Side detection-type multipoint touch screen based on frustrated total internal reflection

A technology of suppressed total internal reflection, multi-touch screen, applied in the input/output process of data processing, instruments, electrical digital data processing and other directions, can solve the problems of noise interference, system complexity, infrared light leakage, etc., to avoid interference , the effect of facilitating system integration and reducing the thickness and volume of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

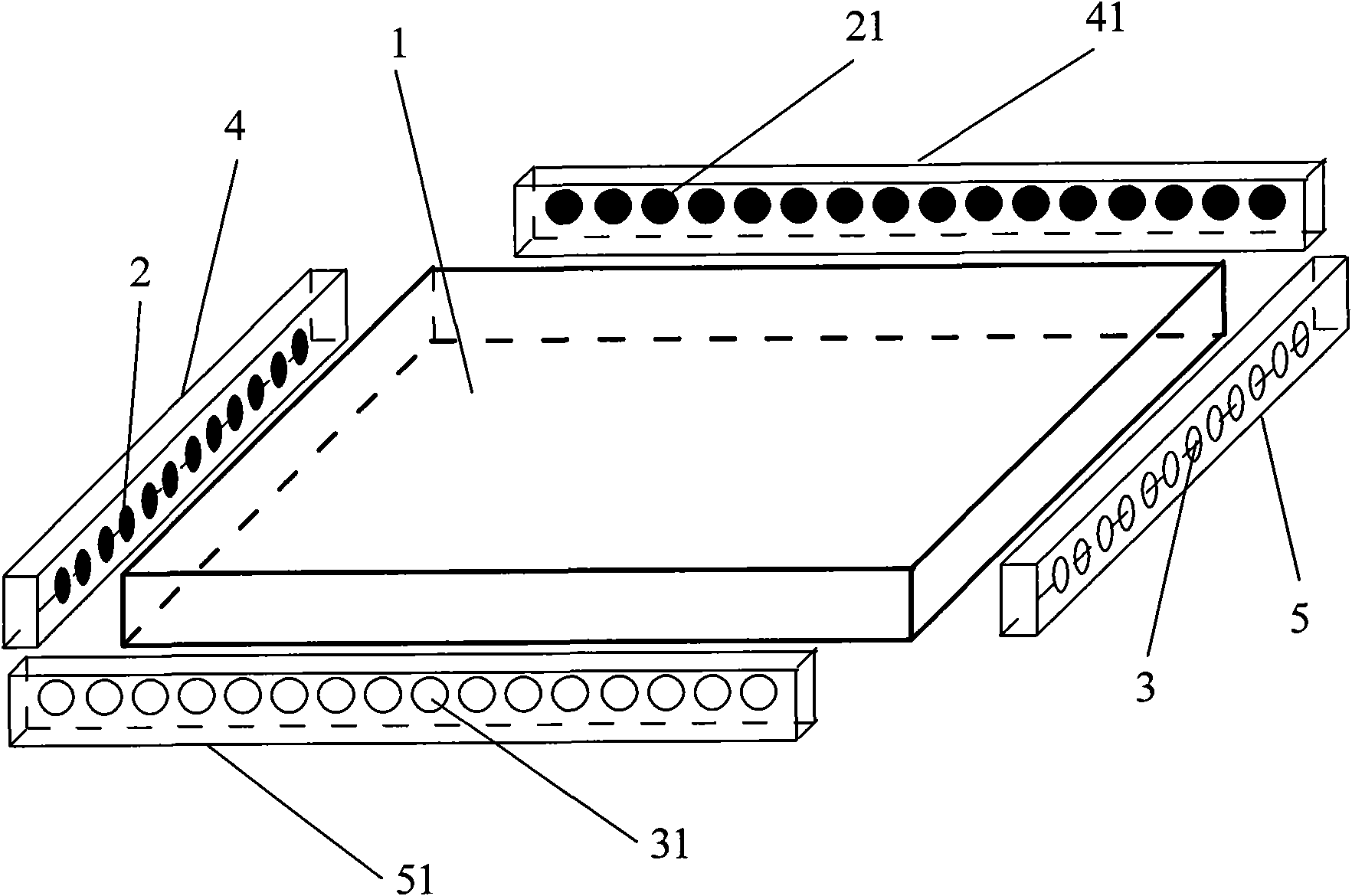

[0025] see figure 1 , the side detection type multi-touch screen based on frustrated total internal reflection includes an optical panel 1 , an LED lamp 2 and a photoelectric receiving tube 3 . The four sides of the optical plate 1 are polished into optical surfaces and form an angle of 90 degrees with the upper and lower surfaces. On the left side of the optical flat panel 1, the left LED lamp 2 is uniformly installed as a light source through the left base plate 4, and the upper LED lamp 21 is uniformly installed on the upper side through the upper base plate 41 as a light source. The left LED lamp 2 and the upper LED lamp 21 are respectively Be fixed in a row on the left bottom plate 4 and the upper bottom plate 41; on the right side, the right photoelectric receiving tube 3 is evenly distributed through the right bottom plate 5, and the lower photoelectric receiving tube 31 is installed on the lower side through the lower bottom plate 51. The photoelectric receiving tubes...

