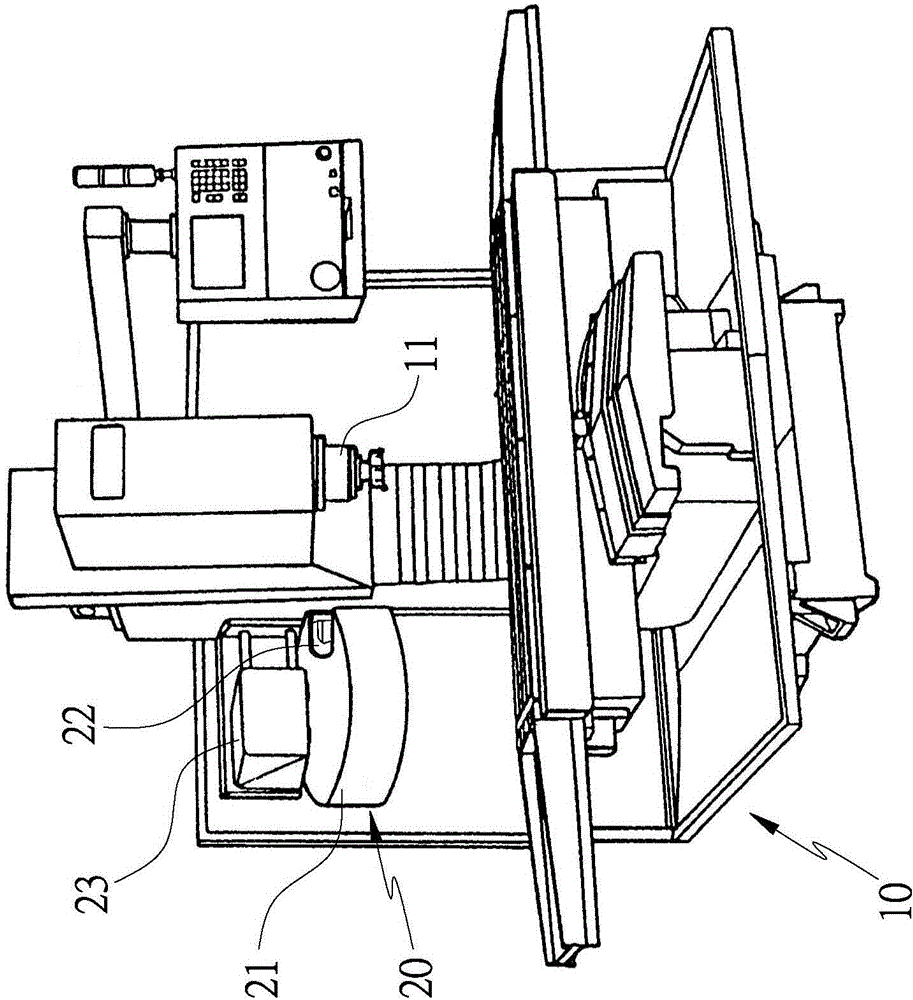

Chain type tool magazine

A chain-type tool magazine and tool magazine technology, applied in the direction of clamping, supporting, positioning devices, etc., can solve the problems of occupying machine tool configuration space, assembling troubles, and occupying configuration space, etc., to achieve small size, easy assembly, and saving The effect of configuration space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to enable your examiner to have a further understanding of the present invention, the preferred embodiments are hereby given together with the accompanying drawings, and are described in detail as follows:

