Patents

Literature

174results about How to "Save configuration space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

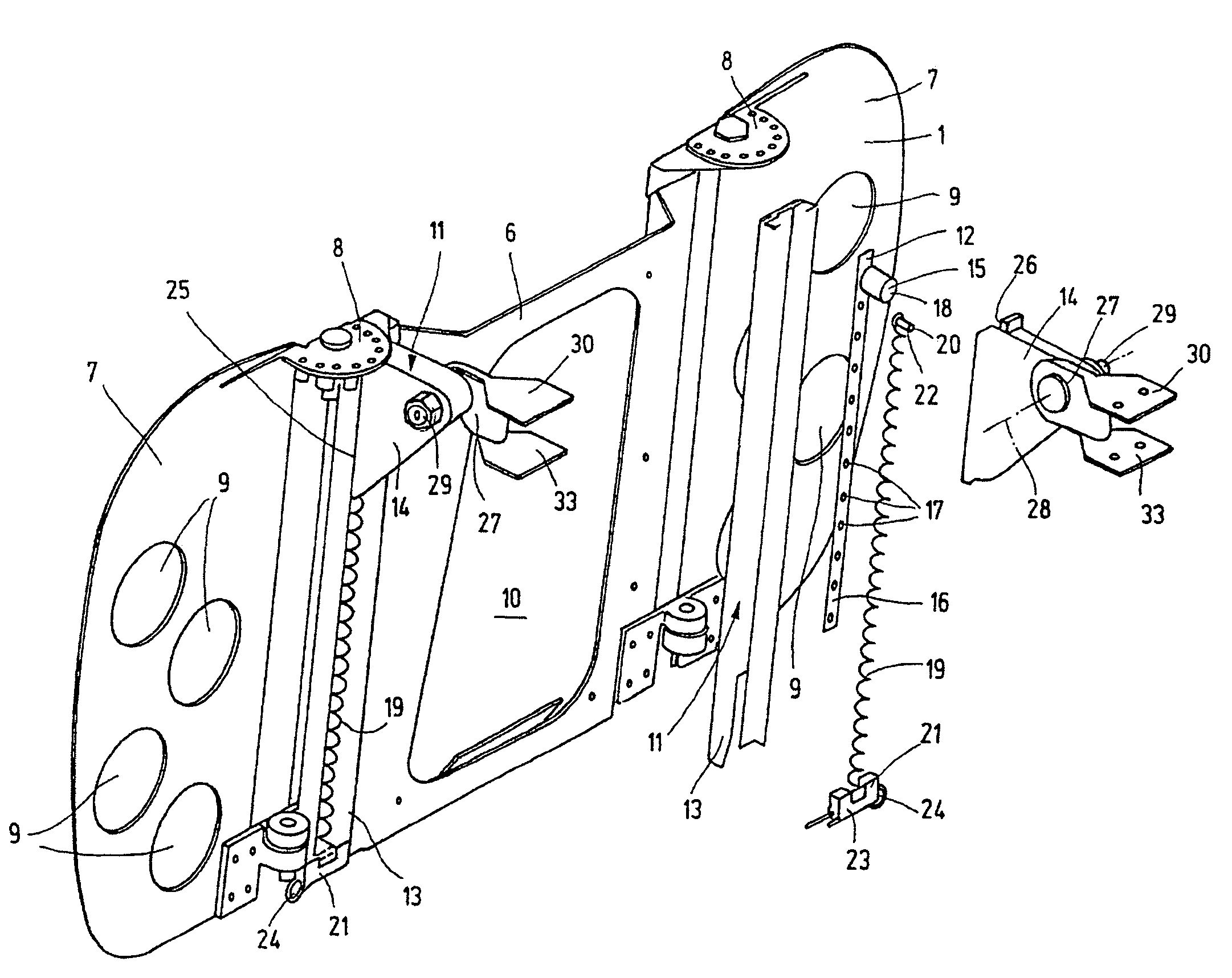

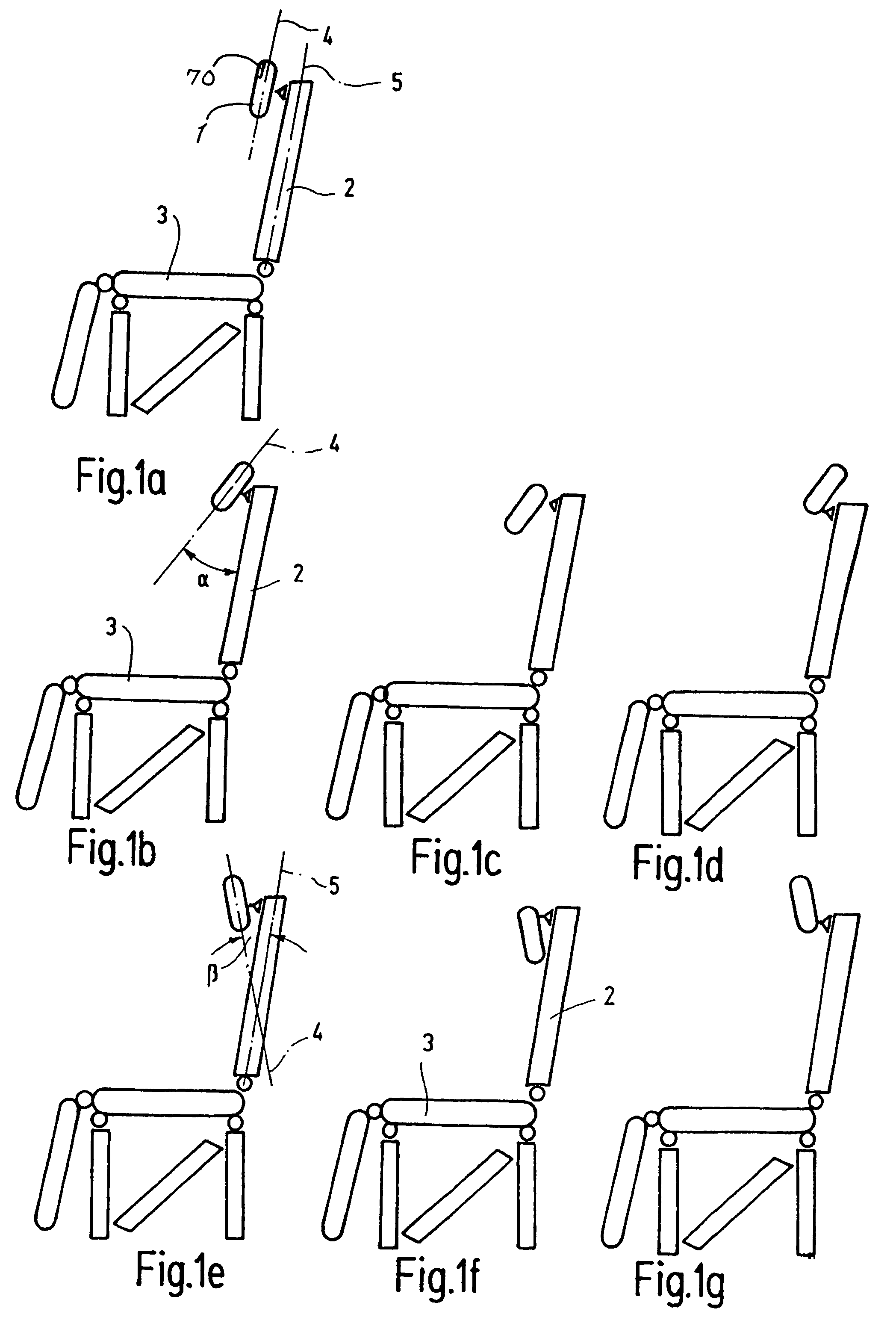

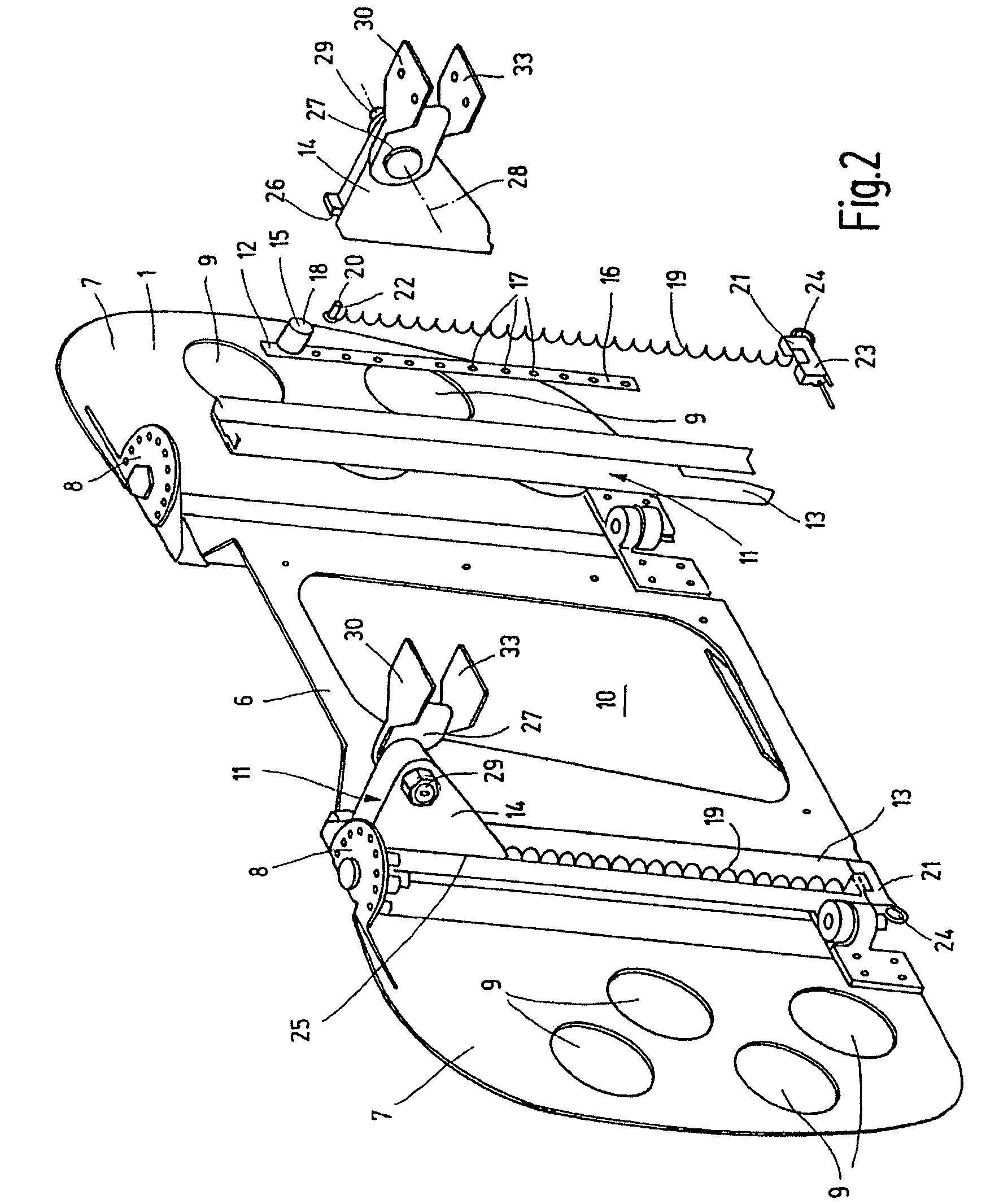

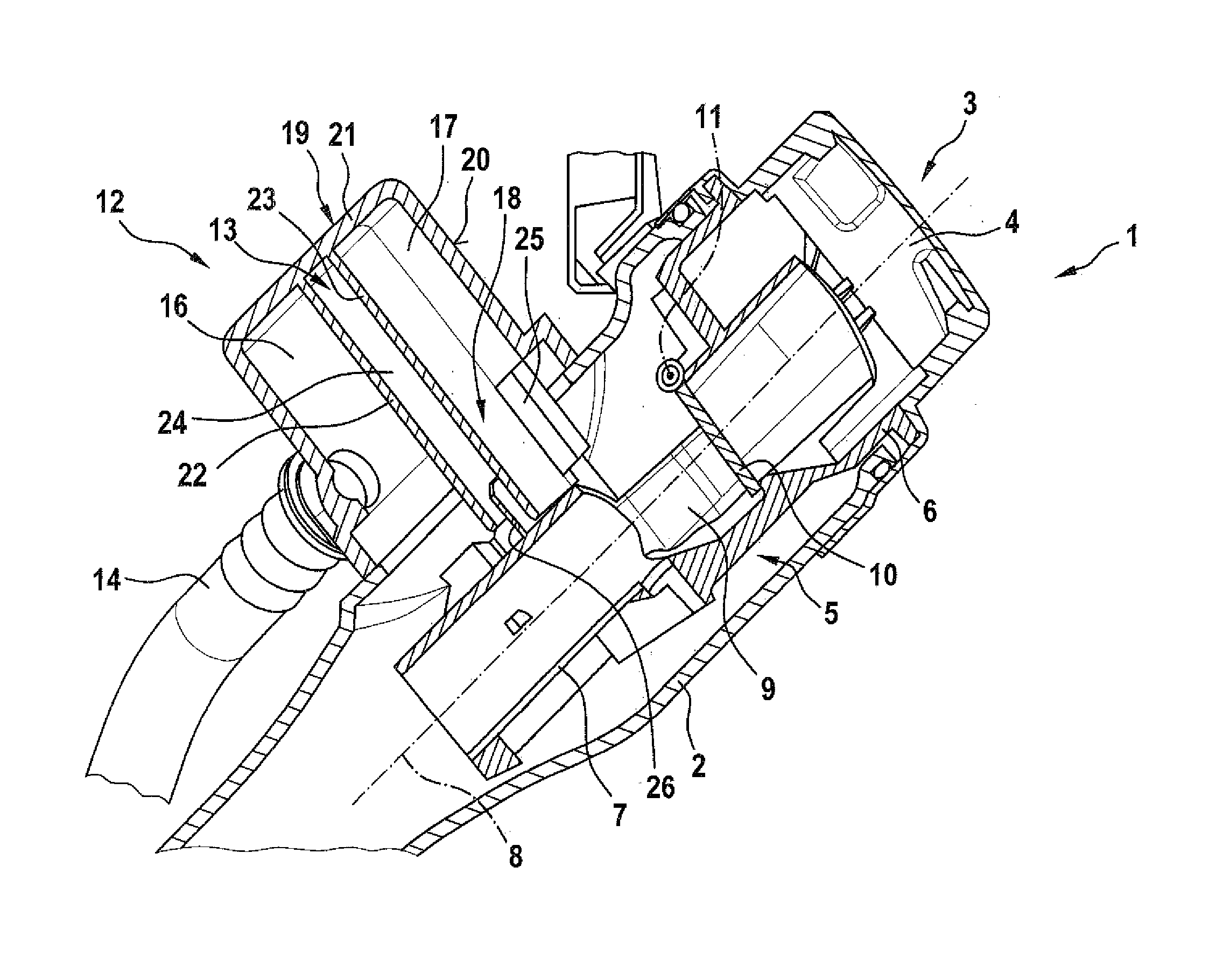

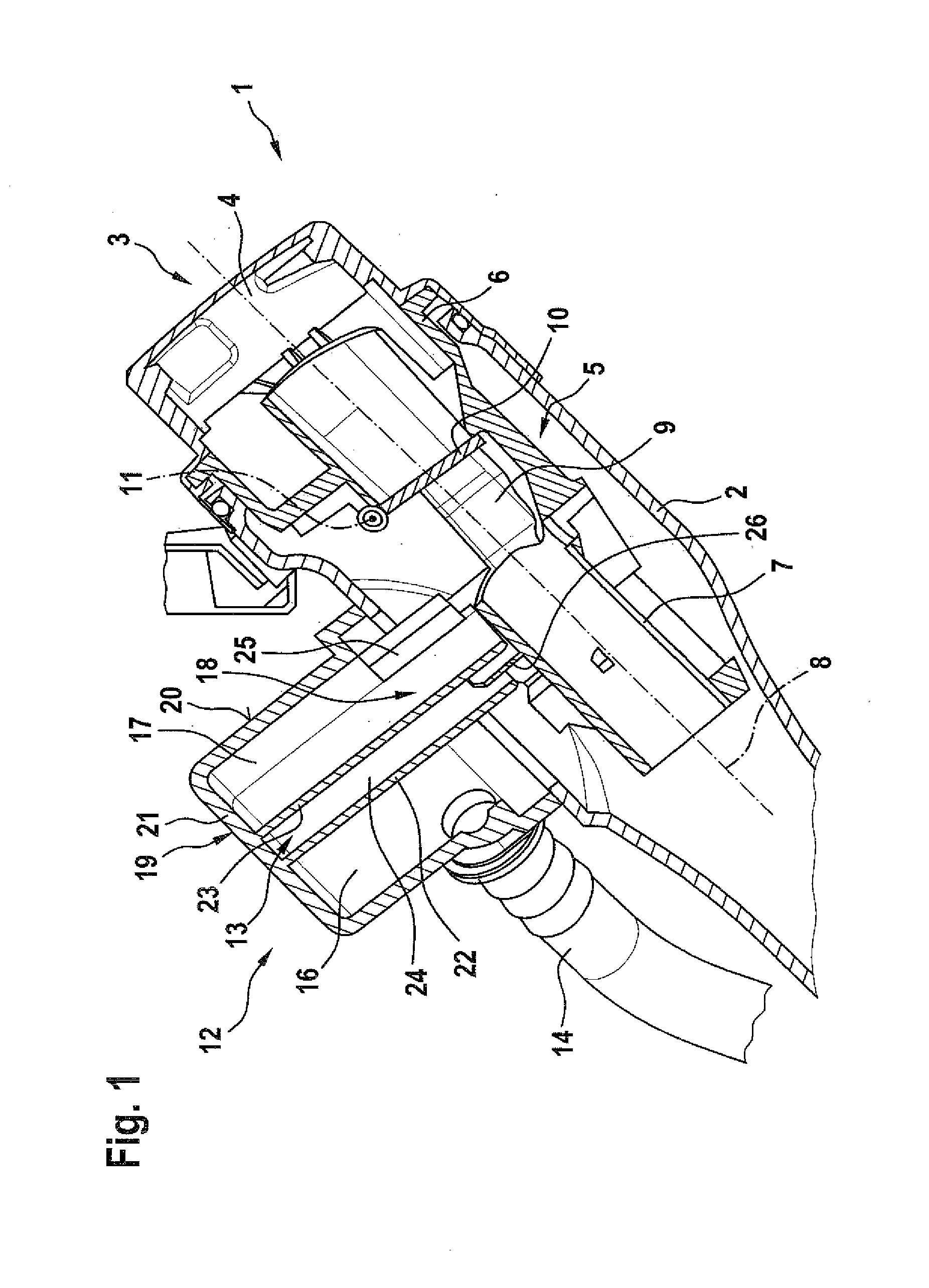

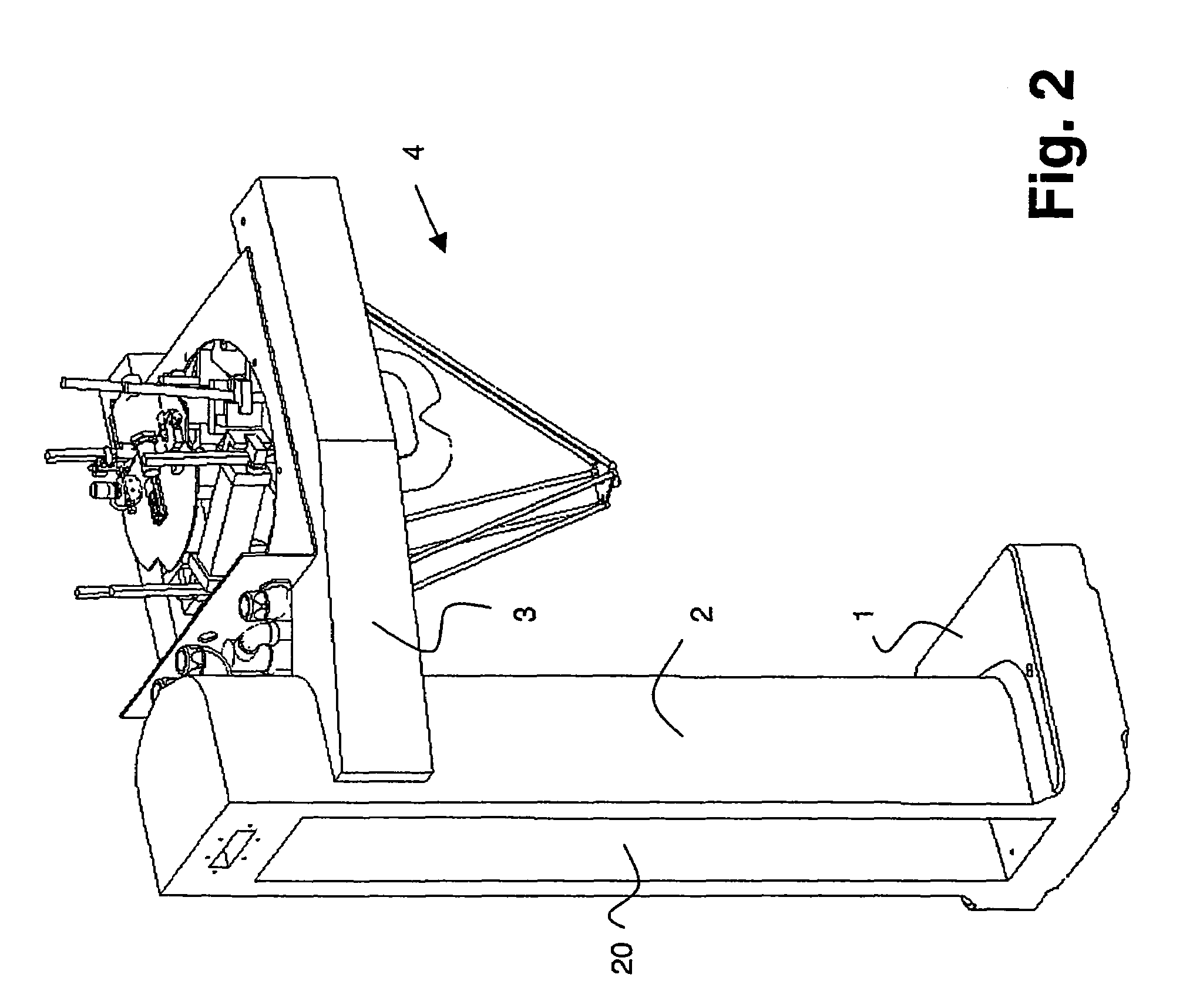

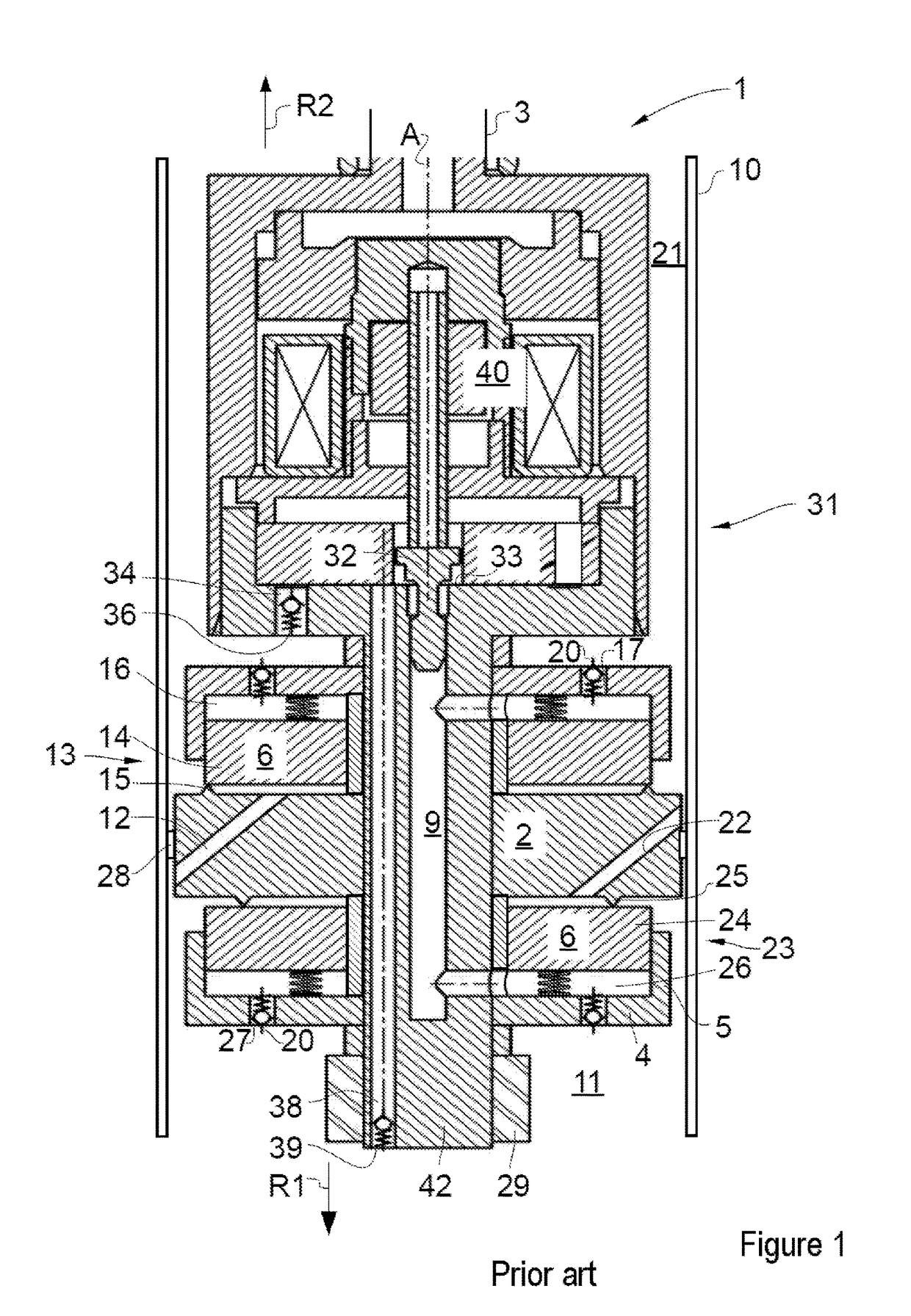

Headrest for a seat

InactiveUS7080886B2Design cost be lowHeight and tilt adjustment option be increaseVehicle seatsOperating chairsEngineeringMechanical engineering