Embodiment 2

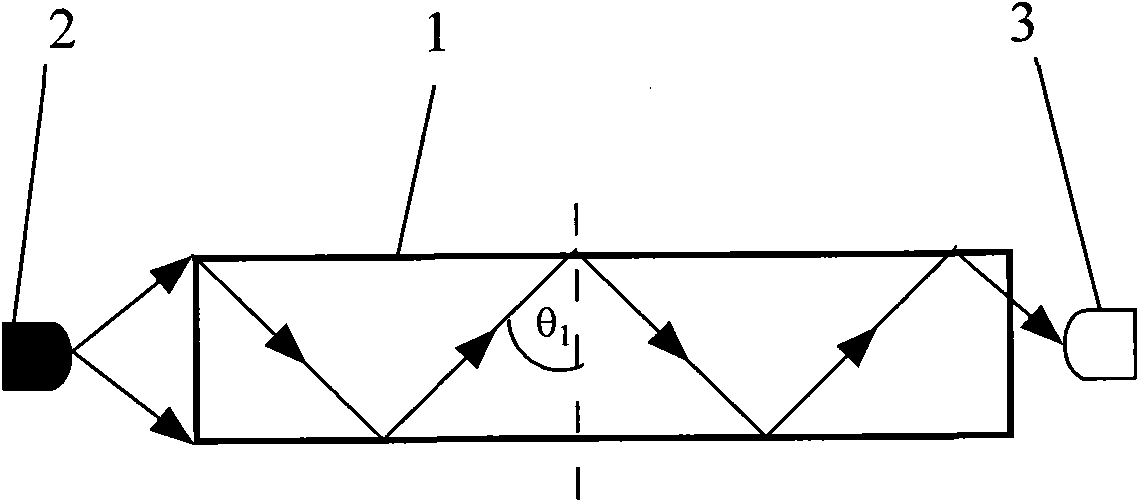

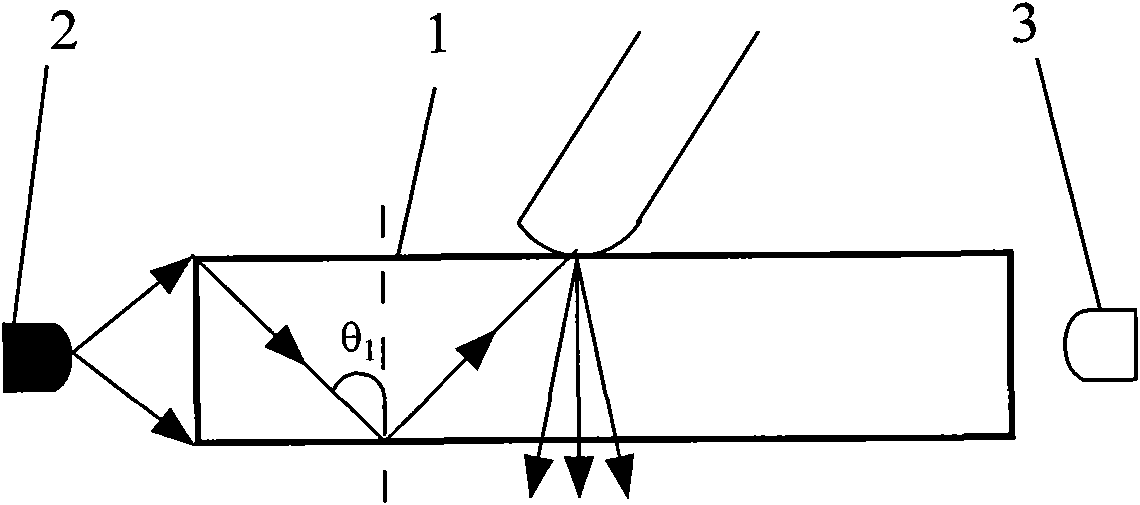

[0032] see Figure 3a , the optical plate 1 is composed of organic optical glass, its upper and lower surfaces are smooth optical surfaces, and the four sides of the optical glass 11 are polished into optical surfaces and form an angle of 45 degrees with the upper and lower surfaces. Install left LED lamp 2 and upper LED lamp 21 on the left side and upper side of optical panel 1, left LED lamp 2 and upper LED lamp 21 adopt visible light band LED, and the optical axis direction of left LED lamp 2 and upper LED lamp 21 is vertical The side of the optical plate 1 forms an angle of 45 degrees with the upper and lower surfaces. The optical axis directions of the right photoelectric receiving tube 3 and the lower photoelectric receiving tube 31 are parallel to the upper and lower surfaces of the optical plate 1 . The transmission of light in the optical flat plate 1 is as Figure 3a and Figure 3b shown. The incident angle of the upper edge light of the left LED lamp 2 on the op...

Embodiment 3

[0036] see Figure 4a , on the basis of Embodiment 1, the optical panel 1 is organic optical glass, and a refractive index matching layer 12 of a polymer material is installed on the touch surface of the optical panel 1 . Its refractive index n 2 and organic optical glass refractive index n 1 Similar, and the hardness of the refractive index matching layer is much lower than that of the organic optical glass, which greatly improves the contact degree between the finger and the optical plate, and enhances the detected touch signal.

[0037] For the case of using optical flat plate 1, such as Figure 4a As shown, assume that the incident angle in the optical plate 1 is θ 1 The transmission angle of the light after the refractive index matching layer and the organic optical glass is refracted is θ 3 , then there is

[0038] no 1 sinθ 1 =n 2 sinθ 3 (3)

[0039] Therefore, according to formula (1), we have

[0040] sin θ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com