Heat transfer side kneading welding heat exchanger with headers and double dividing walls and manufacturing process of heat transfer side kneading welding heat exchanger

A technology of heat exchangers and headers, applied in indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problems of small heat transfer area, low heat transfer efficiency, poor effect, etc., to achieve heat transfer Good, small flow resistance, increase the effect of heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

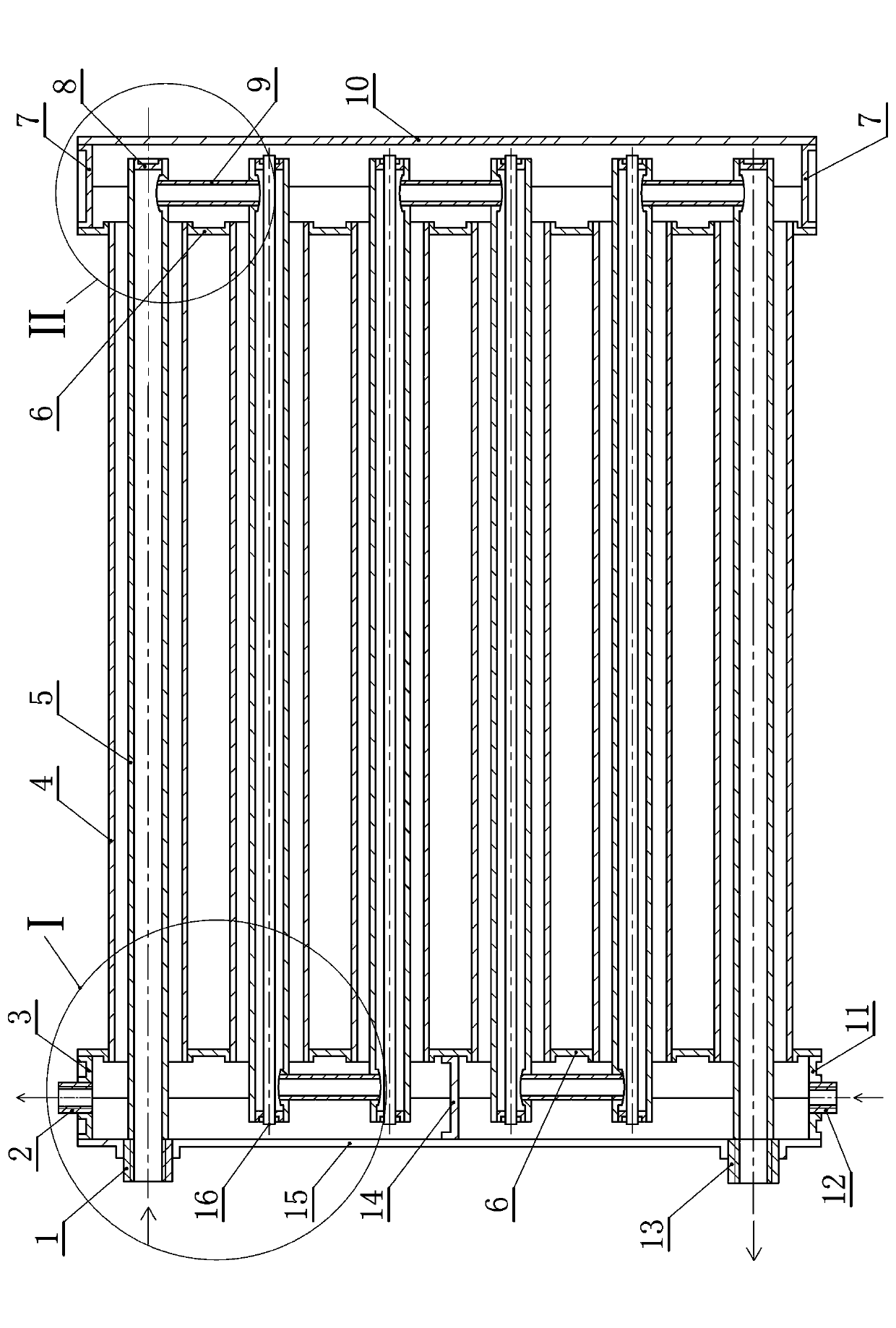

[0069] The present embodiment takes the header as an example to further illustrate the present invention:

