Single-layer multi-point capacitive touch screen

A capacitive touch screen, single-layer multi-point technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve the problems of complex bridging process, high production cost, and many manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

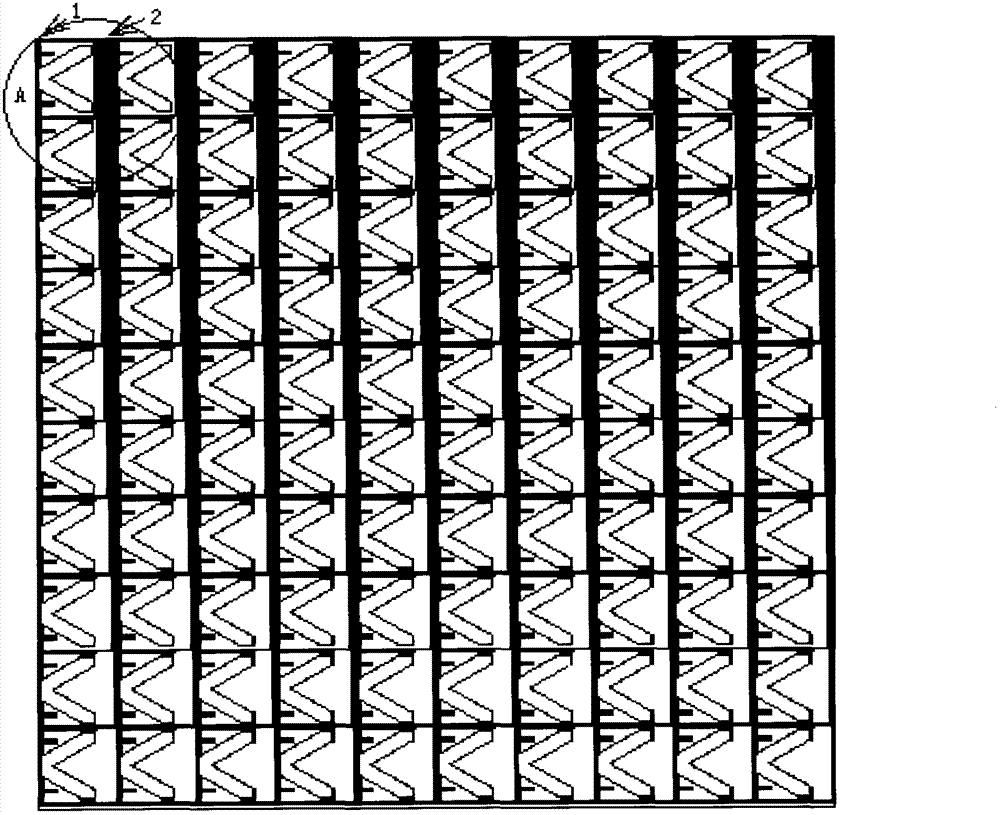

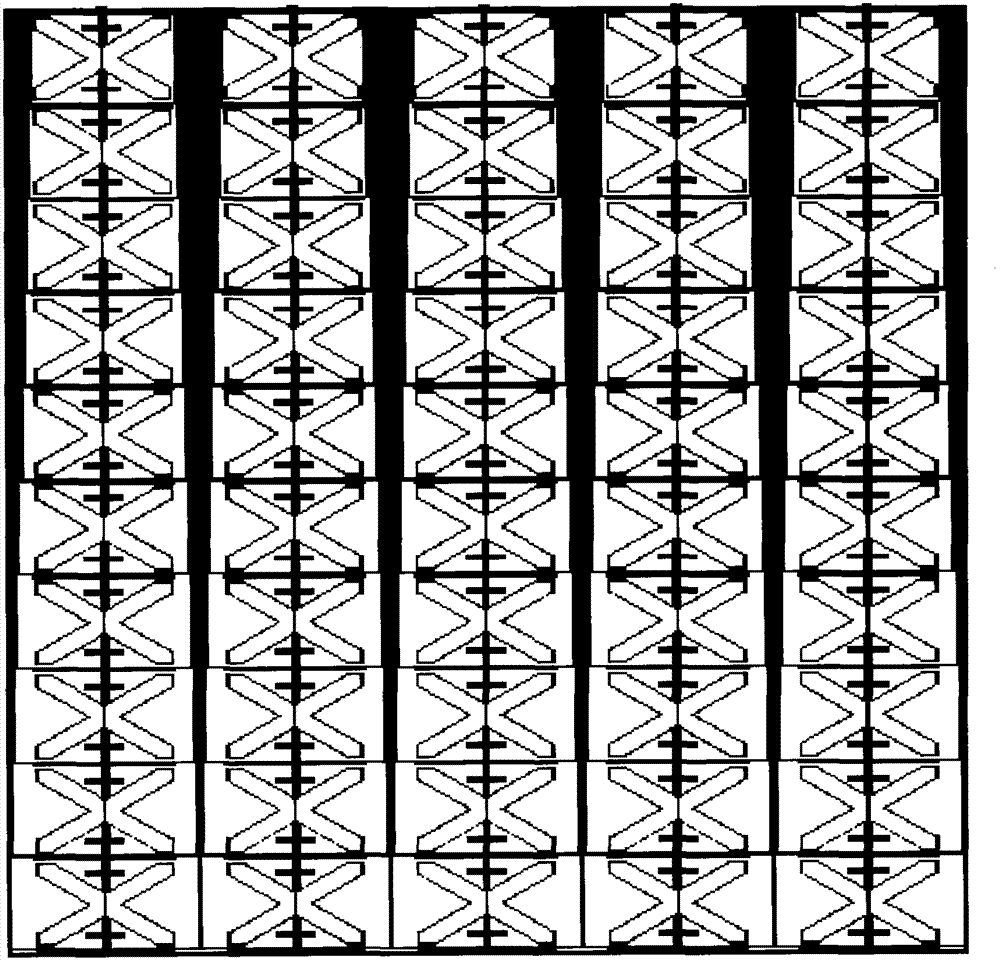

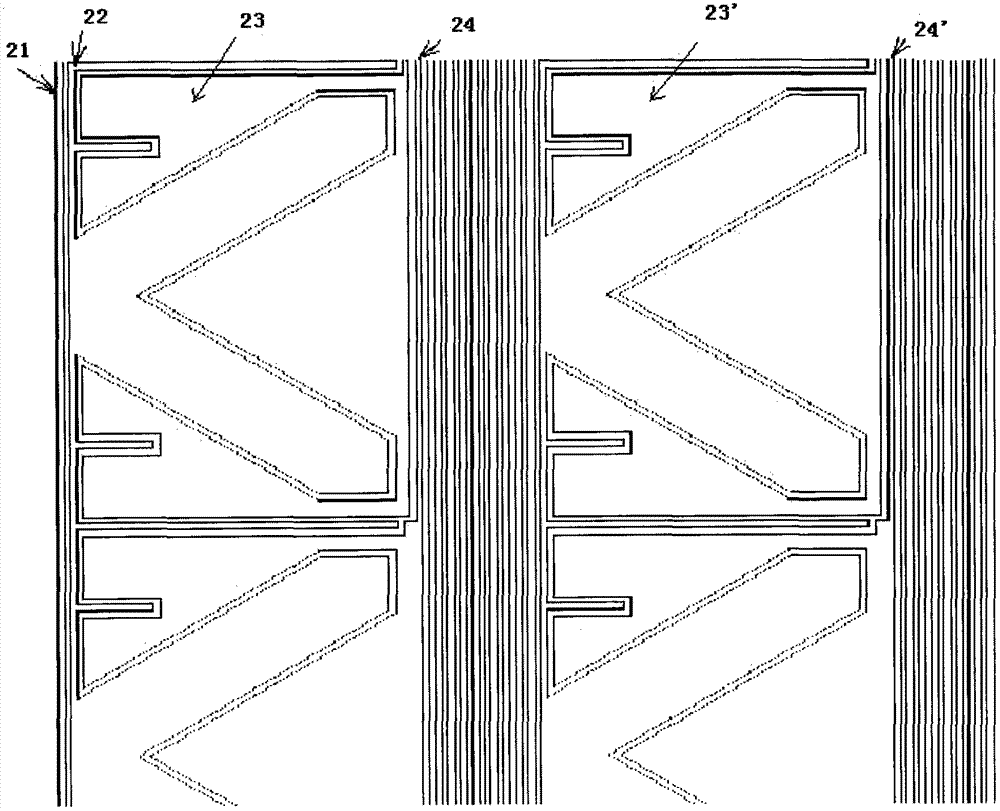

[0020] figure 1 and figure 2 It shows the overall structure of the single-layer multi-point capacitive touch screen of the present application. The single-layer multi-point capacitive touch screen of the present application is composed of multiple groups of repeated electrode units. figure 1 For the overall structure of the touch screen when the electrode units are arranged in sequence, figure 2 It is the overall structure of the touch screen when the repeated electrode units are adjacently arranged symmetrically. Each repeating electrode unit is composed of a driving electrode and a sensing electrode that is complementary in shape to the driving electrode but is isolated from each other and has no electrical connection. figure 1 Among them, 1 is the sensing electrode, and the sensing electrodes in each repeated electrode unit located in the same column are directly connected, and the driving electrode in each repeated electrode unit has a driving electrode lead-out line 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com