Owner:RECARO AIRCRAFT SEATING

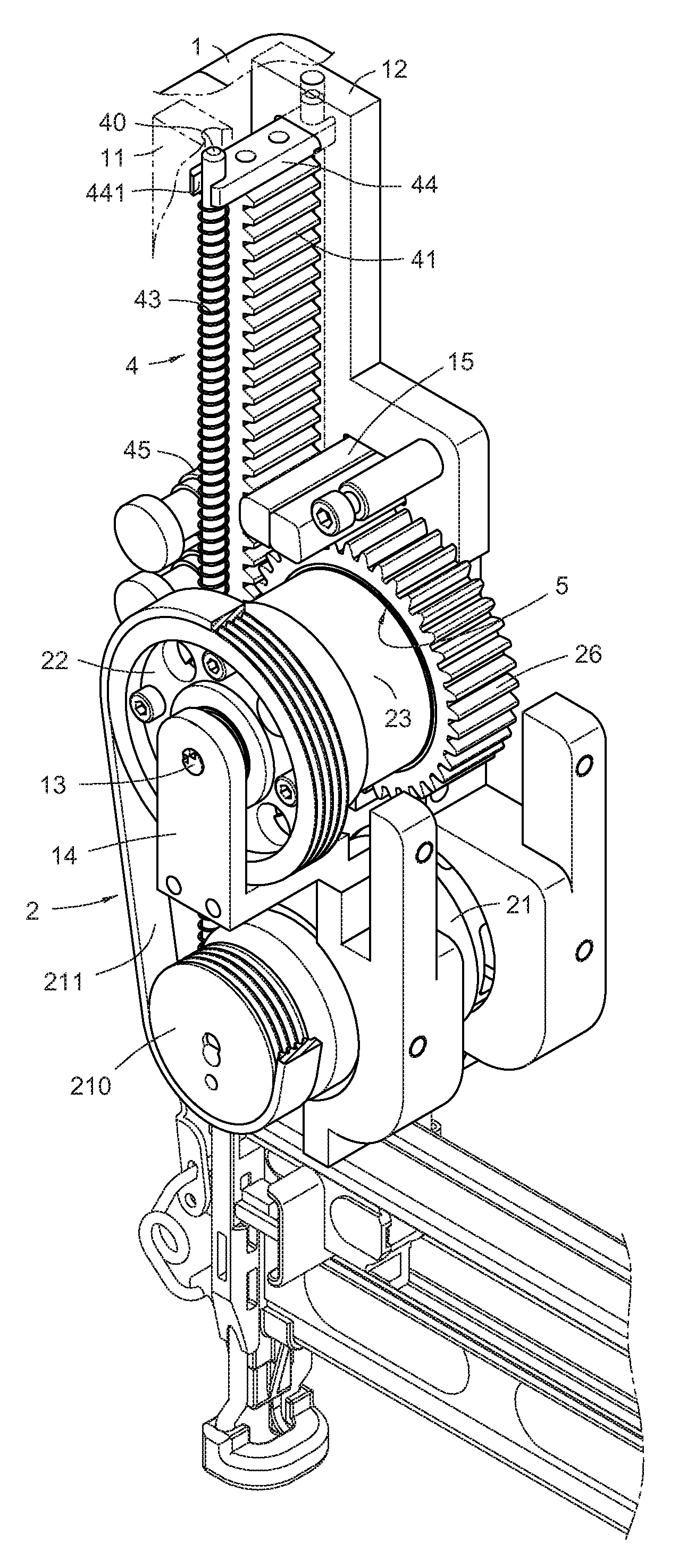

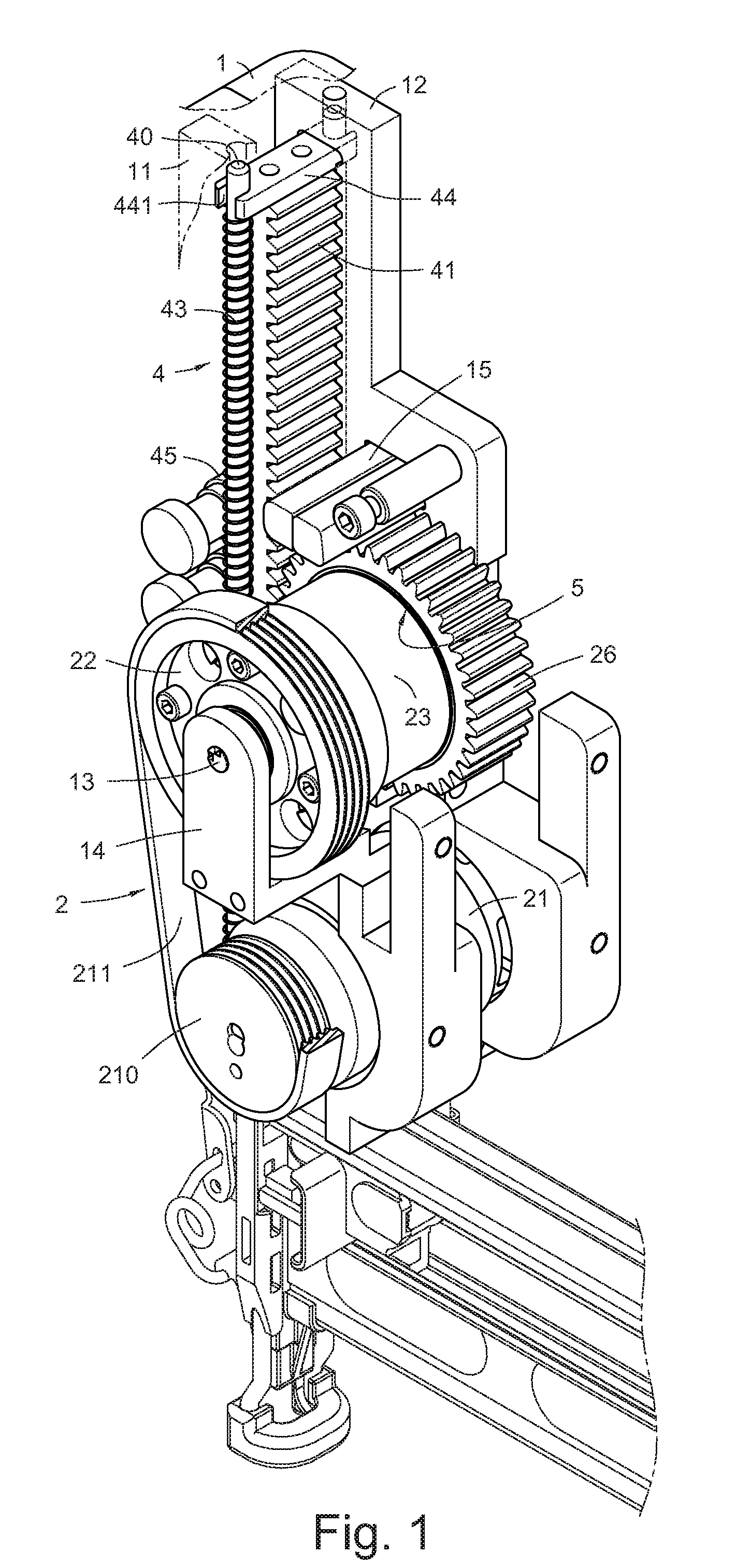

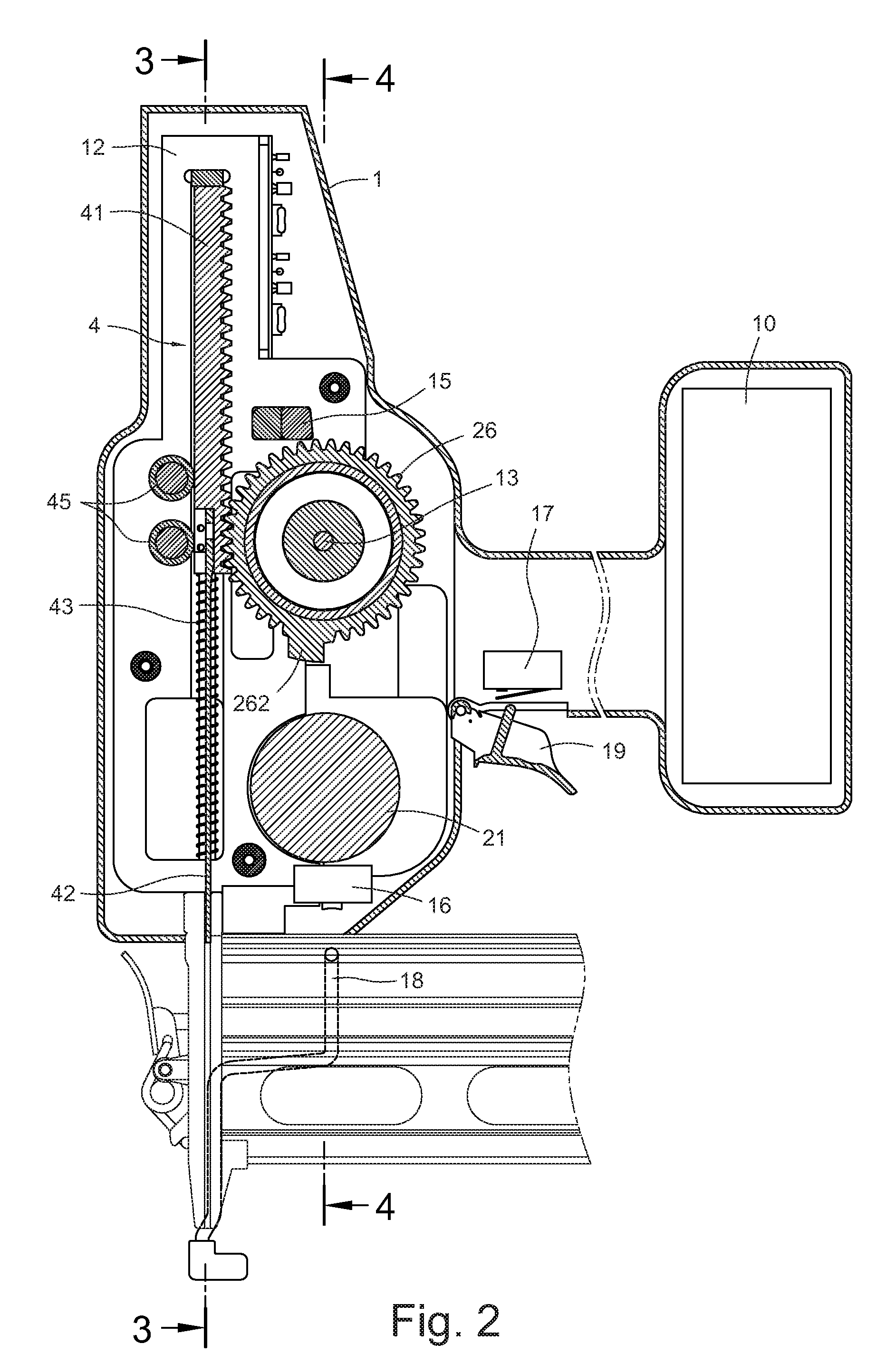

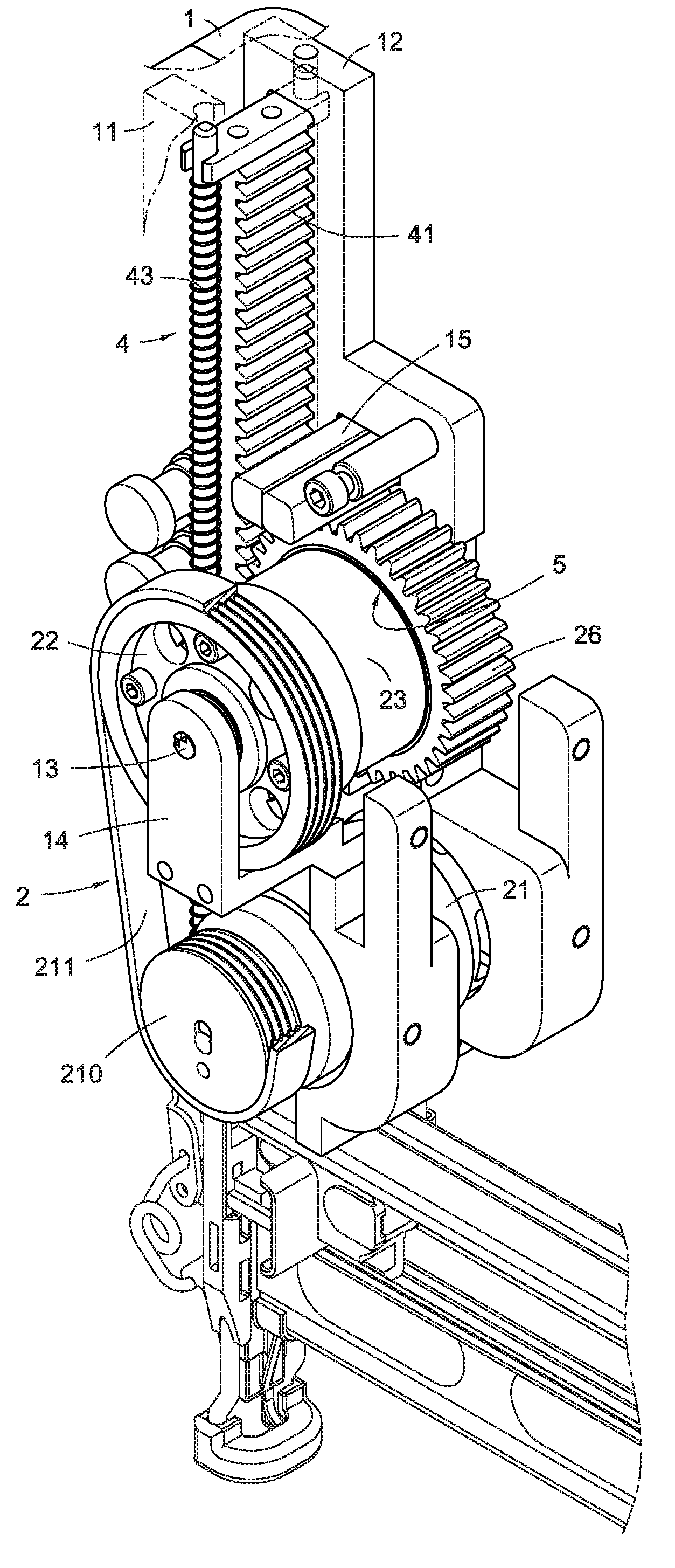

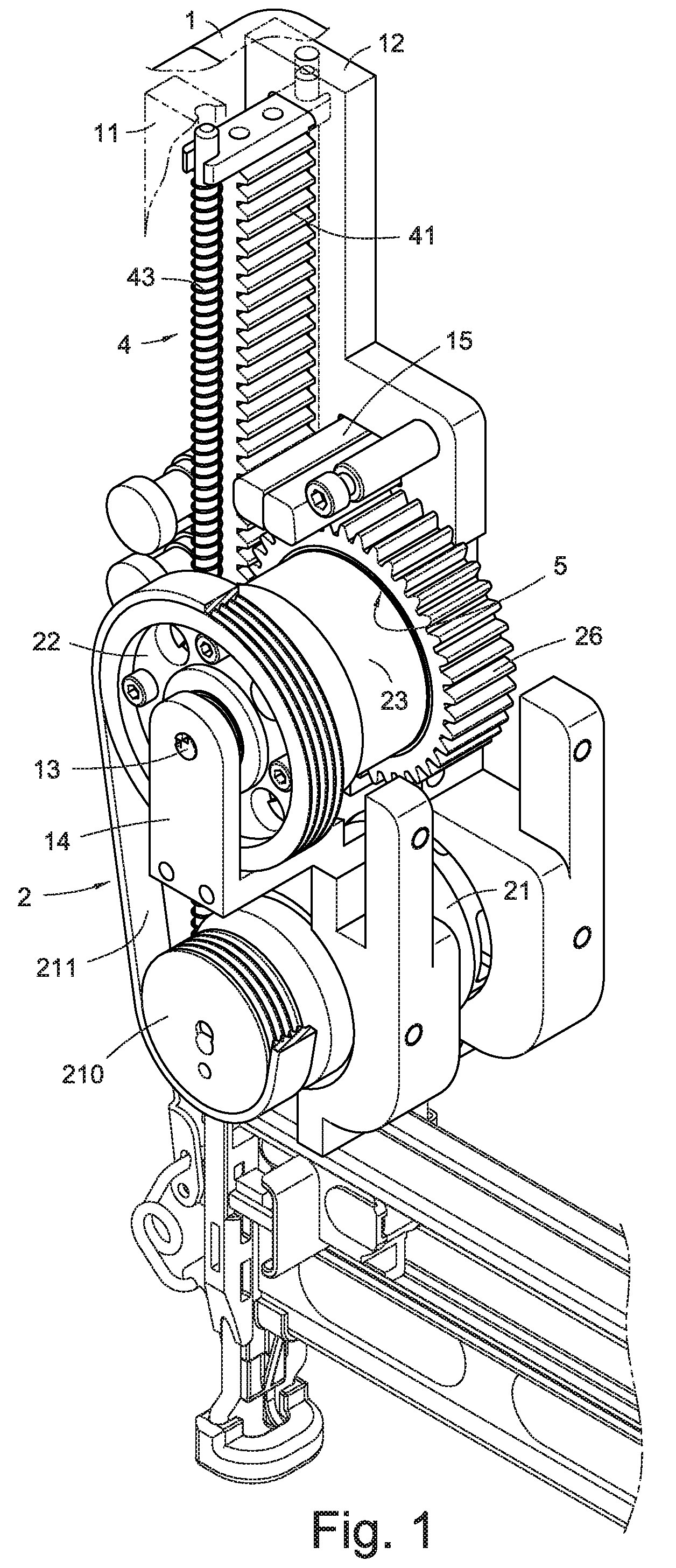

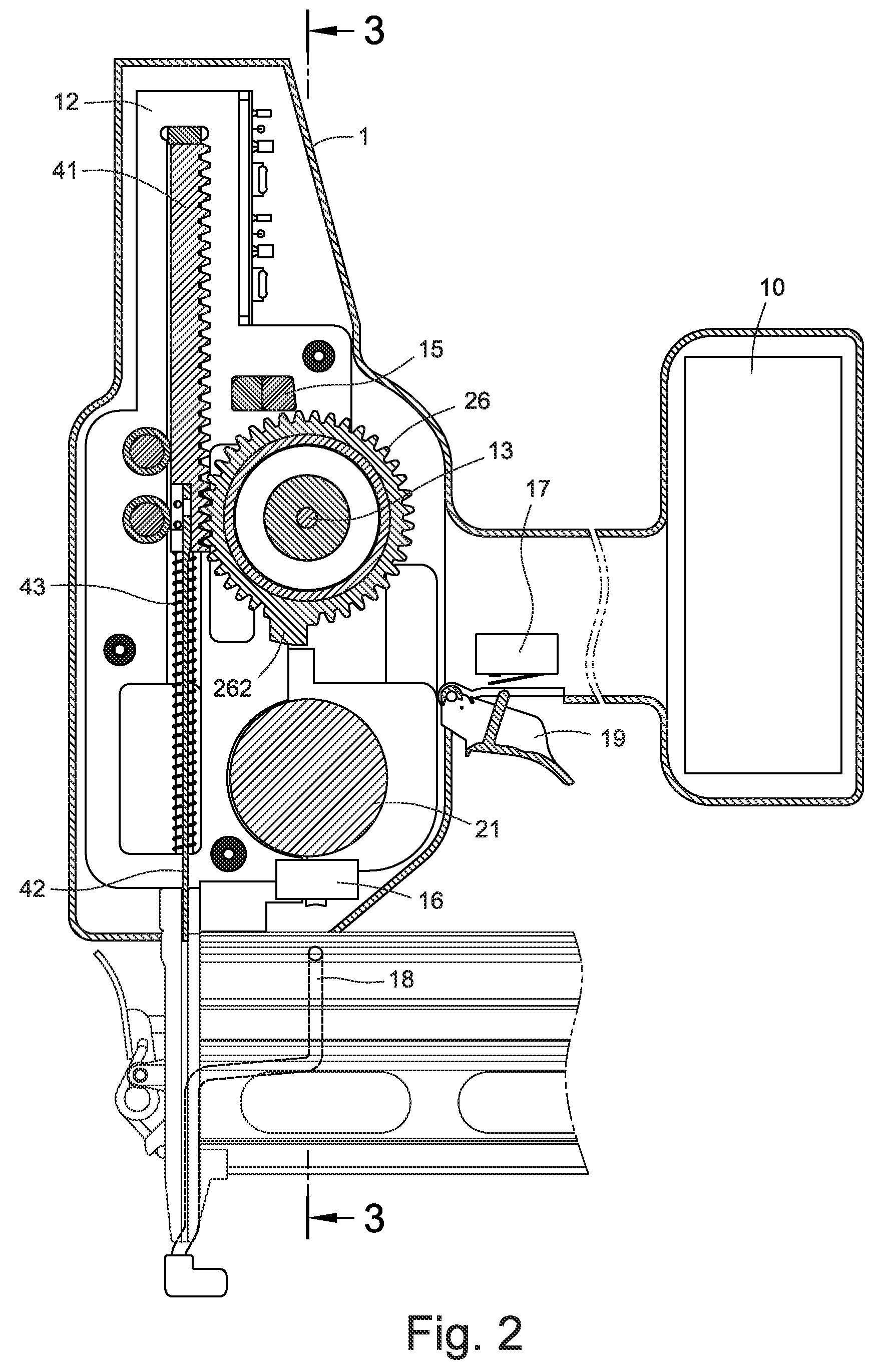

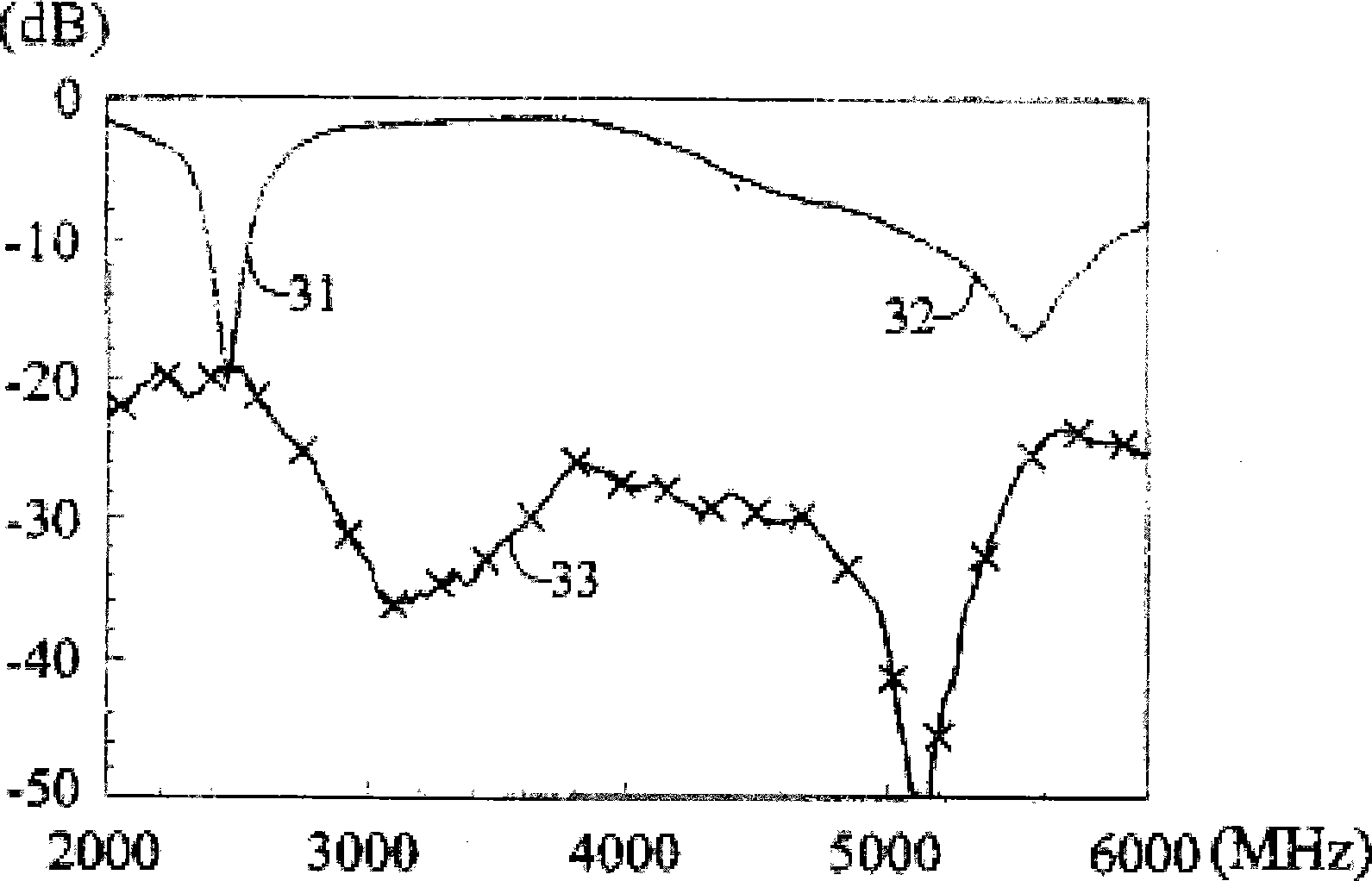

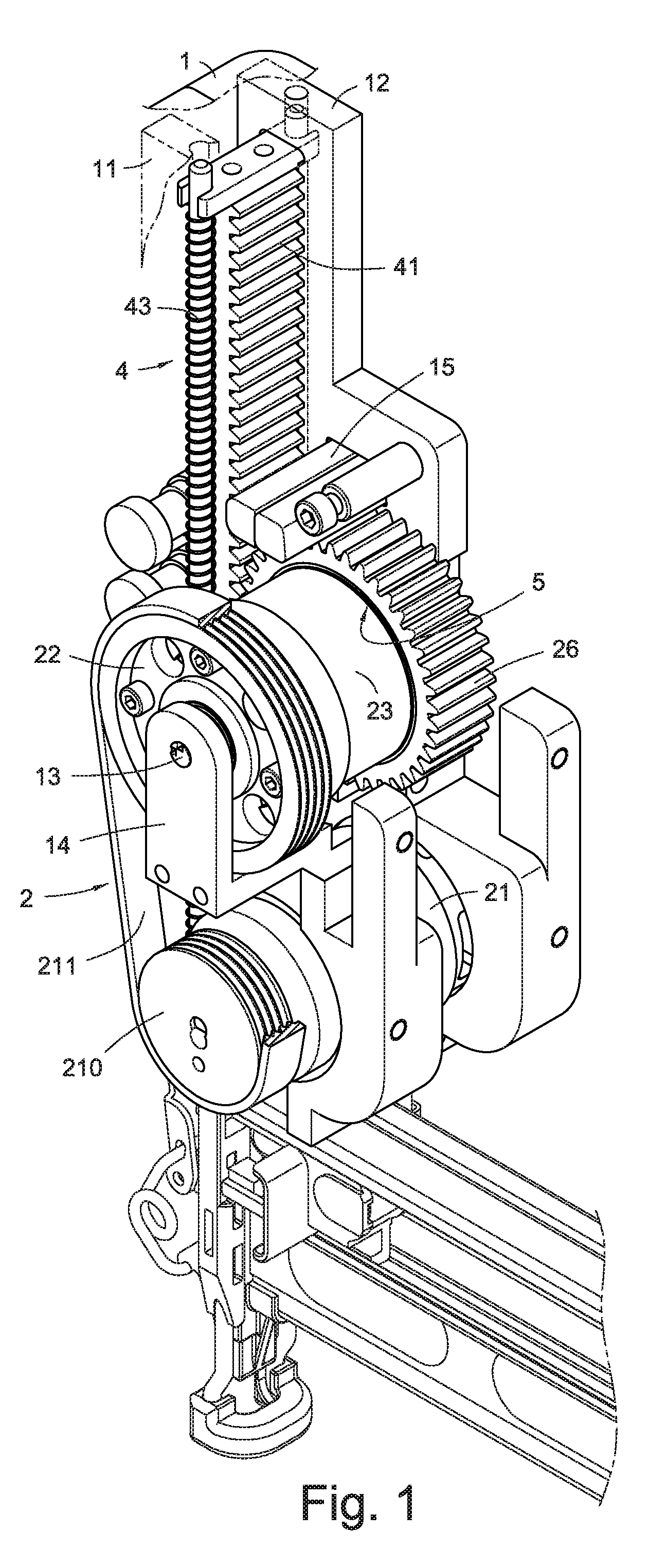

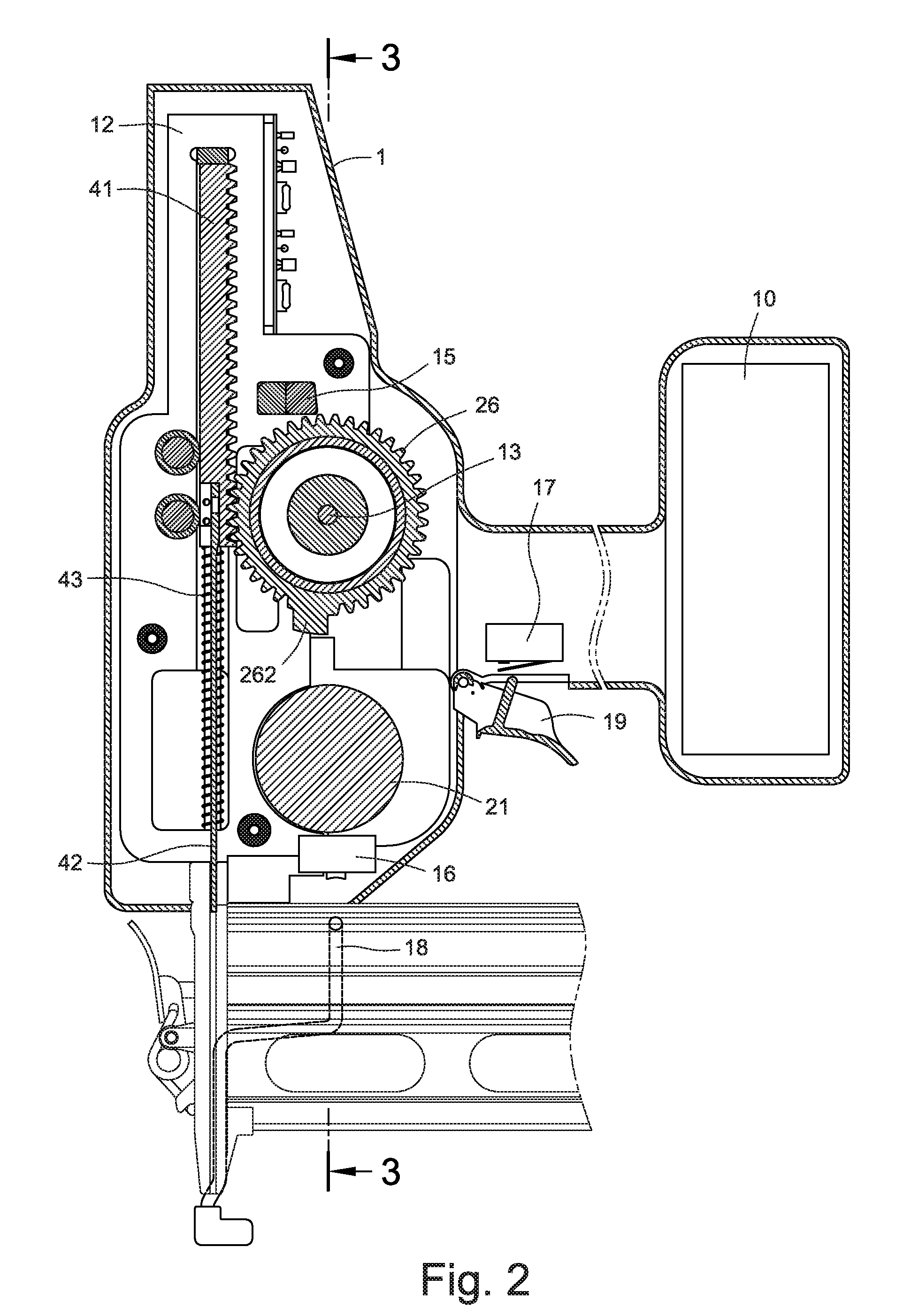

Transmission Mechanism for Electric Nail Gun

InactiveUS20090095787A1Simple processReduce decreaseStapling toolsNailing toolsDrive wheelSpring force

A transmission mechanism for an electric nail gun includes a linear transmission unit and a rotary transmission unit in a housing of the electric nail gun. The rotary transmission unit includes an electric driven driving wheel. The linear transmission unit includes a rack and a hitting bar. The hitting bar is disposed at a bottom of the linear transmission unit. The rack is in mesh with the driving wheel, slidably installed in the housing by a spring force, and configured to receive driving from the driving wheel and to drive the hitting bar to move linearly downward so as to hit a nail.

Owner:DE POAN PNEUMATIC

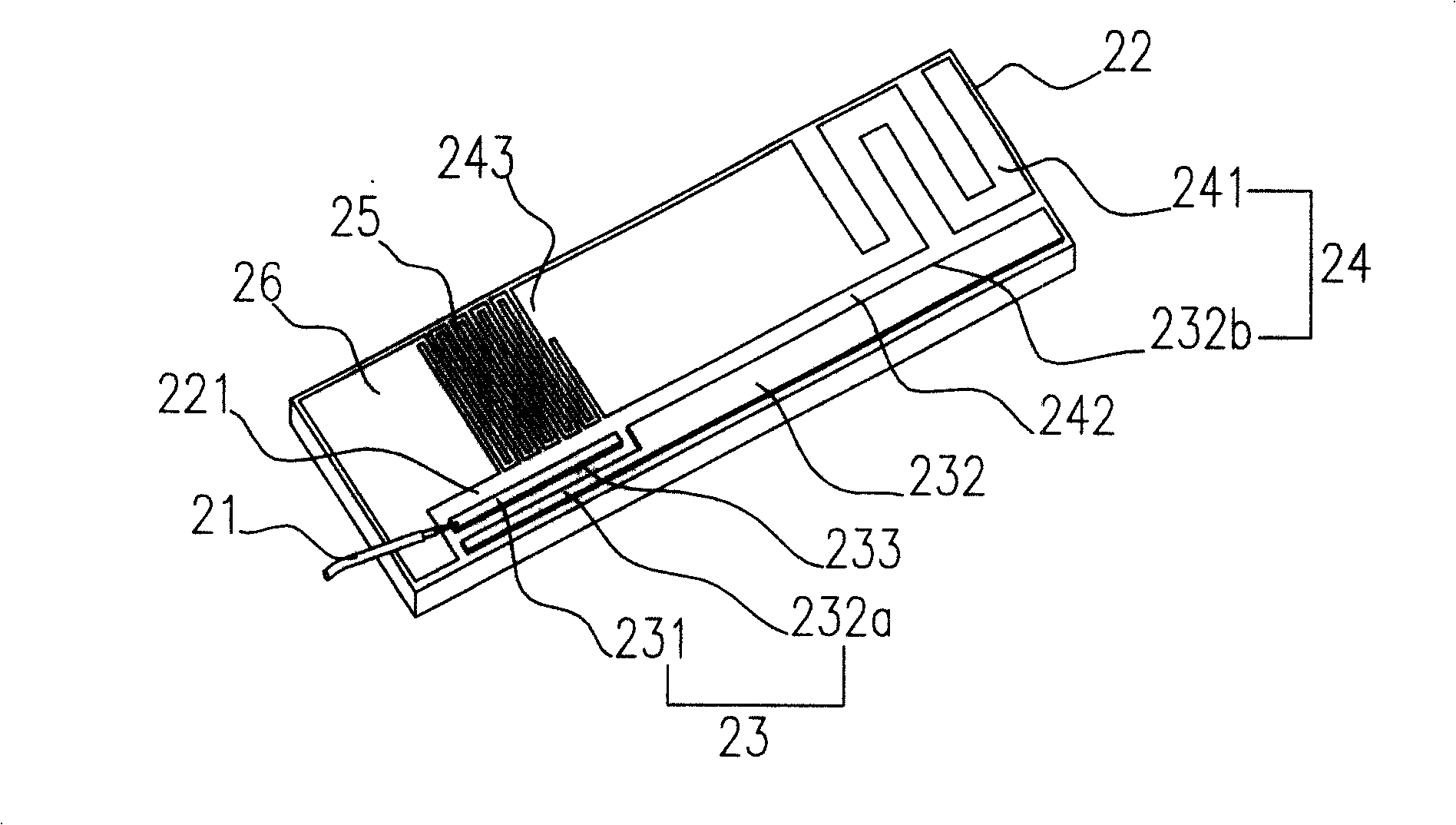

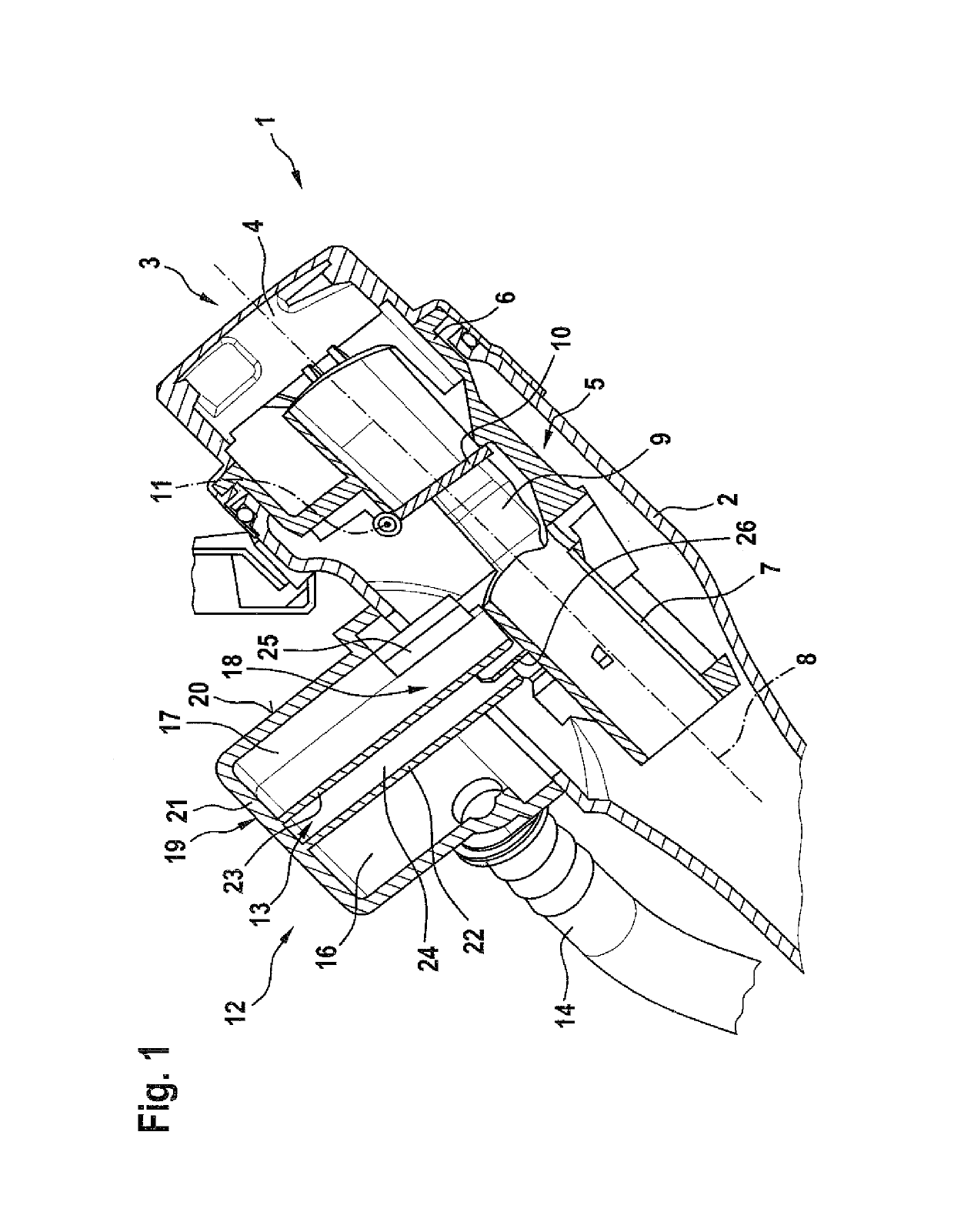

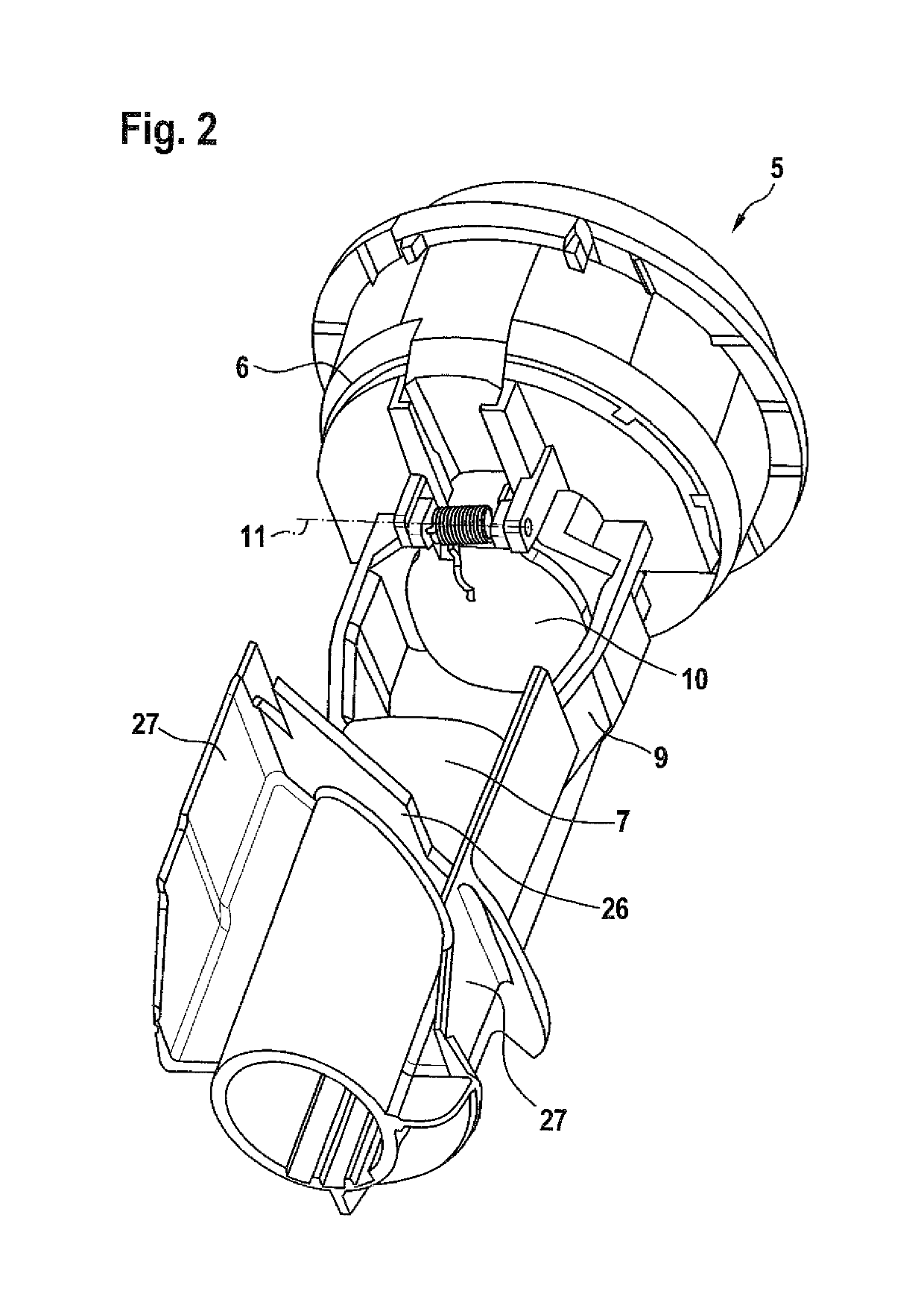

Transmission mechanism for electrical nail gun

A transmission mechanism for an electrical nail gun includes a rotary transmission unit and a linear transmission unit in a housing of the electrical nail gun. The rotary transmission unit includes a motor driven by electricity, a flywheel driven by the motor and extending to form a cylinder thereon, a solenoid activated by electricity, and a moveable driving wheel adjacent to an end side of the cylinder. A clutch is formed between the cylinder and the driving wheel. The solenoid is buried in the cylinder so that a magnetic conductivity loop is constructed around the solenoid to produce the magnetic field when the solenoid is activated. The driving wheel is attracted to move to an engagement position to be driven by the flywheel, thereby driving the linear transmission unit to impact a nail when the solenoid is activated by electricity, and the driving wheel returns to a disengagement position to disengage from the flywheel, thereby stopping driving the linear transmission unit when the solenoid is demagnetized.