[0070] The round tube header double-wall heat transfer pinch welding heat exchanger and its manufacturing process of the present invention include: two headers, two or more tap water connected to the outer pipe between the two headers; the characteristics are: : The tap water is connected to the outer pipe with a heating pipe, and the tap water heat-absorbing inner pipe is inserted into the heating pipe to form a double-row channel for heat transfer with double partitions. The heating pipe is connected. For heating outlet. The heating inlet and heating outlet are connected to the upper and lower parts of the side wall at one end of the header, and the tap water inlet and tap water outlet are connected to the upper and lower parts of the head blocking plate (end cover) of the same header.

[0071] The manufacturing process of the present invention (taking the circular tu...

Embodiment 2

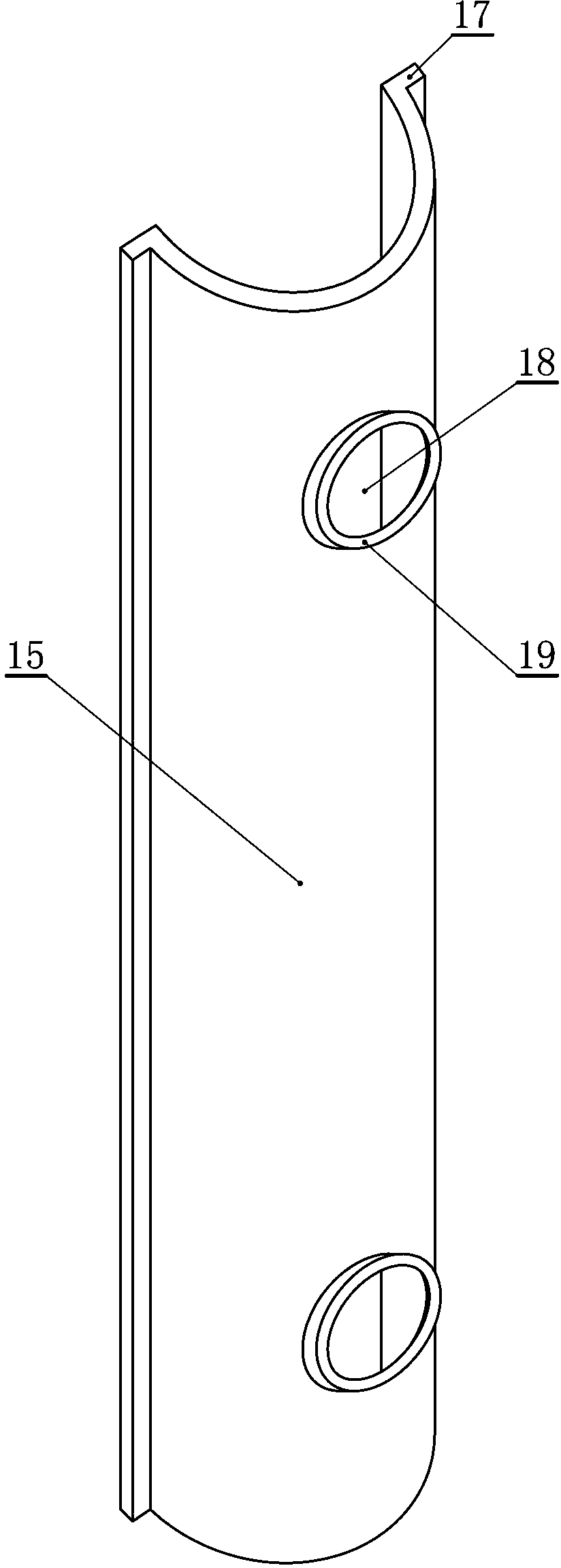

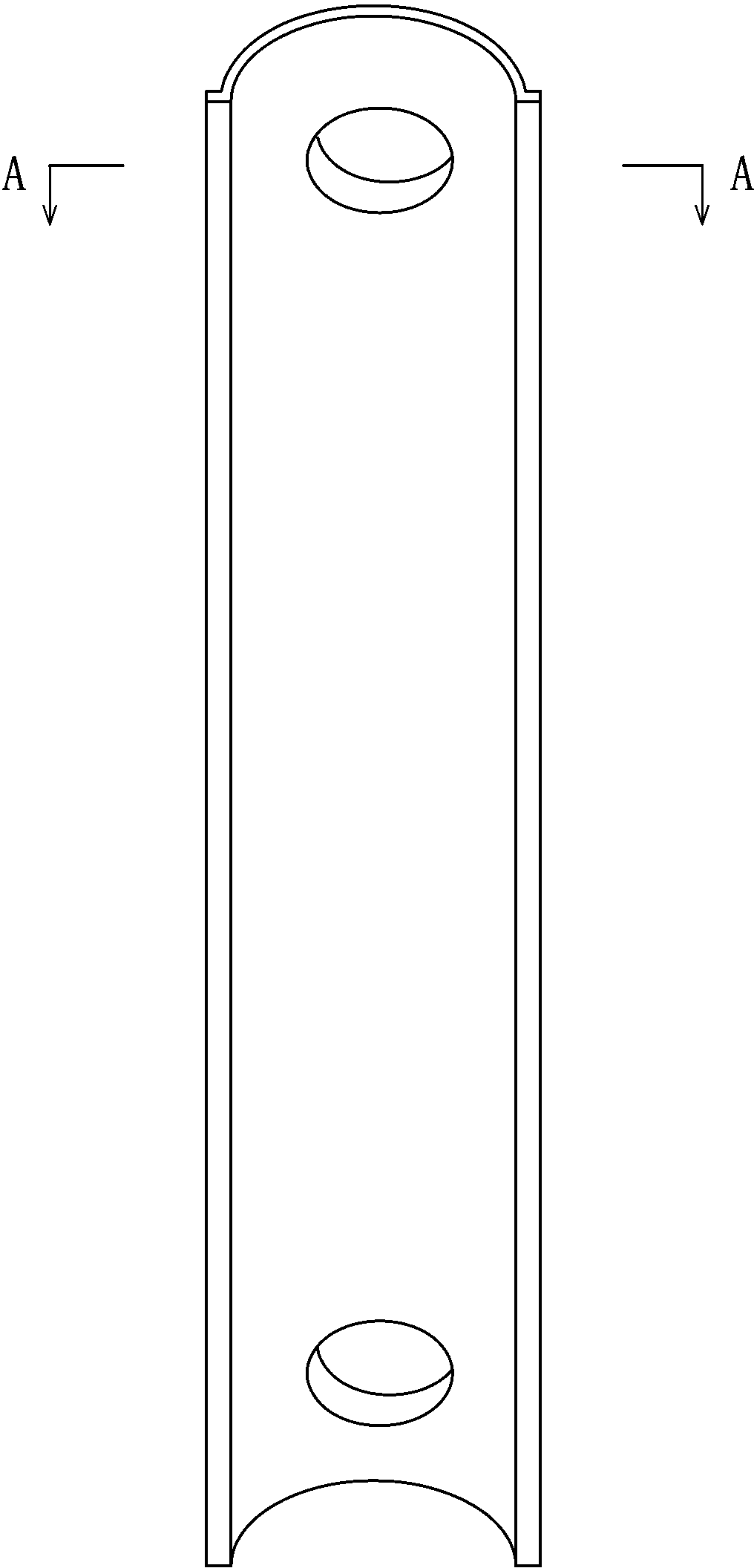

[0081] In this embodiment, the present invention is described by taking the header as a D-shaped header as an example.

[0082] 1. The center hole of the orifice plate of the D-shaped header is punched inward according to the diameter of the outer pipe connected to the tap water, and the edge height of the hole is 2-2.5 mm, and the edge height of the two sides of the orifice plate is 2-3 mm, and the C-shaped plate is pressed and strengthened. There are 4 ribs, and the outer pipe connected to the tap water is inserted into the drawing hole of the orifice plate of the D-shaped header without gaps. The heating pipe, the straight pipe connected to the heat supply, and the tap water heat-absorbing inner pipe are connected, and the whole is movable, and can expand freely when heat expands and contracts, reducing the water leakage rate of the heating system. After the heating and heating pipe system is connected, it is qualified if there is no water leakage after the pressure test. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com