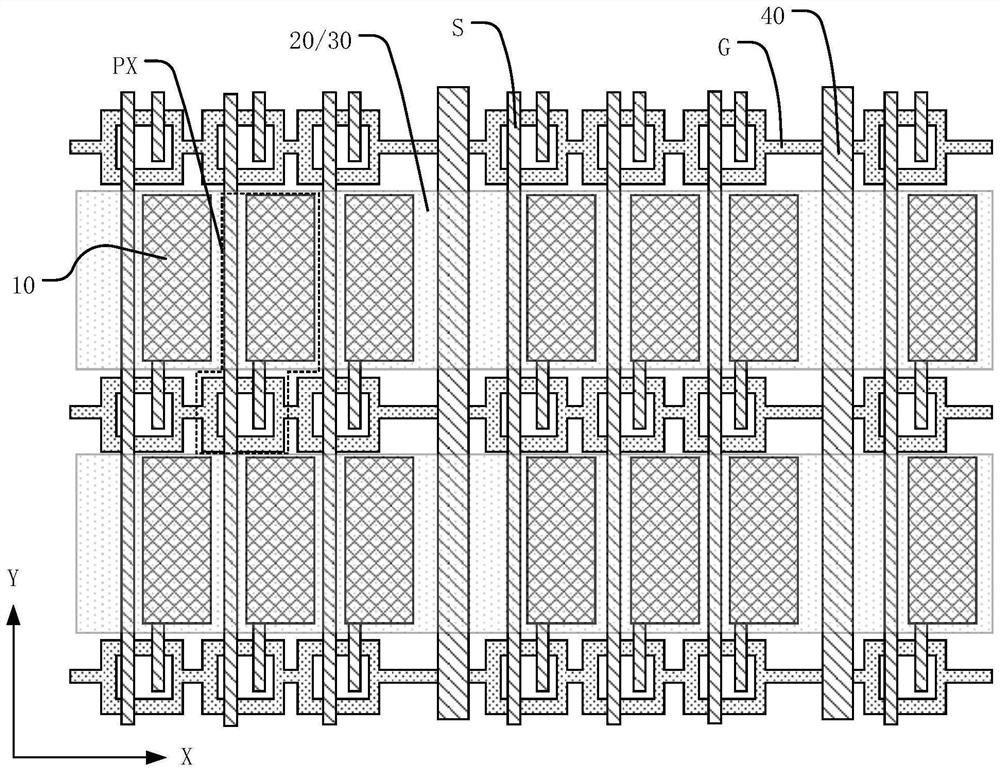

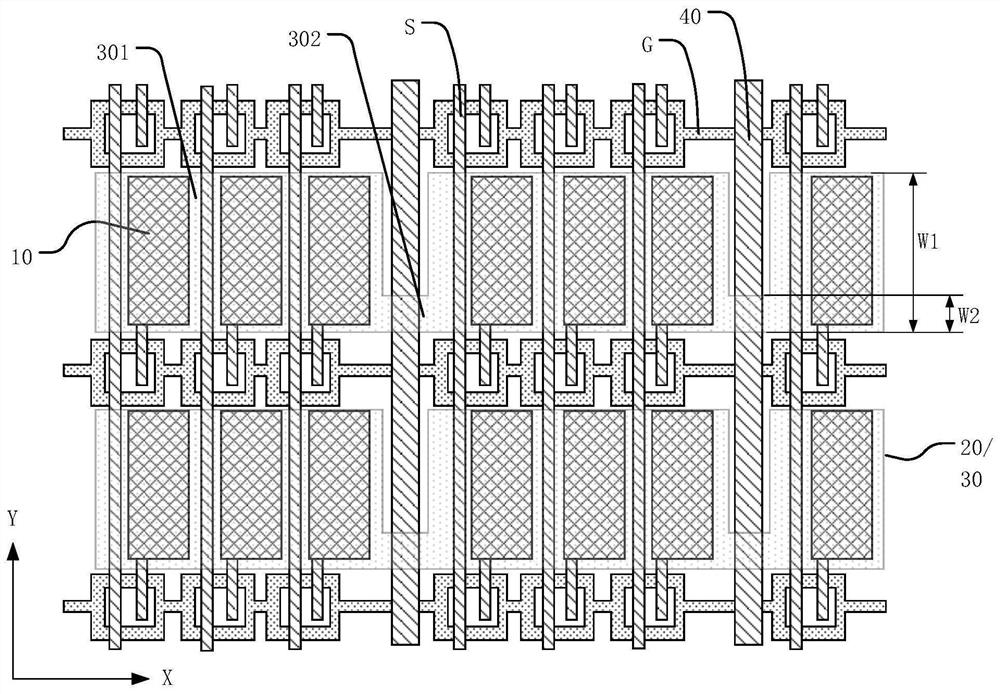

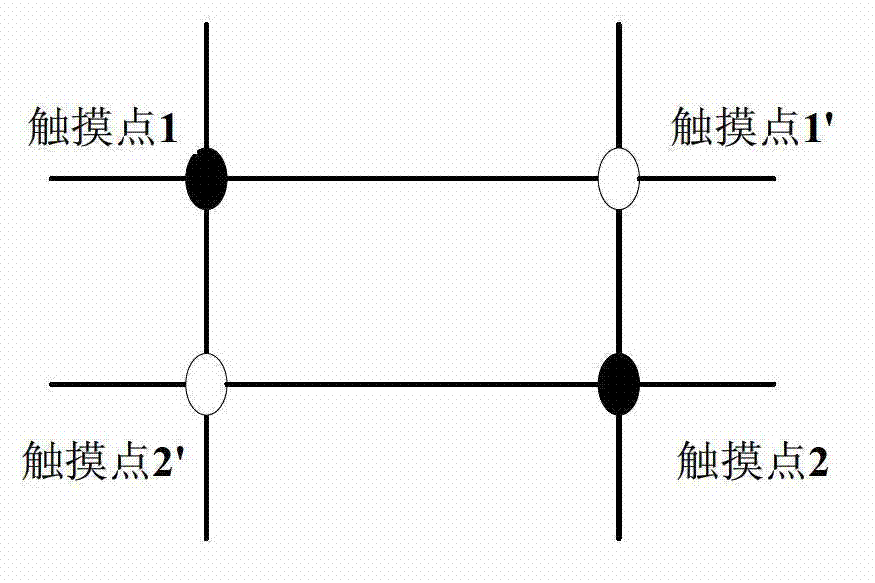

Display panel and display device

ActiveCN113282187AImprove touch sensitivityRealize the touch effectInput/output processes for data processingComputational physicsImage resolution

The invention discloses a display panel and a display device, and belongs to the technical field of display, the display panel comprises a plurality of scanning lines, a plurality of data lines and a plurality of sub-pixels, and each sub-pixel at least comprises a pixel electrode and a common electrode; the display area comprises a plurality of first touch electrodes and a plurality of second touch electrodes, the first touch electrodes multiplex the common electrodes, and the second touch electrodes are located between the adjacent sub-pixels in the first direction; at least part of the first touch electrode wire is located in the first non-display area, and the rest part of the first touch electrode wire is located in the second non-display area; the first touch electrodes are electrically connected with the driving chip through the first touch electrode wires, and the second touch electrodes are electrically connected with the driving chip. The display device comprises the display panel. According to the display panel, the number of the touch wires arranged in the display area can be reduced, the touch effect of high resolution and high touch sensitivity can be achieved, the lower frame of the display panel can be reduced, and the narrow frame design of the display panel is achieved.