Owner:DE POAN PNEUMATIC

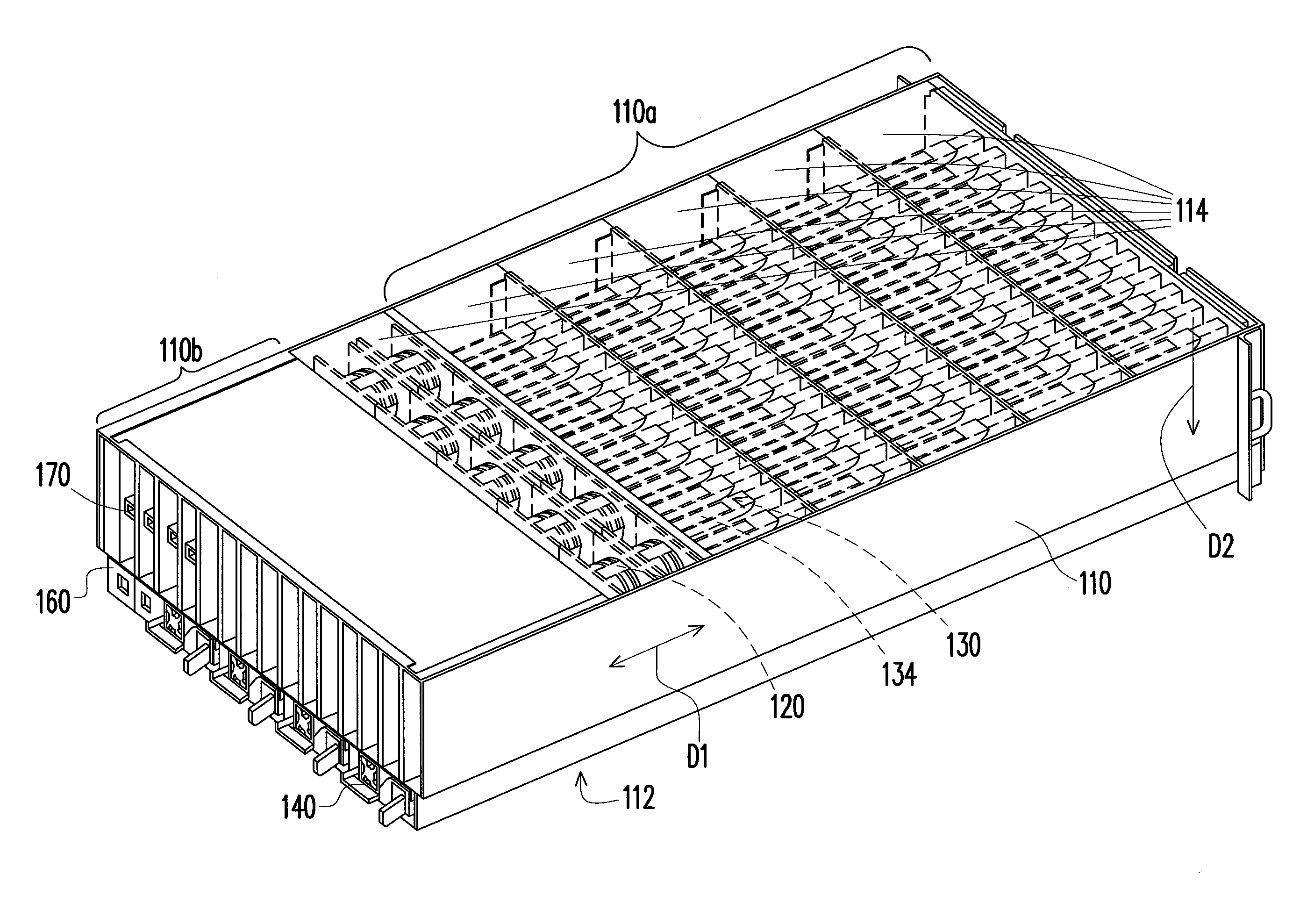

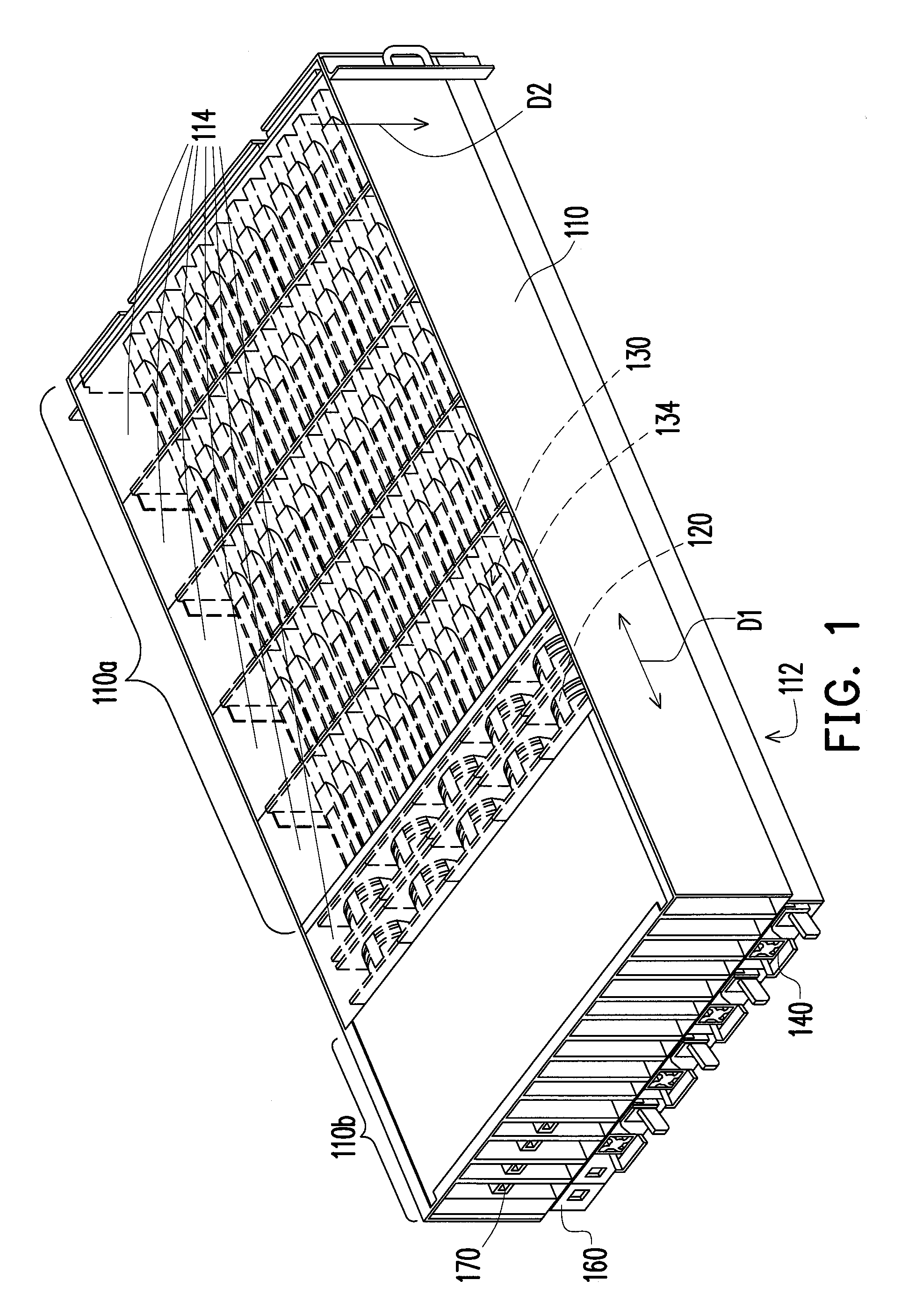

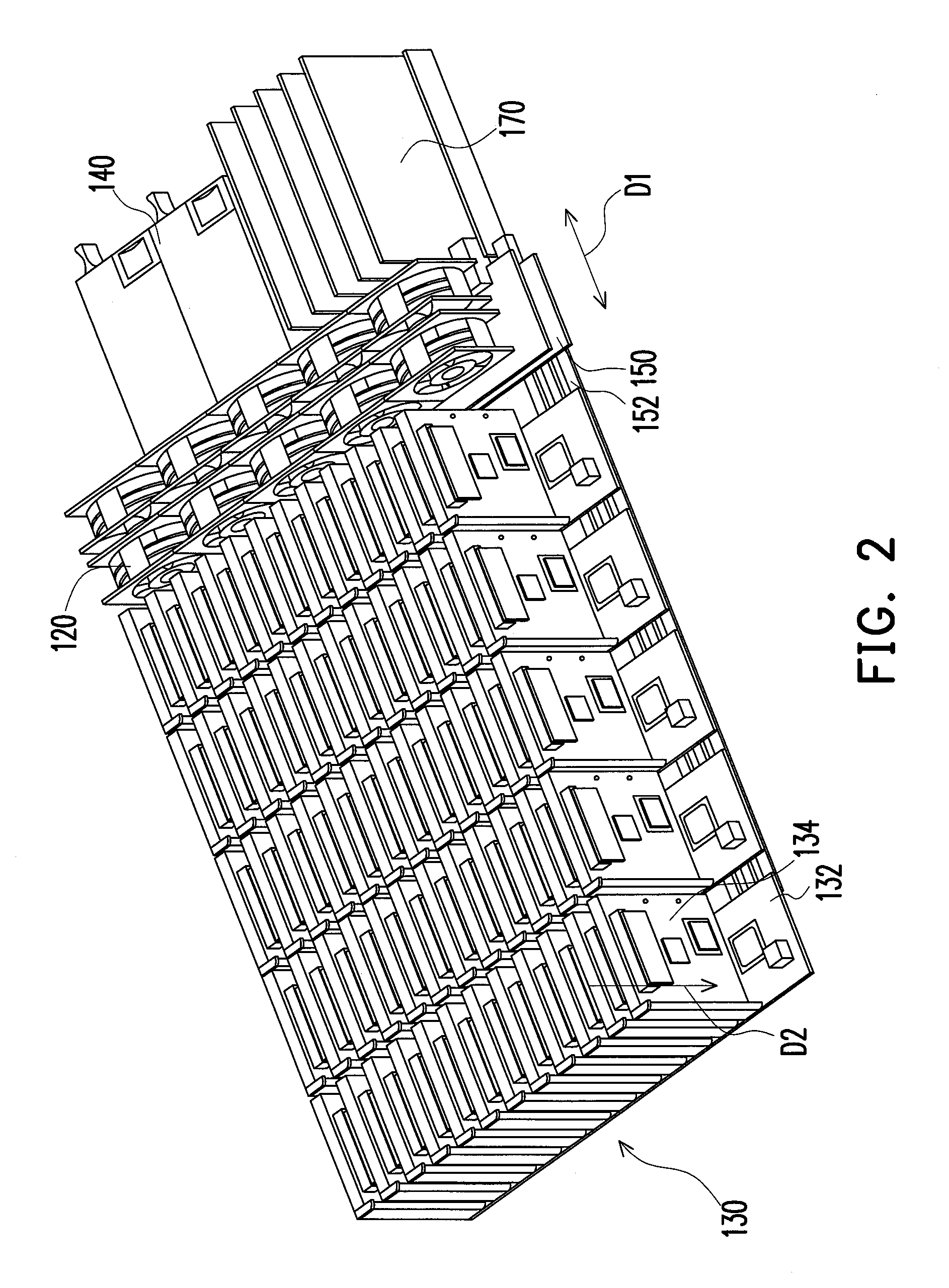

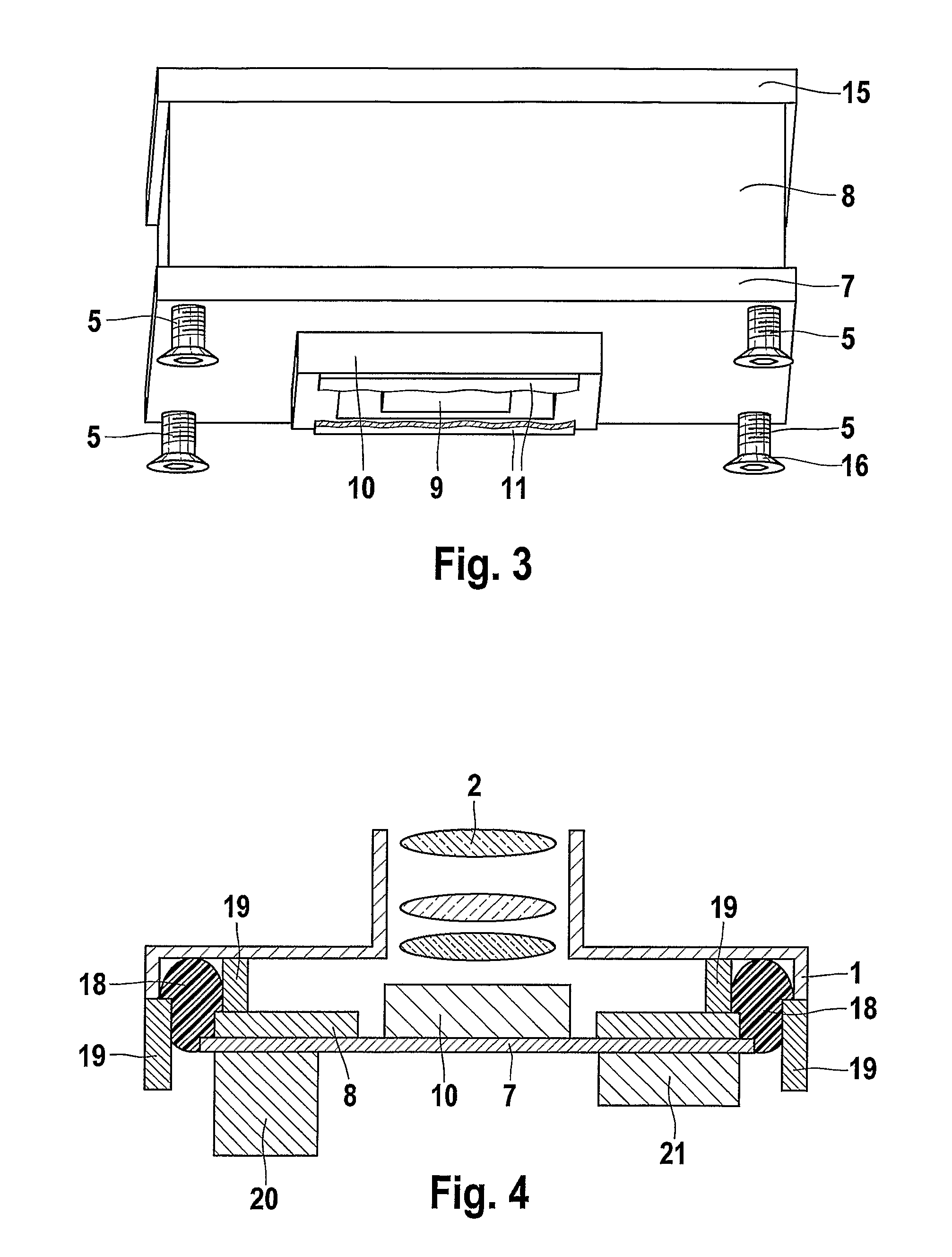

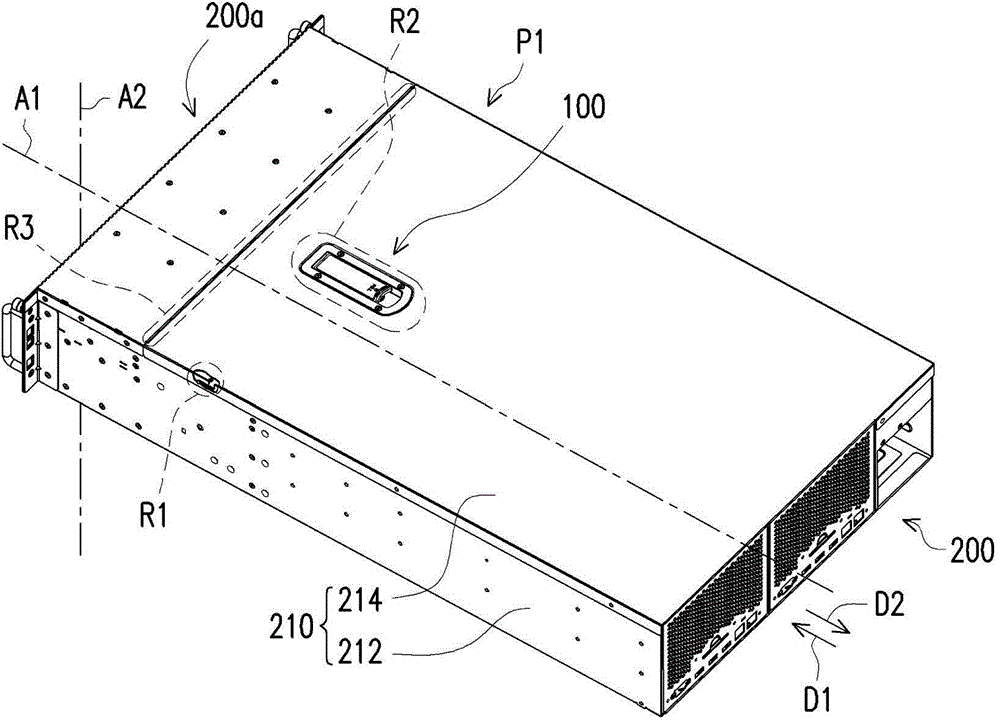

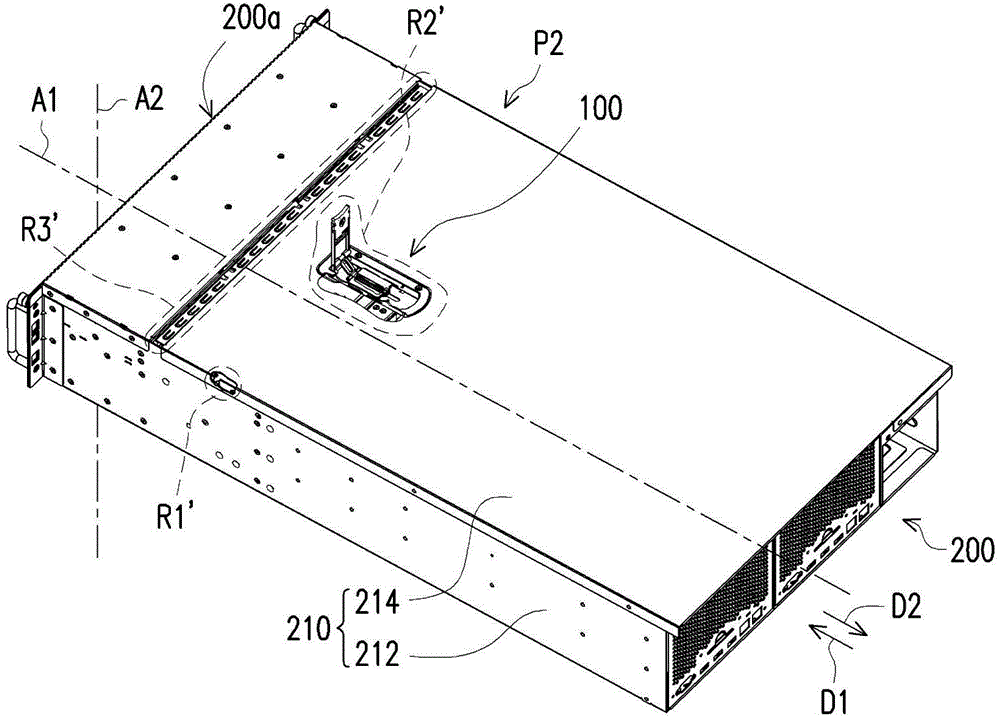

Server

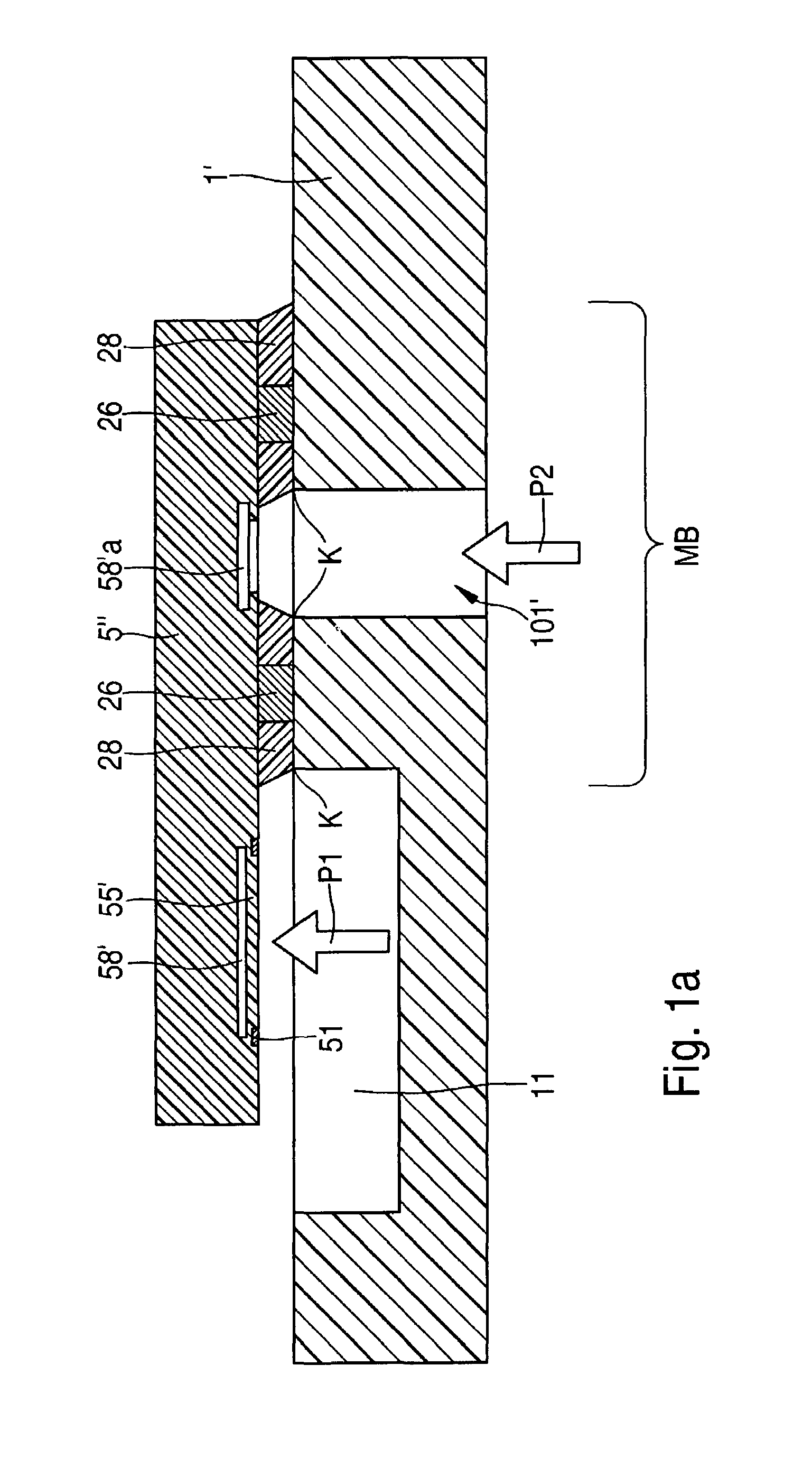

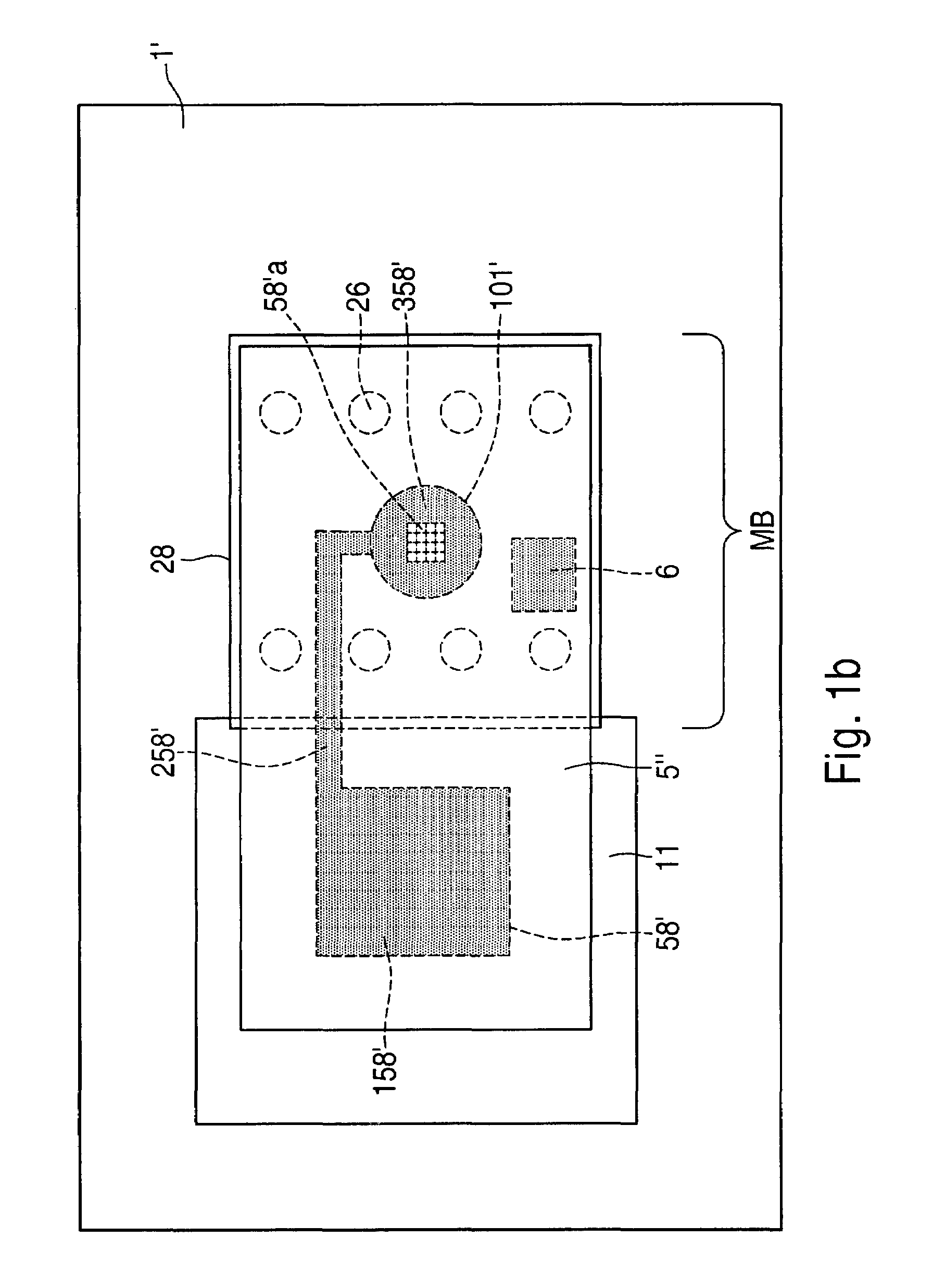

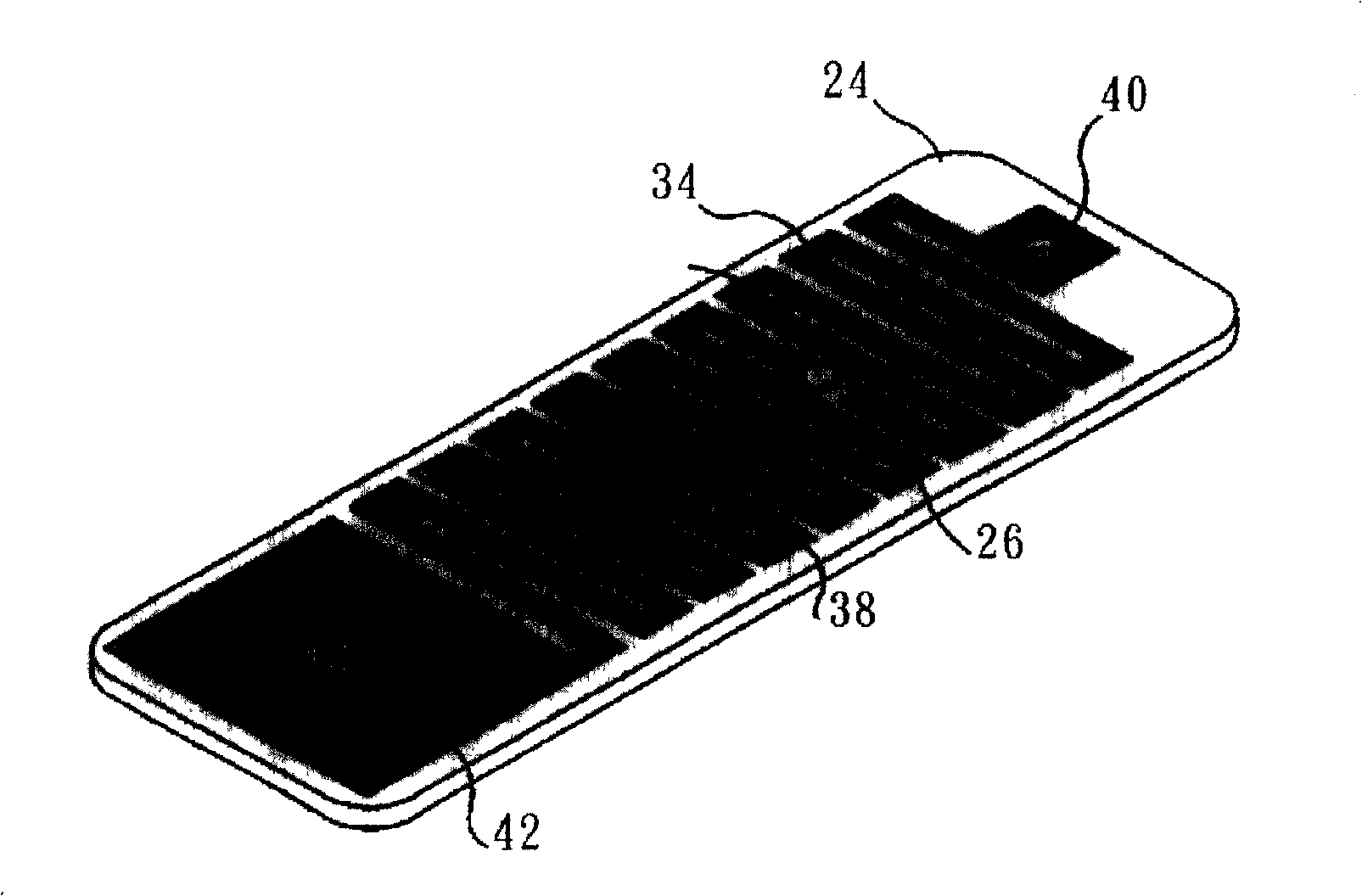

InactiveUS20130077223A1Save configuration spaceImprove cooling efficiencyDigital data processing detailsElectrical apparatus contructional detailsComputer moduleEngineering

A server includes a case, a fan module, and a main board module unit. The fan module is disposed in the case and divides the case into first and second spaces. An air flow is sucked into and blown out of the fan module along a first direction. The main board module unit includes a main board module back plate and main board modules. The main board module back plate is horizontally laid in the first space. Each main board module having a hard disk is detachably inserted in the main board module back plate along a second direction, and electrically connected to the main board module back plate. Two maximum area surfaces of each main board module are parallel with the first direction. Air flow channels are formed between the main board modules extending along the first direction.

Owner:INVENTEC CORP

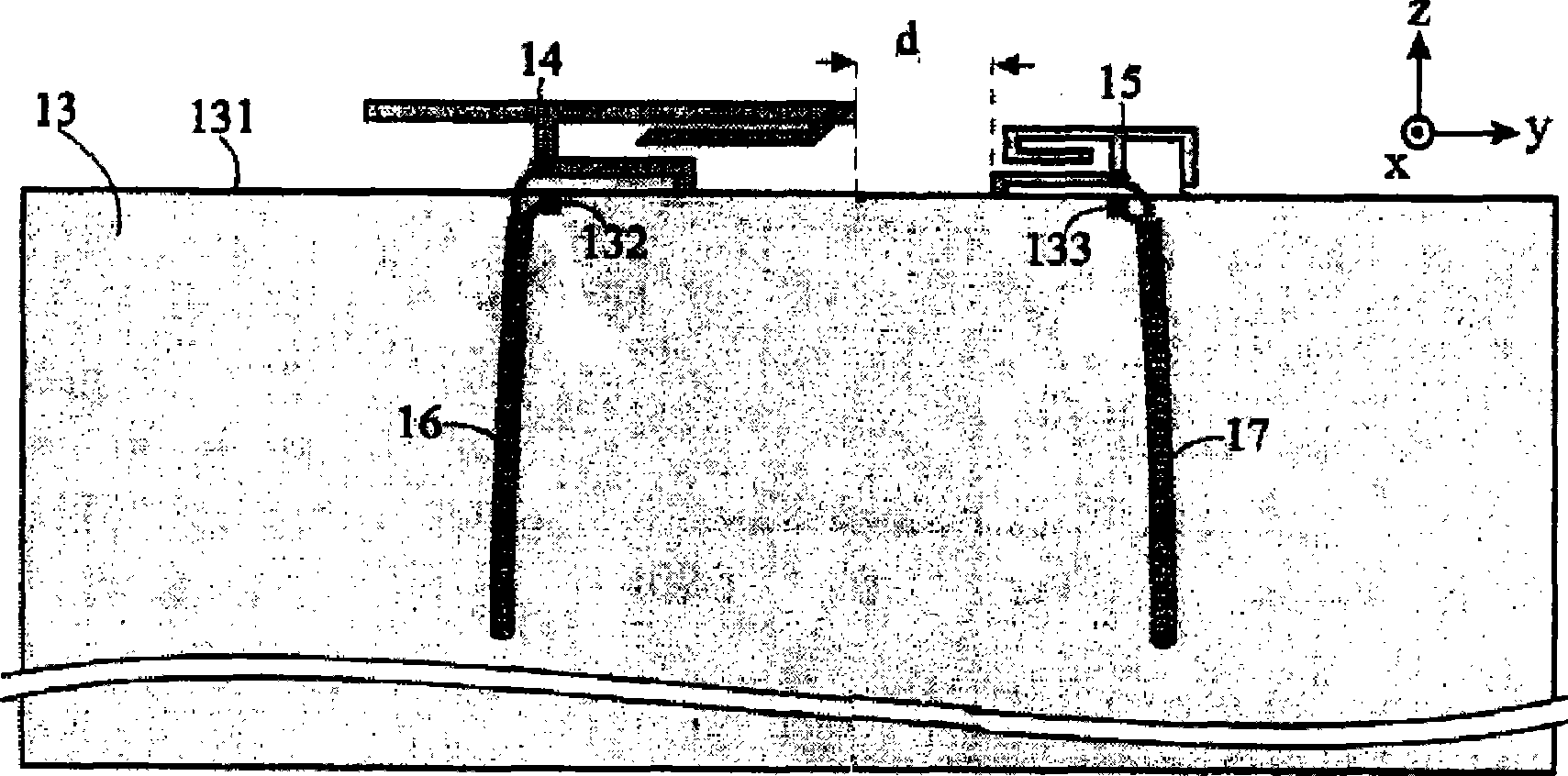

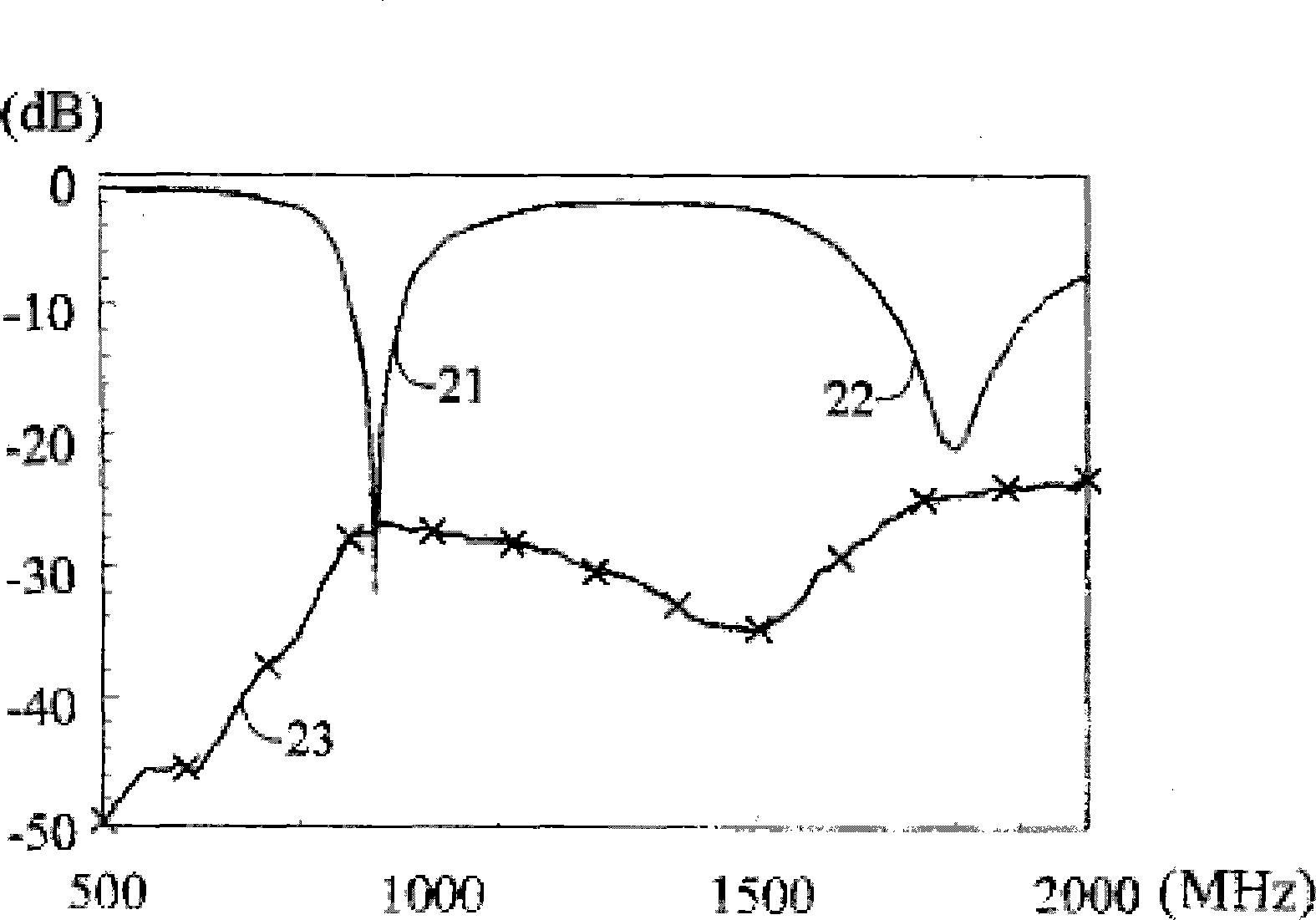

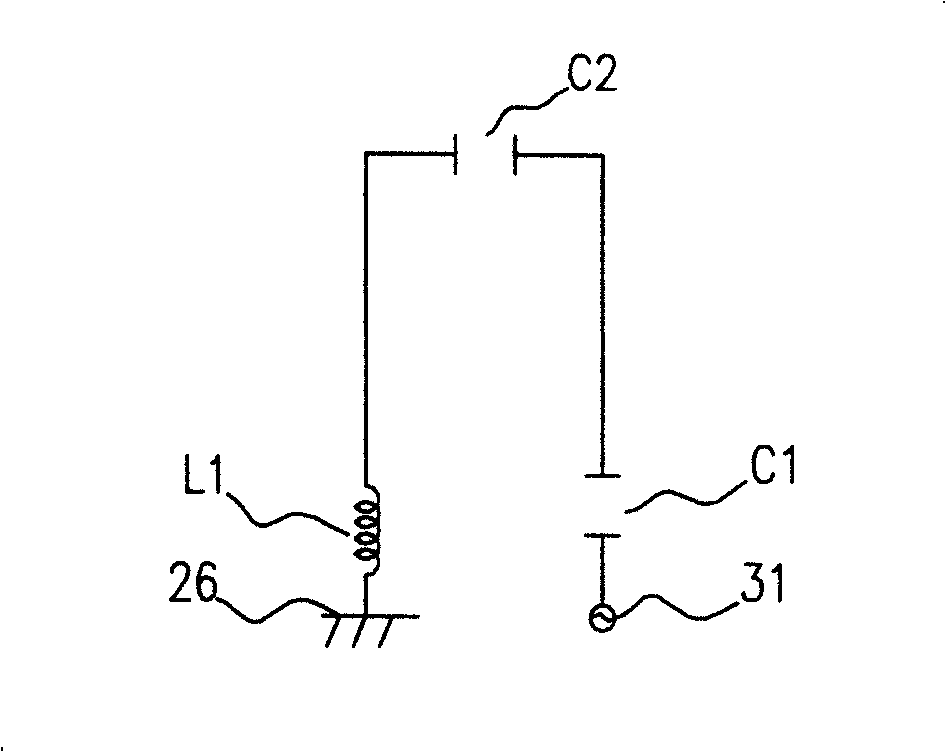

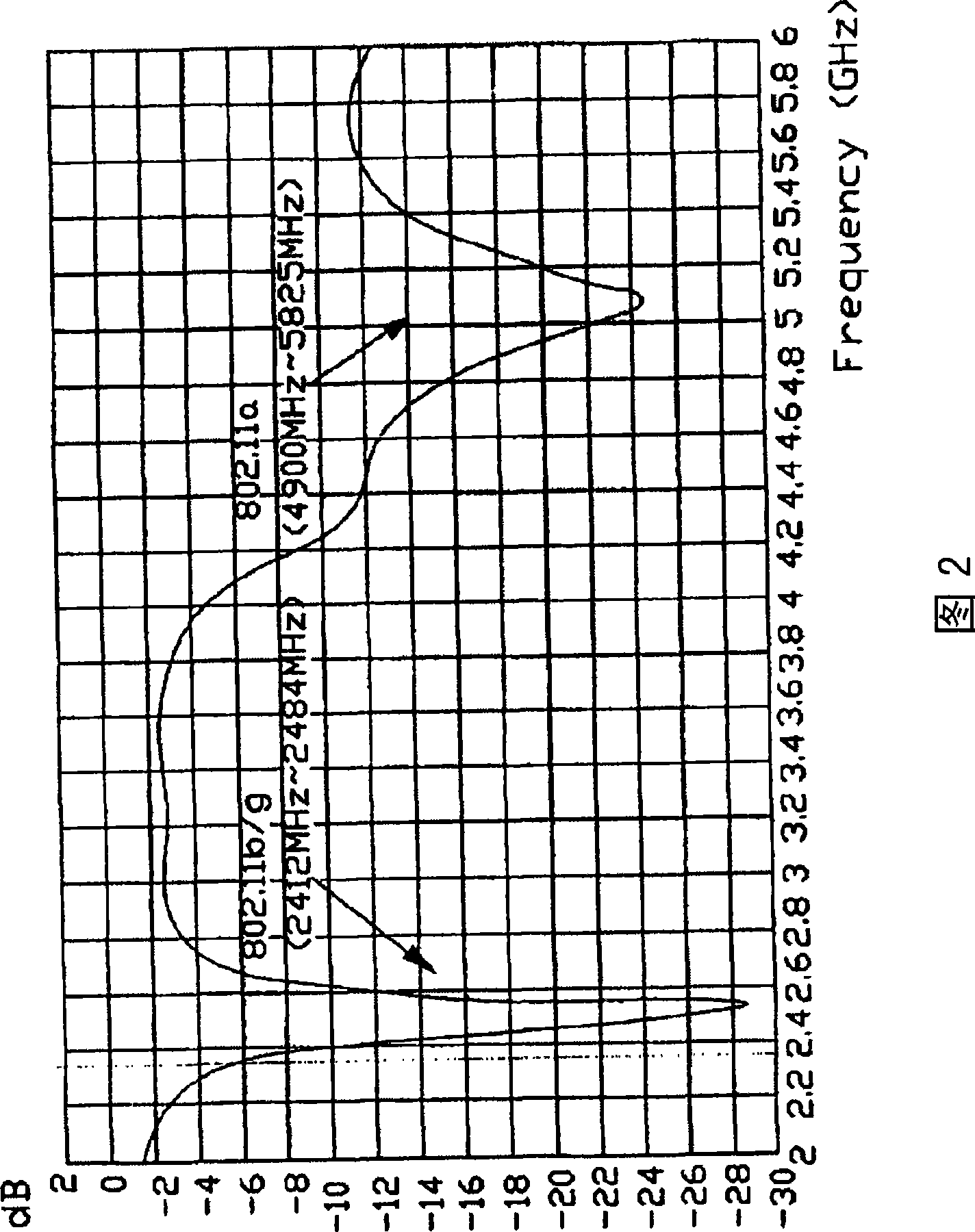

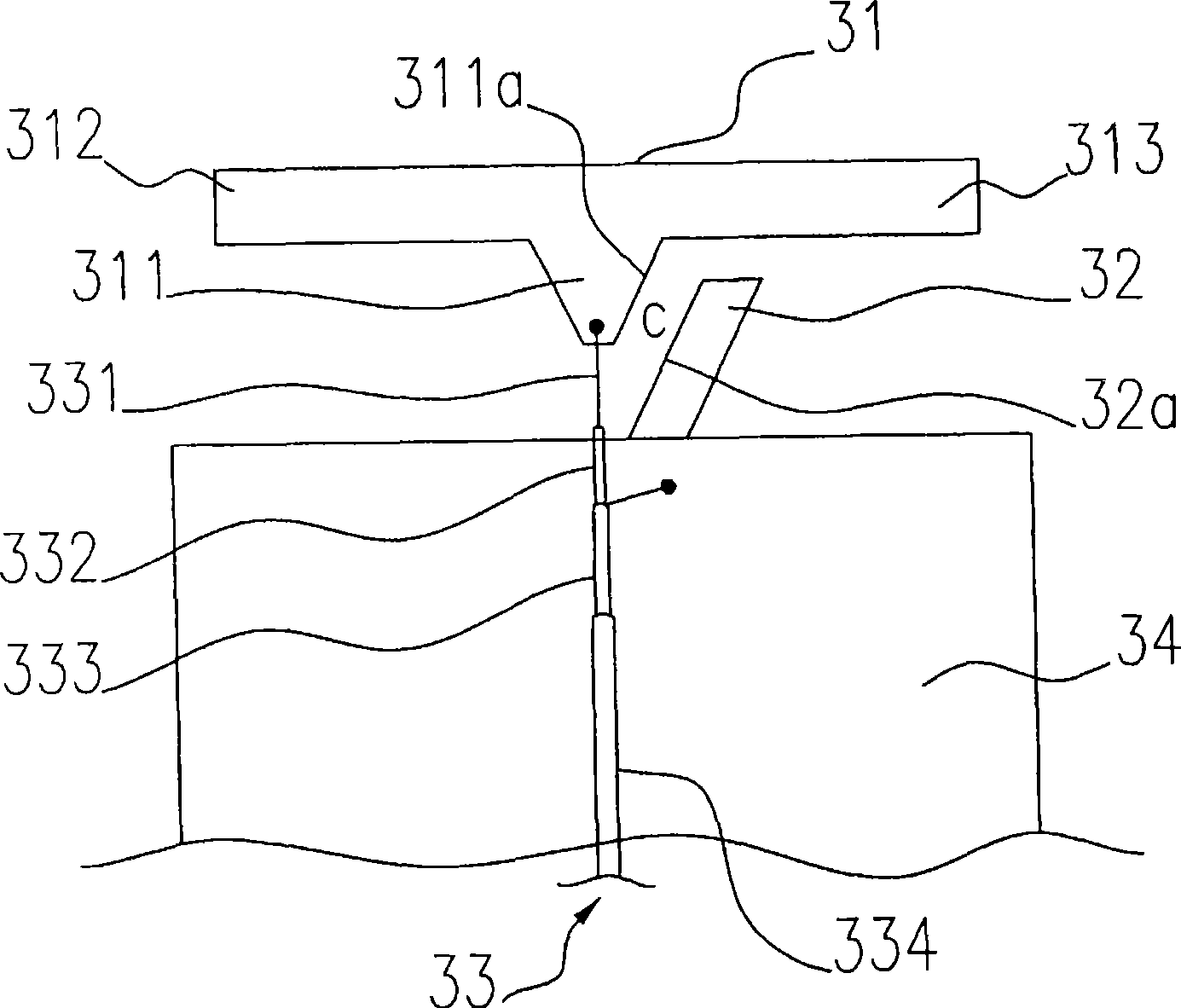

Multi-antenna integrated module

ActiveCN101388494AAdjust input impedanceAvoid interferenceIndependent non-interacting antenna combinationsMulti antennaElectrical conductor

The invention relates to a multi-antenna integrated module group, which comprises a first antenna, a second antenna and a common unit, wherein the first antenna is provided with a coupled unit, and the coupled unit is provided with a first coupling portion and a second coupling portion, the second antenna is provided with a coupled conductor, and the common unit is provided with a combined conductor, a combined short-circuit portion and a combined grounding portion. A gap is formed between the other lateral side of the combined conductor of the second conductor, and the connecting interface of the first conductor and the second conductor is connected with an end portion of the combined short-circuit portion, and the other end portion of the combined short-circuit portion is connected with the combined grounding portion.

Owner:昆山展腾电子科技有限公司

Transmission Mechanism for Electrical Nail Gun

A transmission mechanism for an electrical nail gun includes a rotary transmission unit and a linear transmission unit in a housing of the electrical nail gun. The rotary transmission unit includes a motor driven by electricity, a flywheel driven by the motor and extending to form a cylinder thereon, a solenoid activated by electricity, and a moveable driving wheel adjacent to an end side of the cylinder. A clutch is formed between the cylinder and the driving wheel. The solenoid is buried in the cylinder so that a magnetic conductivity loop is constructed around the solenoid to produce the magnetic field when the solenoid is activated. The driving wheel is attracted to move to an engagement position to be driven by the flywheel, thereby driving the linear transmission unit to impact a nail when the solenoid is activated by electricity, and the driving wheel returns to a disengagement position to disengage from the flywheel, thereby stopping driving the linear transmission unit when the solenoid is demagnetized.

Owner:DE POAN PNEUMATIC

Height-Adjustable Pedestal for a Vehicle

InactiveUS20130220168A1Reduce dependenceExtended service lifeVehicle arrangementsSuperstructure subunitsEngineeringSpring force

The invention relates to a height-adjustable pedestal for use in a vehicle including a height adjustable pedestal platform, a spring having a spring force according to a corresponding spring characteristic, and a lever mechanism that is interconnected between the spring and the pedestal platform in such a way that the spring force is transferred by the lever mechanism to the pedestal platform in the form of a lifting force that counteracts the weight force of the pedestal platform to facilitate the height-adjustment of the pedestal platform. In a further embodiment, the lever mechanism at least partially compensates for a variation of the spring force that occurs according to the spring characteristics.

Owner:TEVER TECHN VERTRIEBS & BETEILIGUNGS & BERATUNGS

Camera

InactiveUS20070292124A1Reduce manufacturing costHarden fastTelevision system detailsColor television detailsImage sensorVideo camera

A camera in particular for a motor vehicle having at least one image converting element. The image converting element includes at least one image sensor and is connected to at least one additional element of the camera, e.g., the housing of the camera, by at least one interlock.

