Active matrix panel

An active matrix and panel technology, applied in optics, instruments, electrical components, etc., can solve the problems of larger configuration space and smaller aperture ratio, reducing configuration space, increasing aperture ratio, and reducing pixel pitch. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

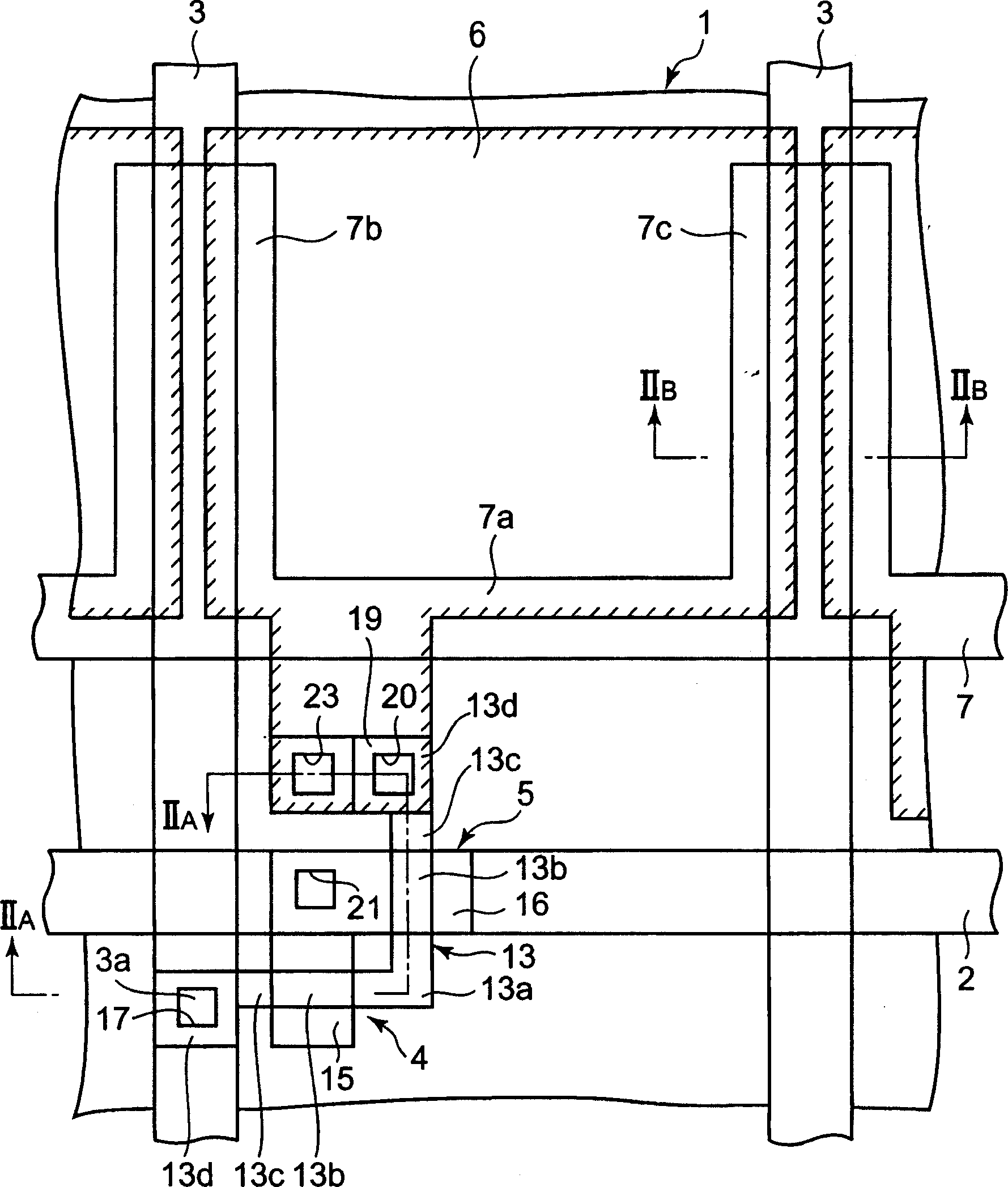

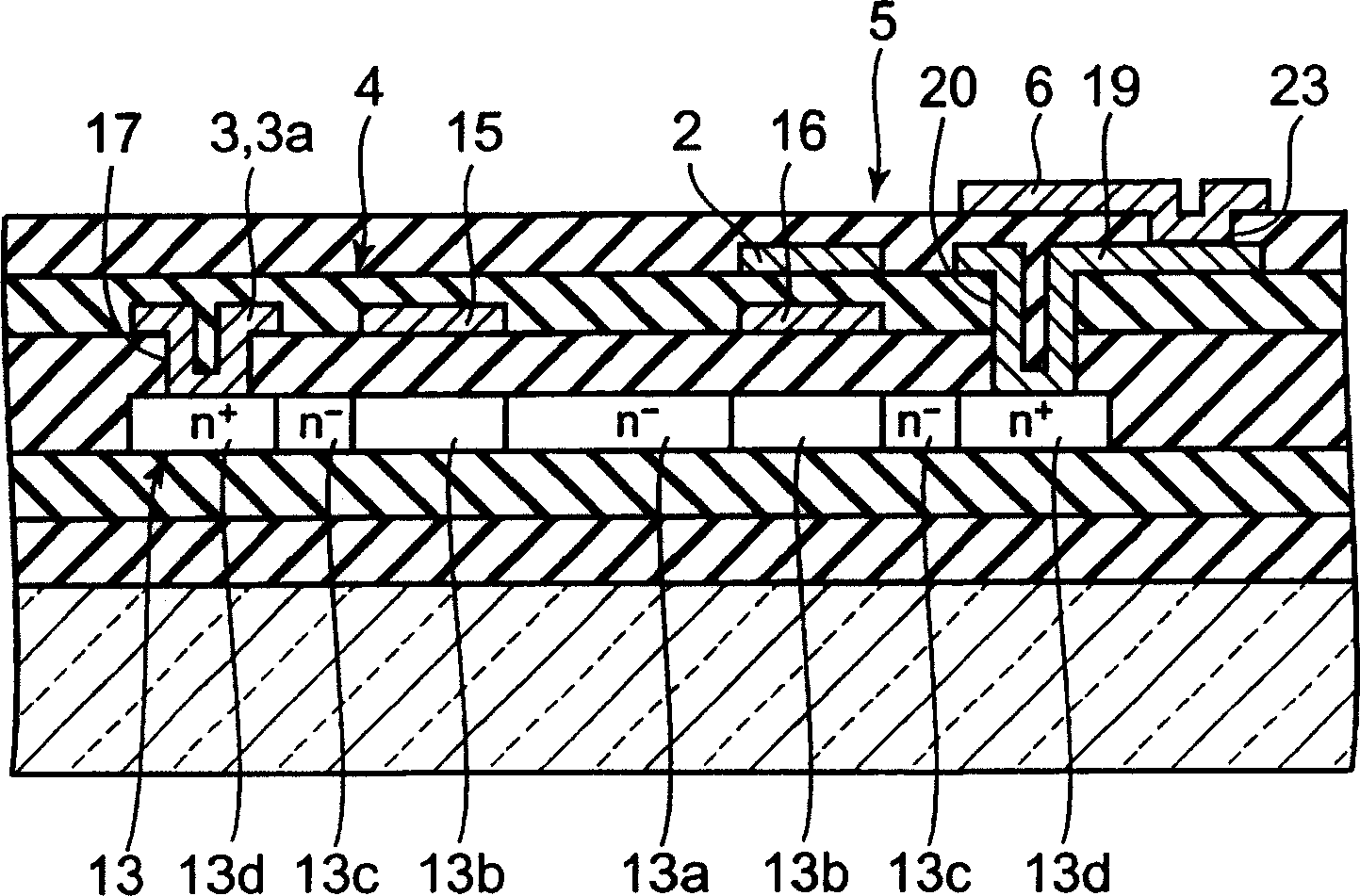

[0028] figure 1 It is a perspective plan view showing a main part of the active matrix panel of the liquid crystal display device according to the first embodiment of the present invention. The active matrix panel has a glass substrate 1 . Scanning lines 2 and data lines 3 are arranged in a matrix on one side of the upper surface of the glass substrate 1, and two thin film transistors (switching elements) 4, 5, pixel electrodes 6 and auxiliary electrodes connected in series are arranged near their intersections. Capacitive electrode 7. Here, in order to make figure 1 To be clear, the edge portion of each pixel electrode 6 is hatched with an oblique short solid line.

