Array pressure sensing device and pressure identification method thereof

A sensing device and identification method technology, applied in the direction of measuring device, measuring force, instrument, etc., can solve the problem of inability of resistive touch sensing device to multi-line scanning drive and high gray scale pressure identification, complicated coding operation, It is impossible to show the pressure distribution of the resistive touch panel, so as to reduce the time of identification and calculation, improve the ability of high grayscale identification and high sensitivity touch sensing, and the effect of simple linear mathematical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, it will be described in detail below with reference to the accompanying drawings and examples, but the following drawings and examples are only for auxiliary illustrations, and the present invention is not limited to the accompanying drawings and examples.

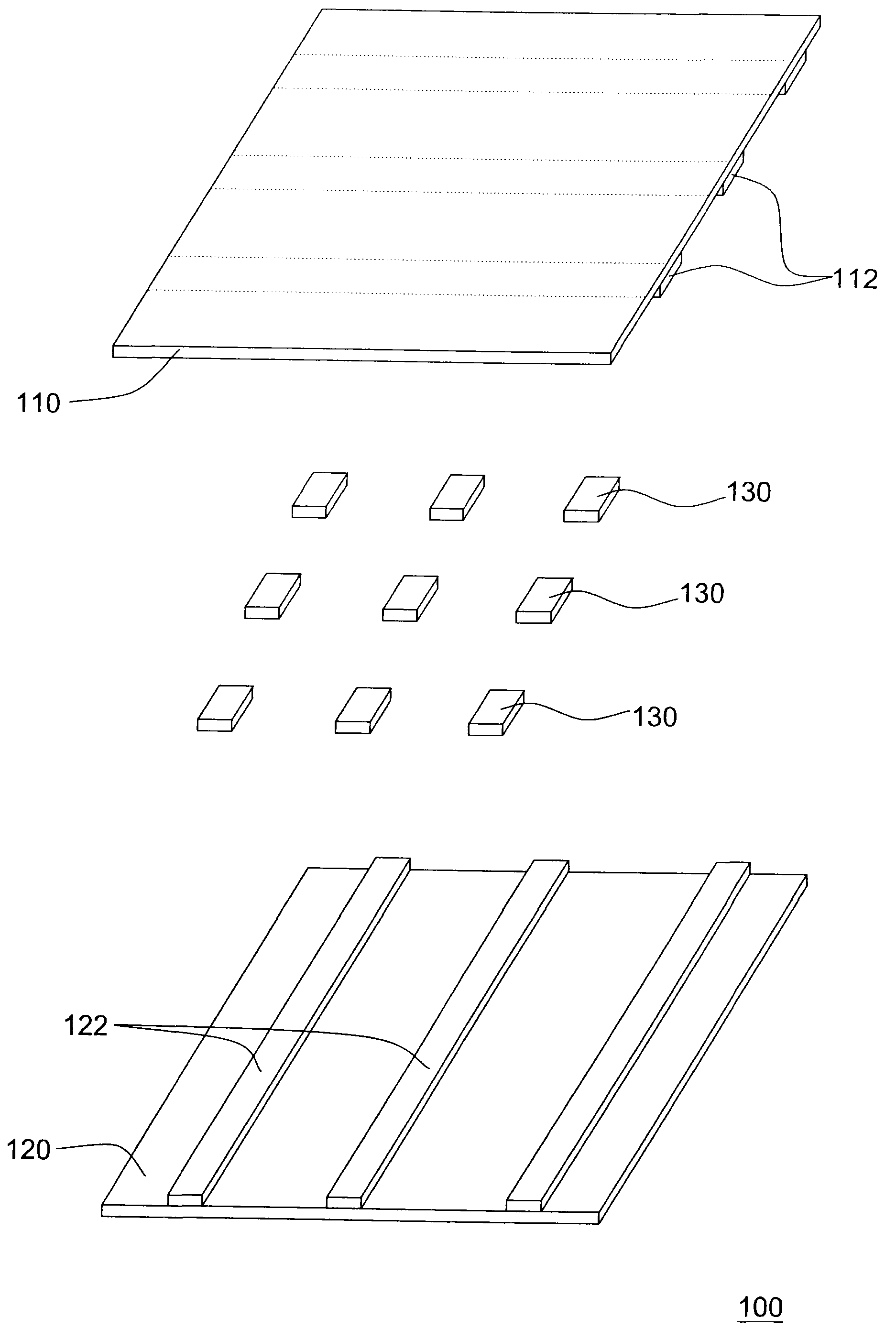

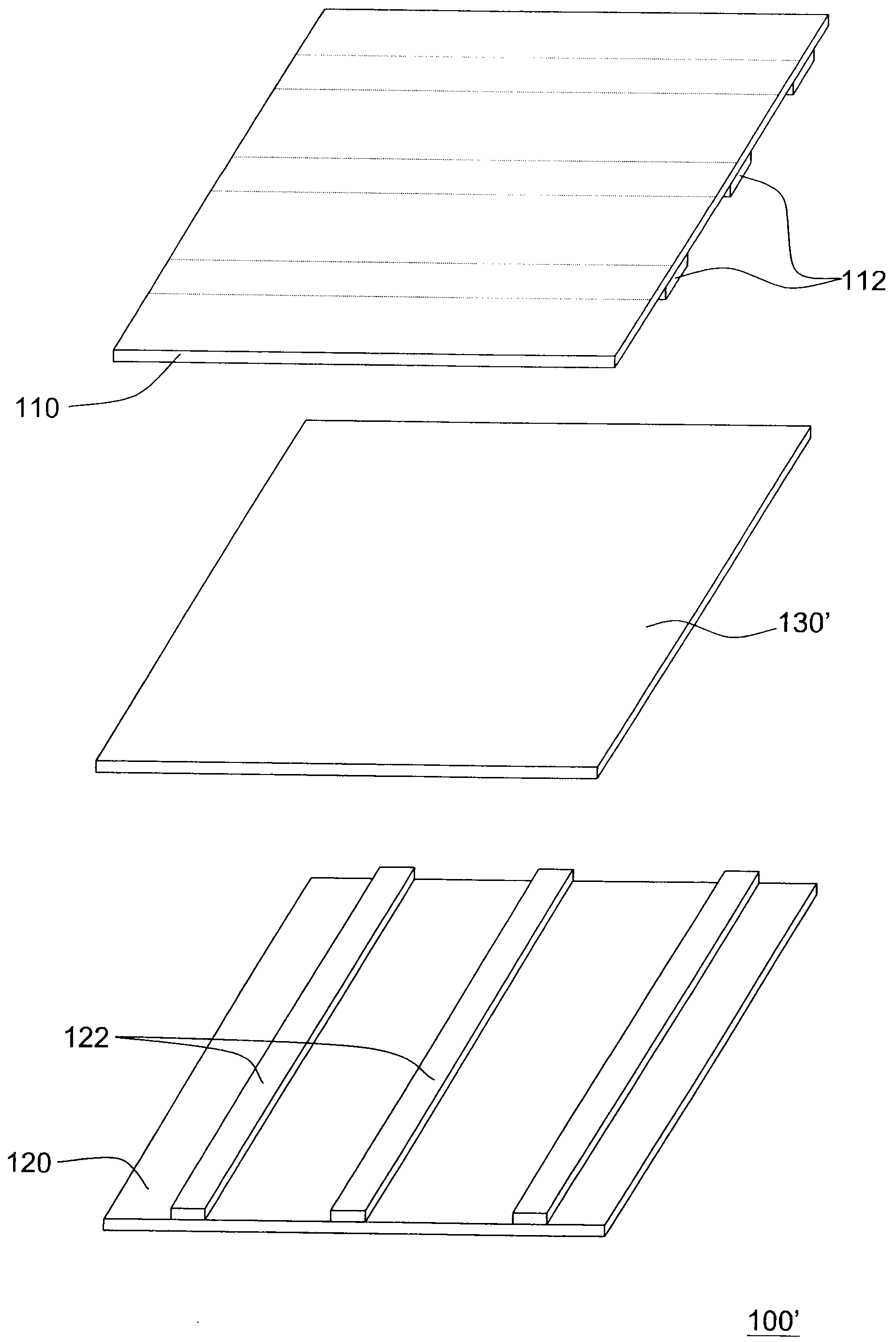

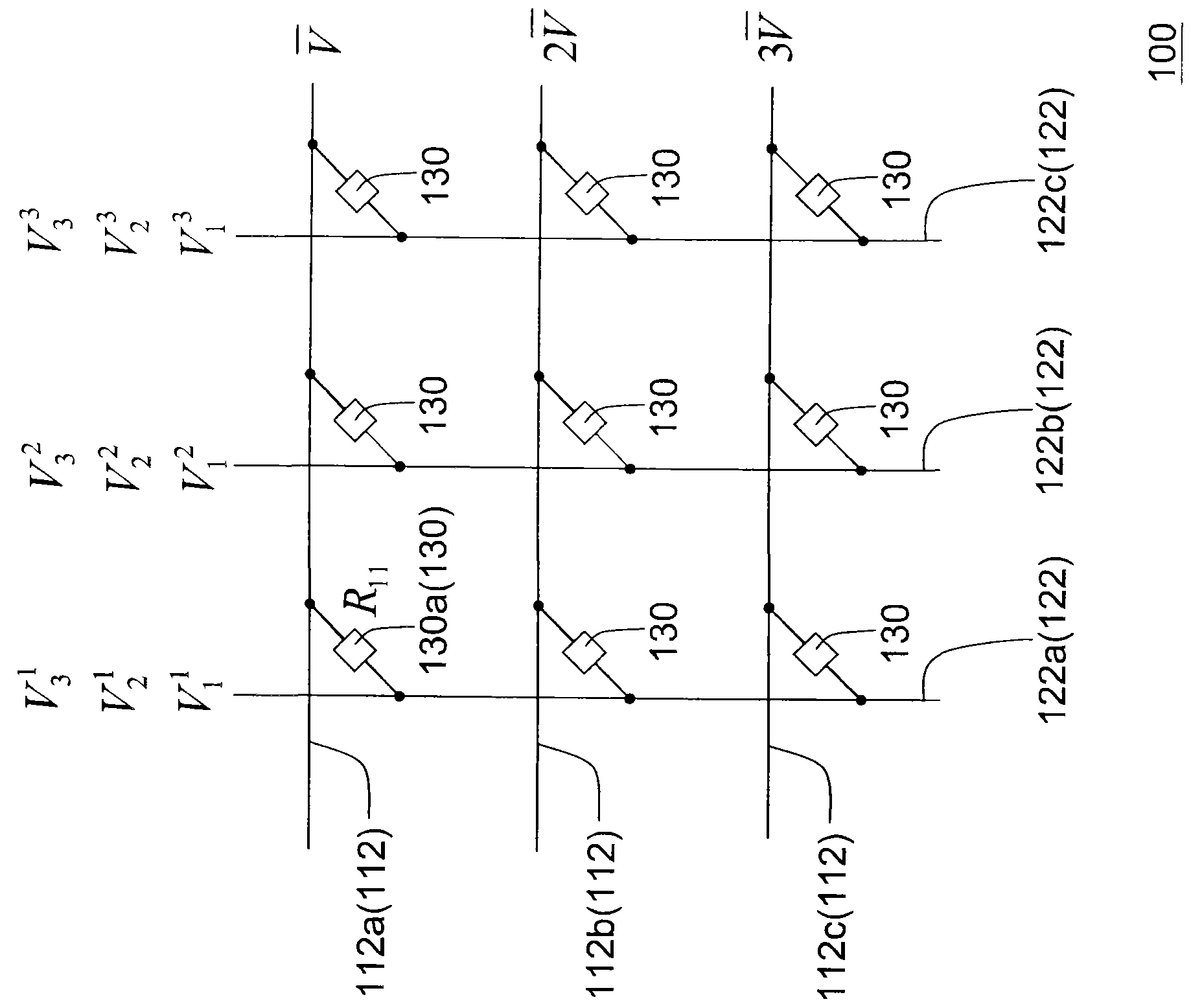

[0067] figure 2 It is a schematic diagram of an array pressure sensing device according to an embodiment of the present invention, and for simplicity and clarity, figure 2 The concept of how to multi-touch and quantize pressure in the present invention is expressed in the form of a circuit diagram, and is first described in a three-line structure. Please refer to figure 2 , the array pressure sensing device 200 of the present invention includes a plurality of first axes 210 (210a, 210b, 210c), a plurality of second axes 220 (220a, 220b), a plurality of piezoresistive units 230, a third axis 240,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com