Owner:ROBERT BOSCH GMBH

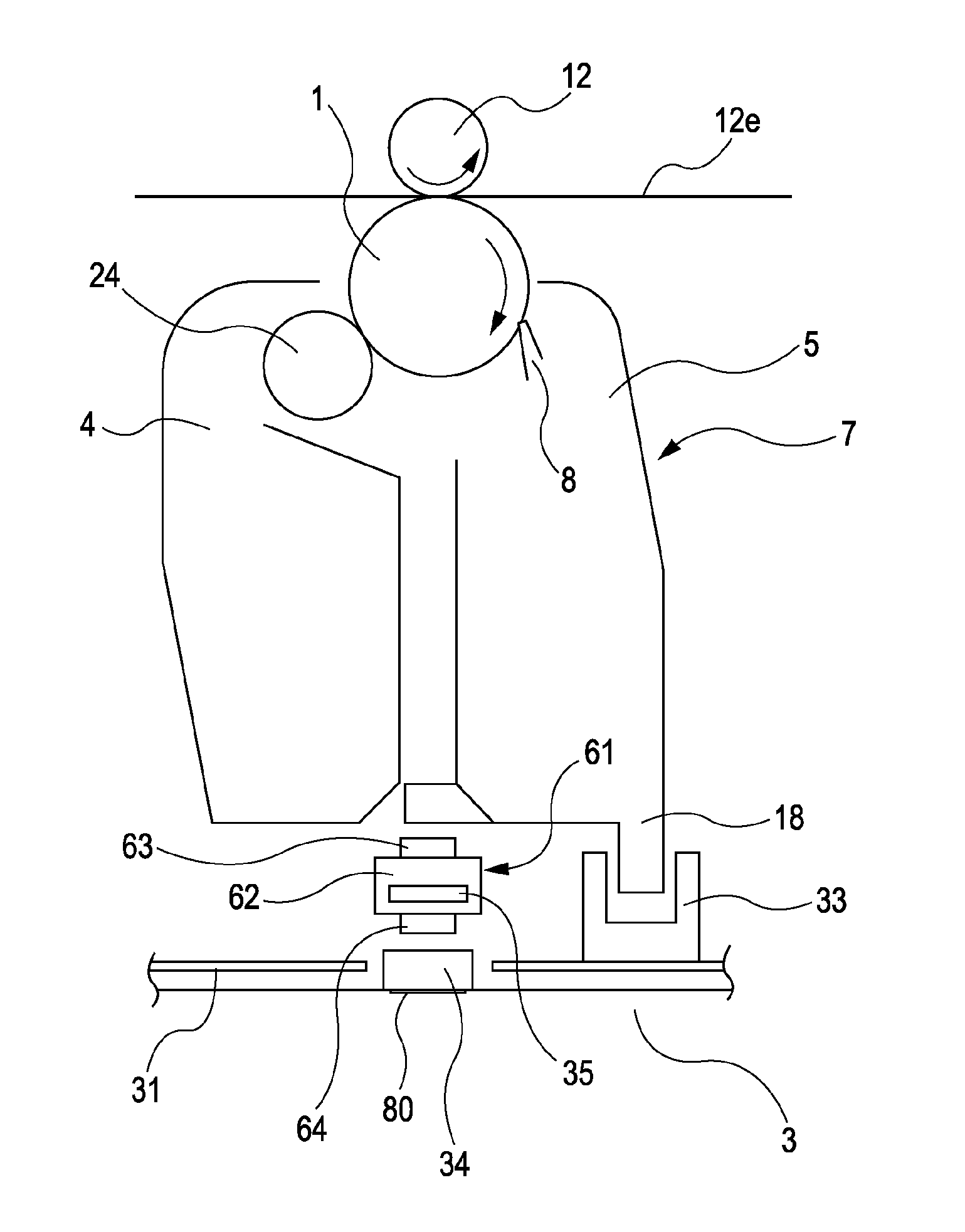

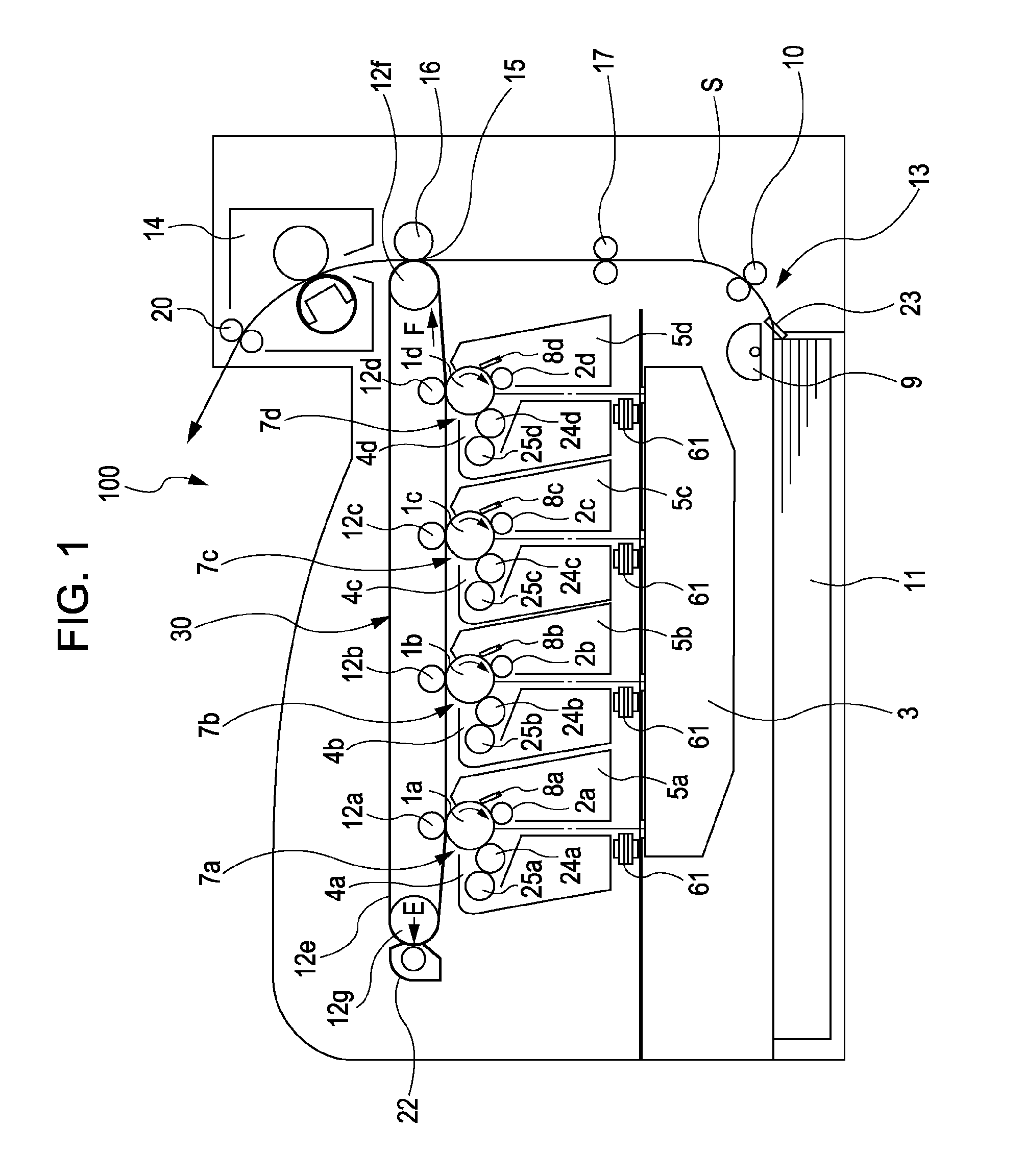

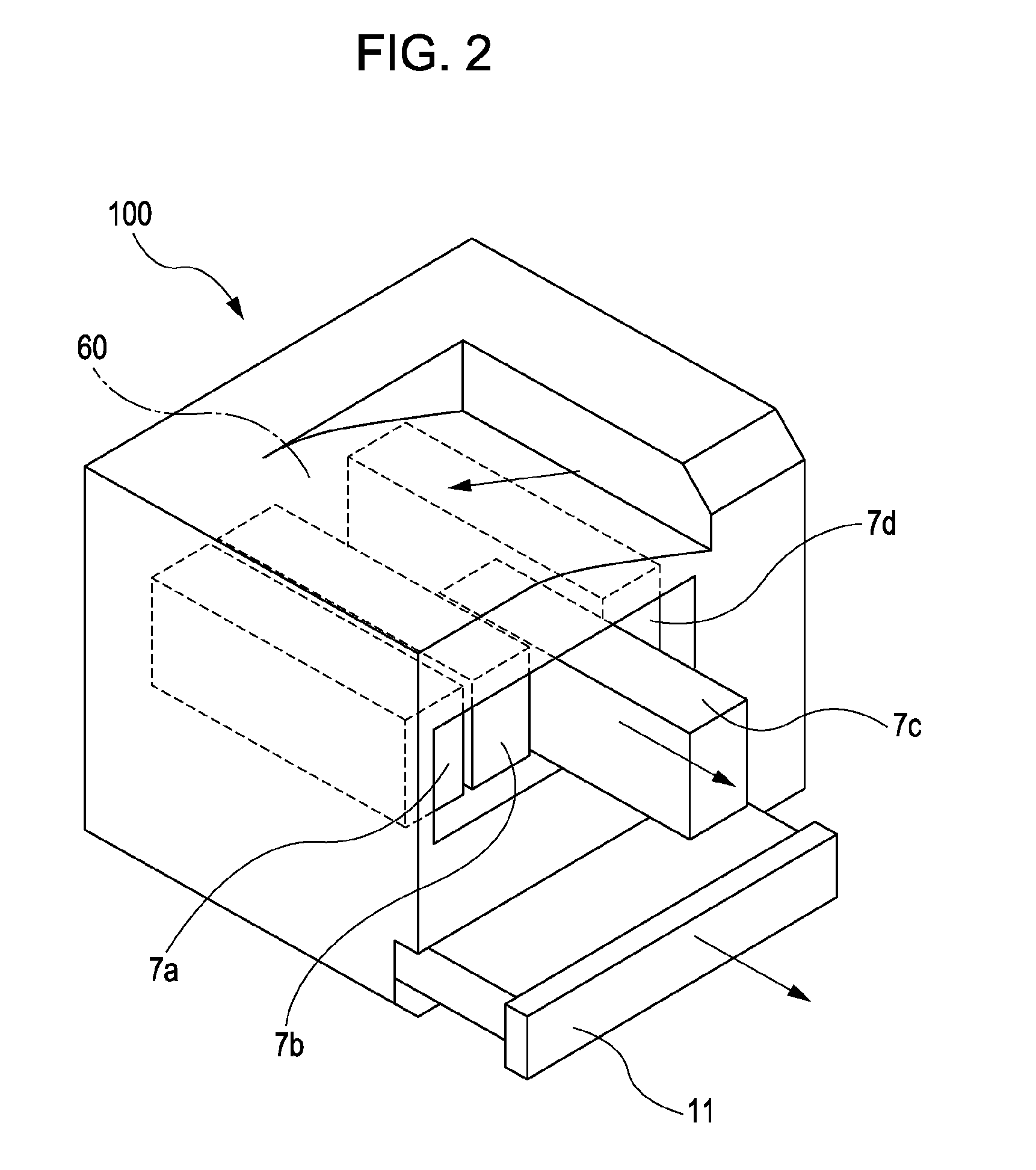

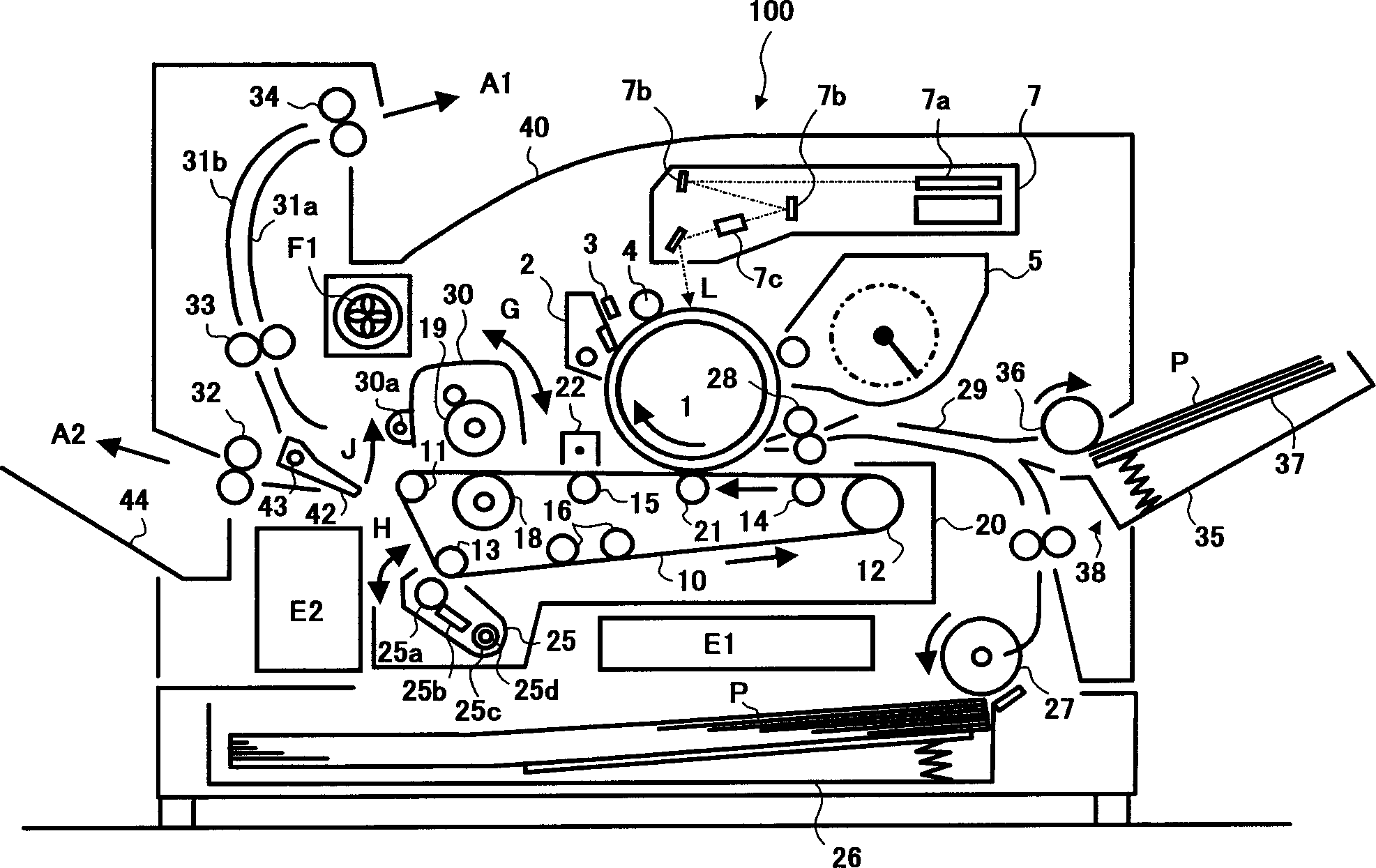

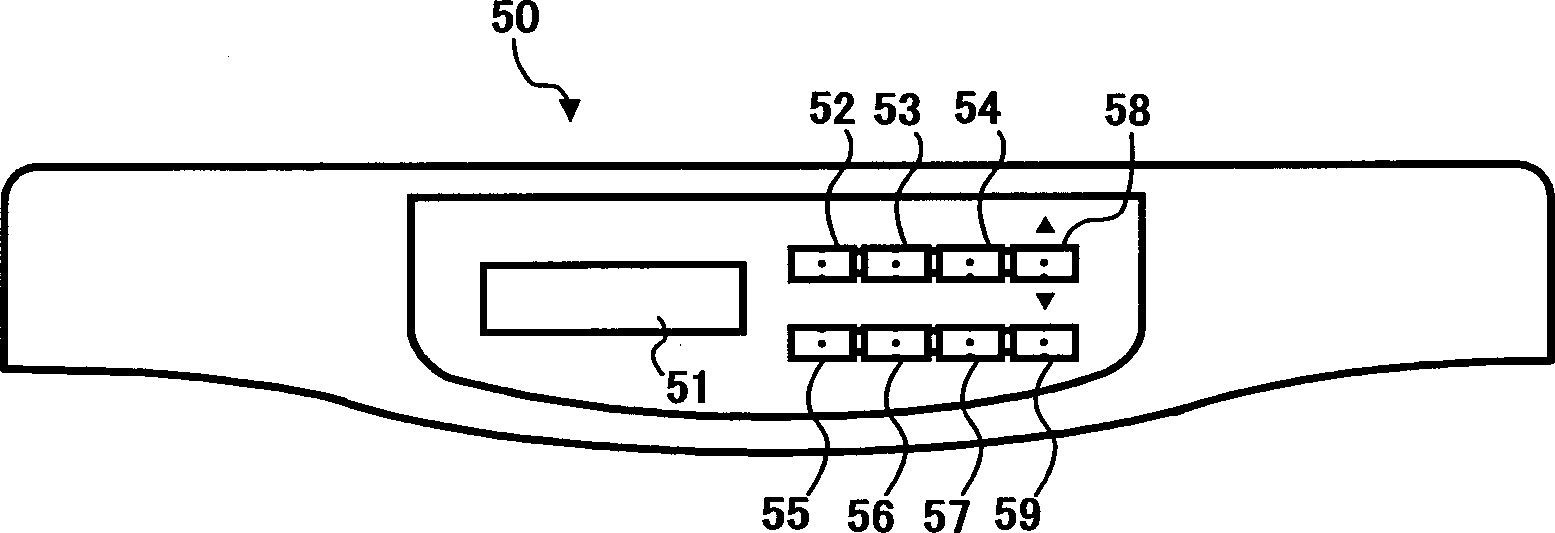

Image forming apparatus having a cleaning member configured to clean a transparent member of an optical device

ActiveUS20090269102A1Easy to cleanSave configuration spaceInking apparatusElectrographic process apparatusLaser scanningImage formation

An image forming apparatus including a laser scanner configured to irradiate a photoconductive drum with light and having a cover glass transmitting the light, a laser shutter movable between a closed position, where the laser shutter blocks an optical path of the light emitted from the laser scanner through the cover glass toward the photoconductive drum, and an open position, where the laser shutter opens the optical path, and a cleaning member with which the cover glass is cleaned, the cleaning member being supported by the laser shutter in such a manner as to be movable along the laser shutter.

Owner:CANON KK

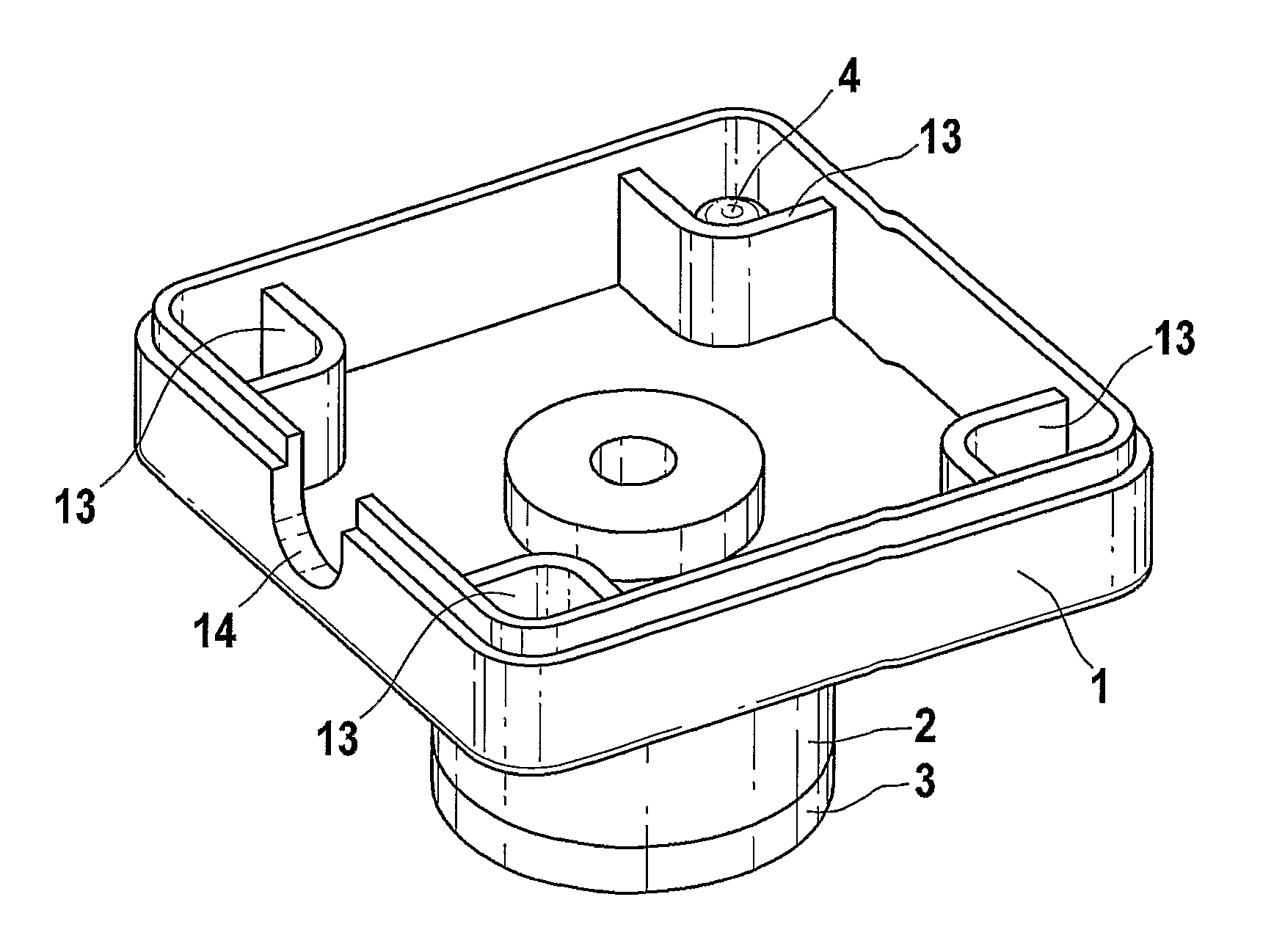

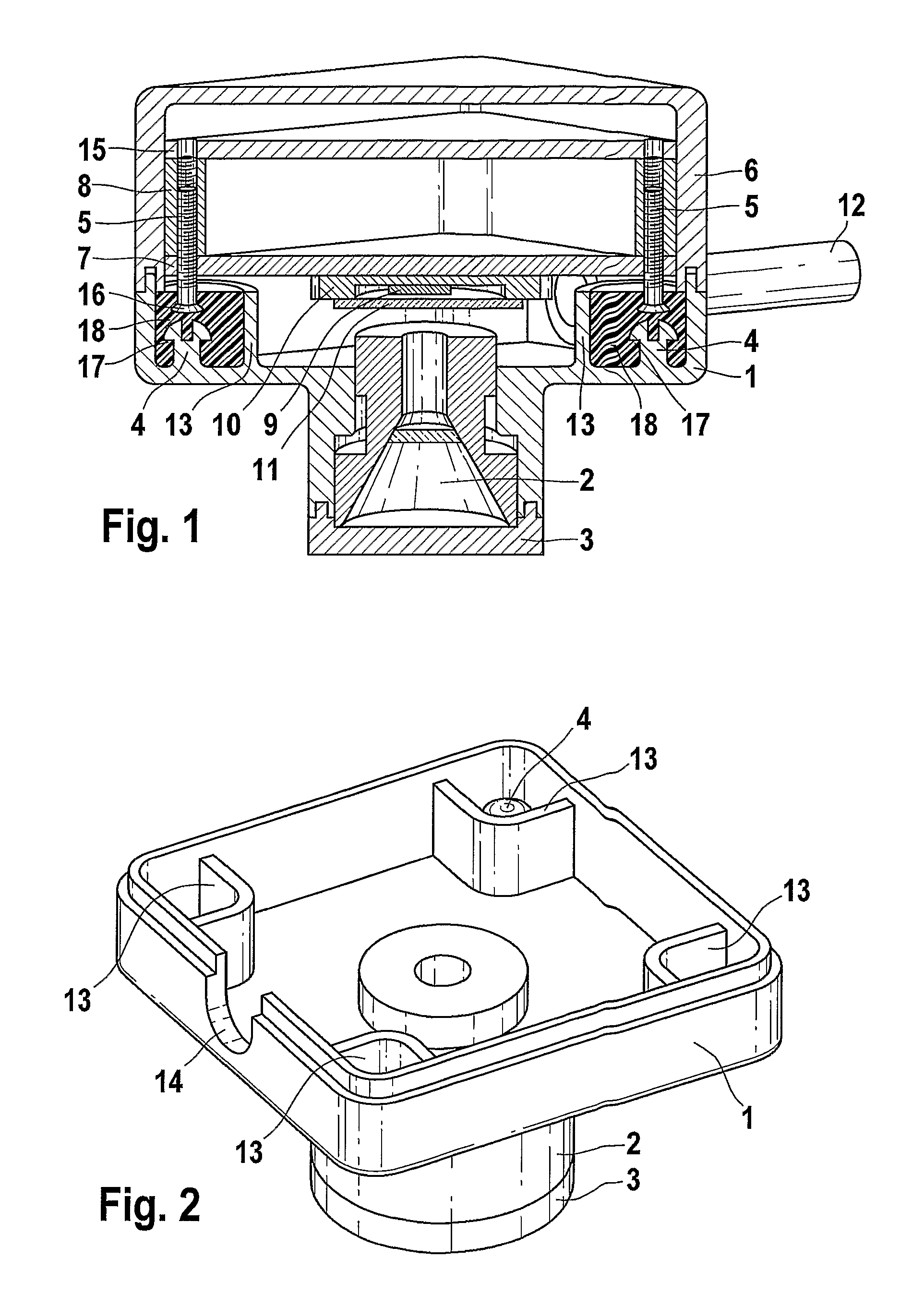

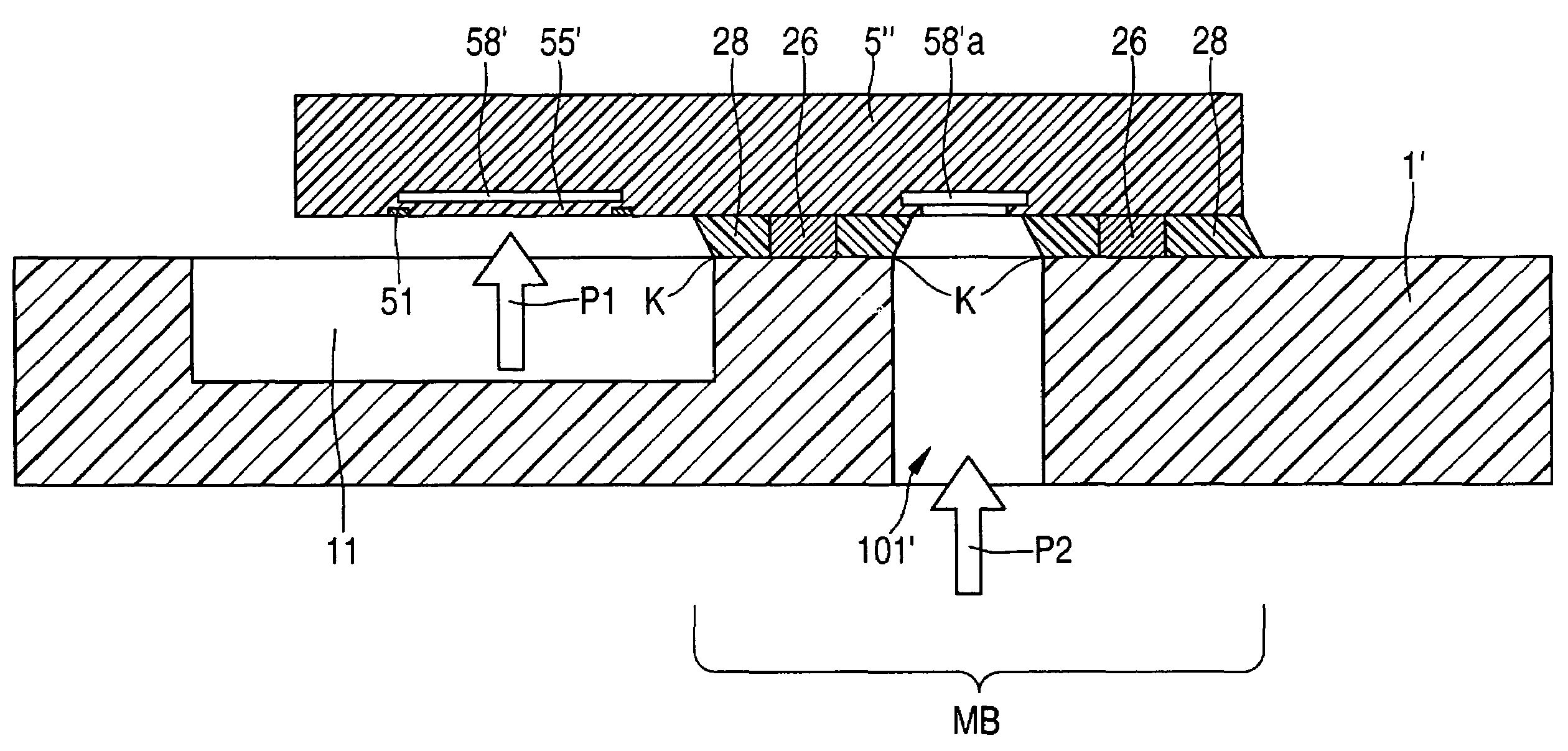

Method For Mounting Semiconductor Chips, and Corresponding Semiconductor Chip System

InactiveUS20080128840A1Simple and cost-effective configurationCost-effectiveFluid pressure measurement by electric/magnetic elementsSolid-state devicesSemiconductor chipFlip chip

A method is described for mounting semiconductor chips and a corresponding semiconductor chip system. The method may include providing a semiconductor chip having a surface that includes a diaphragm region and a peripheral region, the peripheral region having a mounting region, and a cavity being disposed underneath the diaphragm region, which extends into the mounting region and ends there in an opening. The method may also include providing a substrate which has a surface having a recess; mounting the mounting region of the semiconductor chip in flip-chip technology onto the surface of the substrate in such a way that an edge of the recess lies between the mounting region and the diaphragm region and the opening faces in the direction of the substrate. Additionally, the mounting region is underfilled using an underfilling, the edge of the recess serving as separating region for the underfilling so that no underfilling reaches the diaphragm region; and a through hole is provided through the substrate to the opening of the cavity.

Owner:ROBERT BOSCH GMBH

Imaging method and device

InactiveCN1351285AFormation conditions are suitableQuality improvementElectrographic process apparatusCardboardImage transfer

An image forming apparatus that is capable of forming an appropriate image even on a special transfer sheet, such as a thick and rigid transfer sheet (e.g., a cardboard and an envelope) and a long transfer sheet, etc. In the image forming apparatus, when the thick and rigid transfer sheet is used, a transfer bias applied to first and second transfer devices is increased by about 10 to 30% compared to that applied when a normal transfer sheet is used, and a temperature of fixing rollers is increased by about 10 to 30% compared to that when the normal transfer sheet is used. When the long transfer sheet that is longer than a circumferential length of a second image bearing member is used, an image transfer onto the second image bearing member is prohibited. In addition, the temperature of the fixing rollers is increased by about 10 to 30% compared to that when the normal transfer sheet is used.