[0029] Edge portions on the left and right sides of the pixel electrode 6 coincide with the data lines 3 disposed on the left and right sides. exist figure 1 Among them, the auxiliary capacitor electrode 7 has: a linear electrode portion 7a arranged in parallel with the scanning line 2, a rectangular elec...

no. 2 Embodiment approach

[0054] Figure 9 A perspective plan view showing main parts of an active matrix panel of a liquid crystal display device according to a second embodiment of the present invention, Figure 10A is along Figure 9 the X A -X A cutaway view of the line, Figure 10B is along Figure 9 the X B -X B Cutaway view of the line. In addition, here in order to make Figure 9 To be clear, the edge portion of each pixel electrode 6 is hatched with a slanted short solid line.

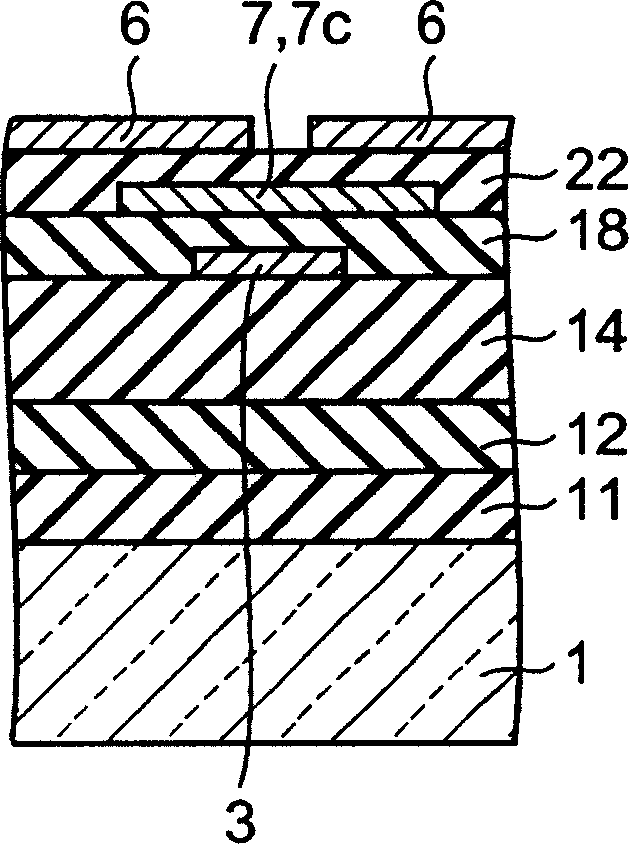

[0055] Next, neutralize the active matrix panel figure 1 The difference from the situation shown in Fig. 2 will be described. One difference is that the interlayer insulating film 18 is omitted, and on the upper surface of the second underlying insulating film 12 including the upper surface of an n-type high-doped concentration region 13d of the semiconductor thin film 13, a data electrode 3a serving also as the drain electrode 3a is formed. Line 3 forms an island-shaped source on the upper surface of anoth...

no. 3 Embodiment approach

[0058] In each of the above-mentioned embodiments, the case where the present invention is applied to a coplanar type suitable as an active matrix panel having a semiconductor thin film transistor made of polysilicon has been described. However, the present invention is not limited thereto, and can also be applied to Inverse staggered type suitable for active matrix panels with semiconductor thin film transistors made of amorphous silicon.

[0059] Figure 11 A perspective plan view showing main parts of an active matrix panel of a liquid crystal display device according to a third embodiment of the present invention. The active matrix panel has a glass substrate 41 . Scanning lines 42 and data lines 43 are arranged in a matrix on the upper surface of the glass substrate 41 , and two thin film transistors 44 and 45 connected in series, pixel electrodes 46 and storage capacitor electrodes 47 are arranged near their intersections. Here, in order to make Figure 11 To be clear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com