Dual heat source radiating module

A heat dissipation module and dual heat source technology, which is applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc., can solve problems such as difficulty in dissipating hot air, rising temperature in configuration space, and limitation of air flow space, etc., to reduce Design cost, enhanced heat dissipation effect, and effect of saving configuration space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

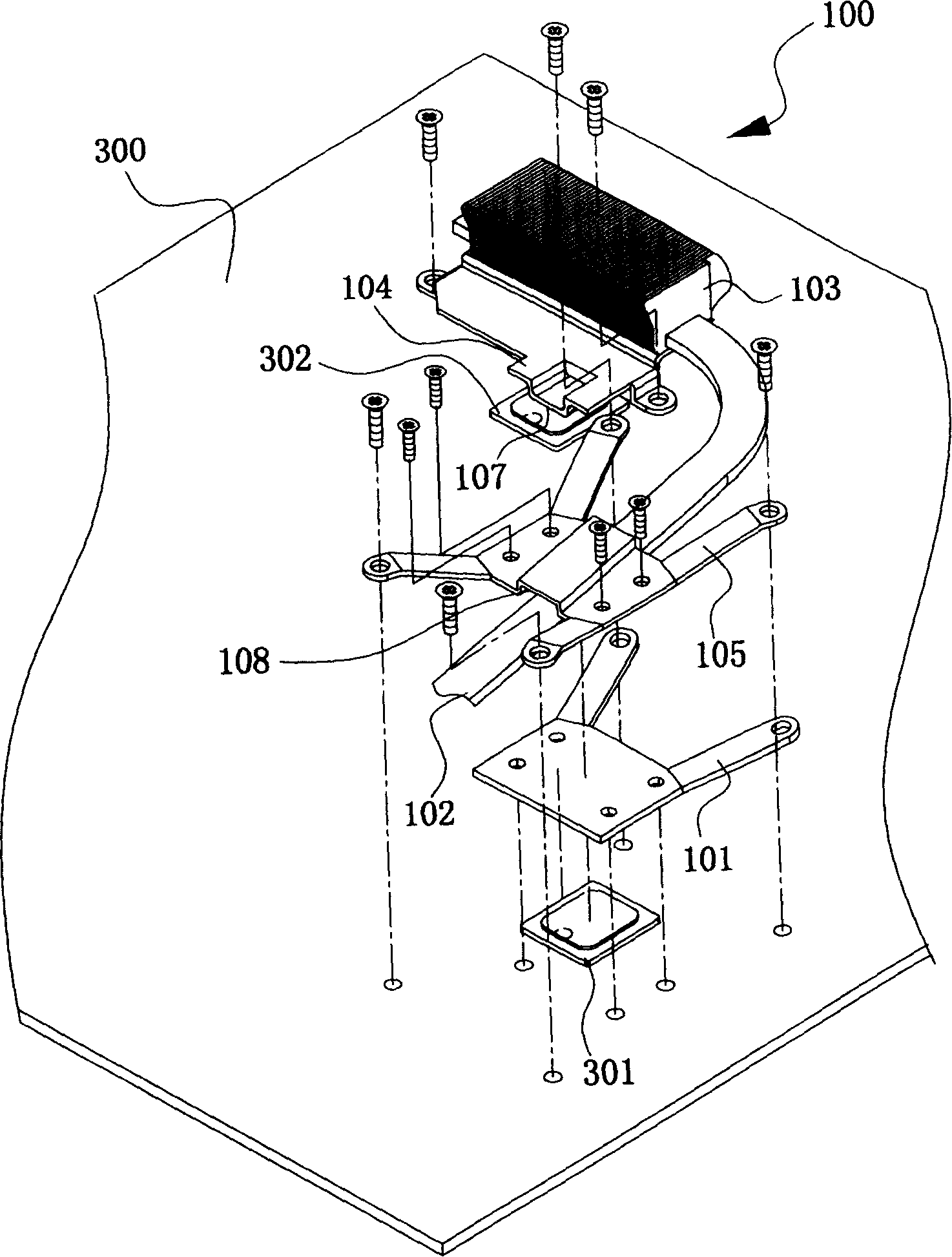

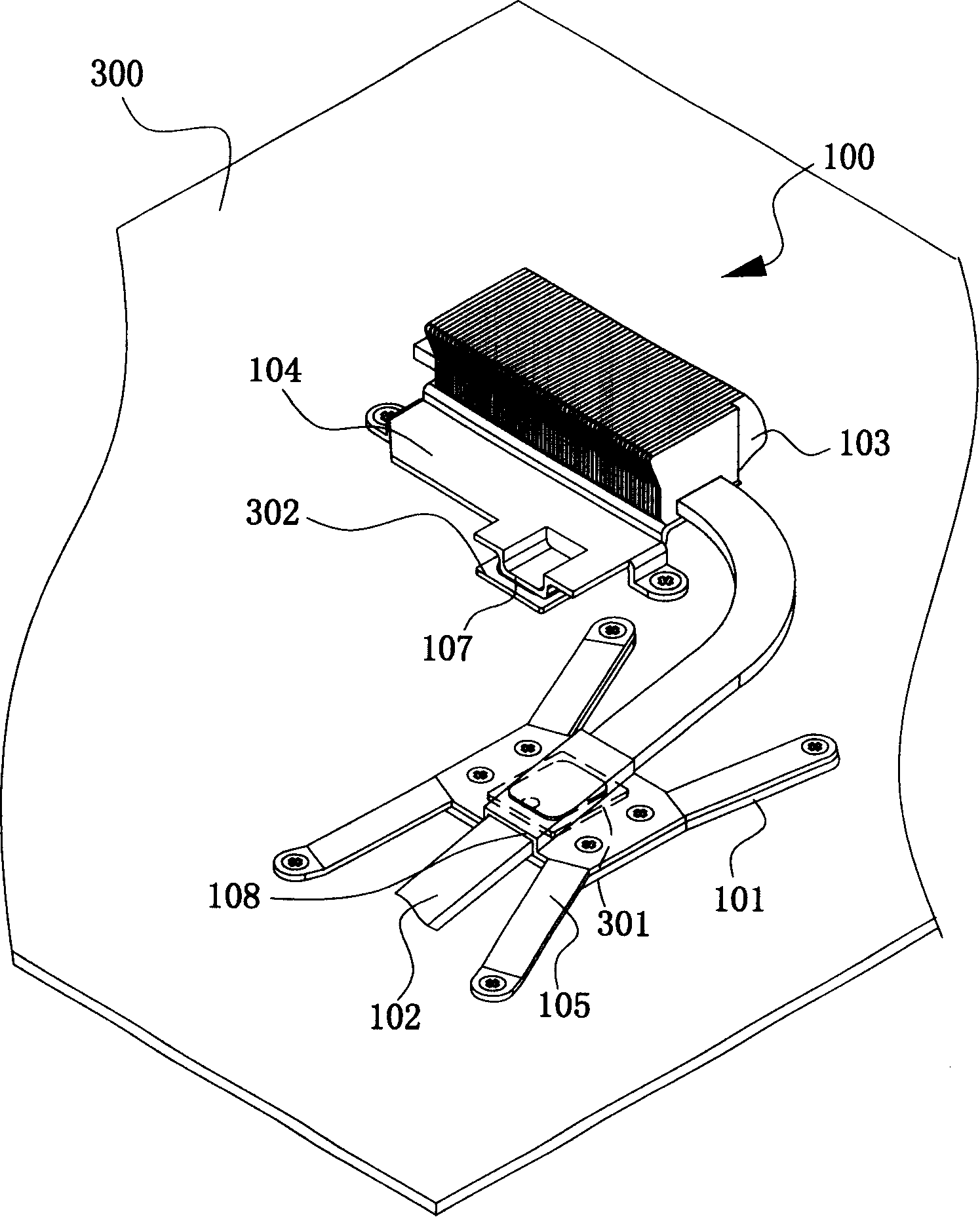