Owner:RICOH KK

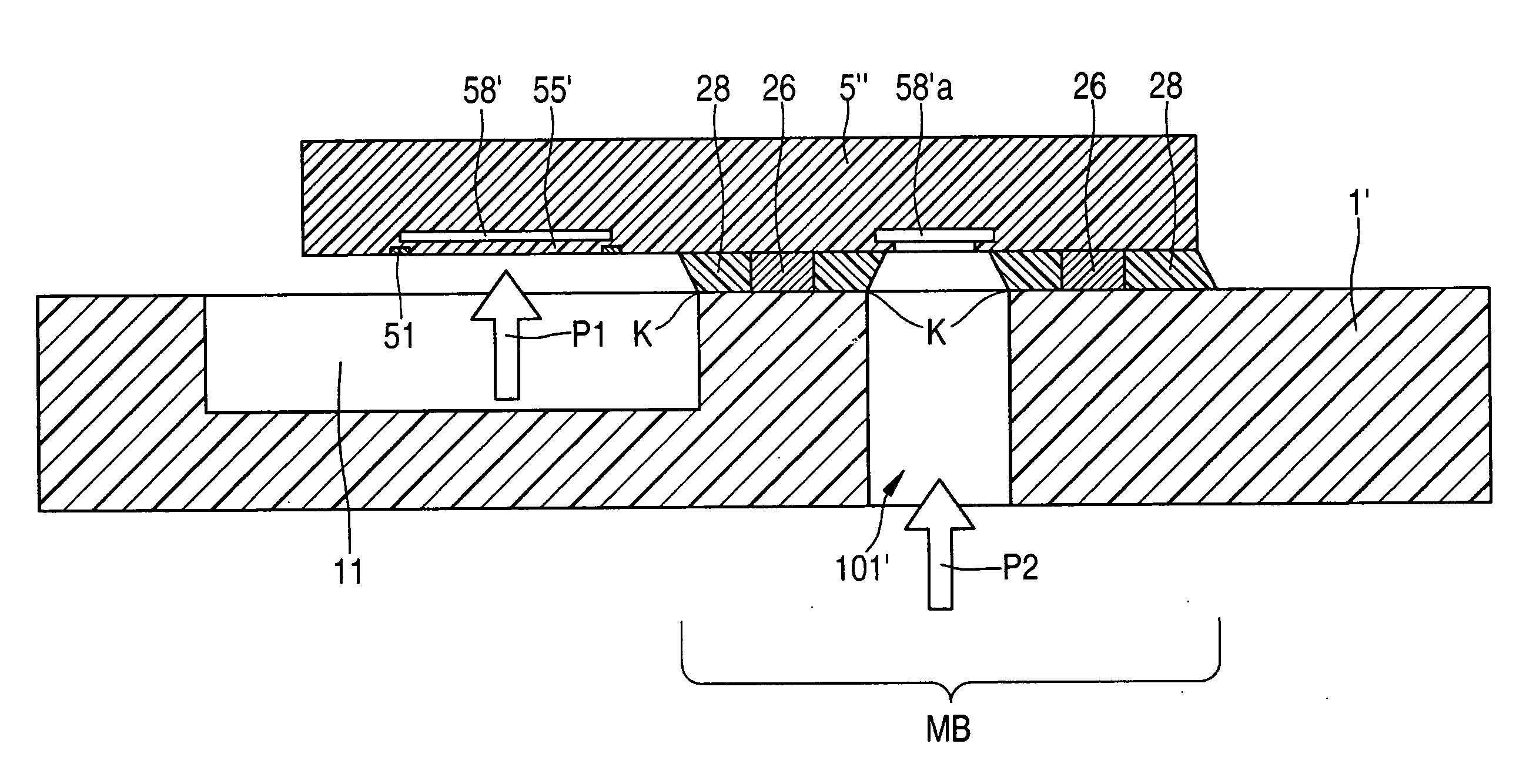

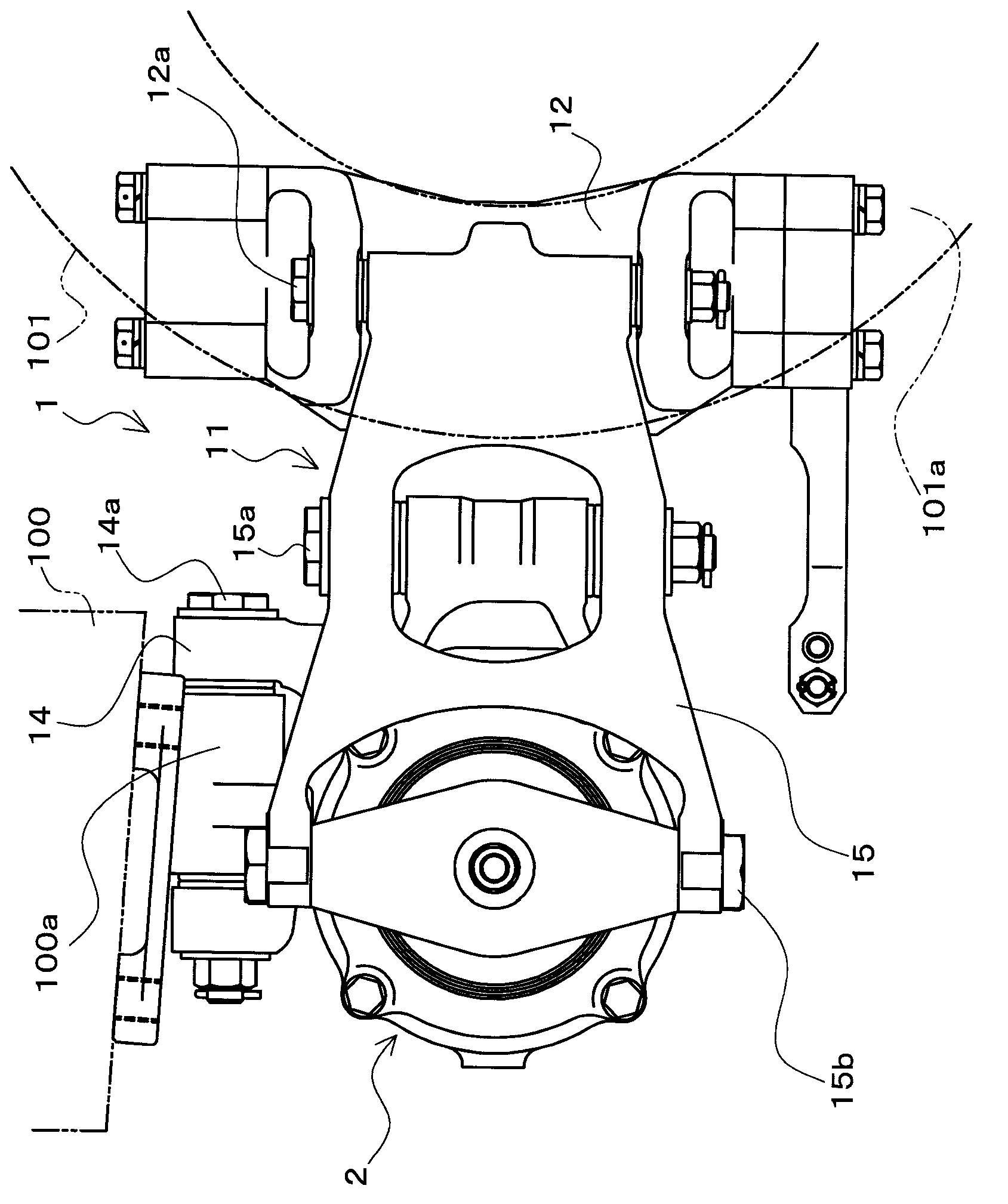

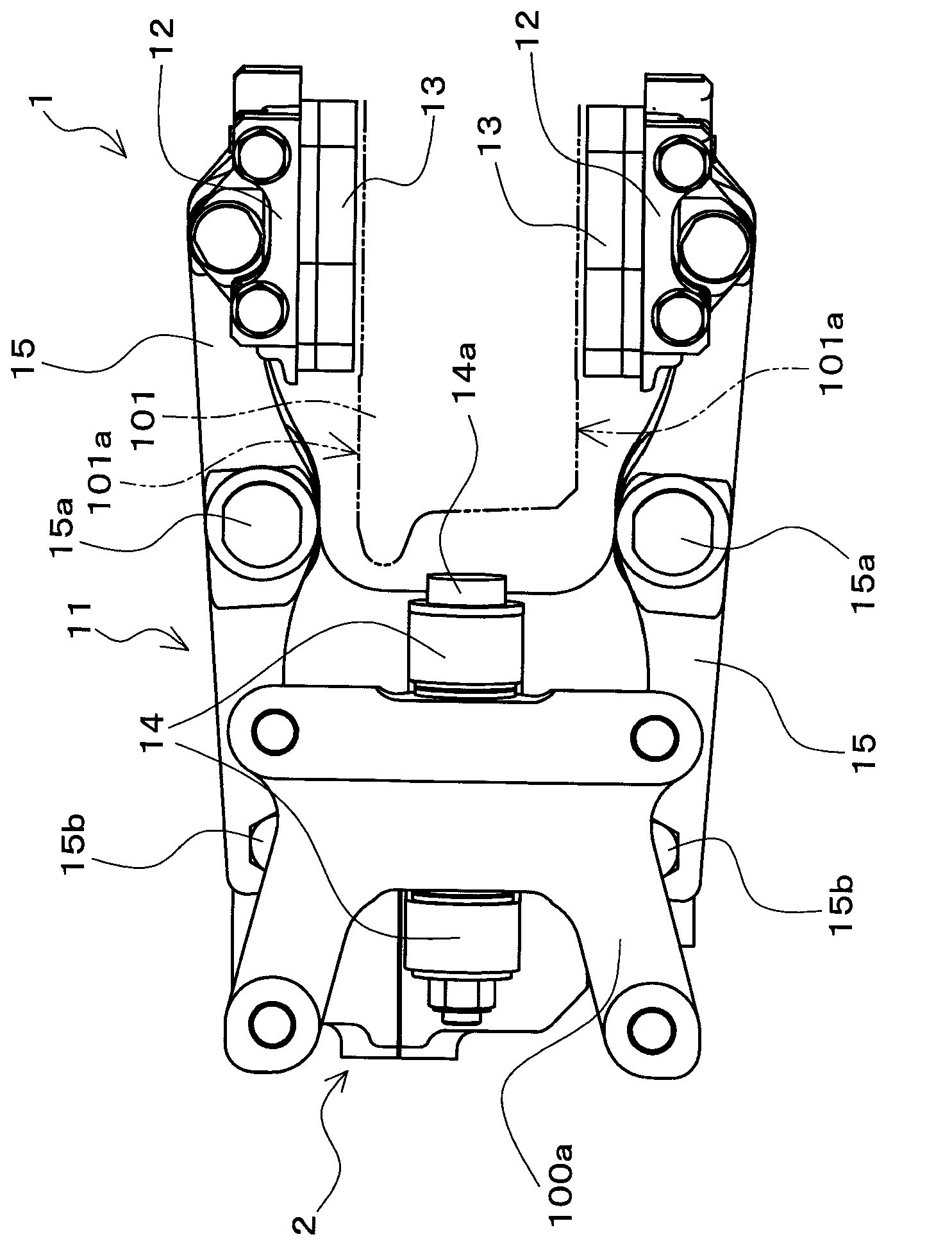

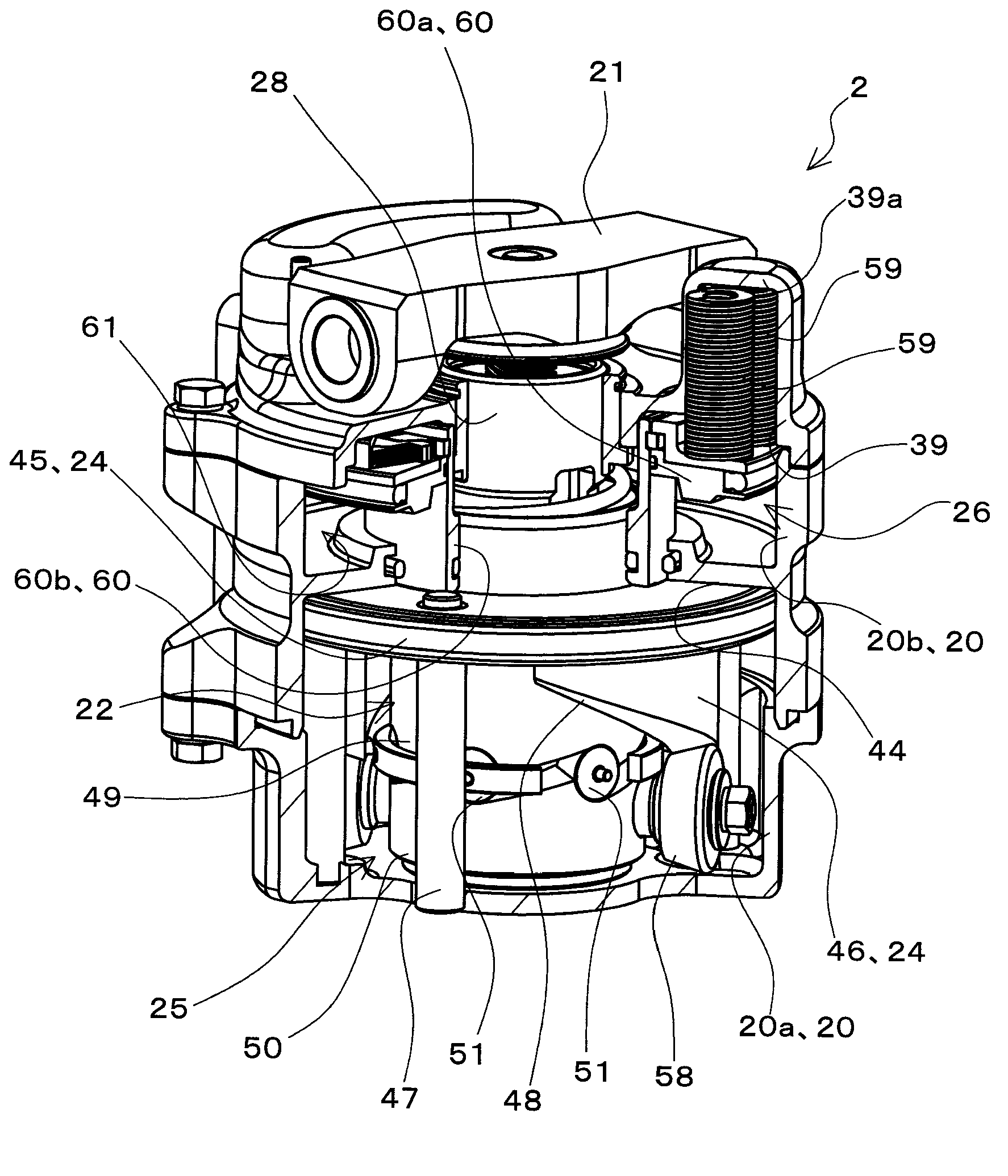

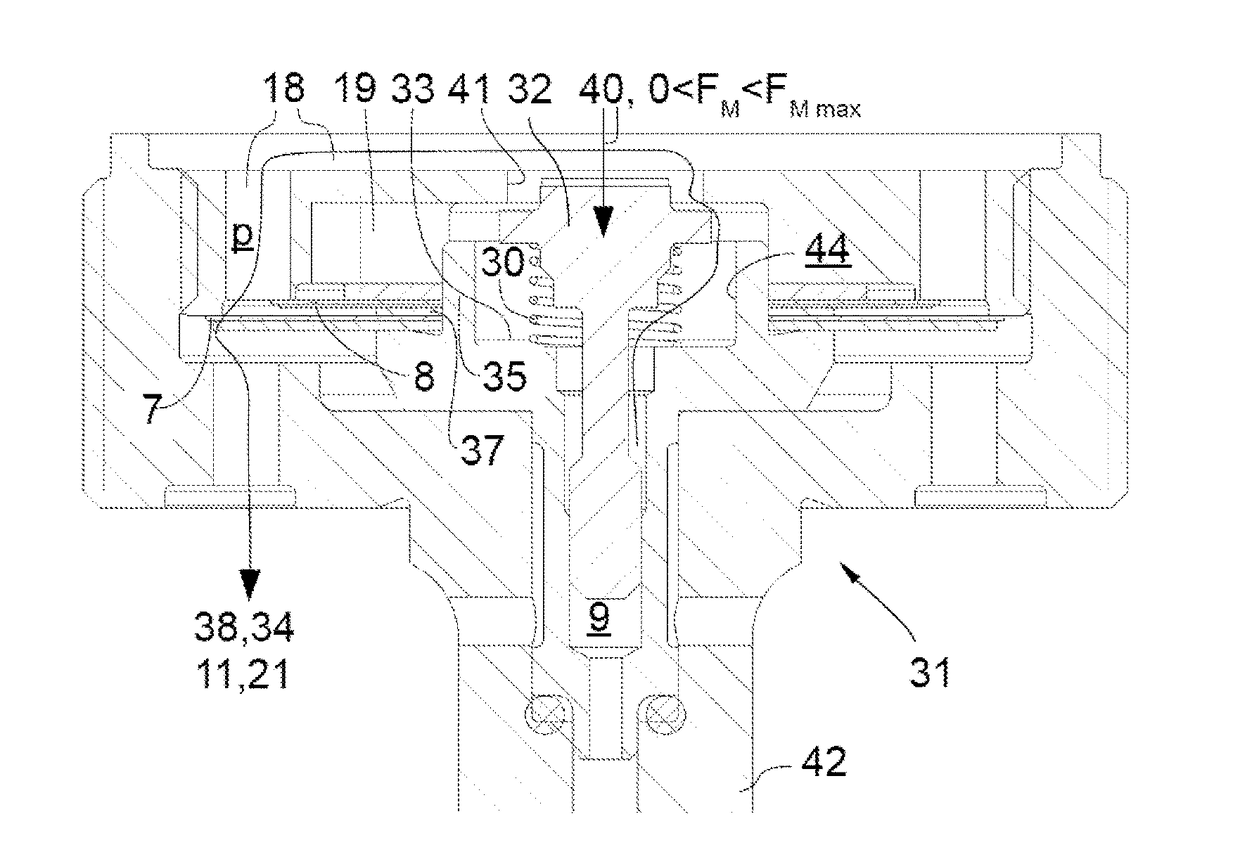

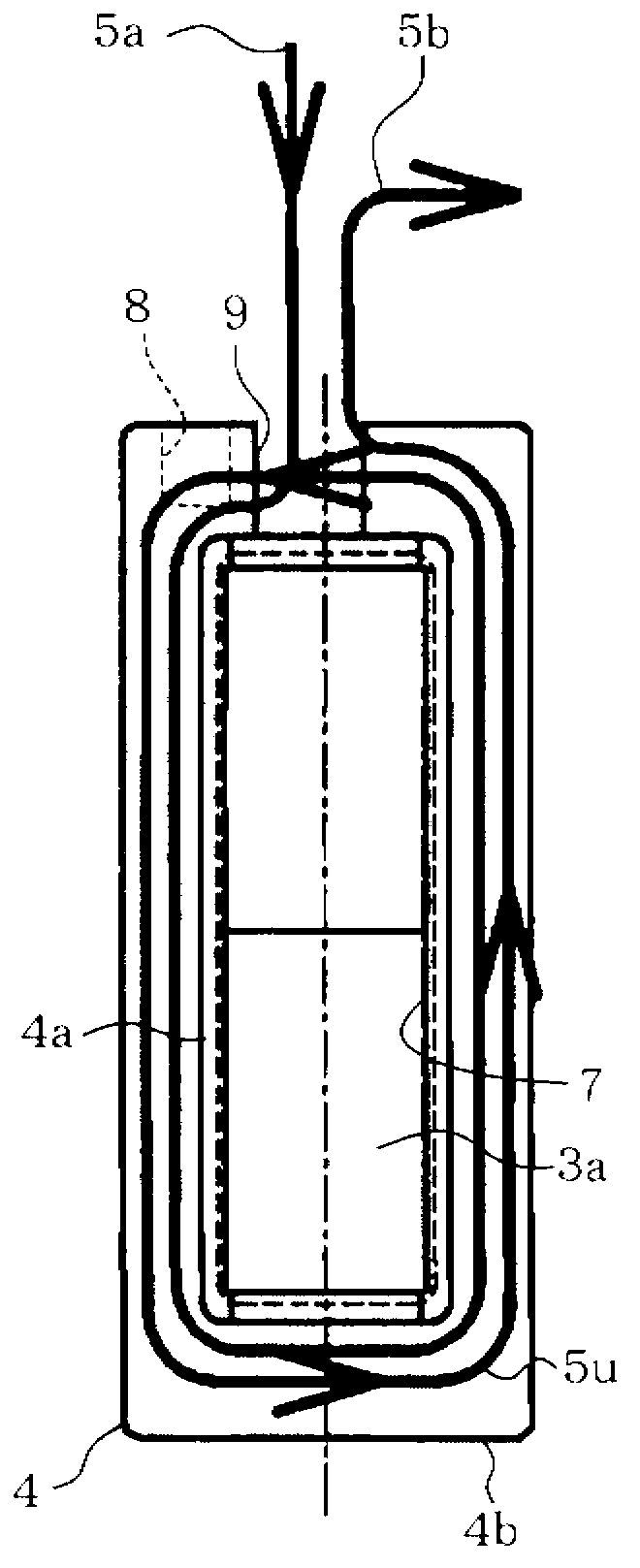

Brake cylinder device and disc brake device

InactiveCN102985718ASave configuration spaceGreat driving forceAxially engaging brakesBrake actuating mechanismsEngineeringMechanical engineering

Disclosed is a compact brake cylinder device which, while avoiding increases in the size of the device, is capable of increasing the braking force outputted from a brake output unit which moves together with a rod. A rod (22) is provided inside of a cylinder body (20) so as to freely move in the advancing and retracting directions of the cylinder shaft direction. A piston (24) partitions a pressure chamber (44) inside of the cylinder body (20), surrounding the circumference of the rod (22), and moves in a linear direction parallel to the movement direction of the rod (22). By supplying a pressure fluid to the pressure chamber (44), the piston (24) resists the biasing force of a biasing spring (23) and moves in the retracting direction relative to the cylinder body (20). At that time, a force-multiplication mechanism (25) converts the linear direction drive force generated by the piston (24) to a rotational direction, moves the rod (22) in the advancing direction, and multiplies the drive force from the piston (24) to act on the rod (22). A brake output unit (21) moves together with the rod (22) in the advancing direction and outputs a braking force.

Owner:NABLESCO CORP

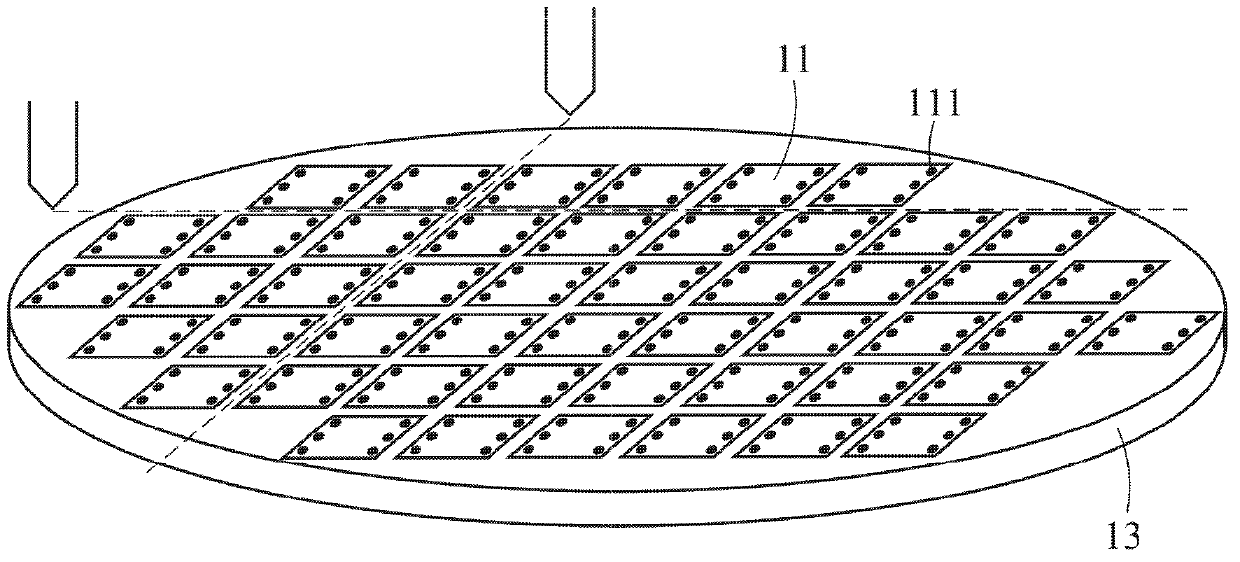

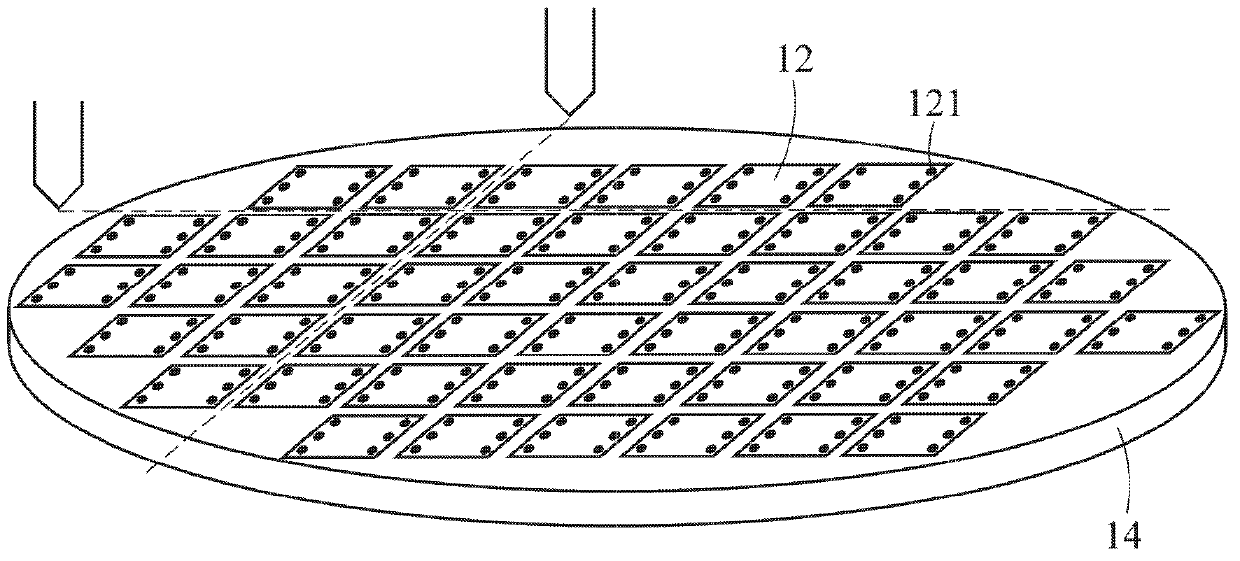

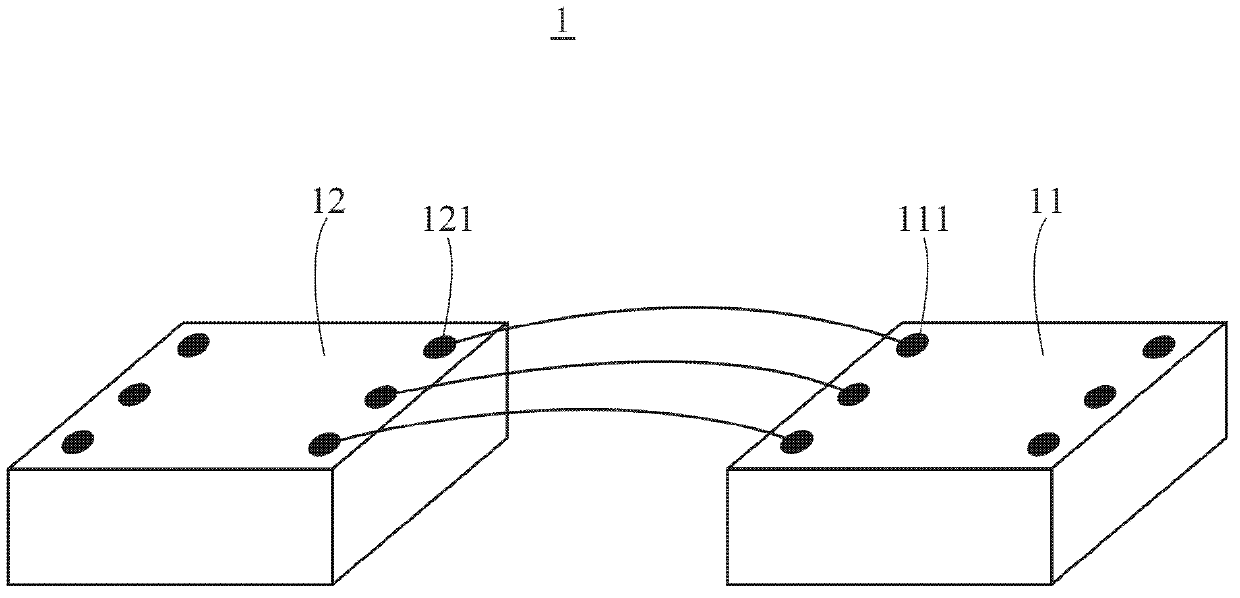

Structure of stacking chips and method for manufacturing the same

ActiveCN103325799ASave configuration spaceSave spaceSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionEngineering

A structure of stacking chips and a method for manufacturing the structure of stacking chips are provided. A wafer with optical chips and a glass substrate with signal processing chips are stacked with each other, and then subjected to ball mounting and die sawing to form the stacked packaging structure. The optical chips and the signal processing chips form the electrical connection on the surface of the glass substrate via the through holes thereof.

Owner:CHIPMOS TECH INC

Method for mounting semiconductor chips, and corresponding semiconductor chip system

InactiveUS7563634B2Simple and cost-effective configurationCost-effectiveFluid pressure measurement by electric/magnetic elementsSolid-state devicesSemiconductor chipEngineering

A method is described for mounting semiconductor chips and a corresponding semiconductor chip system. The method may include providing a semiconductor chip having a surface that includes a diaphragm region and a peripheral region, the peripheral region having a mounting region, and a cavity being disposed underneath the diaphragm region, which extends into the mounting region and ends there in an opening. The method may also include providing a substrate which has a surface having a recess; mounting the mounting region of the semiconductor chip in flip-chip technology onto the surface of the substrate in such a way that an edge of the recess lies between the mounting region and the diaphragm region and the opening faces in the direction of the substrate. Additionally, the mounting region is underfilled using an underfilling, the edge of the recess serving as separating region for the underfilling so that no underfilling reaches the diaphragm region; and a through hole is provided through the substrate to the opening of the cavity.

Owner:ROBERT BOSCH GMBH

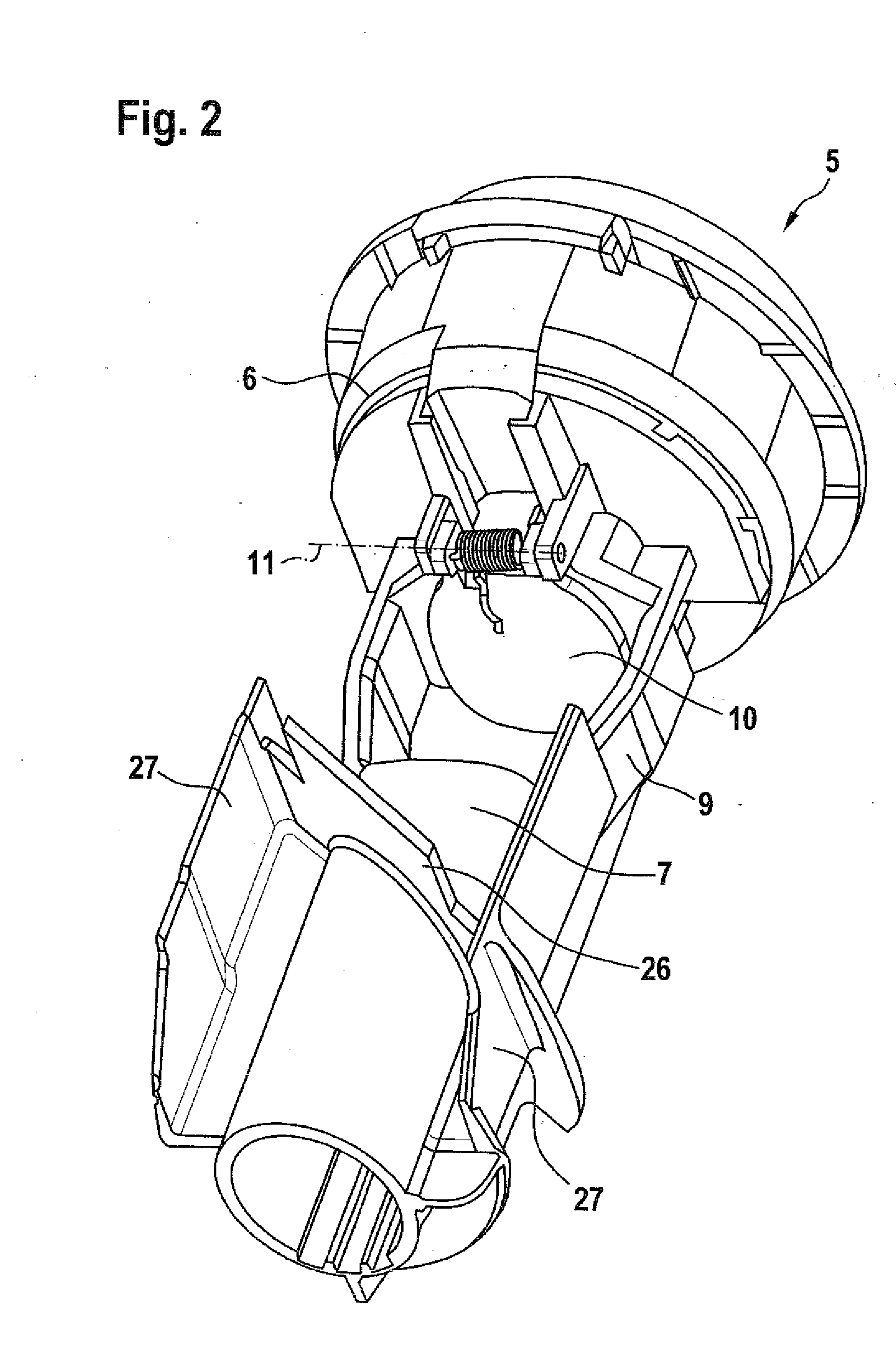

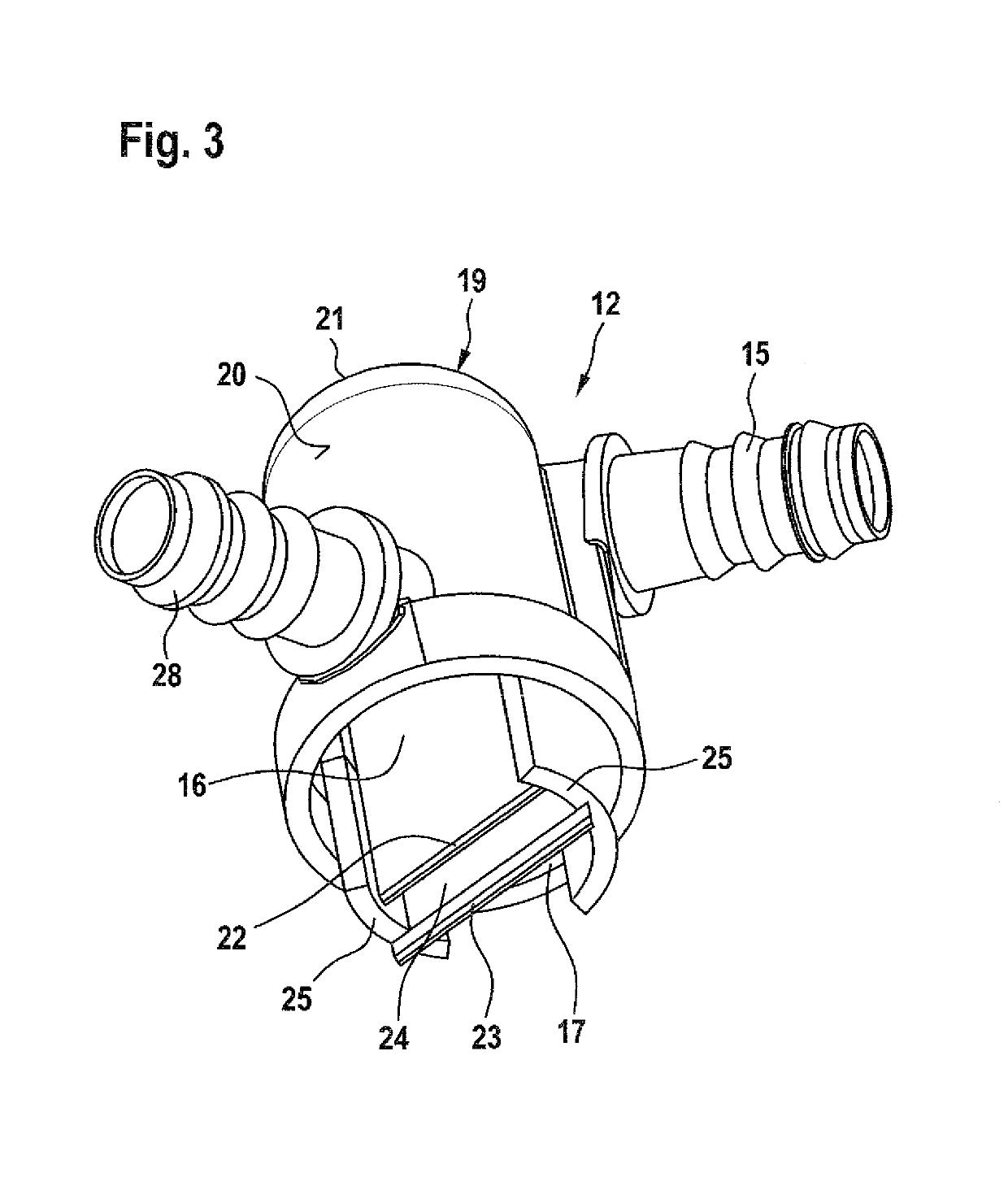

Operating medium tank arrangement for a motor vehicle

An operating medium tank arrangement for a motor vehicle includes an operating medium tank; a filling tube for refueling the operating medium tank, wherein the filling tube is fluidly connected on one side to the operating medium tank and on the other side has an insertion opening for receiving a refueling device; a guide insert arranged in the filling tube for guiding the refueling device; and a liquid separator including a separator chamber which is divided into a first sub-chamber and a second sub-chamber, wherein the first sub-chamber is fluidly connected to the operating medium tank via a ventilation line, wherein the second sub-chamber is fluidly connected to a filter device, wherein the separator chamber is fluidly connected to the filling tube for purging operating medium separated in the liquid separator into the filling tube, and wherein the first sub-chamber and the second sub-chamber are fluidly connected with each other via a labyrinth separator which is formed by the liquid separator and the filling tube.

Owner:AUDI AG

Back ring type coupled aerial

InactiveCN101257143AIncrease configuration lengthIncreased configuration convenienceRadiating elements structural formsAntennas earthing switches associationElectrical conductorCoupling

The invention provides a loop type coupling antenna, which includes: a feed-in wire, a coupling conductor, a first coupling part, a second coupling part, a second conductor and a ground surface, one end of the coupling conductor belongs to the first coupling part, another end belongs to the second coupling part; the feed-in wire connects with the first coupling part for providing a feed-in signal to the first coupling part; the feed-in signal couples to the second coupling part through the coupling conductor; one end of the second conductor connects with the second coupling part, another end connects with the ground surface that conduct signal of the second coupling part to the ground surface by using the second conductor. Impedance match can be adjusted efficiently by using the first coupling part, and antenna operation frequency width can be increased. The second coupling part and the second conductor reduce resonant frequency, and shorten wavelength of resonant path center frequency.

Owner:连展科技电子(昆山)有限公司

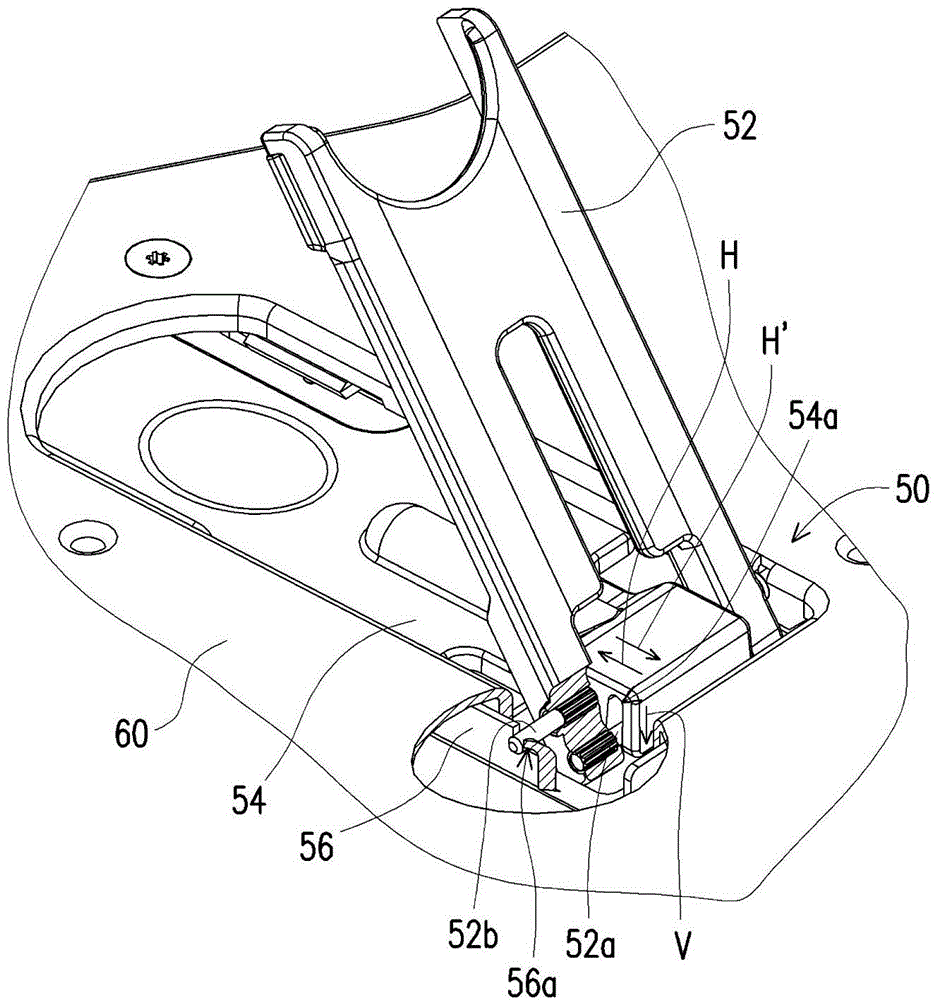

Handle module

ActiveCN105089349ASave configuration spaceSufficient sliding travelWing handlesFastening meansEngineeringComputer module

A handle module adapted to a chassis is provided. The chassis includes a main body and a cover. The handle module includes a base, a handle, a sliding component and a linking rod. The base is disposed on the cover. The handle is pivoted to the base. The sliding component is connected to the main body and is slidably disposed on the base. Two ends of the linking rod are pivoted to the handle and the sliding component respectively. When the handle closed to the base is rotated relative to the base to be expanded from the base, the handle pulls the sliding component to slide relative to the base along a first axis by the linking rod, so as to drive the cover to move from a first position to a second position relative to the main body along the first axis.