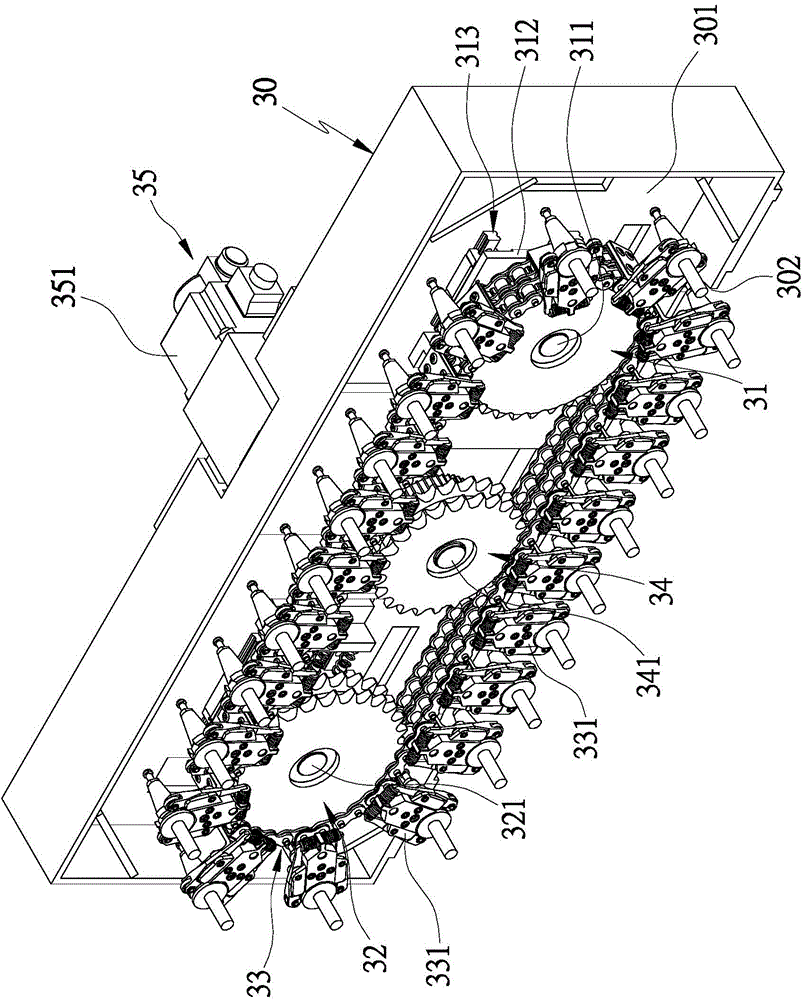

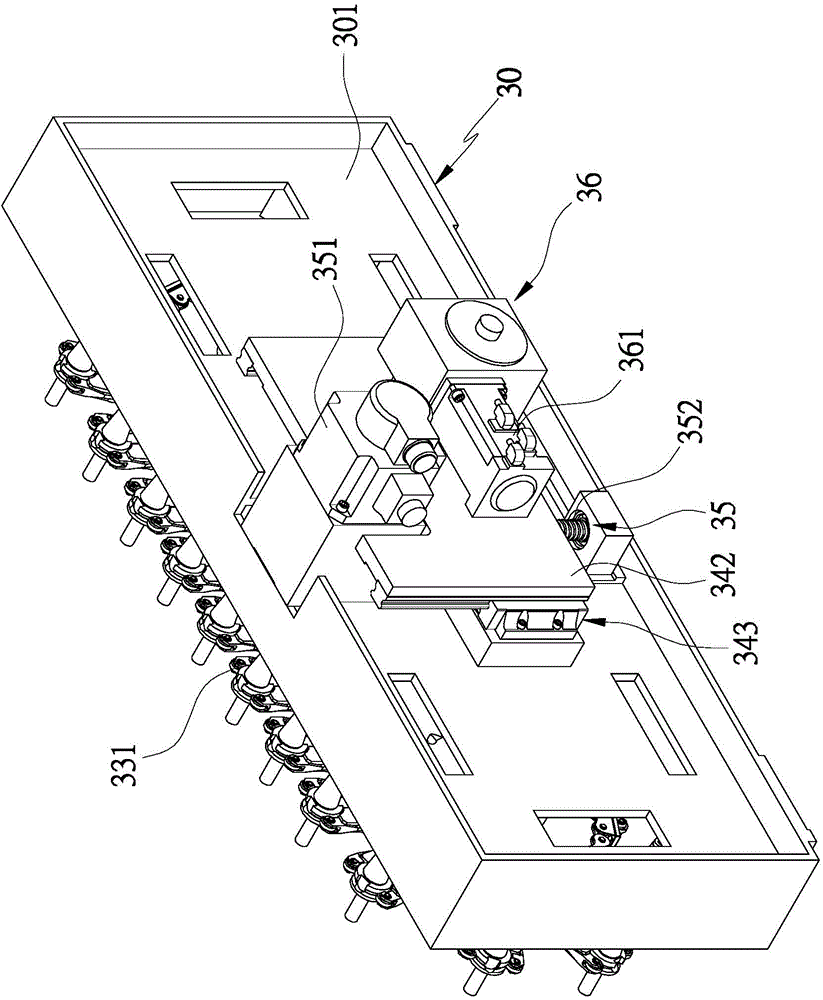

[0046] see Figure 2 to Figure 5 As shown, the chain tool magazine of the present invention is provided with a generally rectangular tool magazine body 30. The front side of the tool magazine body 30 is open, the rear side is provided with a seat plate 301, and the bottom is provided with an opening 302. The tool magazine body 30 is slidably provided with at least two driven sprockets in the horizontal direction, and an elastic push structure is provided on the two driven sprockets for elastically pushing against the two driven sprockets; in this embodiment , the tool magazine body 30 is provided with a first driven sprocket 31 and a second driven sprocket 32, the first driven sprocket 31 is pivotally mounted on the first sliding seat 312 with a first pivot 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com