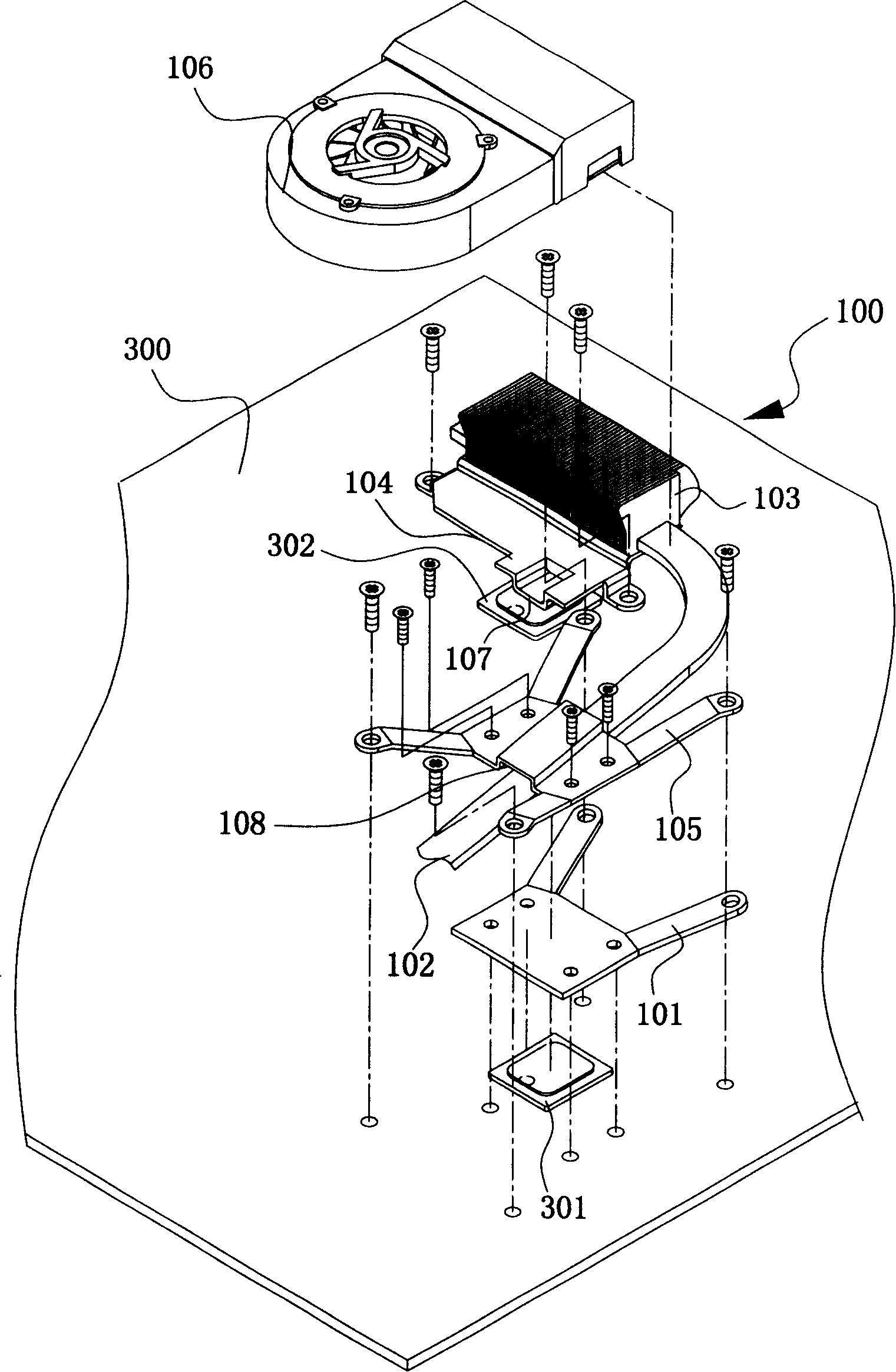

[0030] Please also refer to Figure 1A and Figure 1B , which is an exploded view and a combined view of the structure of the present invention, a dual heat source cooling module 100 is fixed on a circuit board 300, and the circuit board 300 has a first heating element 301 and a second heating element 302, and the dual heat source dissipates heat When the module 100 is fixed on the circuit board 300, it is used to dissipate the heat of the first heating element 301 and the second heating element 302, and the circuit board 300 can be a motherboard, so the first heating element and the second heating element can be It is a combination of a central processing unit (CPU) and a north bridge chip, and of course it can also be a combination of other two chips.

[0031] The dual heat source cooling module 100 includes a first heat conducting plate 101 , a heat pipe 102 , a heat dissipation element 103 and a second heat conducting plate 104 .

[0032] Wherein, the first heat conductin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com