Owner:WISTRON CORP +1

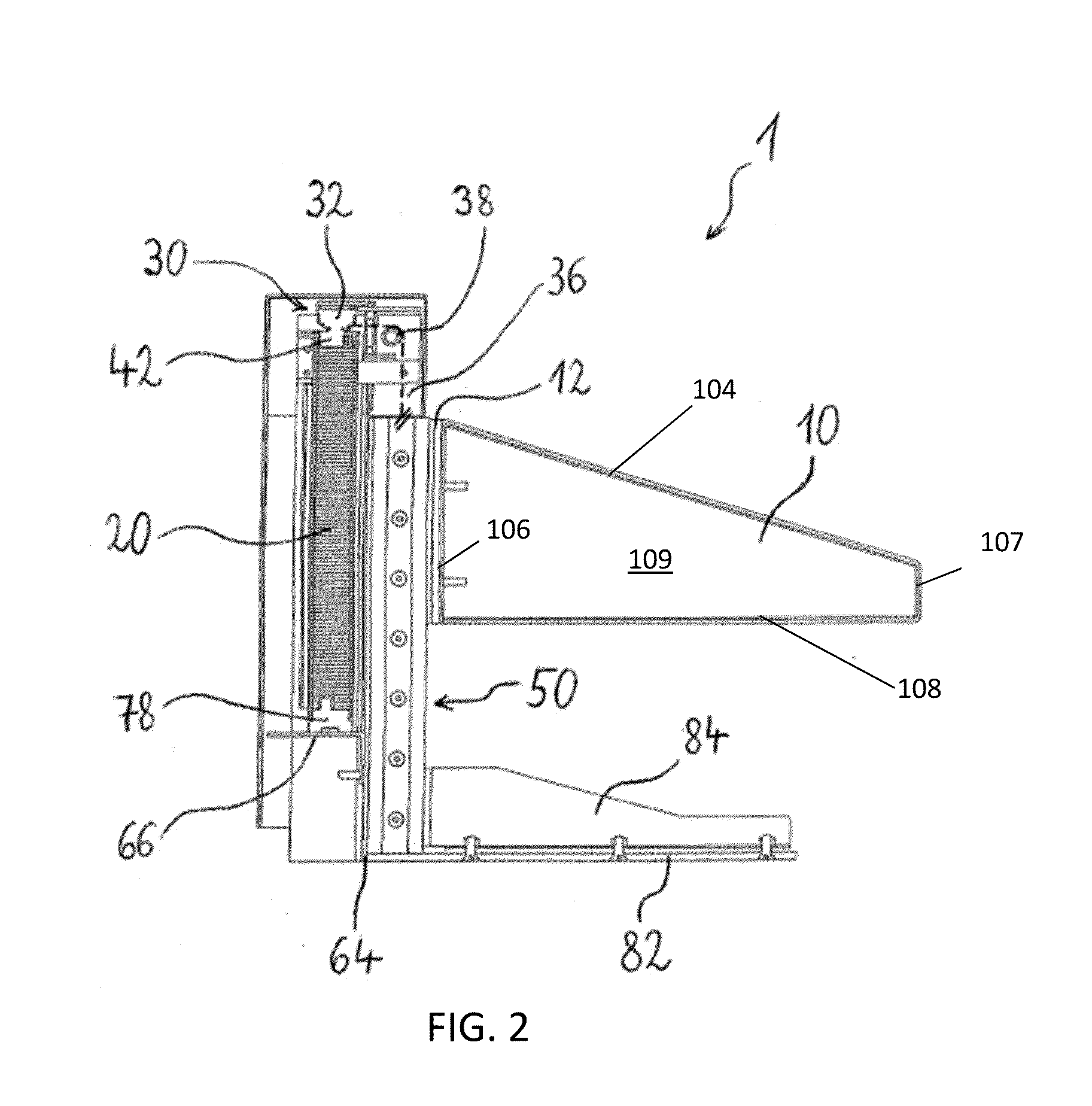

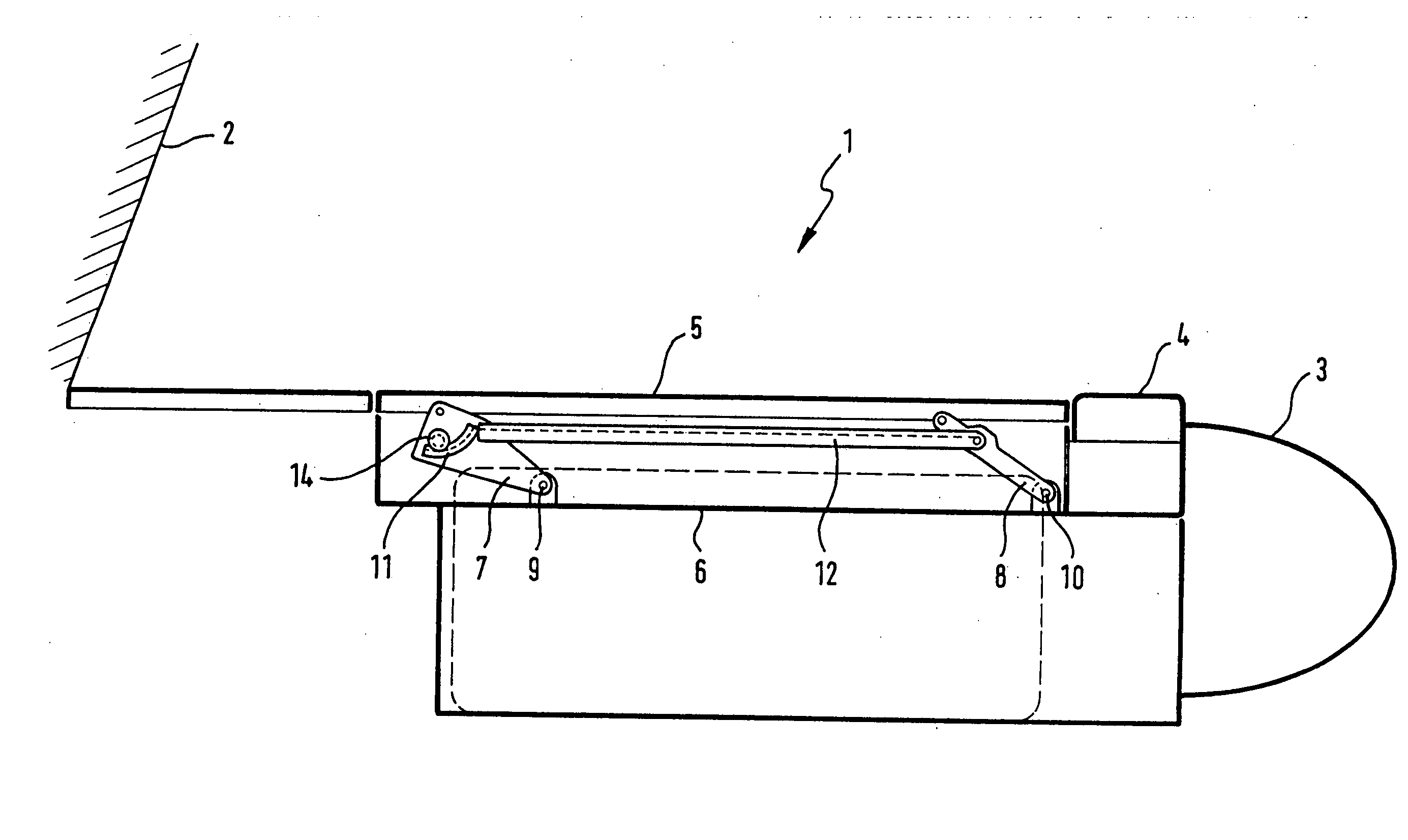

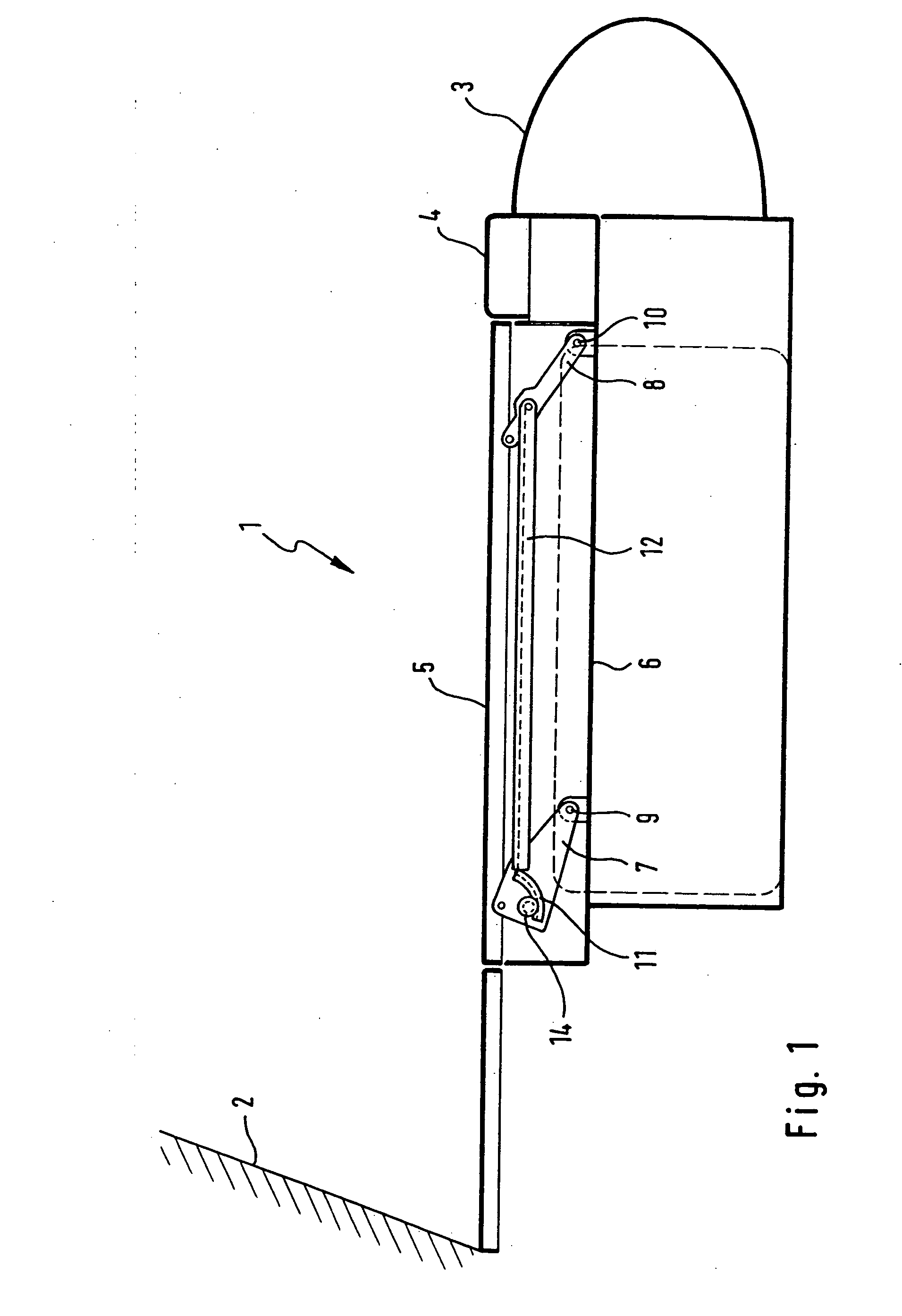

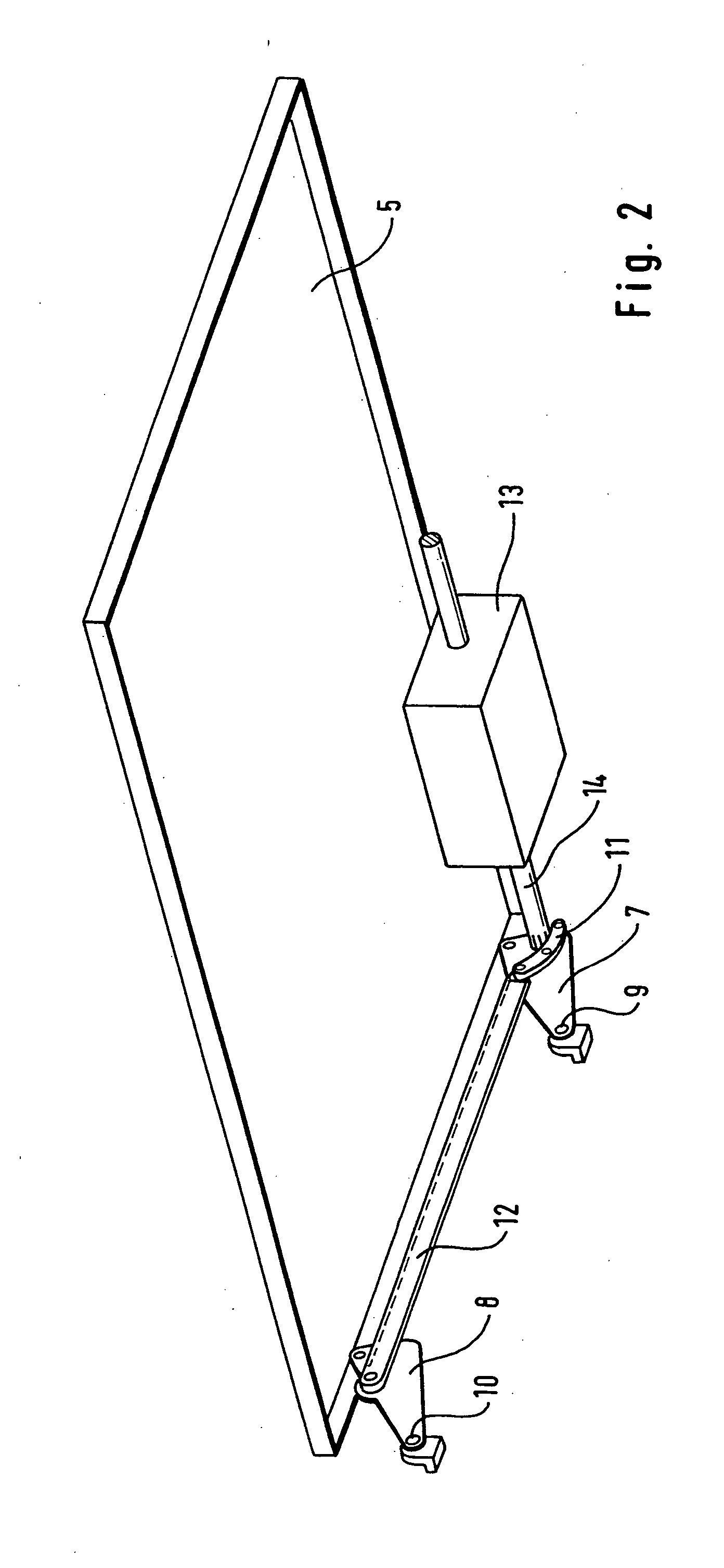

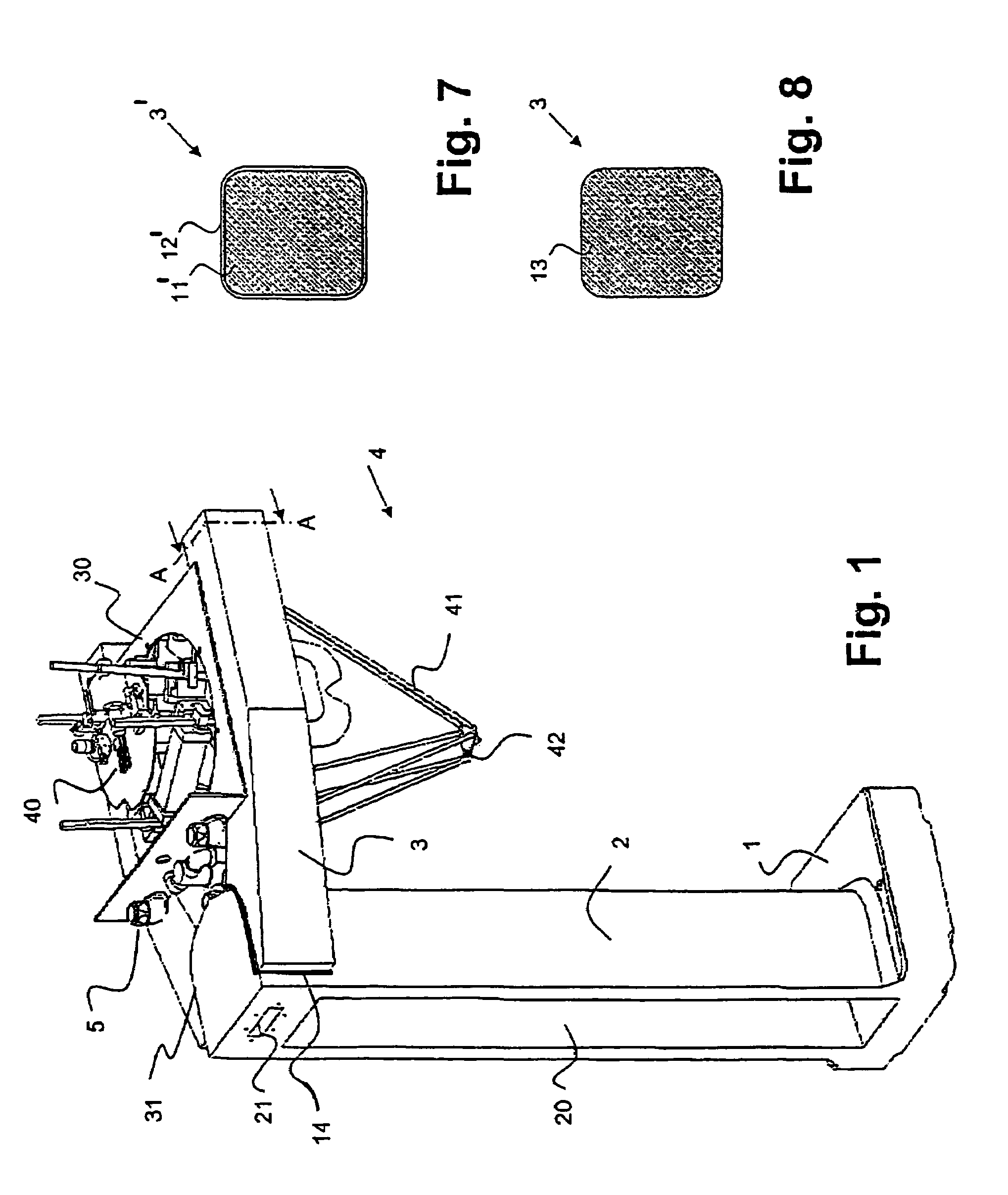

Loading floor for a vehicle and loading apparatus

InactiveUS20050002768A1Usable loading areaRaise and loading floorRefuse receptaclesLoading/unloading vehicle arrangmentEngineeringMechanical engineering

Owner:FAURECIA INNENRAUM SYST

Operating medium tank arrangement for a motor vehicle

ActiveUS10245942B2Efficient separationSignificant positive effectLarge containersFuel supplyMobile vehicleLine tubing

An operating medium tank arrangement for a motor vehicle includes an operating medium tank; a filling tube for refueling the operating medium tank, wherein the filling tube is fluidly connected on one side to the operating medium tank and on the other side has an insertion opening for receiving a refueling device; a guide insert arranged in the filling tube for guiding the refueling device; and a liquid separator including a separator chamber which is divided into a first sub-chamber and a second sub-chamber, wherein the first sub-chamber is fluidly connected to the operating medium tank via a ventilation line, wherein the second sub-chamber is fluidly connected to a filter device, wherein the separator chamber is fluidly connected to the filling tube for purging operating medium separated in the liquid separator into the filling tube, and wherein the first sub-chamber and the second sub-chamber are fluidly connected with each other via a labyrinth separator which is formed by the liquid separator and the filling tube.

Owner:AUDI AG

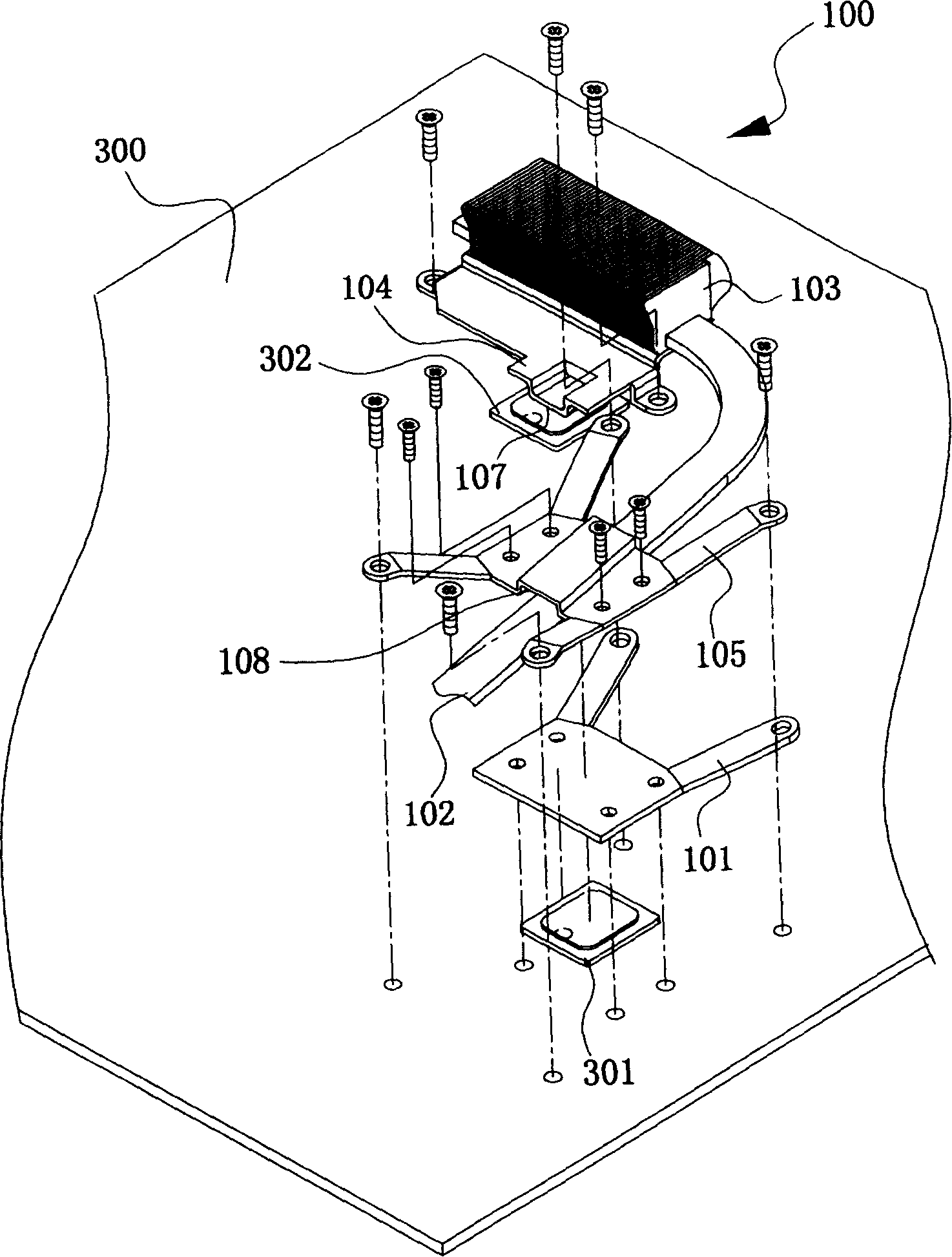

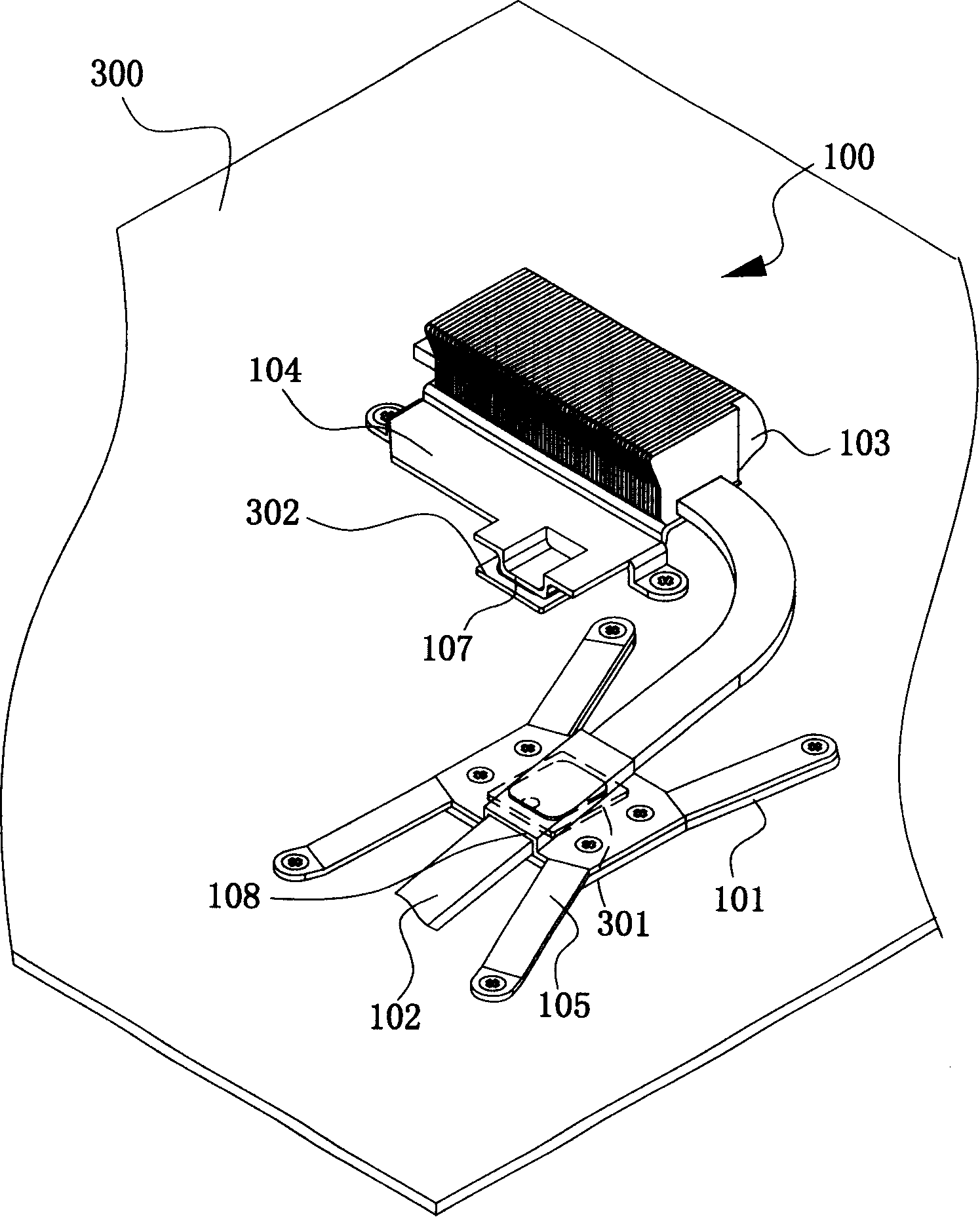

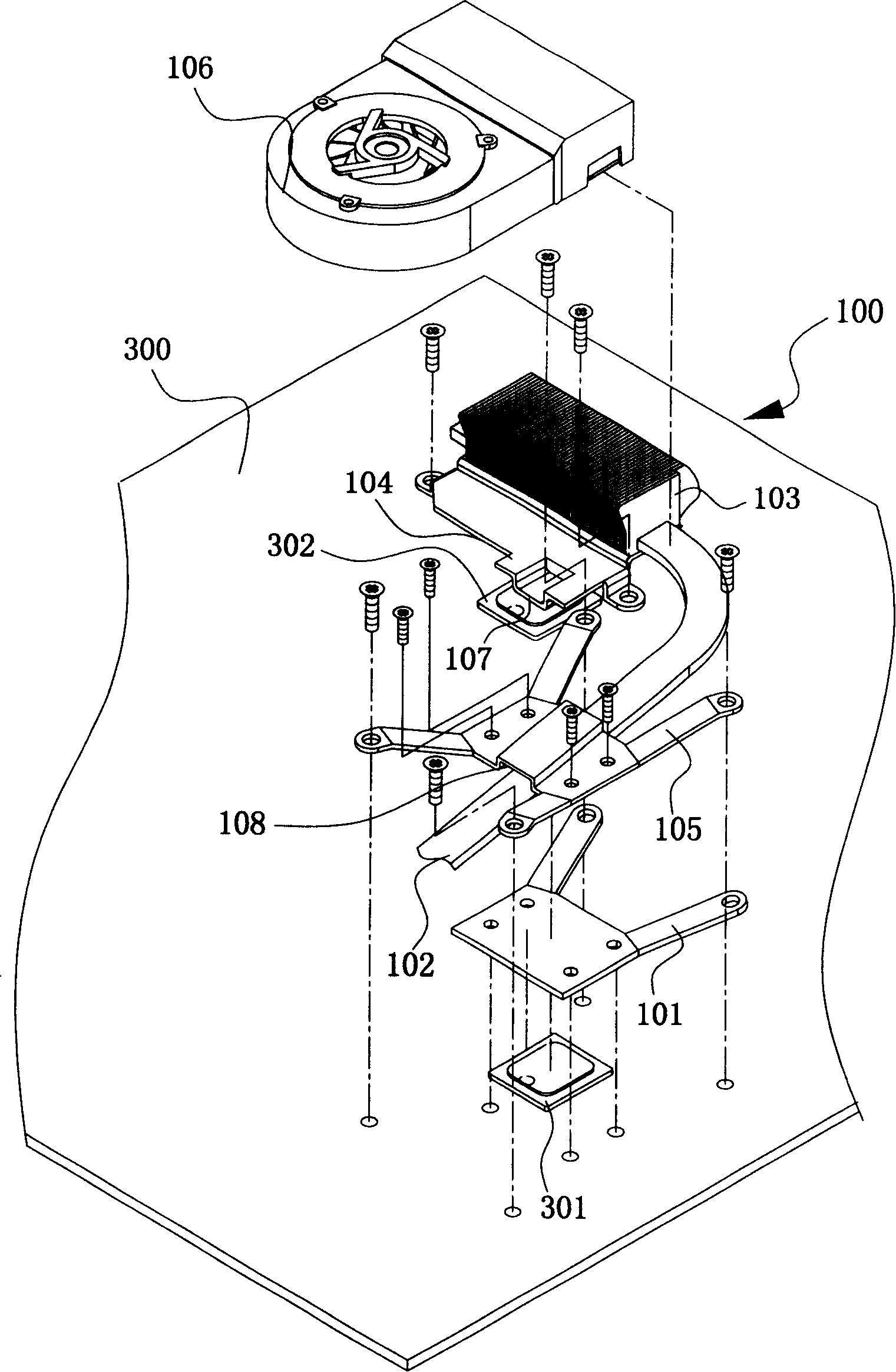

Dual heat source radiating module

InactiveCN101203122AReduce design costSave configuration spaceDigital data processing detailsSemiconductor/solid-state device detailsHeat conductingEngineering

A double-heat source thermal module dissipates the heat generated from a first heating element and a second heating element, and comprises a first heat conducting pipe, a heat dissipating element, a heat pipe which is respectively connected with the first heat conducting pipe and the heat dissipating element, a second heat conducting plate which is formed by the extension of the heat dissipating element; wherein, the first heat conducting pipe and the second heat conducting pipe contact the first heating element and the second heating element respectively to conduct the heat of the two heating elements; the first heat conducting plate conducts the heat to the heat dissipating element through the heat pipe; since the second heat conducting plate is formed by the extension of the heat dissipating element, the heat can be directly conducted to the heat dissipating element, thereby reducing the configuration length of the heat pipe, rapidly concentrating the heat to the heat dissipating element to dissipate the heat and effectively reducing the configuration space of the thermal module.

Owner:INVENTEC CORP

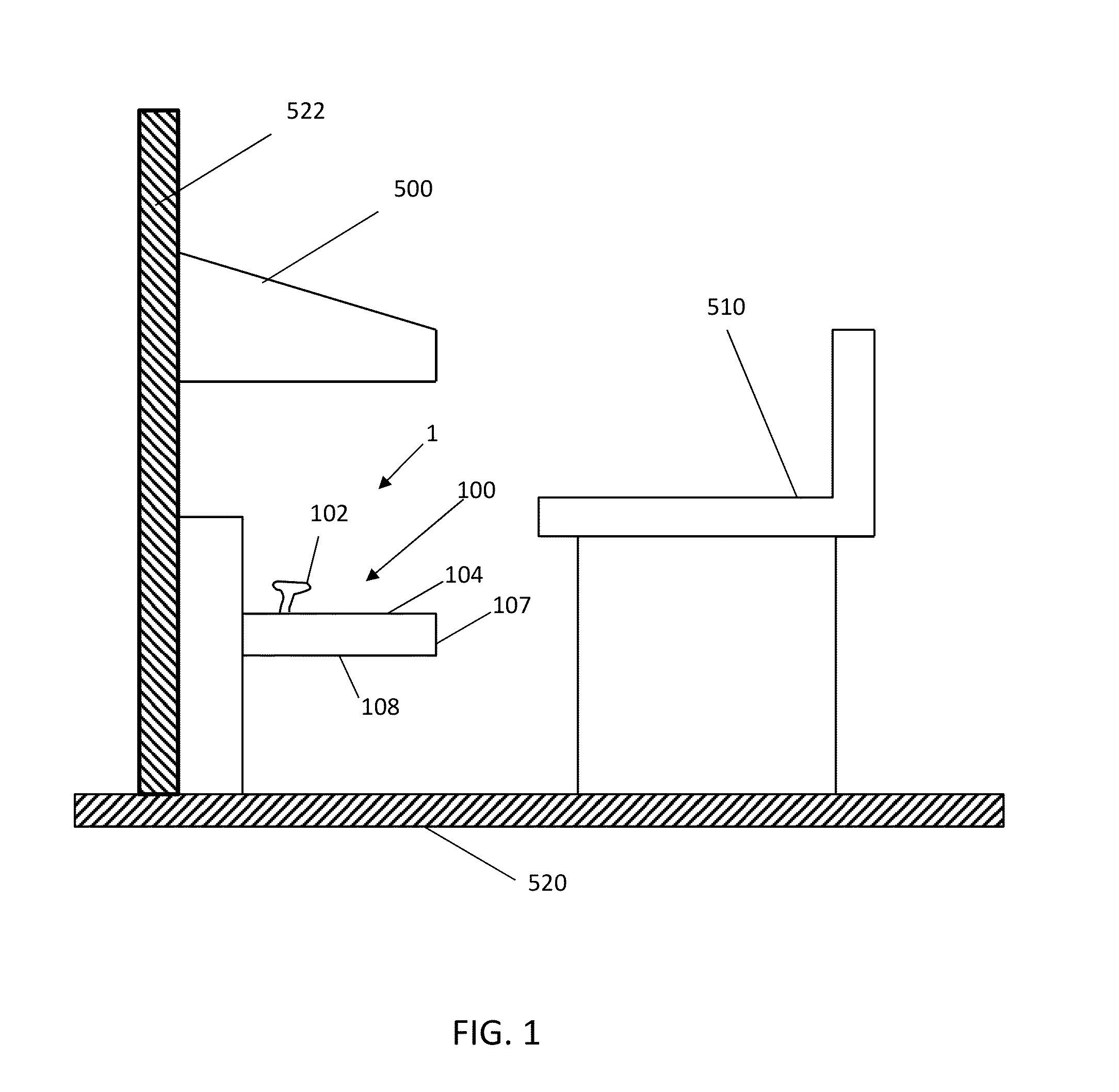

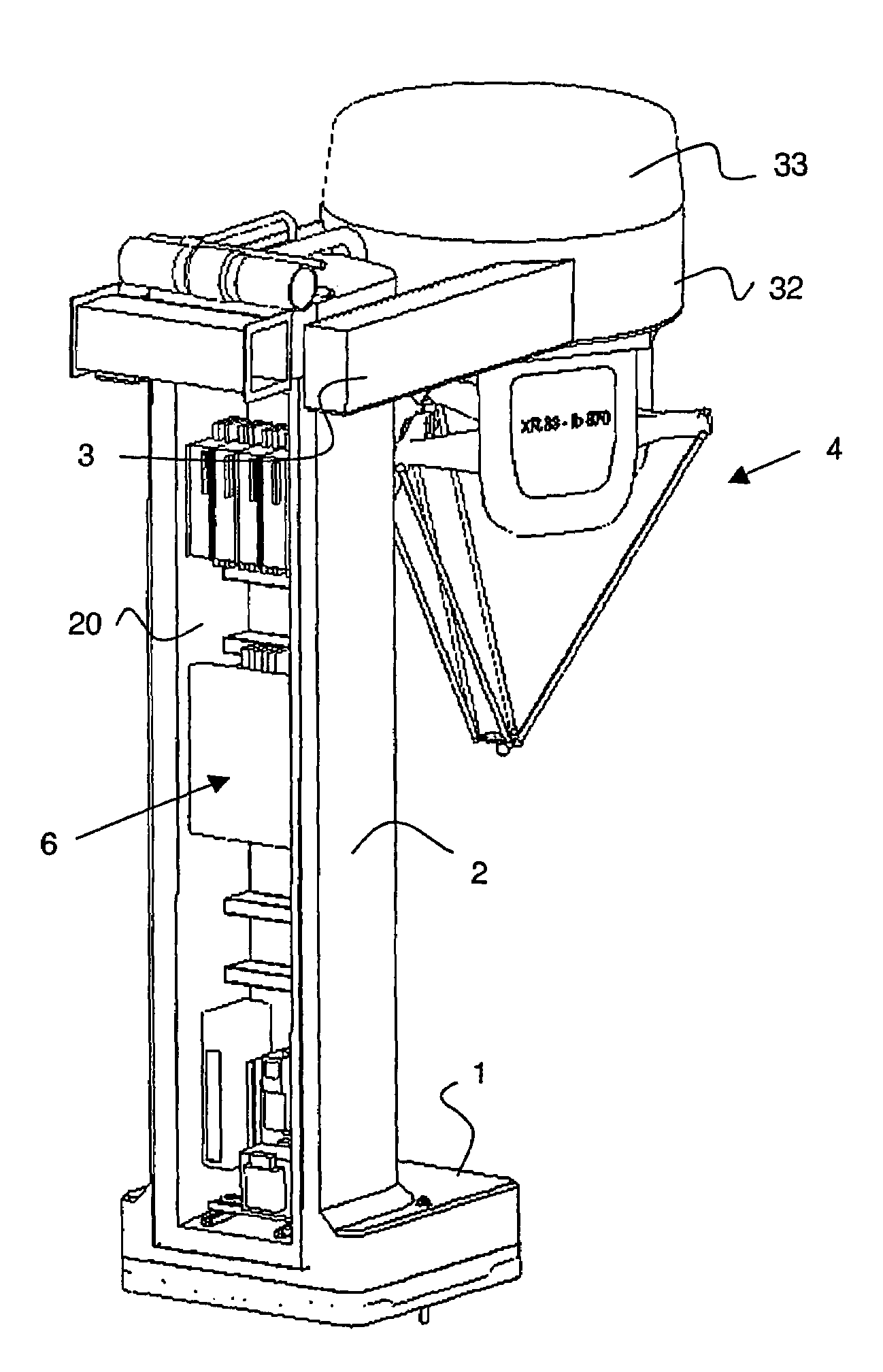

Device for carrying and fastening a robot

InactiveUS7331253B2Good vibration reduction effectSave spaceProgramme-controlled manipulatorJointsDelta robotControl theory

A device for carrying and fastening a robot (4), in particular a delta robot, is designed in a gallows shape. It has a foot (1), a column (2) adjoining the foot (1), and at least one cantilever arm (3), fastened to this column (2), for fastening the robot (4). The cantilever arm (3) in this case is fastened to the column (2) in a fixed position. The device consists at least partly of a composite material, in particular a cast mineral. This device for carrying and fastening a robot is extremely space-saving and nonetheless has good vibration-damping properties.

Owner:ROBERT BOSCH GMBH

Multi-frequency antenna

InactiveCN101442151AWith ultra-wideband characteristicsSimple structureSimultaneous aerial operationsRadiating elements structural formsPhysicsFrequency band

The invention relates to a multi-frequency antenna, which comprises a ground plane, a radiation conductor, a parasitic conductor and a feed-in wire, wherein the radiation conductor comprises a feed-in part, a first radiation arm and a second radiation arm; the feed-in wire comprises a central wire and an external wire; the feed-in part is provided with a coupling edge; the parasitic conductor is connected with the ground plane and provided with a coupling edge which is arranged along a profile of the coupling edge of the feed-in part, and a gap is formed between the coupling edge of the parasitic conductor and the coupling edge of the feed-in part; the central wire is connected with the feed-in part; and the external wire is connected with the ground plane. The low-frequency resonance mode is excited through the first radiation arm and the second radiation arm and the high-frequency resonance mode is excited through the parasitic conductor, so that an antenna system integrally covers various operation frequency bands and has the characteristic of ultra wide band; and simultaneously the composition structure of the antenna is simplified.

Owner:连展科技电子(昆山)有限公司

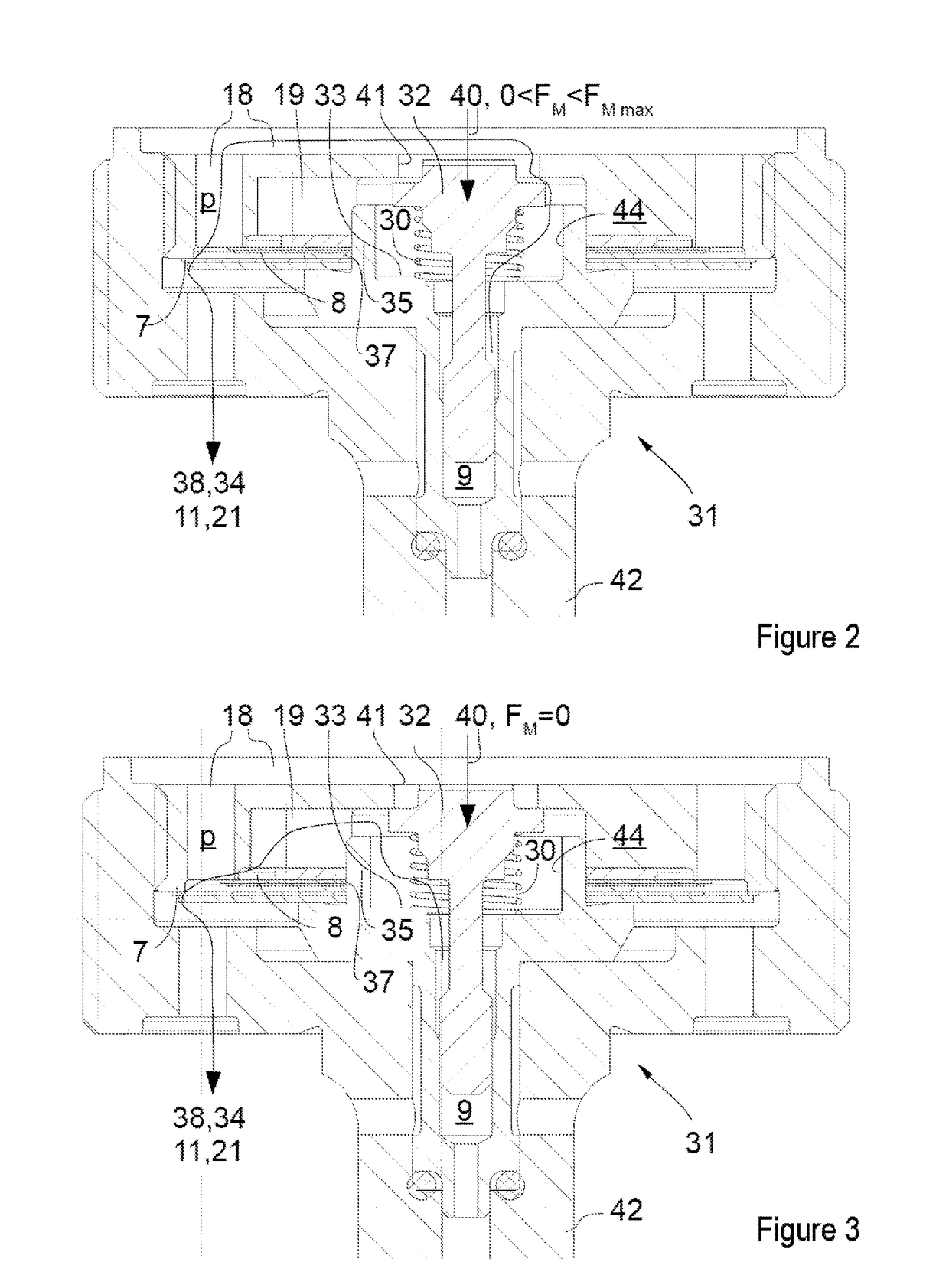

Method for operating a controllable shock absorber for motor vehicles

ActiveUS20170234396A1Reduce in quantityAvoid instabilitySpringsShock absorbersControl roomControl valves

A method for operating a controllable shock absorber may involve damping movement of a valve body by loading the valve body with a back pressure on an outflow side. Further, the controllable shock absorber may include a cylinder tube, a piston within the cylinder tube that divides the cylinder tube into two working spaces and includes a couple fluid leadthroughs connecting the working spaces, and first and second valve assemblies for damping piston movement in first and second actuating directions that are disposed on the leadthroughs. Each valve assembly may have a pilot control chamber and a valve plate that is either seated on or spaced apart from a valve seat in closed and open valve positions. Each valve plate can be prestressed closed by pressure loading the pilot control chamber. The pressures of the pilot control chambers can be set by a pilot control valve that comprises a movable valve body. As a result, an outflow cross section between the pilot control chambers and the working spaces can be set. The valve body may be loaded on an outflow side with a back pressure, as a result of which movement of the valve body is damped.”

Owner:THYSSENKRUPP BILSTEIN +1

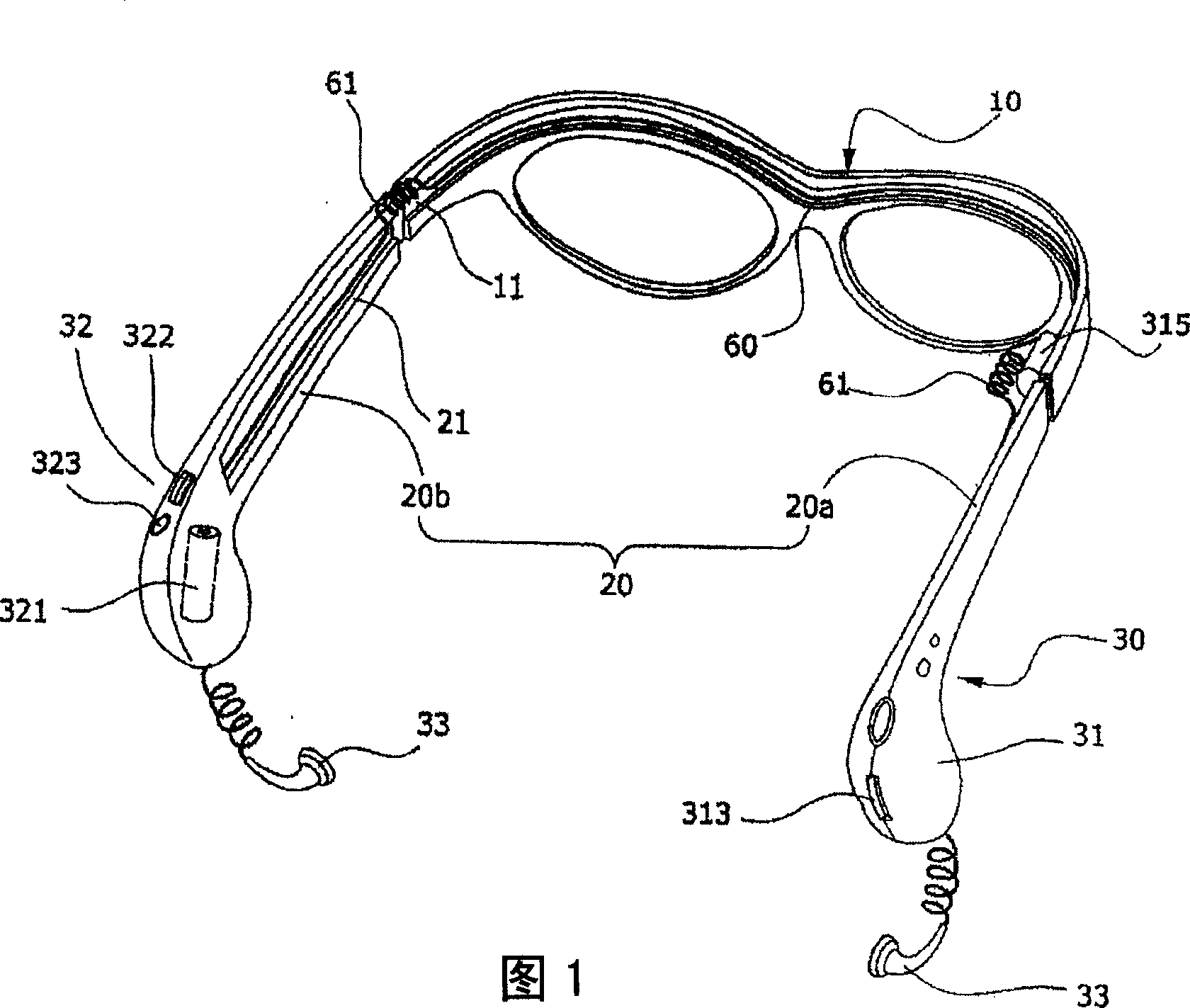

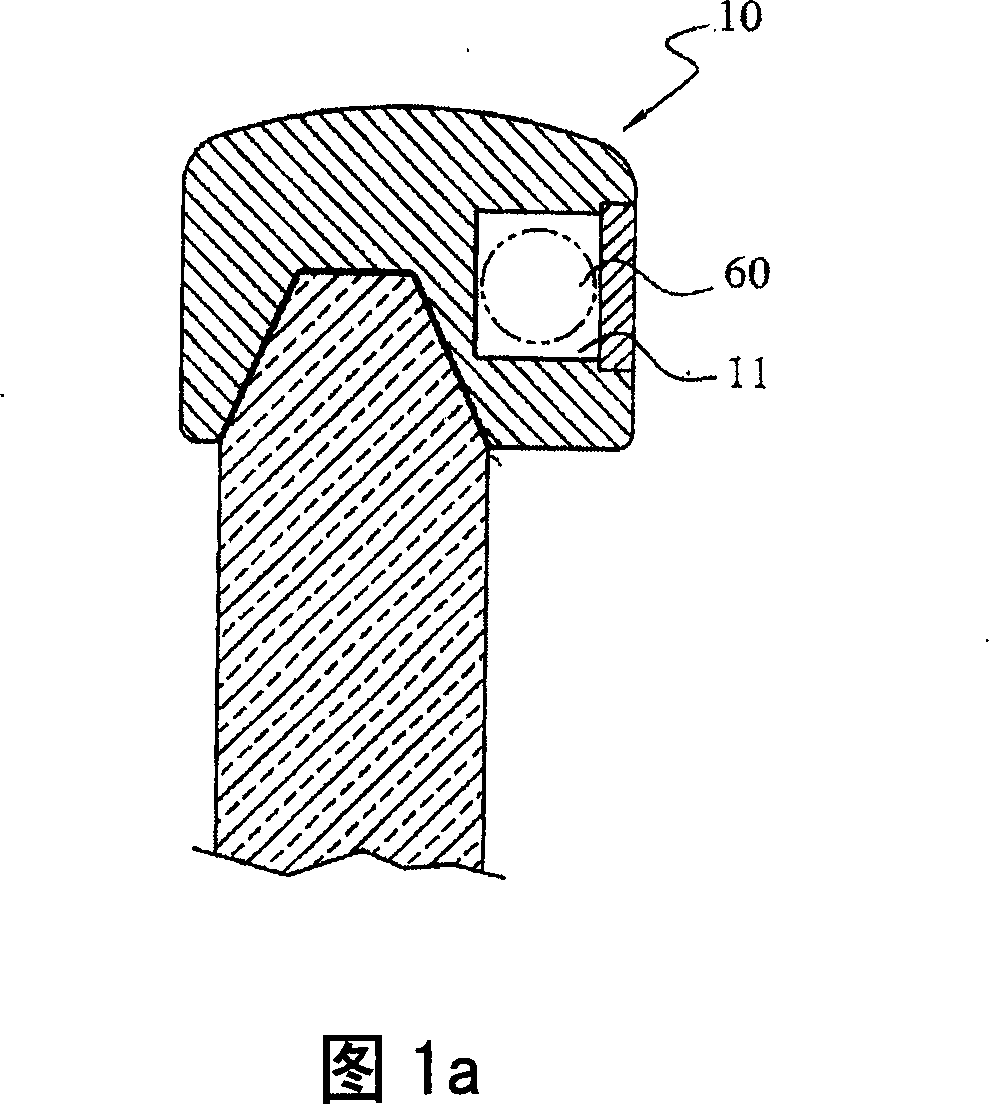

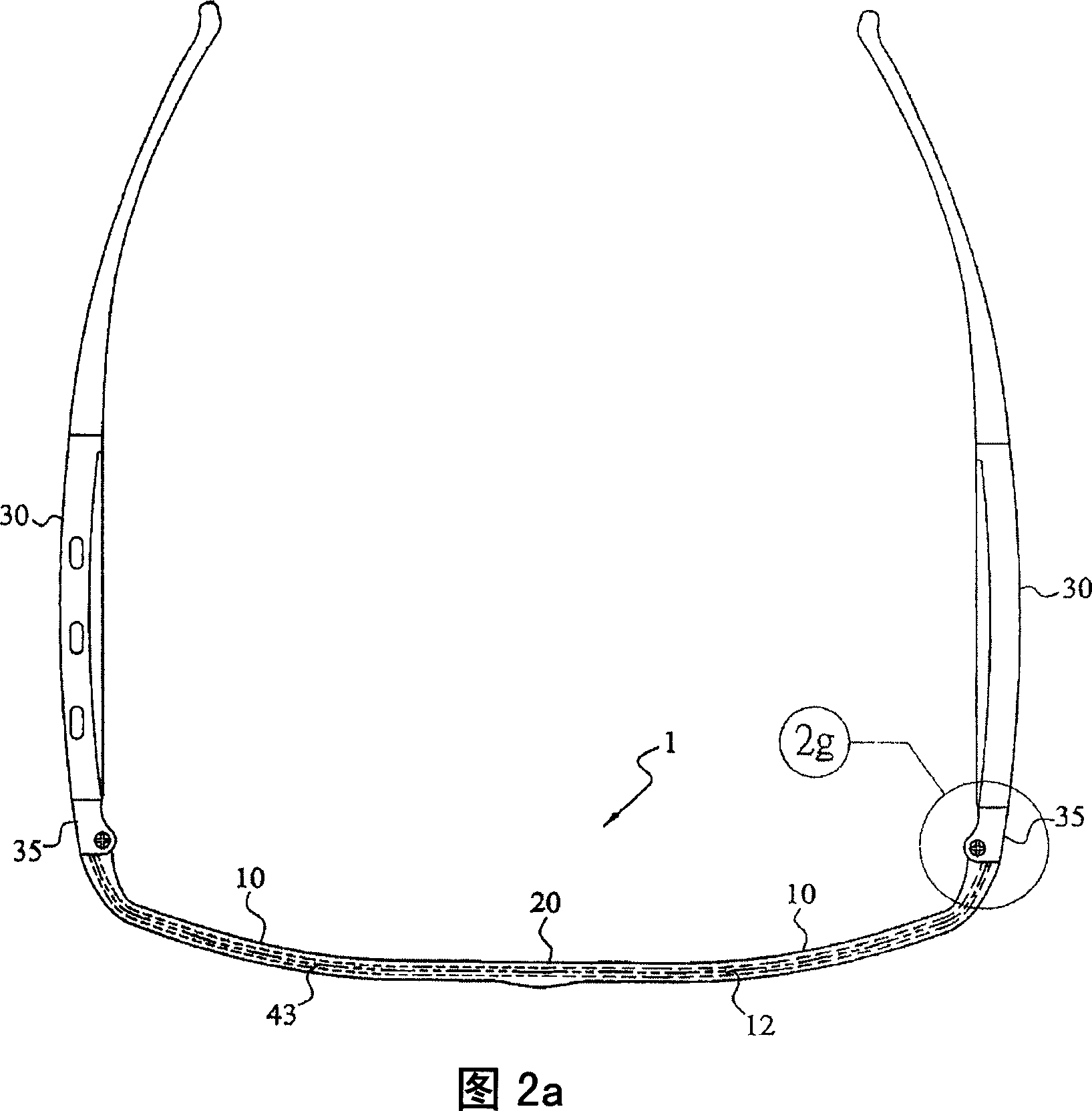

Thin glasses frame structure with electronic device

A kind of thin glass frame structure that has electronic installation include a pair of eyeglass frames, they separately form a rabbet joint which embeds a eyeglass inside of this eyeglass frame and a bridge between the two eyeglass frames; a pair of brackets, they are separately set on both sides of the two eyeglass frames through the hinge; one circuit board, it is located on one bracket and its electron circuit is used to incept or play electron message; one power equipment, it is located on another bracket and provides the power to this circuit board through the leading wire; and a pair of earphones, it used to export the electron message. Among them, on top of the earphones, there forms a trunking which is used to accept the leading wire along the eyeglass rabbet joint. This trunking impenetrates the bridge and the hinge. This invention can make the glass frame thinner and lighter.