Owner:SHANGHAI AVIC OPTOELECTRONICS

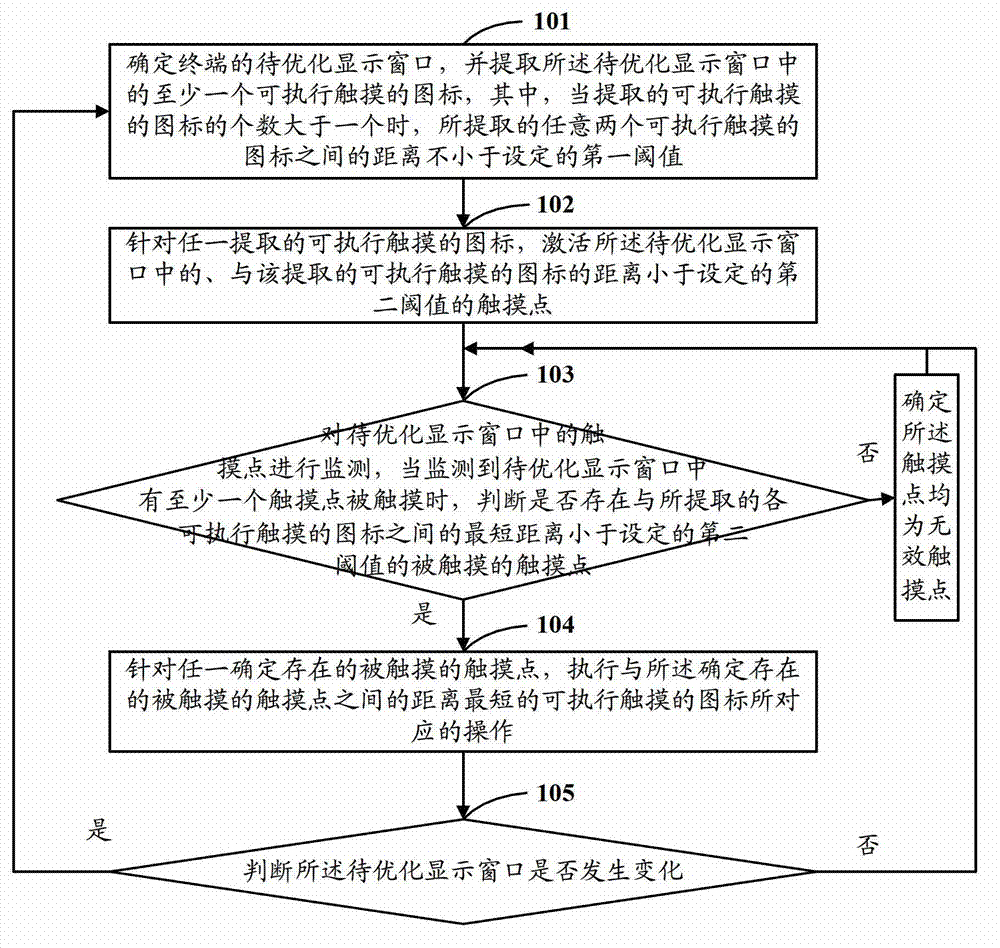

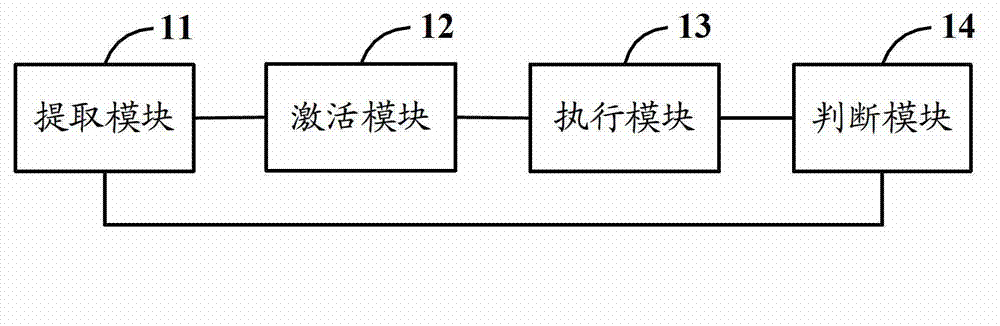

Method and device for achieving self-adaptive touch detection of touch screen

InactiveCN103092444AReduce computational complexityImplement multi-touchInput/output processes for data processingShortest distanceTouchscreen

The invention discloses a method and a device for achieving self-adaptive touch detection of a touch screen. The method includes: extracting at least one touch-executable icon in a display window to be optimized, wherein the distance between any two touch-executable icons is larger than or equal to a set first threshold value, and respectively activating the touch points, wherein the distance between each touch point and each extracted touch-executable icon is smaller than a set second threshold value; and when the situation that at least one touch point is touched in the display window to be optimized is monitored, and the existence of the touch point is confirmed, wherein the shortest distance between the touch point and each extracted touch-executable icon is smaller than the set second threshold value, executing the operation corresponding to the touch-executable icon, wherein the distance between the touch-executable icon and each existence-confirmed touched touch points is shortest. Due to the scheme, on the premise that partial touch points can be activated, multi-touch is achieved, and the effect that computational complexity of the touch screen is reduced can be achieved.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Anti-interference multipoint capacitance touch-control membrane system

InactiveCN104063106AAccurate measurementNot affectedInput/output processes for data processingCapacitanceInterference resistance

The invention discloses an anti-interference multipoint capacitance touch-control membrane system which comprises a multipoint capacitance touch-control membrane and a measuring circuit board, wherein the multipoint capacitance touch-control membrane is connected with the measuring circuit board through a flexible printed circuit board; the measuring circuit board is connected with a computer through a USB (Universal Serial Bus) line; two layers of PET membranes are arranged as the substrates of the multipoint capacitance touch-control membrane; a plurality of nanometer leads are uniformly distributed between the two layers of PET membranes along X and Y directions; the measuring circuit board is composed of a high-precision measuring module, a measuring module shielding shell, a high-speed USB module and a USB power filtering module. The anti-interference multipoint capacitance touch-control membrane system has the characteristics of multipoint touch control, strong anti-interference property, strong instantaneity, high communication rate, and the like.

Owner:SUZHOU TOUCH PLANET ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com