Stator for rotating machine, holder for use with stator, rotating machine, and automobile

A technology for a rotating electrical machine and a retainer, applied in the automotive field, can solve problems such as difficulty in miniaturization and increased configuration space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

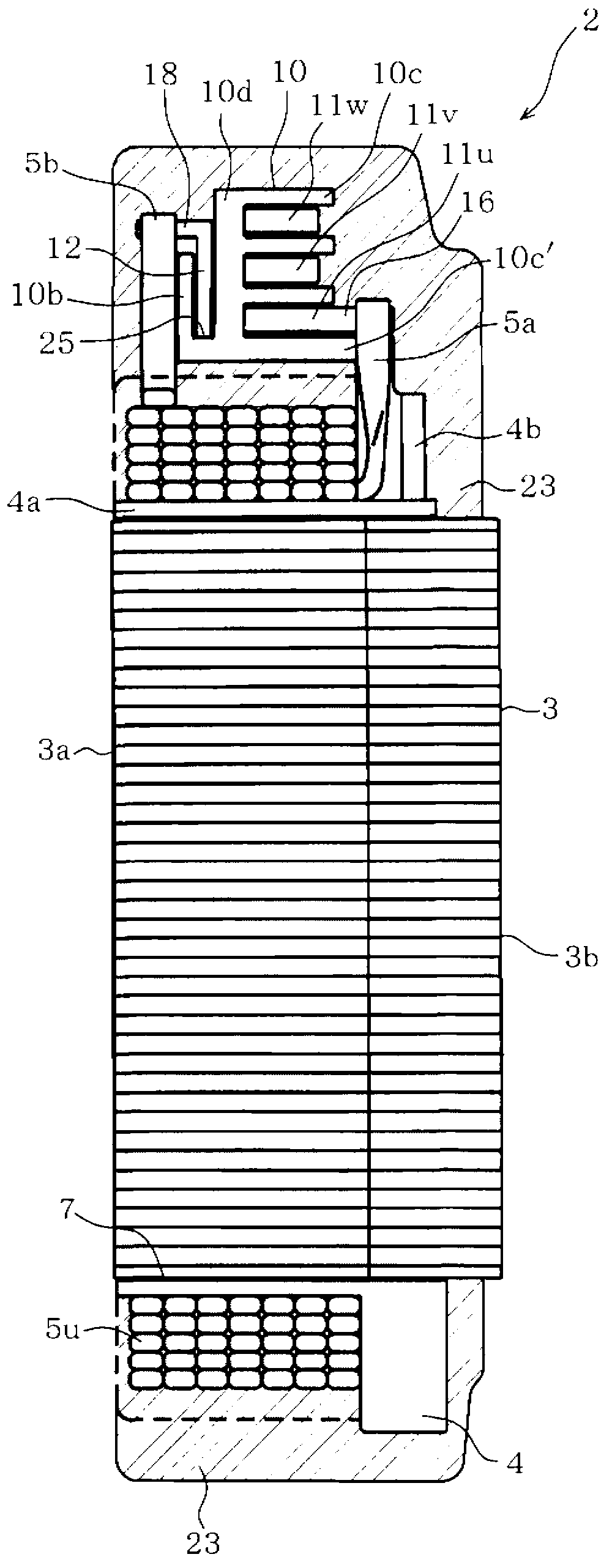

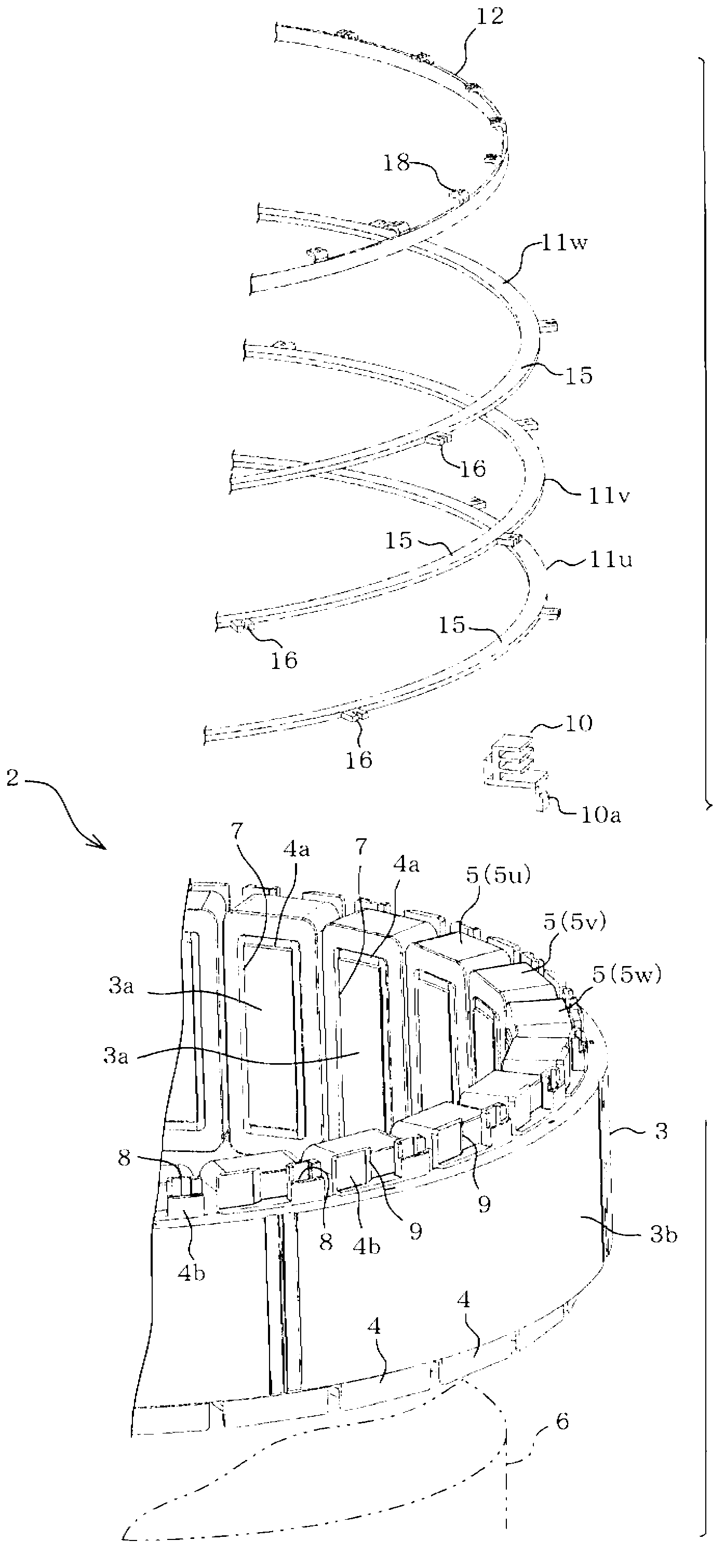

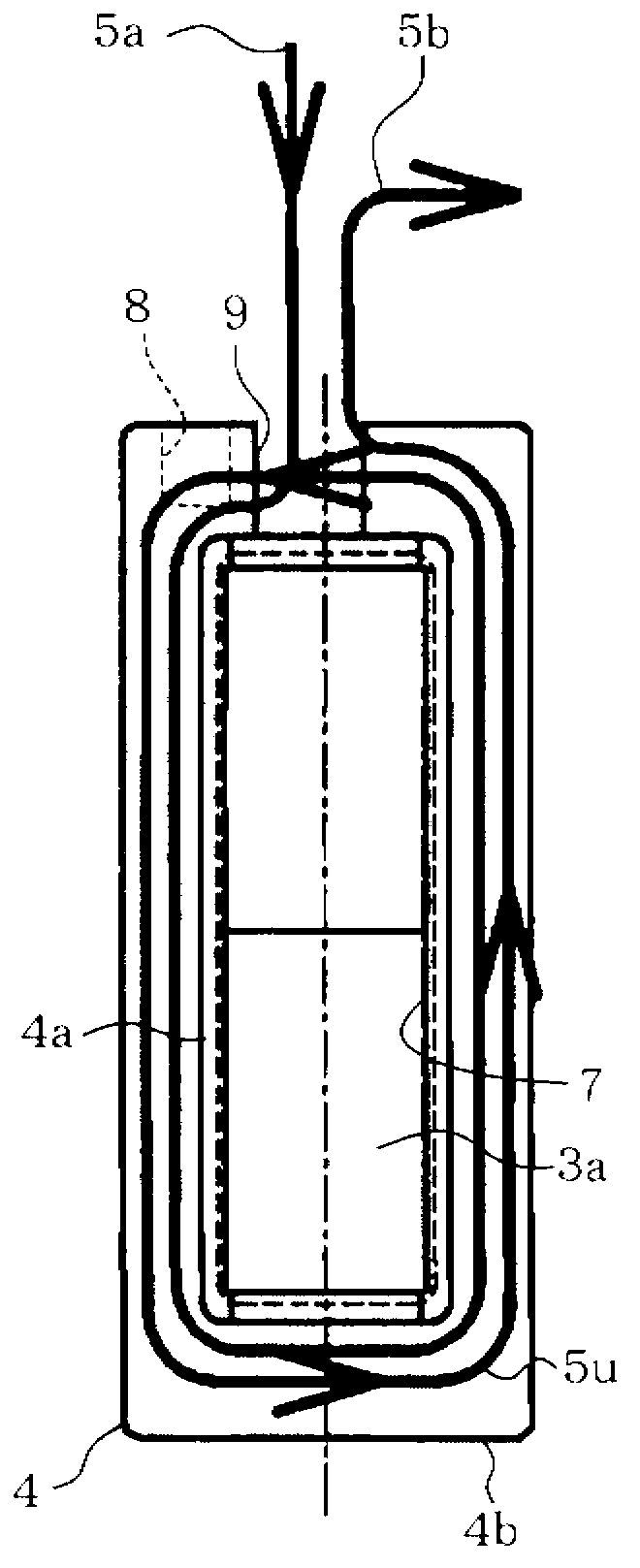

[0016] Below, refer to Figure 1 to Figure 7 , an embodiment applied to a drive motor used in an electric vehicle and driven by an inverter will be described. in addition, Figure 7 An electric vehicle equipped with the driving motor 1 as a rotating electrical machine is shown.

[0017] Such as figure 2 As shown, the stator 2 of the drive motor 1 includes a substantially cylindrical stator core 3 formed by laminating a large number of annularly configured electromagnetic steel sheets. The stator core 3 has: a cylindrical yoke 3b; and a plurality of (for example, 24) teeth 3a provided at equal intervals in the circumferential direction on the inner peripheral portion of the yoke 3b. Each tooth 3a is configured in a square column shape, and is formed so as to protrude from the inner peripheral surface of the yoke 3b in the center direction. Three-phase (U-phase, V-phase, and W-phase) windings 5 (U-phase winding 5 u , V-phase winding 5 v , and W-phase winding 5 w ) are wou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com