Owner:周家麐

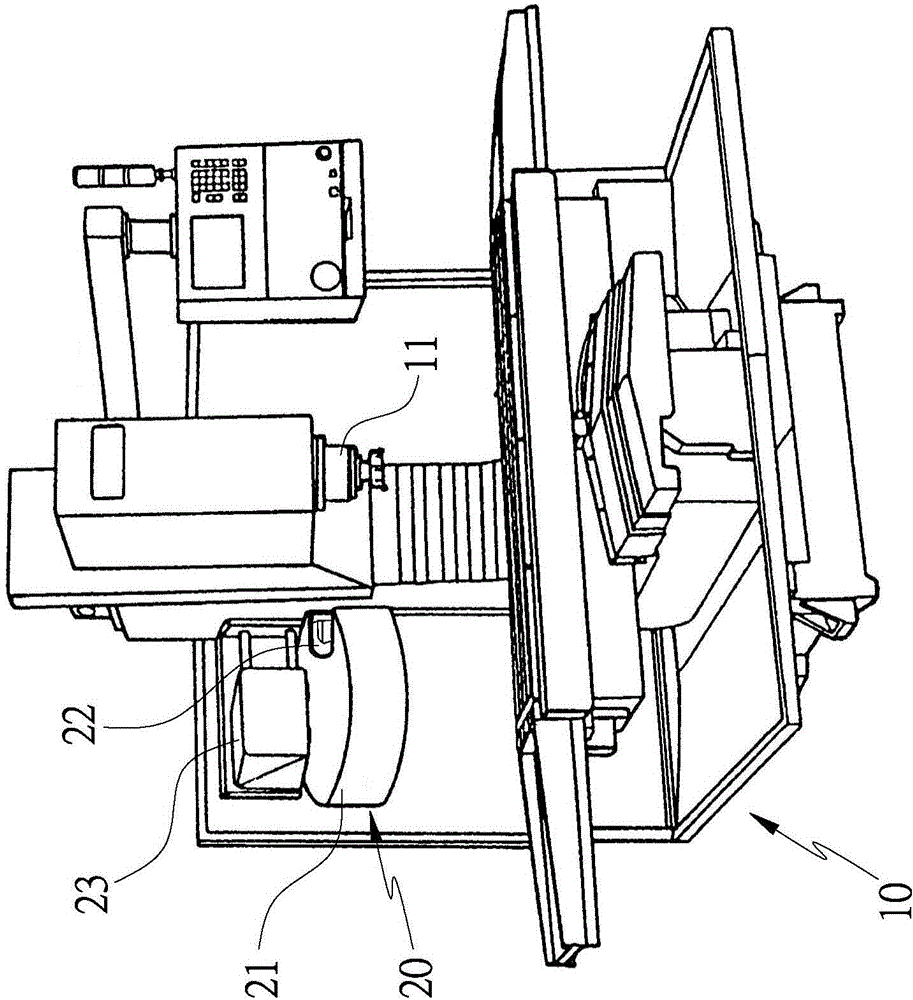

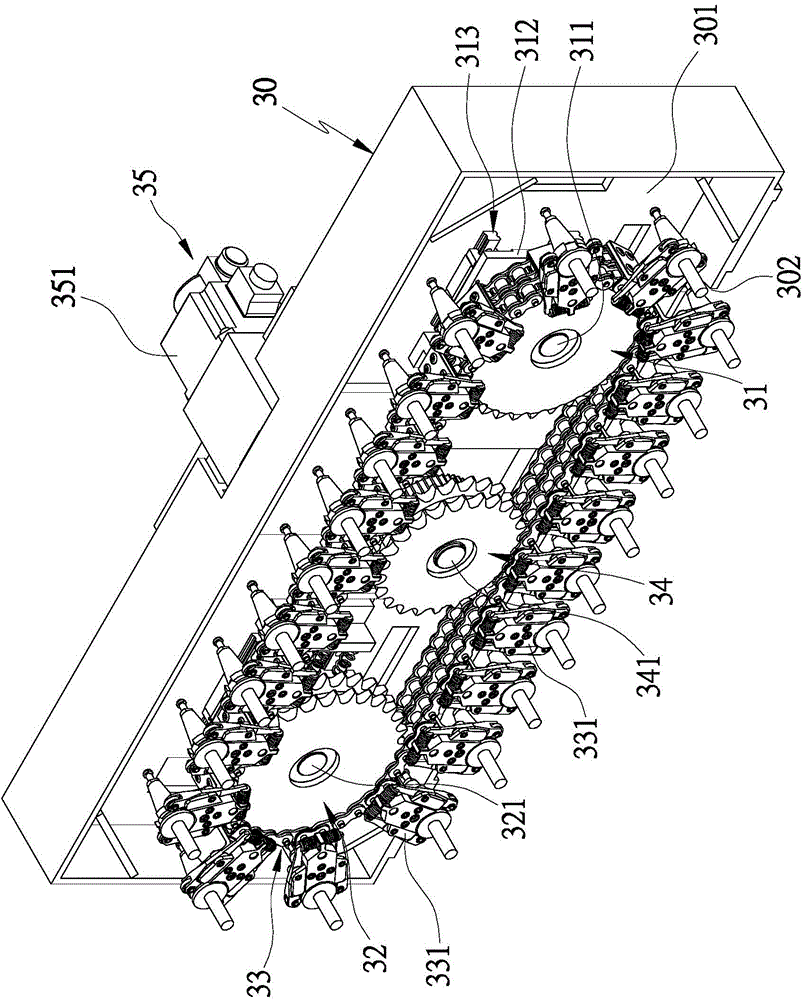

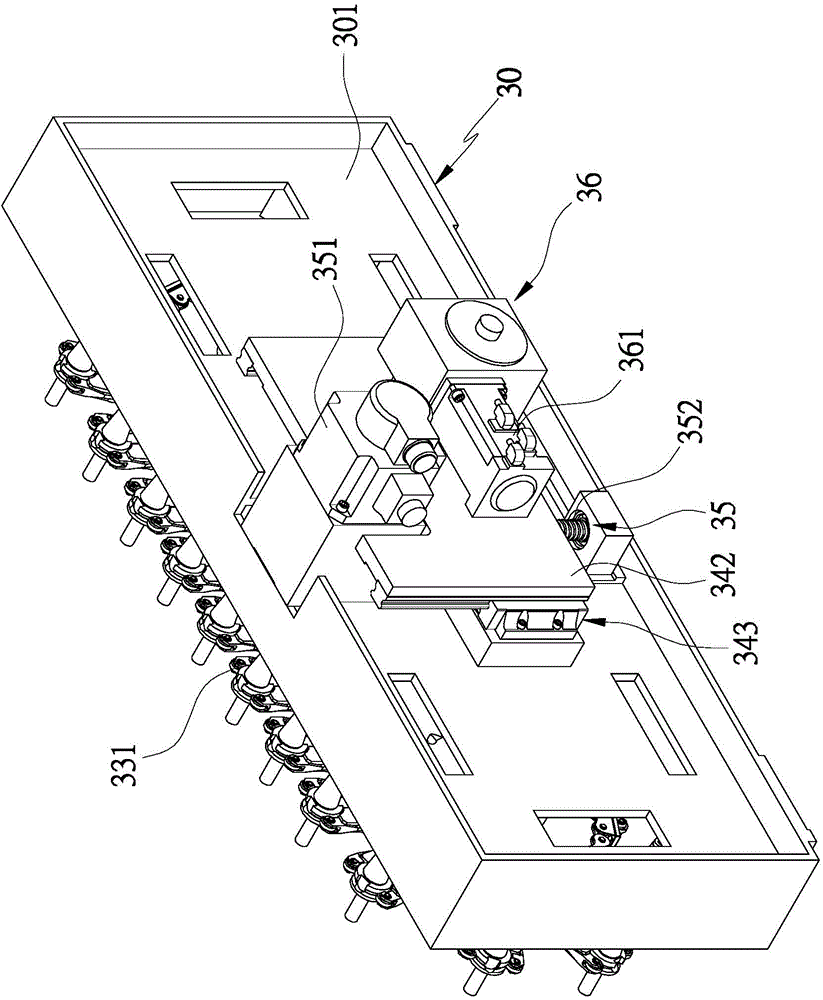

Chain type tool magazine

InactiveCN104802011AAchieve practical purposeReduce volumePositioning apparatusMetal-working holdersSprocketChain type

Disclosed is a chain type tool magazine. A tool magazine body is provided with at least two driven chain wheels; a chain which comprises a plurality of cutter placement frames is arranged on the driven chain wheels in a winding mode; each driven chain wheel is provided with an elastic pushing structure so as to abut against and push the driven chain wheels to be meshed with the chain; the tool magazine body is provided with a driving chain wheel; the driving chain wheel is connected with a displacement driving mechanism and a rotating driving mechanism; the driving chain wheel is driven by the displacement driving mechanism to move to be meshed with the chain to push and guide the cutter placement frames arranged on the chain to a cutter replacement position; the driving chain wheel is driven by the rotating driving mechanism to rotate to drive the rotary actuation of the chain so as to enable the preset cutter placement frames arranged on the chain to rotate into a column to the cutter replacement position. Accordingly, a sufficient number of different machining cutting tools can be placed in a straddled mode and the size of the tool magazine body is effectively reduced due to the plurality of cutter placement frames of the chain and the preset machining cutting tools arranged on the chain are driven by the pushing and guiding of the driving chain wheel to rotate into a column to the cutter replacement position and accordingly the cutter replacement operation can be directly executed through a machining main shaft and the practical benefits of the saving on the configuration space and the easy assembly are achieved.

Owner:邱菩宣

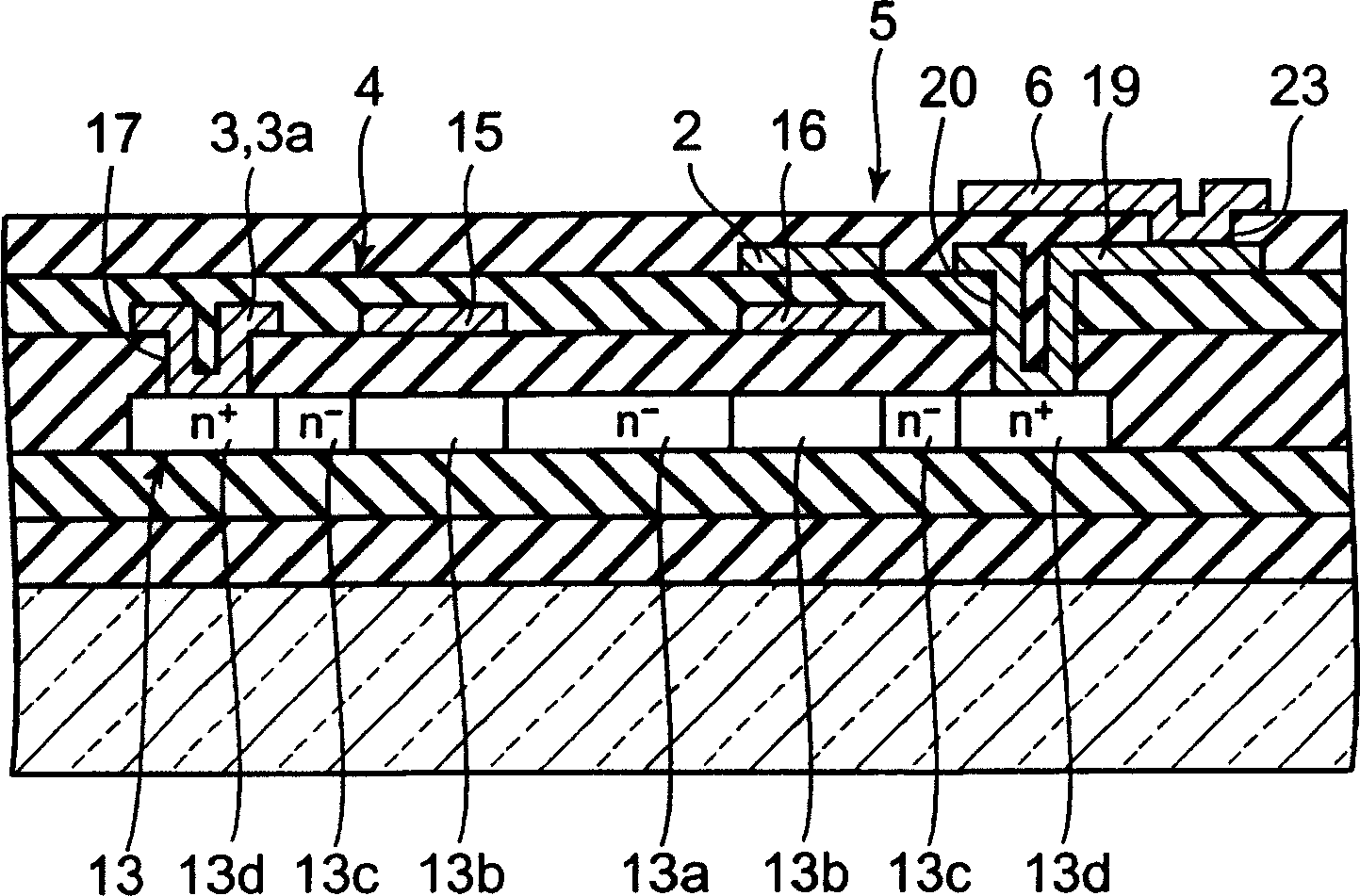

Active matrix panel

ActiveCN1652167ASave configuration spaceReduce pixel pitchTransistorSolid-state devicesActive matrixScanning beam

The invention provides an active matrix panel, which comprises a plurality of scanning beams (2), a plurality of data lines (3), and a plurality of switch elements (4,5) separately connected with the scanning beams (2) and the data lines (3); the switch elements (4,5,44,45) separately comprises semiconductor films (13,54), gate insulating films (14,53) and gate electrodes (15,16,51,52). The lateral configuration space occupied by the two thin film transistors (TFT) can be reduced, thereupon, the pixels interval can be reduced, or the aperture ratio can be increased.

Owner:INTERDIGITAL CE PATENT HLDG

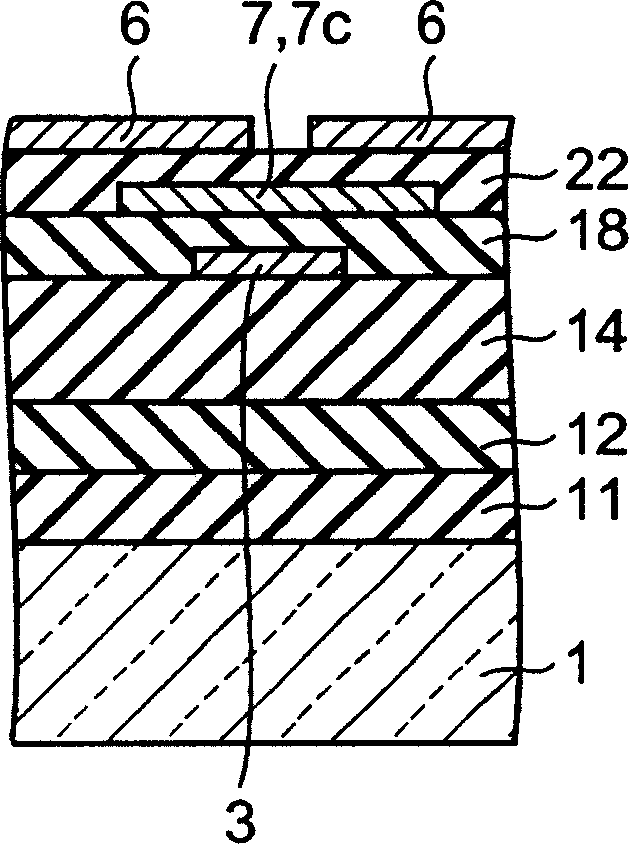

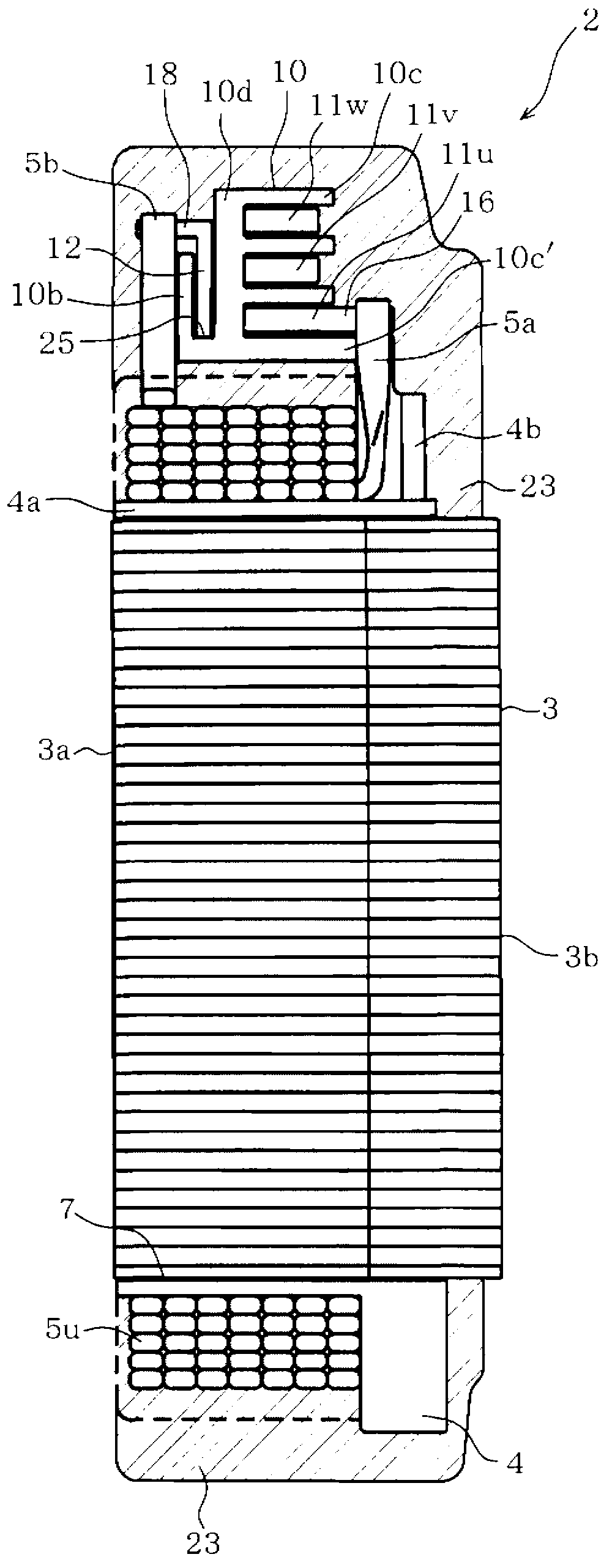

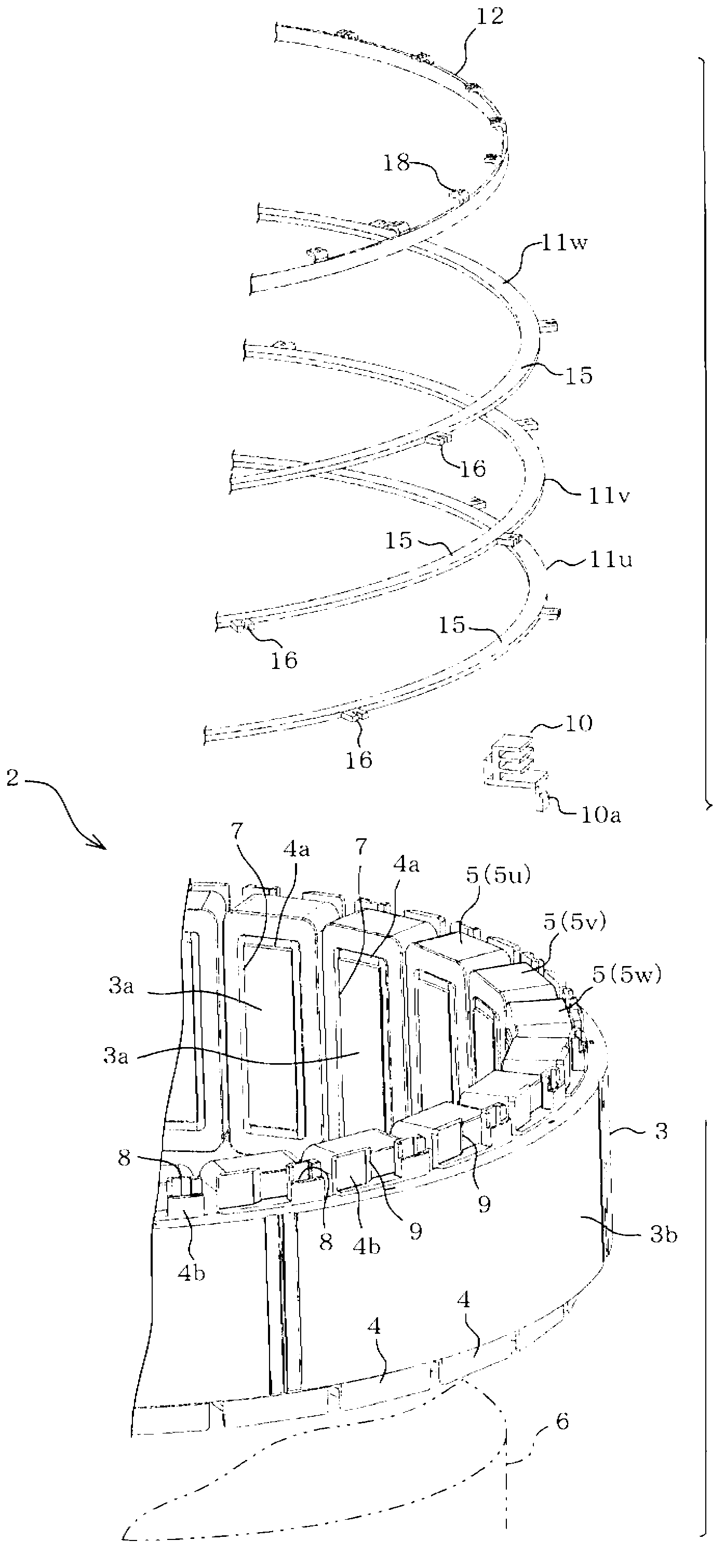

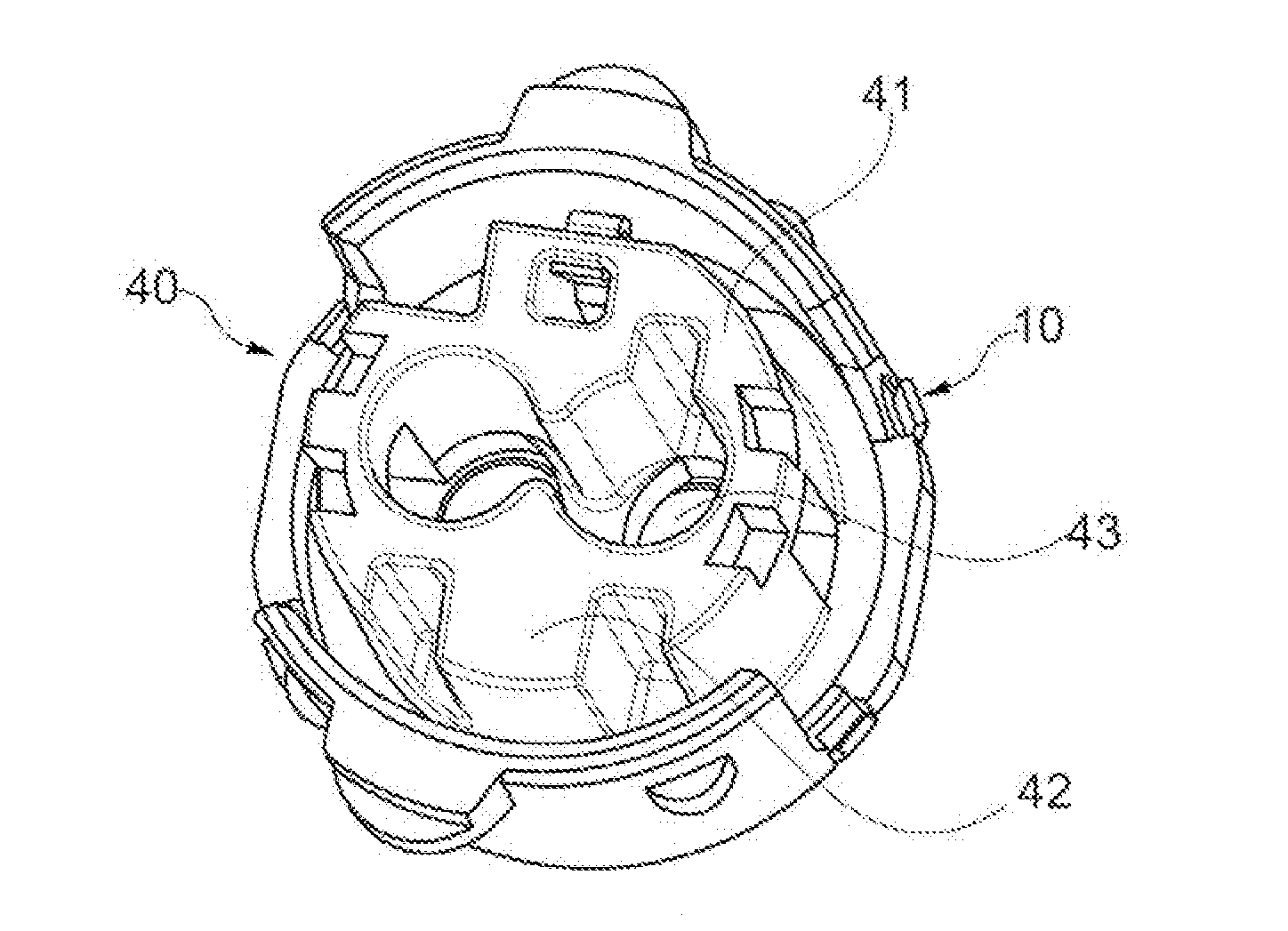

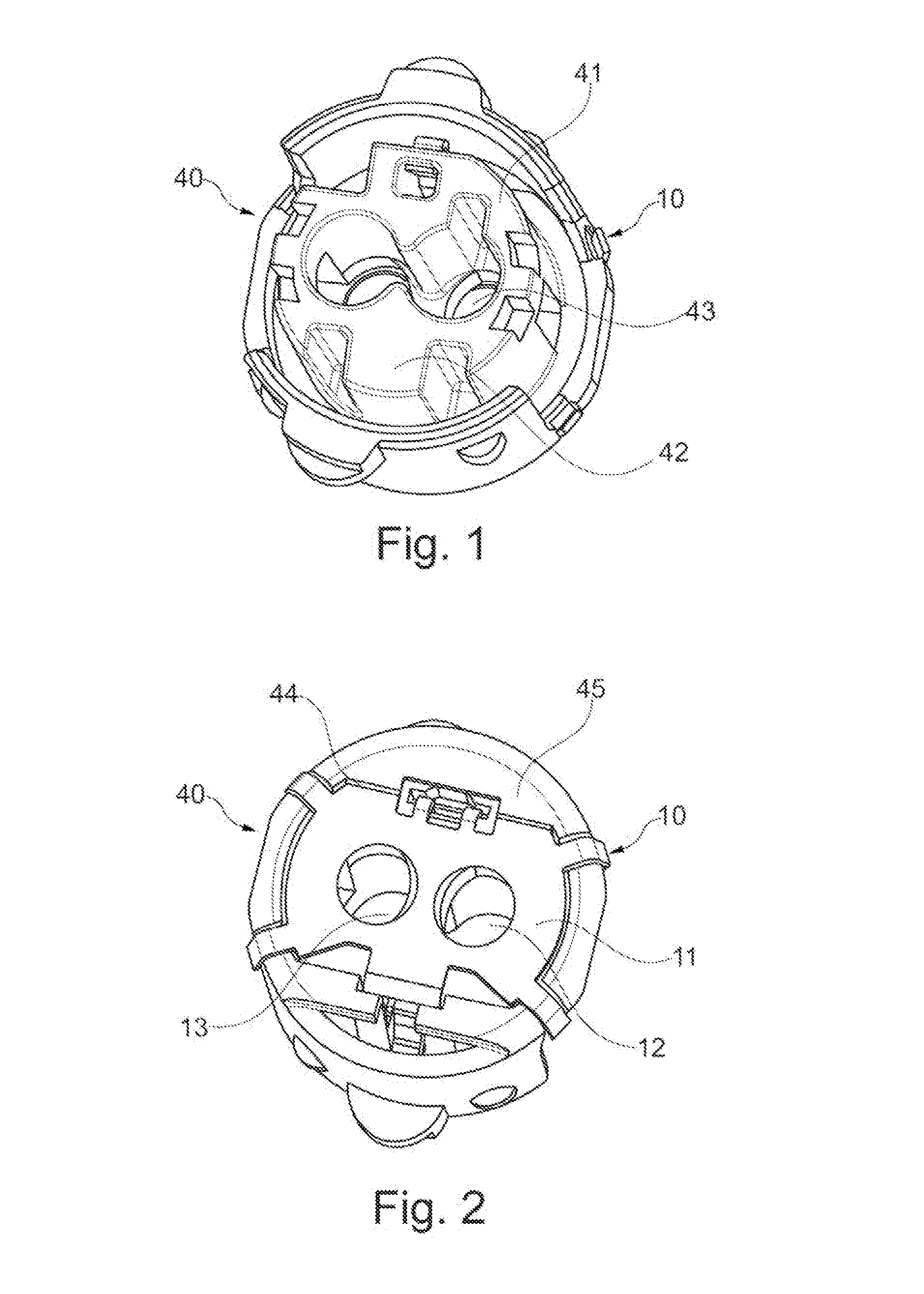

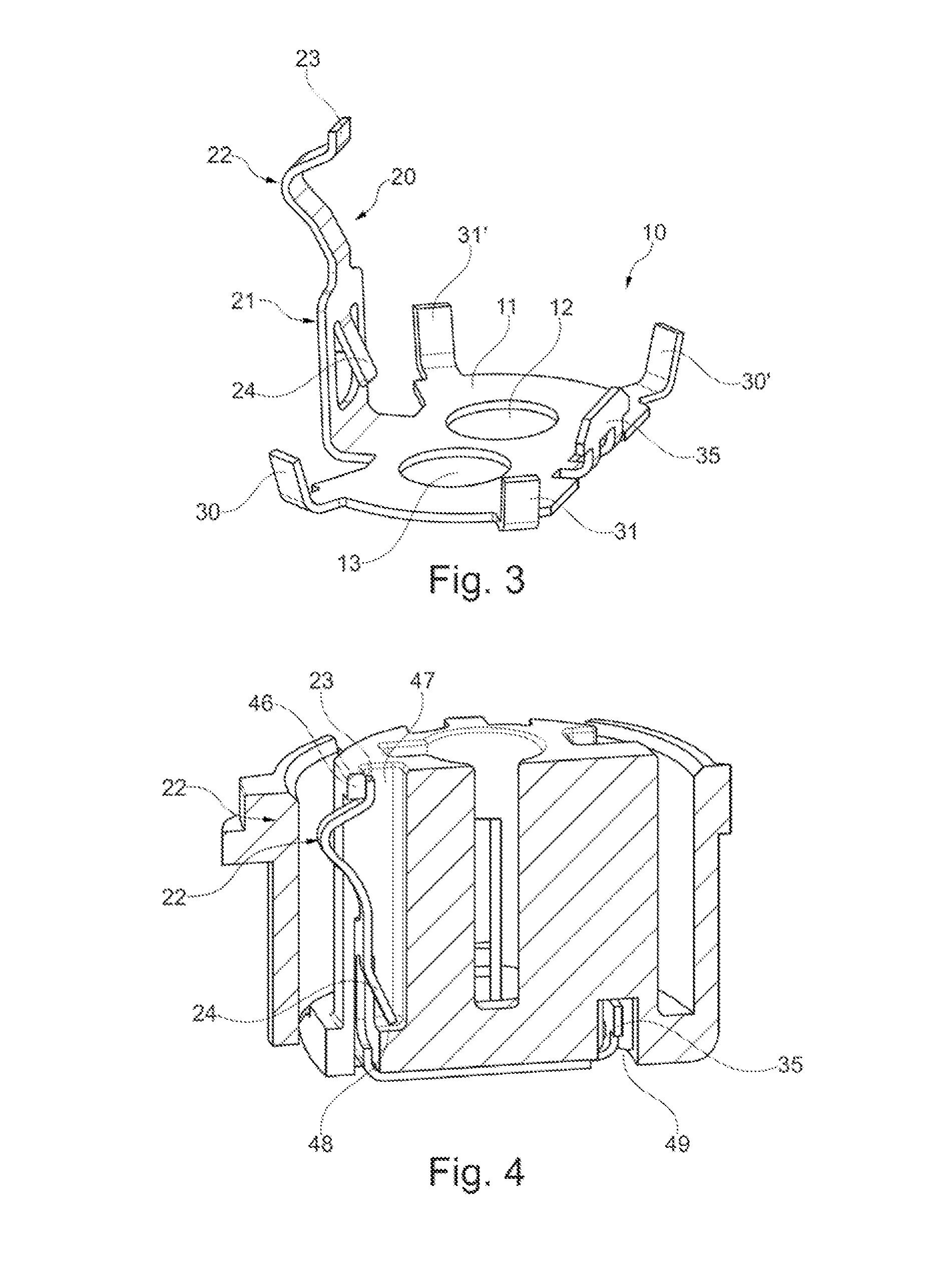

Stator for rotating machine, holder for use with stator, rotating machine, and automobile

InactiveCN103094999AReduce axial sizeReduce radial sizeWindings insulation shape/form/constructionElectric devicesElectrical and Electronics engineeringStator

A stator(2) of a rotating machine(1) includes a stator core (3), a plurality of winding wires wound on the stator core (3), a first bus ring(11u, 11v, 11w), a second bus ring(12), and a holder device. The first bus ring(11u, 11v, 11w) has a first radial dimension and selectively connects electrically with each of the wires. The second bus ring(12) has a second radial dimension different from the first radial dimension and selectively connects electrically with each of the wires. The holder device holds the first bus rings (11u, 11v, 11w) and the second bus ring (12). The holder device includes a first and a second support portion. The first support portion supports the first bus rings (11u, 11v, 11w) aligned along an axial direction of the stator core(3). The second support portion supports the second bus ring (12) on a radially outward or inward side of the first bus rings(11u, 11v, 11w).

Owner:KK TOSHIBA +1

Grounding clip for an airbag ignition system

ActiveUS20160181731A1Smooth connectionRobust designVehicle connectorsPedestrian/occupant safety arrangementGround contactEngineering

The invention relates to a grounding clip for an airbag ignition system adapted to be mounted to an airbag retainer insert. The clip comprises a first grounding contact in form of a spring tongue, adapted to contact a grounding contact of a squib connector and a second grounding contact adapted to contact an electroconductive part of an airbag squib. The clip comprises a flat base connecting the first and second grounding contacts with each other, wherein the spring tongue has a straight portion that extends perpendicular from the flat base and wherein the free end of the spring tongue comprises a bent portion that is not perpendicular to the base.

Owner:APTIV TECH LTD

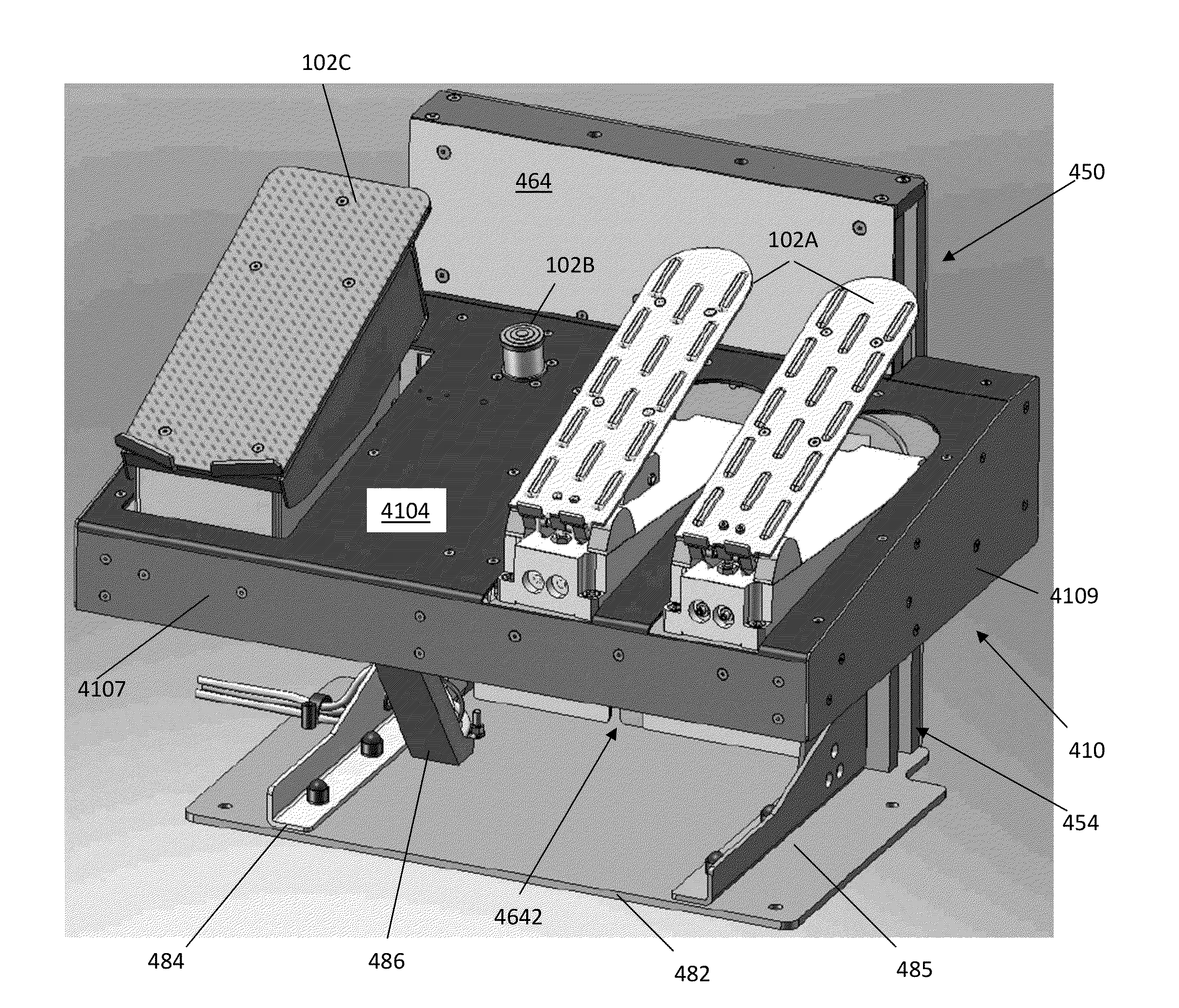

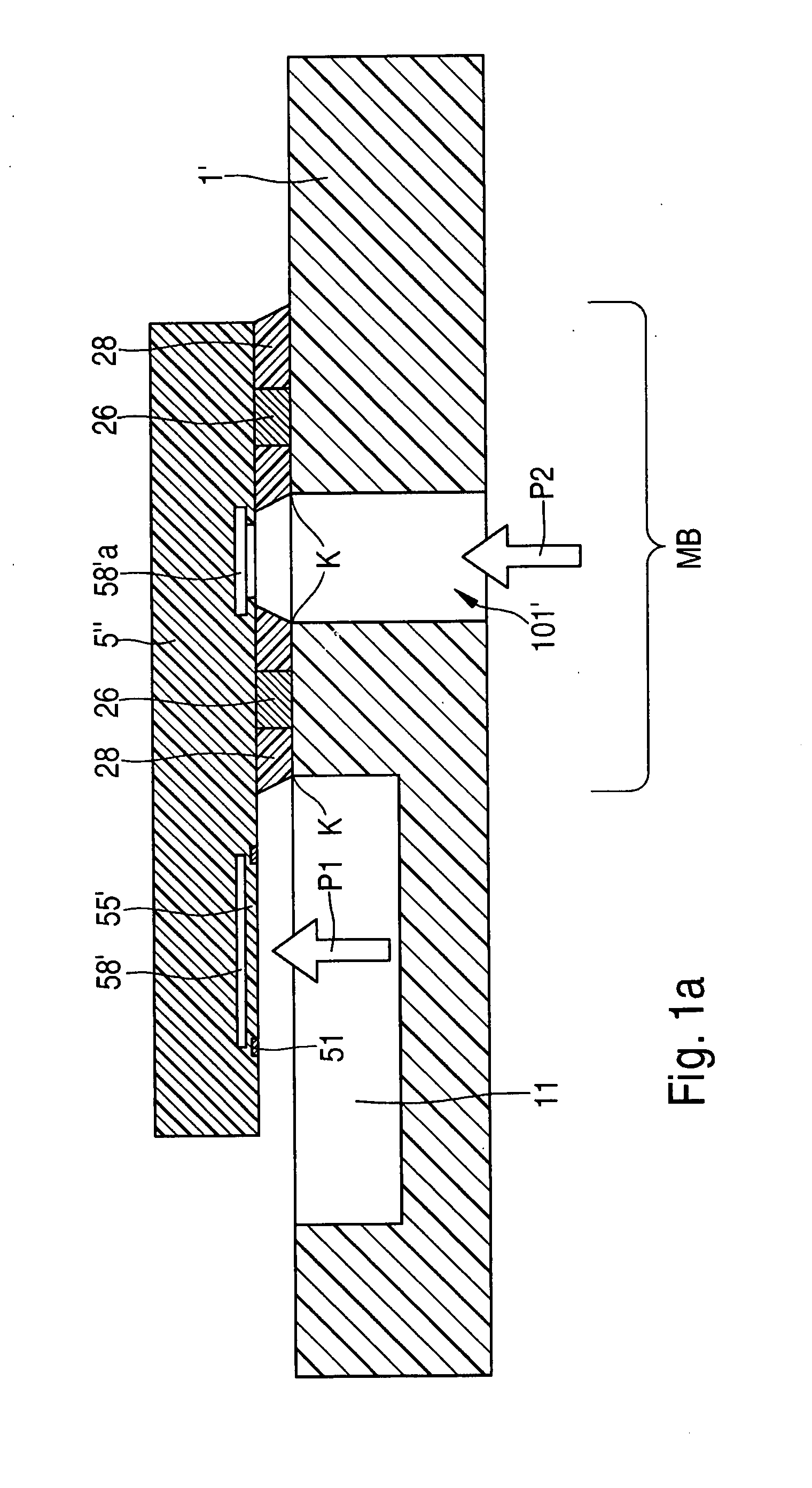

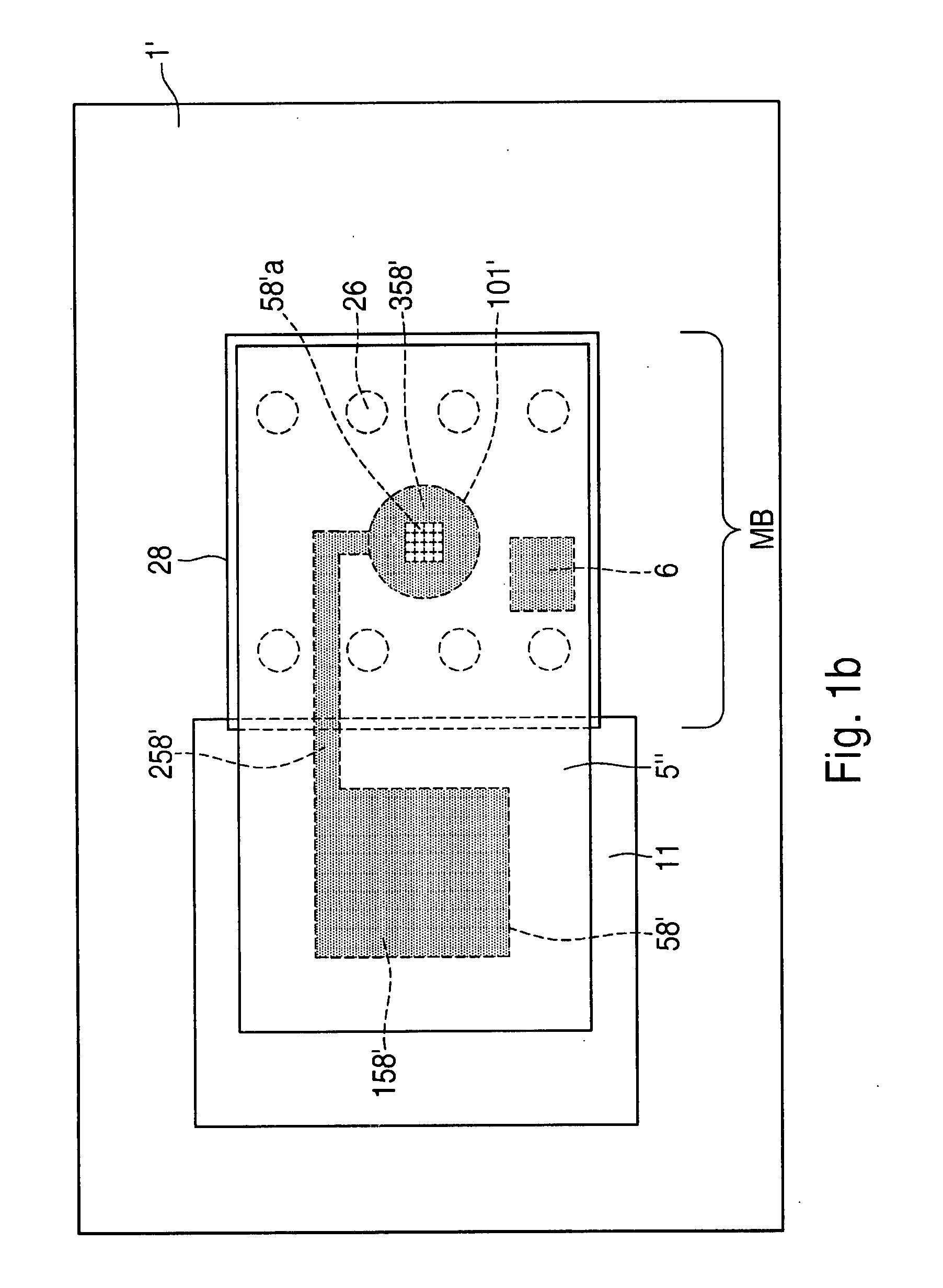

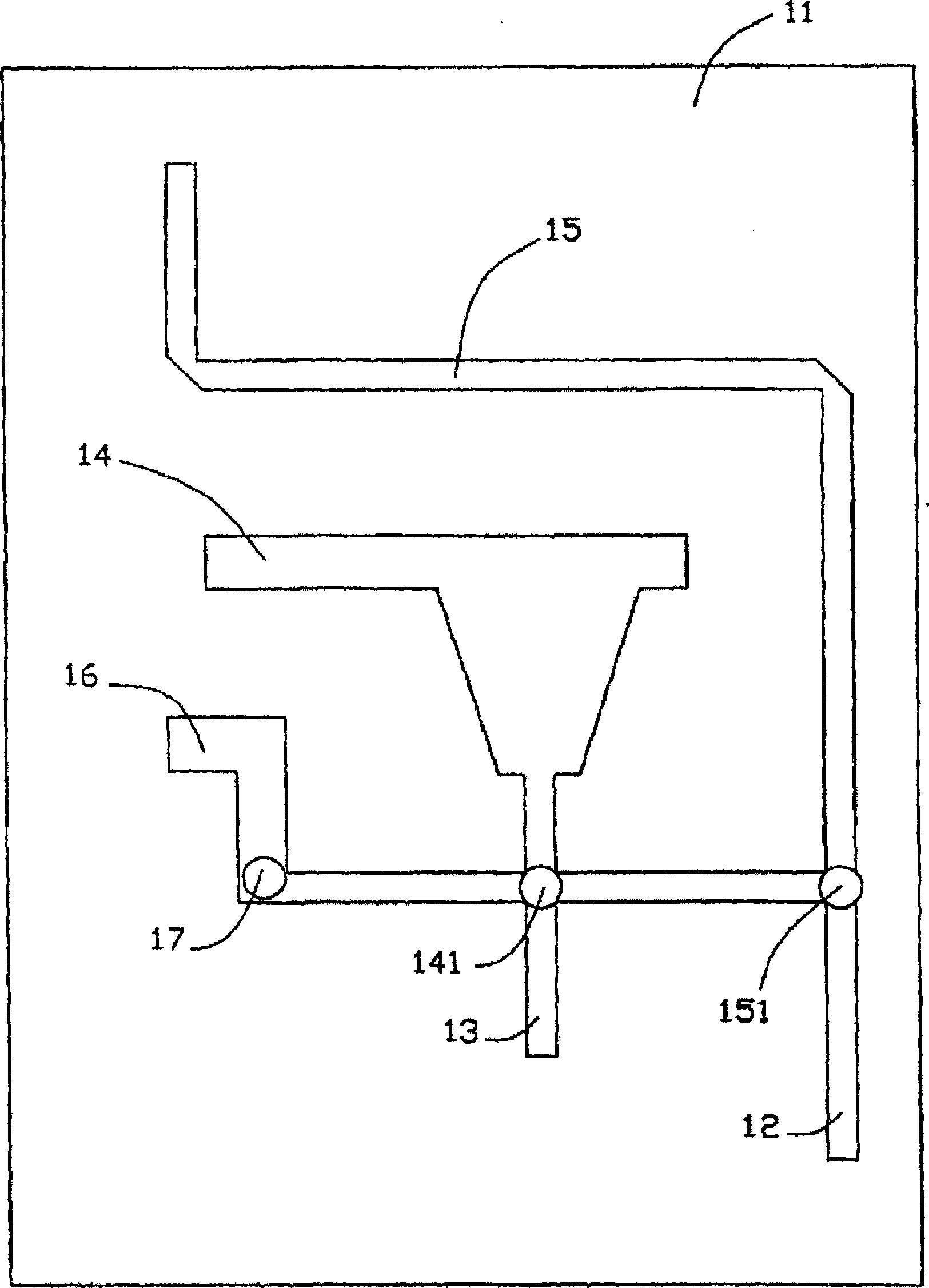

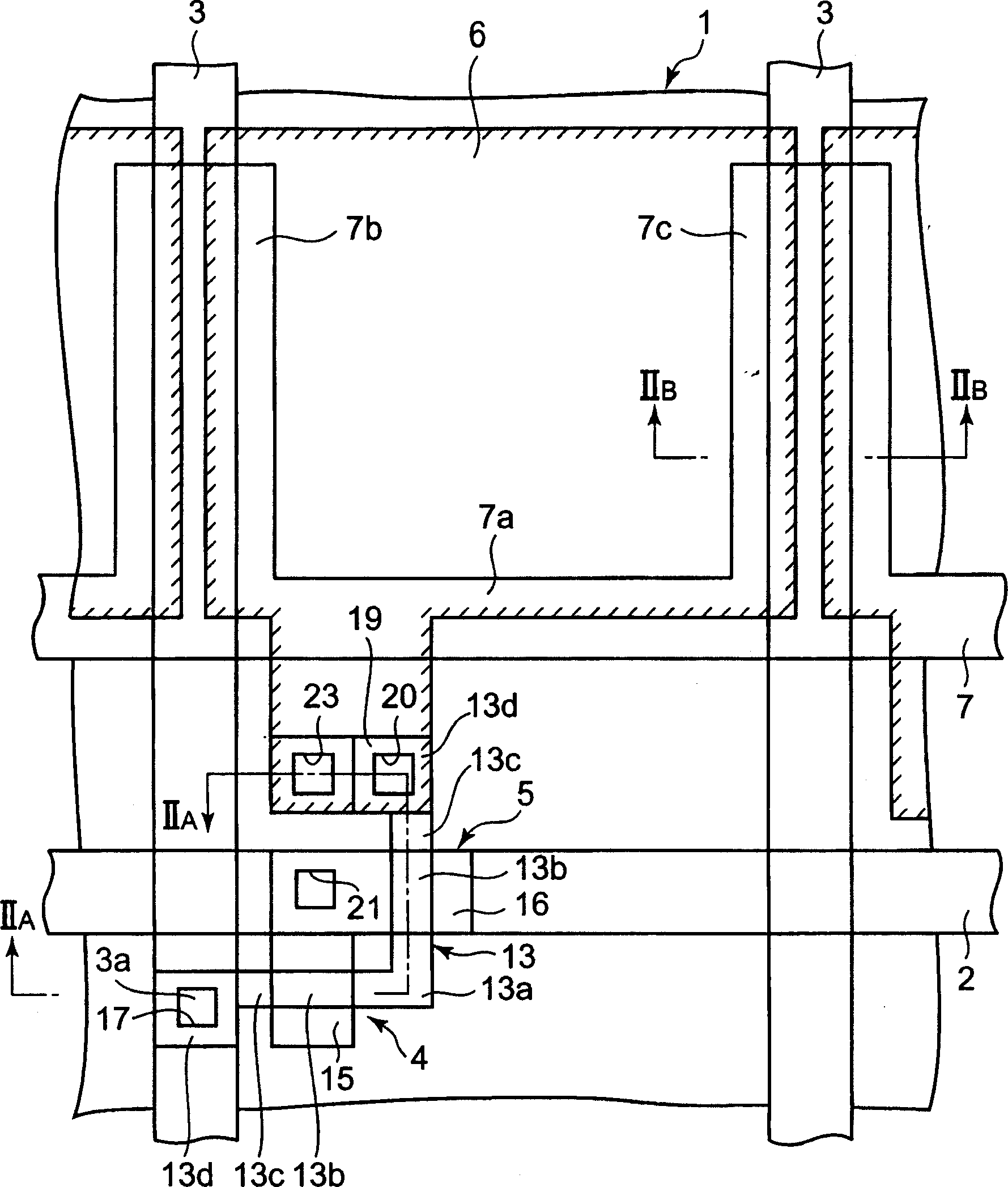

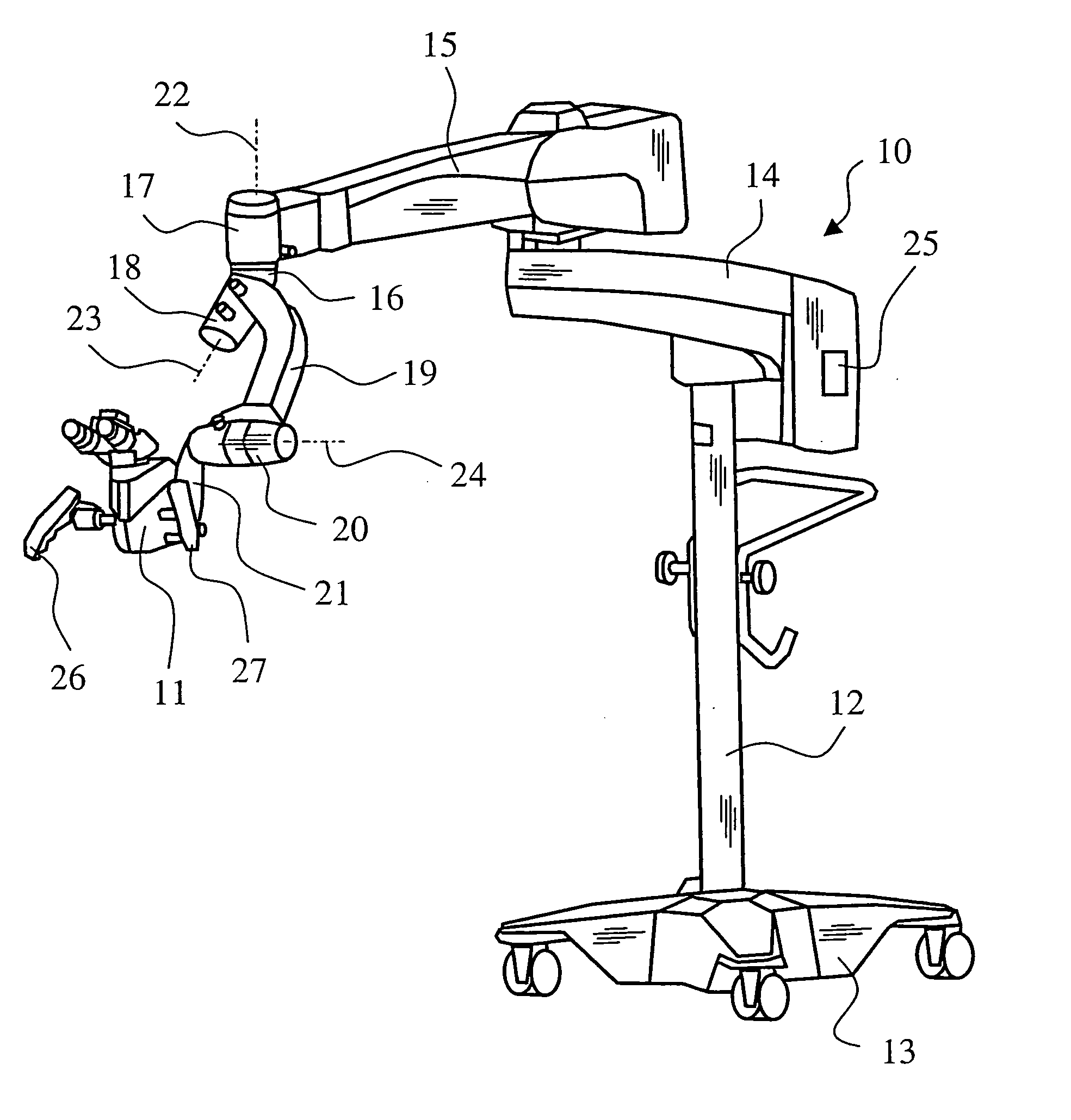

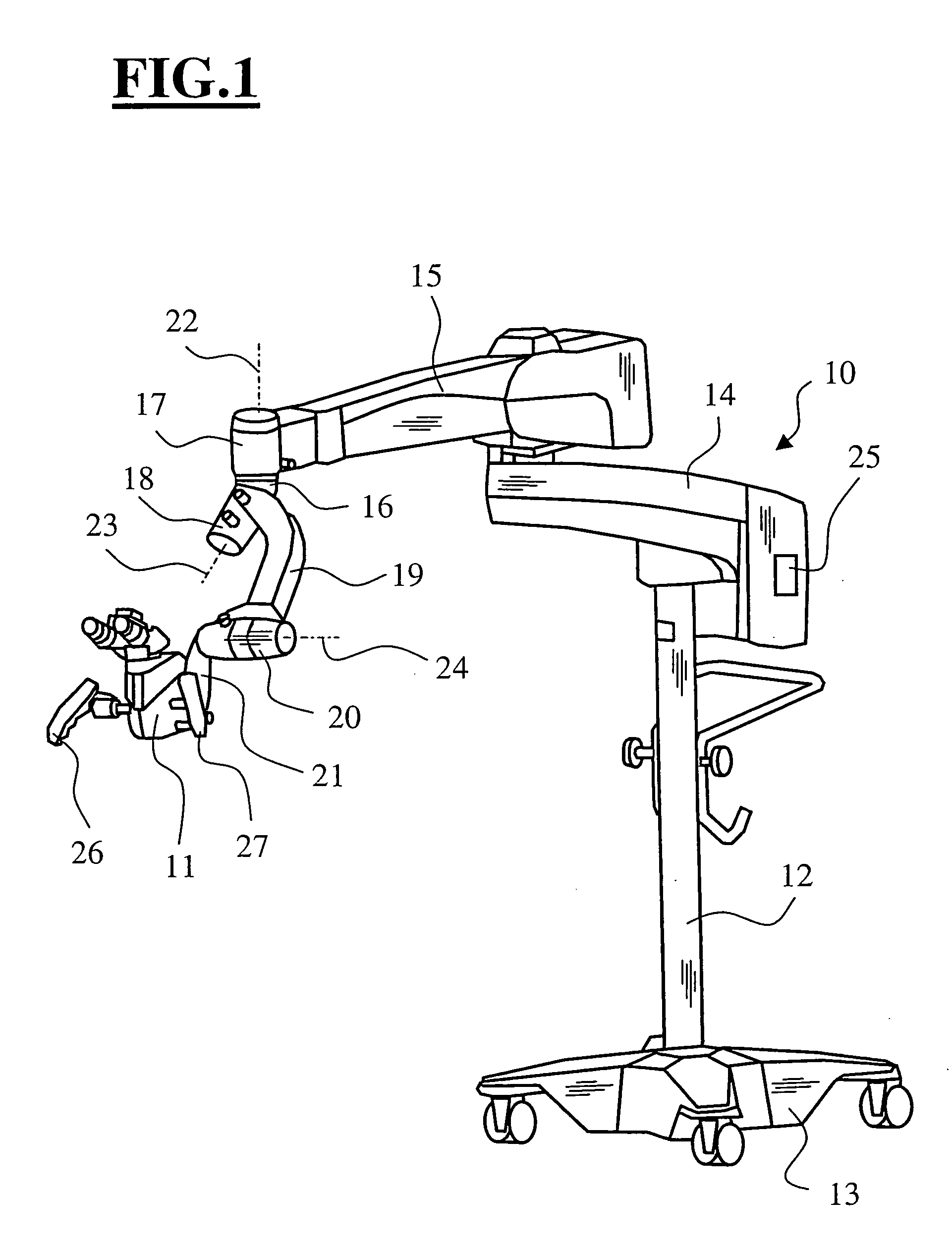

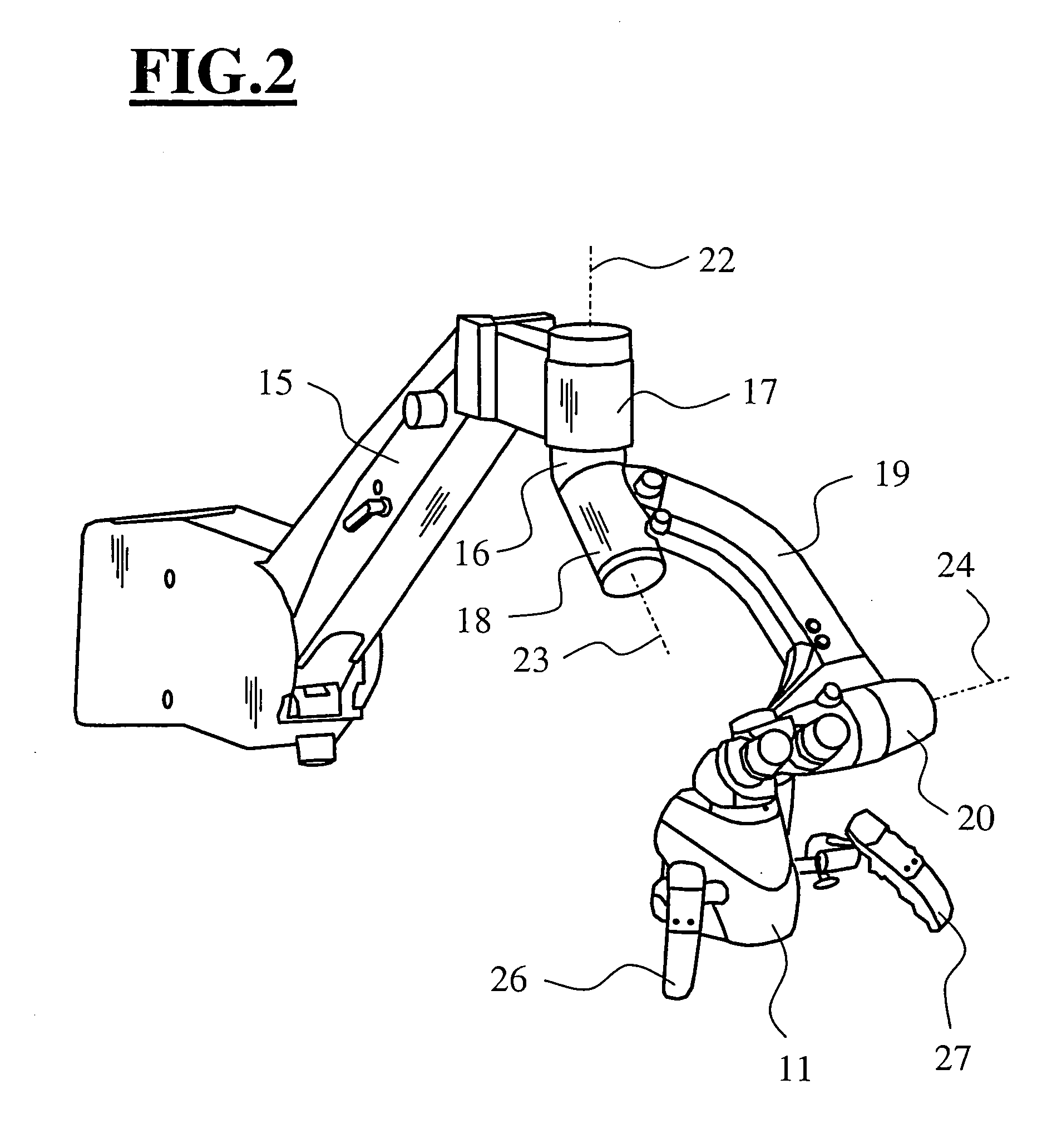

Carrier system for a medical apparatus

InactiveUS20050109903A1Improve mobilitySave configuration spacePortable framesLighting support devicesWave shapeCarrier system

A carrier system (10) for a medical apparatus (11) is disclosed. The carrier system includes rotation joints (17, 18, 20). A supply line harness runs in the carrier system (10) and is run so that it is covered. The rotation joint (18) includes a tube-shaped holding member on which fingers are formed which hold a rotation joint. A joint element, which is rotatably journalled in a joint receptacle, is provided in the rotation joint (20). The joint element has a wave-shaped section which is connected via a connecting section to an annularly-shaped section functioning to accommodate a connecting arm.

Owner:CARL ZEISS STIFTUNG

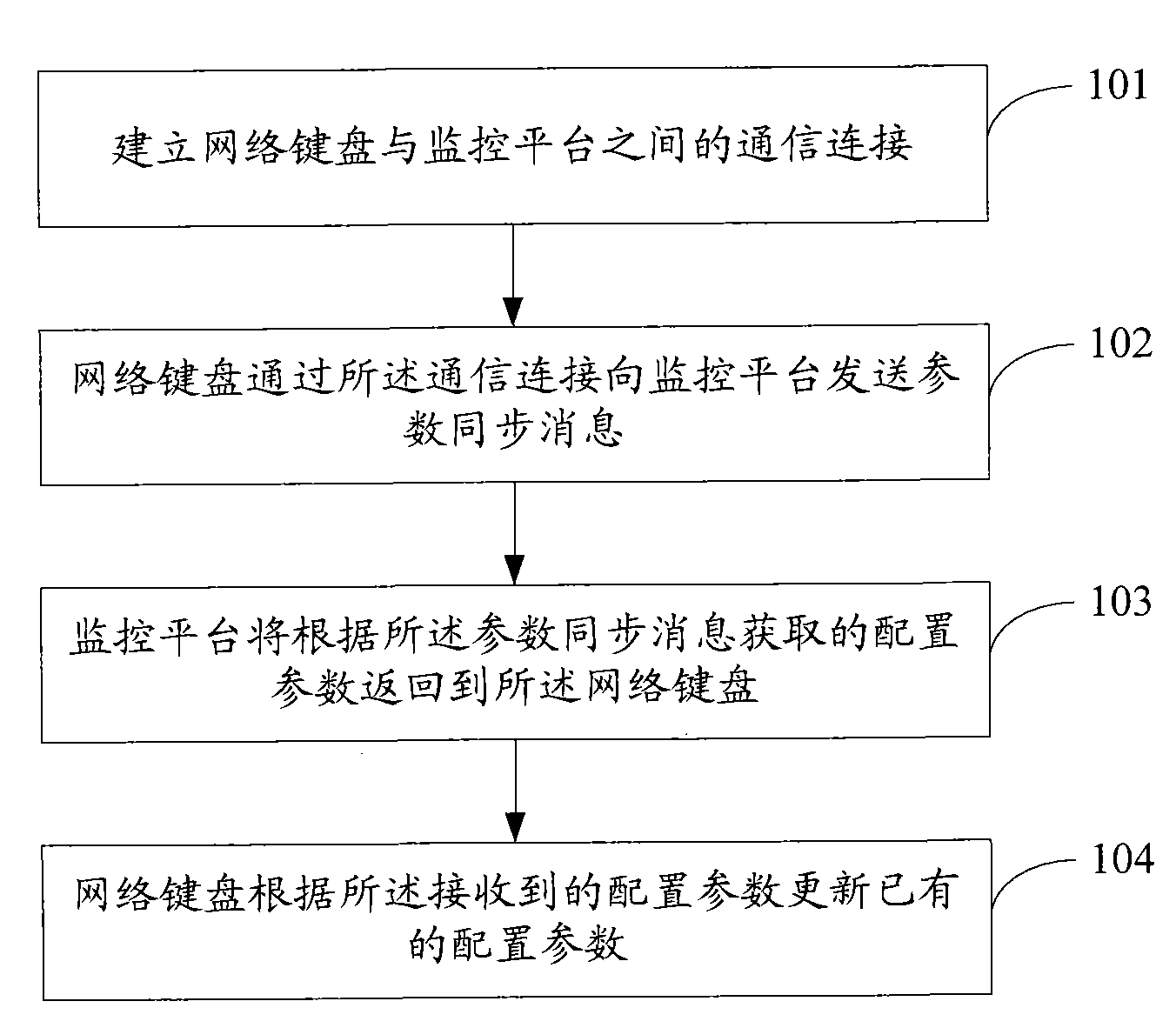

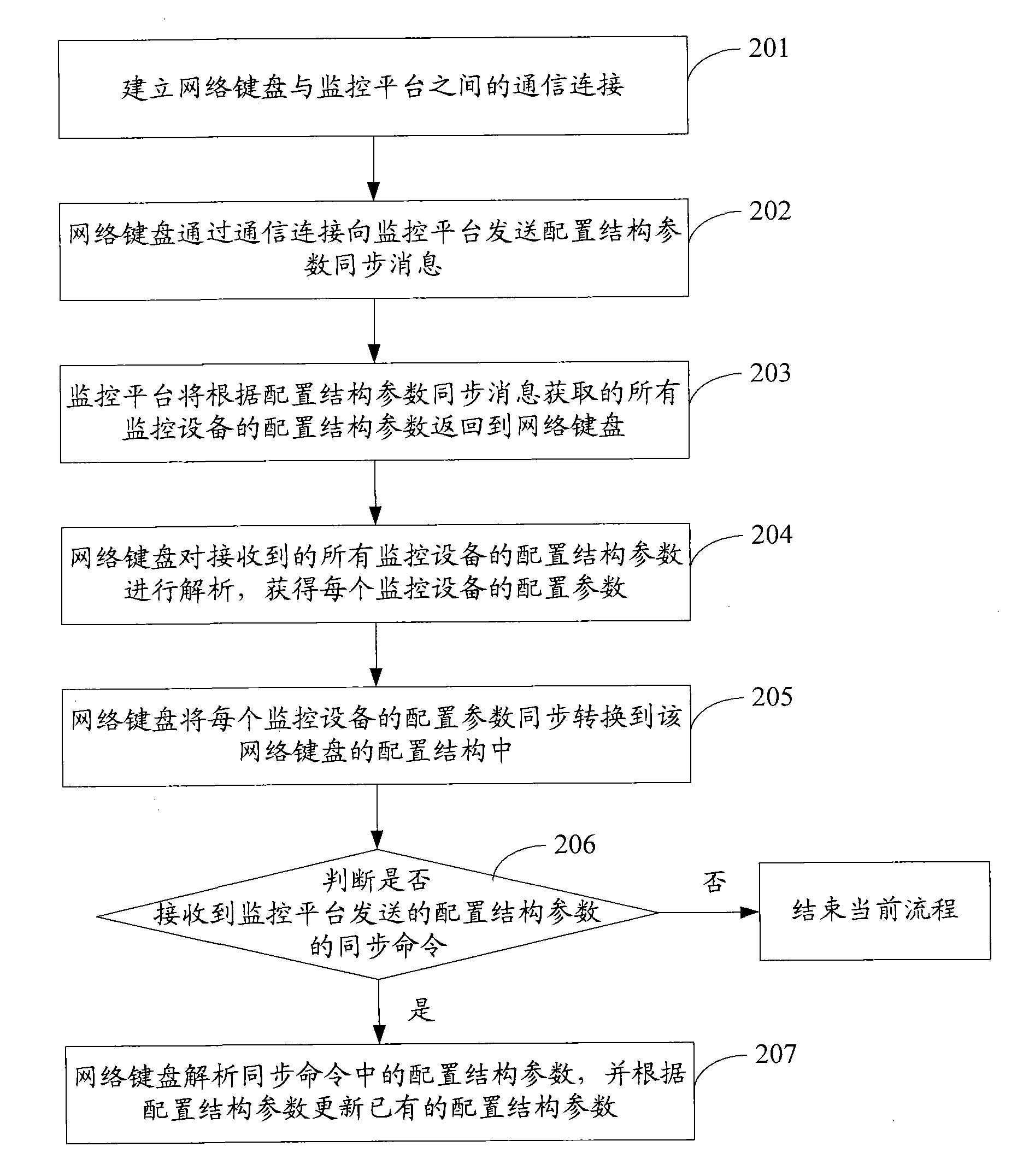

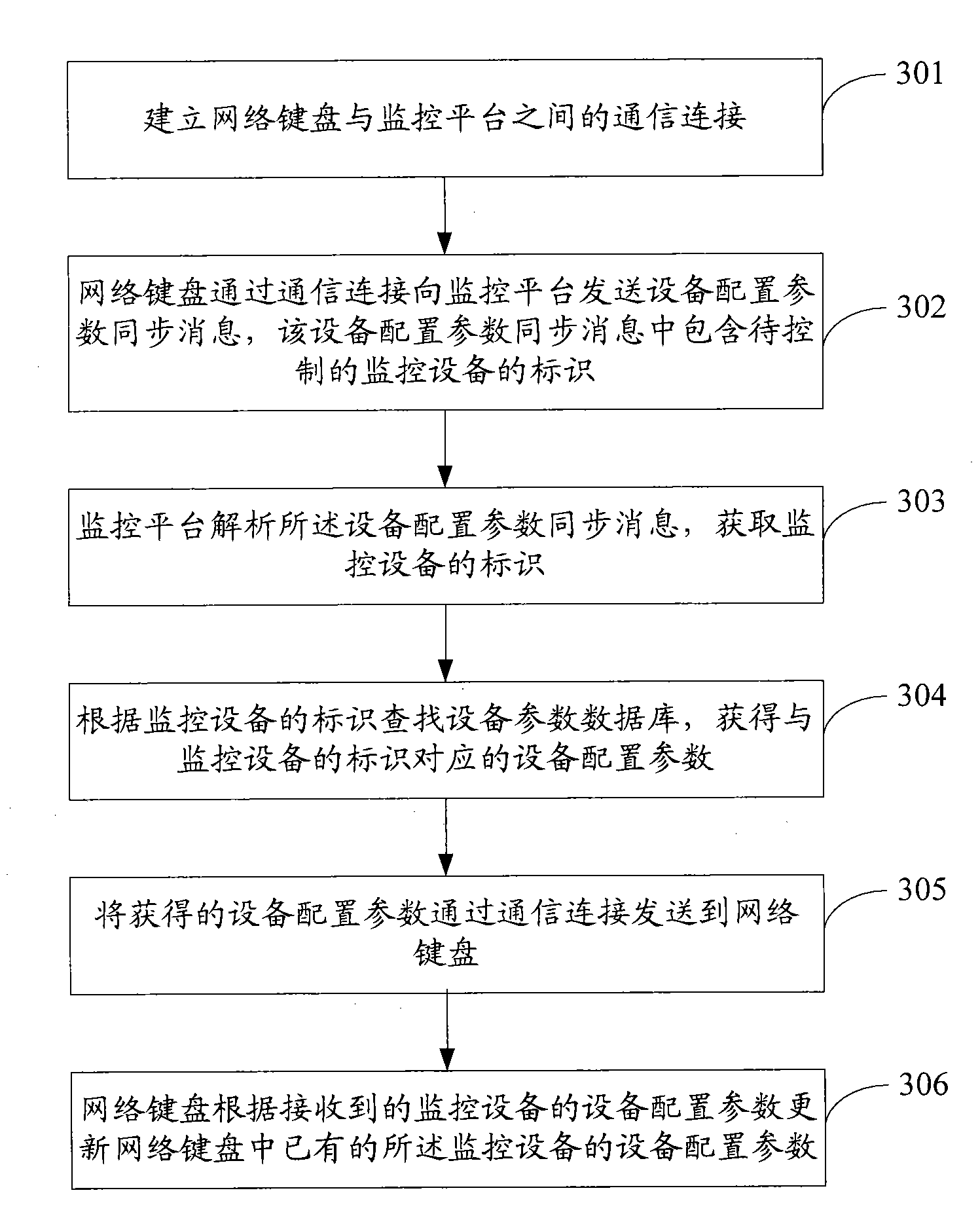

Method, system, network keyboard and monitoring platform for parameter synchronization

InactiveCN101883149AReduce configuration workloadEnsure consistencyTransmissionMonitor equipmentWorkload

The embodiment of the invention discloses a method, a system, a network keyboard and a monitoring platform for parameter synchronization. In the method, a communication linkage between the network keyboard and the monitoring platform is established; the network keyboard sends a parameter synchronization message to the monitoring platform through the communication linkage; the monitoring platform returns acquired configuration parameters on the basis of the parameter synchronization message to the network keyboard; and the network keyboard updates available configuration parameters based on the received configuration parameters. Since the network keyboard synchronizes the configuration parameters of the monitoring platform through the established communication linkage between the network keyboard and the monitoring platform in the embodiment of the invention, parameters of monitoring equipment do not need to be separately configured on the network keyboard, and the configuration parameters are shared between the network keyboard and the monitoring platform. Thus, the workload for configuring the network keyboard is reduced.

Owner:HANGZHOU HIKVISION DIGITAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com